Malzeme Bilimi ve Mühendisliği - Anadolu Üniversitesi Mühendislik

advertisement

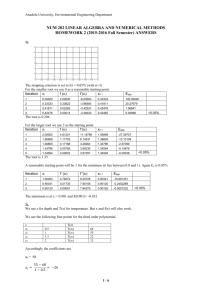

PROJE FUARI 2009 ________________________________________________________________ IMPROVEMENT THERMAL AND MECHANICAL PROPERTIES OF CORDIERITE GLASS-CERAMICS Aybike ÜRKMEZ Supervisor: Assost. Dr. Semra KURAMA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir The effects of the system of Strontium-Aliminum-Silicate (SAS) on cordietire glassceramics and mechanical properties are examined in this project. SAS is added to cordierite system with % 1-5 weight fraction and sintered at 1200°C, 1250°C and 1300°C. In density measurement due to the Archimedes principle, while sintering temperature and SAS amount was increasing, increasing on the density has seen ( density value of pure kordiyarit is 1.7 g/cm3 and for %5 SAS is 2.1 g/cm3). By the way, increasing of these parameters decrease the water absorbtion, and also mechanical properties increase with increased SAS amount. Keywords: Cordierite-based glass ; Strontium-Aluminum-Silicate; Thermal conductivity; Mechanical Properties MLZ-1 PROJE FUARI 2009 ___________________________________________________________________________ THERMAL CONDUCTIVITY OF α-β SiALON CERAMICS WITH SEGREGATED NETWORK OF SiC PARTICLES Aynur GEREDE Danışman: Doç.Dr.Alpagut KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this particular work the effect of segregated network of SiC particles on the thermal conductivity of α-β SiAlON ceramics were reported. Apart from conventional particle reinforced composite approach, formation of a segregated network of SiC particles in the βSiAlON matrix is achieved by employing a simple mechanical mixing of SiAlON granules and nano SiC particles. SiAlON granules that have commercial name 25A were obtained by spray drying. Samples were prepared within four different amount of SiC(2.5, 5,7.5,10 volume %). Composite powders were sintered by gas pressure sintering (GPS) and spark plasma sintering methods. In order to determine thermal conductivity of the prepared samples, thermal diffusivity and heat capacity values were obtained by using laser flash and differential thermal analysis (DTA) respectively. Additionally mechanical behavior of the materials was investigated in terms of hardness and fracture toughness by using Vickers indentation method. In conclusion it was found that thermal conductivity of composites strongly depends on the sintering method. Thermal conductivity values of GPS samples was higher than SPS samples due to the phase formations. Also with this new approach by decreasing percolation point of the material higher thermal conductivity values can be obtained by low amount of SiC additions. MLZ-2 PROJE FUARI 2009 ___________________________________________________________________________ LOW COST WALL TILE GLAZES Eyyüp Baki SANDAL Supervisor: Assoc.. Prof. Emrah DÖLEKÇEKİÇ Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir The whitness, opacity, smooth surface texture and glossiness of wall tile glazes are most usually provided by the usage of zircon containing frtis. On the other hand the change in demand – supply balances of Zircon mines has been caused to increase the cost of this material and its is to be known that according to the performed studies the replacement of the Zircon with appropriate raws offers to decrease the production costs with significant values. In this study its observed that the occured glass-ceramic systems which are perfomed by optimizing Al2O3/alkali and CaO/MgO ratios. According to the required characterization methods the resulatant structures, phases ,the efficiency of the study and its effect on cost is evaulated. Keywords: wall tile, glaze, fast firing, Zircon-free, cost MLZ-3 PROJE FUARI 2009 _________________________________________________________________________ CORDIERITE BASED WATER FILTER Betül OKUR Supervisor: Assist. Prof. Dr. Semra Kurama Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this study, feature of the porous structure of cordierite ceramic has been addressed through the use microfiltration. PVA (Polivinylalcohol) was used in order to obtained desired porosity. Water permeability and particle filtration properties were conducted according to pore size and porosity of prepared samples. After the raw materials had been mixed, planetary milling was used for grinding, and then uniaxial press was done to the powders. Samples were sintered for various temperatures such as between 1100-1300 ⁰C. Cordierite phase was determined at temperatures 1250 and 1300 ⁰C. Weight loss, bulk density, apparent density, % porosity, and % water absorption of samples were measured by Archimedes Method. Measurement of pore size and distribution were done by mercury porosimeter. Phase analysis of sintered samples were characterized by X-ray diffraction (XRD) and microstructure of sintered samples were determined by scanning electron microscope (SEM). Thermal stability of the starting material was determined by thermogravimetric analysis device (TGA). According to applied tests and results, weight loss and density increase with increasing sintering temperature, but pore size and porosity decreases with increasing sintering temperature. As a result, permeability decreases with increasing temperature depending on porosity. Keywords : Cordierite, porosity, filter, permeability MLZ-4 PROJE FUARI 2009 _________________________________________________________________________ TRANSMISSION ELECTRON MICROSCOPE (TEM) CHARACTERISATION OF Si3N4-Al COMPOSITES Ekin SIMSEK Supervisor Prof. Dr. Servet TURAN Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Ceramic materials have some superior properties like high hardness, good mechanical properties and low density, to take advantages of these and improve the fracture toughness of ceramic materials, composites are produced. Si3N4-Al composites are used many critical application such as; aviation, electronic, automotive. After one-way pressing applied to Si3N4 powders for pre-shaping and porous pellets densify with cold isostatic pressing; with using 7075 Al alloy pressureless infiltration is implemented in horizontal tube furnace, at 1200°C temperature and Ar gas atmosphere. According to the literature when Si3N4 and Al react, AlN and metallic silicon phases are formed. Sample preparation process is very important for TEM characterisation. Slices which have about 400µm thickness are cut and grinded with using 120 and 180 grid SiC papers, so their thickness are decrease to 150µm; with using ultrasonic disc cutter 3mm diameter discs are obtained and with 9, 6, 3 µm diamond lapping films tripod polishing is done and thickness of samples become 30 µm. Sample thickness is get thinner under 100nm with ion milling. Micrographs are obtained from TEM bright field (BF) and dark field (DF), and also scanning electron microscope (STEM) DF and BF; chemical analysis is done with STEM energy dispersive X rays (EDX). Aluminum oxynitride (AlON) is seen as a formed phase after analyses. Results from this study are presented. Keywords: Composite, Characterisation, TEM MLZ-5 PROJE FUARI 2009 ________________________________________________________________________ OPTICAL PROPERTIES OF α -SiAlON CERAMICS Emre KOCA Supervisor Prof. Dr. Hasan MANDAL Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this thesis, effect of rare earth elements and milling time on the luminescence properties of Ca- α-SiAlON ceramics were investigated. Rare-earth-doped α-SiAlON compounds have been reported to be luminescent and may then serve as new materials in different application areas with good thermal and chemical stabilities. In present work, compositions were Ca1-xRExSi12-m-nAlm+nOnN16-n ( with m=2, n=1, x=0.0296) and Yb and Sm used as a rare earth elements. Compositions were prepared by millig 90 and 240 minutes with planatory ball mill and sintered at 1790 °C for 1 hour under 22 bar in nitrogen atmosphere. Their particle sizes measured by using lazer diffraction method and photoluminescence (PL) properties were measured by using flourescence spectrophotometer. İncreasing of the milling time, resulted to decreasing of particle size in both compositions. Emission wavelenghts of the Sm doped compositions were measured 537 nm and 550.5 nm. Emission wavelenghts of the Yb doped compositions were measured 538.9 nm ve 539 nm. Keywords: α-SiAlON Ceramics, Samarium, Ytterbium, Luminescence Properties, Milling Time MLZ-6 PROJE FUARI 2009 _________________________________________________________________________ PROTOTYPE CAR WITH WORKING HYDROGEN ENERGY Ergün BİÇER Burak DELEN Supervisor Prof. Dr. Aydın DOĞAN Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this thesis, effect of rare earth elements and milling time on the luminescence properties of After the industrial revolution, because of using of the fossil fuel increases day by day and therefore, alternative energy sources start to research. Highest priority sources as solar, wind and hydrogen recur to mind. Thanks to hydrogen has a lot of advantages like enviroment-friendly high efficiency, most of person think first energy sources that is hydrogen in the future time. Modern fuel cell is firstly used and then improved at the end of the 19th , it has been used in the used with hydrogen energy. Car competition with hydrogen organize from The Scientific and Technological Research Council of Turkey in 2007, in order to draw attention to hydrogen subject and cheer student to this topic. Anadolu University Hydrocar Project Team first attent to this race with a car which is name “Hidroana”, and succeed 3rd position at the finished line in 2008. It embodies with this result due to get ahead of other important university as İTÜ, Boğaziçi, Bilkent,Yıldız. After with high efficiency new design prototype car which is name “Hidroana Revolution” aim of team increased and attended Shell Eco Marathon Europe race at 7-9th of May 2009 in Germany. This race had big experience for team although any success. Team aim advanced achievement rather than that have own success from last year. Keywords: Renawable energy sources, Hydrogen Energy, The race of Hydrocar of The Scientific and Technological Research Council of Turkey, Shell Eco-marathon Europe MLZ-7 PROJE FUARI 2009 _________________________________________________________________________ COST-EFFECTIVE PRODUCTION OF SiAlON CERAMICS Fatih ERTÜRK Supervisor: Prof. Dr. Ferhat KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir SiAlON ceramics have a high potential for engineering applications due to their good mechanical and chemical and thermal properties. In this study, dense but, low-cost producing of SiAlON ceramics were aimed. For this aim, the compositions were prepared from low-cost Si and Si3N4 powders. Powders were pelletized with cold isostatic pressing. Without changing the composition, with changing particle size, pressure and temperature values, sintering behaviours were examined. The Si and Si3N4 powders which were milled to 1 and 2 μm particle sizes, were nitrided at 1400 ºC with using AlN-Al2O3-CeO2-CaCO3 additive combination. Heat treatment was used as gas pressure and pressureless at 1850 ºC, 1940 ºC and 1990 ºC’de for each sintering. With increasing pressure, it was seen to decrease open pores and it was reached to high relative density values at approximately %99.57 values. Also, it was observed to enhance fracture toughness values. MLZ-8 PROJE FUARI 2009 _________________________________________________________________________ INVESTIGATION OF COLLOIDAL PROPERTIES OF VANADIUM DOPED ZIRCON PIGMENTS Fahri S. BOYLU Supervisor: Assist. Prof. Dr. Emel ÖZEL Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Zircon (ZrSiO4) pigments are commonly used in the ceramic industry for glazes due to their high chemical stability and superior resistance to the dissolution during firing in glazes. These pigments are made by calcining a mixture of SiO2, ZrO2, a dopant ion which produces the colour and a mineralizer. Turquosie blue zircon pigments containing vanadium is produced commercially.In this project, vanadium doped zircon blue pigments was studied. Stabilization of zirconia in aqueous suspension and solubility of V-Zr pigments in water was investigated.The used raw materials zirconium dioxide (ZrO2), silicon dioxide (SiO2), vanadium oxide (V2O6) are mixed. The prepared compositions were calcinated at 1100 °C to pigments. The phases of the prepared pigments after calcination were analysed by using x-ray diffraction (XRD). The pigment powders were milled with a plantary mill in alumina cups with 350 rpm several minutes to achieve intended grain size which is 5.7 µm. ICP and IR was determined. Conductivity and zeta potantial were also determined. Keywords: ZrO2, SiO2, V2O6, Calcination, Pigment, Grain size, XRD, IR, ICP, Conductivity, Zeta potantial, Vanadium doped Zircon, Blue pigment. MLZ-9 PROJE FUARI 2009 _________________________________________________________________________ UTILIZATION OF COPPER ALLOY PRODUCTION WASTES Gözde Ece AYDEMİR Lütfullah Oguzhan GEZ Supervisor Prof. Dr. Nuran AY Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Slag which is formed from copper alloy (brass) production contains oxides of copper, zinc. and other elements. Slag is first processed in mill and brass is recovered. By-product of milling process is a waste which it includes zinc and other elements oxides and is called mill ash. Also another ash called fly ash. Ceramic wall tiles are used in terms of decorative and technical aim as glazed. Zinc oxide and various oxides are in glaze component. In this study, mill ash and fly ash used in the transparent glaze compositions instead of zinc oxide and its effect on glaze properties was investigated. Standard frit has 9% zinc oxide. Frit samples were prepared in which 10, 20 and 30% of zinc oxide was from mill ash and fly ash. Frit was melted at 1450⁰ C and was grinded after quenching. Recipe of glaze containing 95% ground frit was applied on wall tile. Glazed wall tiles were sintered at 1135⁰ C for 35 minutes. Hardness, brightness, color, XRD and SEM-EDS analyses were carried out. Results show that the amount of mill ash or fly ash in glaze composition can not change hardness value and increase brightness. The color of wall tile glaze was transformed from white to blue green with addition of mill ash Key words: Zinc oxide, Waste recovery, Transparent glaze, Ceramic wall tile MLZ-10 PROJE FUARI 2009 ________________________________________________________________________ NANO COATINGS FOR BIOMIMETIC DEVICES: GMR SPIN VALVE SENSORS FOR DNA SENSING Hasan SATILMIŞ Supervisor: Assc. Prof. Dr. R. Mustafa ÖKSÜZOĞLU Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this theoretical sudy type and models of magnetoresistance (GMR) spin valve sensors usable for detection of DNA molecules via sensing of superparamagnetic nanoparticles as potential biomolecular labels in magnetic biodetection technology were studied. In this paper spin valve sensors as highly sensitive biosensors and monodisperse superparamagnetic nanoparticles as magnetic labels for emerging magnetic biodetection technology, detection principles of sensors were presented. In researched papers the scientists achieved higher than 17% electrical resistance difference by the gmr spin valve sensors with paramagnetic nanoparticles for DNA chain molecule detection. Keywords: Spin valve sensor, GMR, Magnetic nanoparticle, Biodetection, Biosensor, Spin vana sensörü, GMR, manyetik nanopartikül, biyoalgılama, biyosensör. MLZ-11 PROJE FUARI 2009 _________________________________________________________________________ AlN-B4C-Al CERAMIC MATRIX COMPOSITES İrem Cansu KALPAKÇI Hülya BÖLEK Supervisor: Asst. Prof. Dr. Gürsoy ARSLAN Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this study, it was aimed to investigate electrical and thermal properties of pressureless melt infiltrated AlN-B4C-Al composites. All composites were produced at and metal type on the thermal and electrical conductivity of the produced composites are investigated. B4C content of the composites were between 20-50 wt.% depending on the designed compositions. Pure Al and 2024 Al alloy were used to infiltrate the porous AlN-B4C preforms. Open porosi the samples were carried out by scanning electron microscopy (SEM). SEM investigations revealed that the microstructures of the composites were homogeneous. X-ray diffraction analyses (XRD) showed that AlN, B4C, Al and Al3BC are the main phases in the produced composites. Thermal diffusivity and heat capacity of the produced composites will be measured by the laser flash and differential scanning calorimetry (DSC) techniques, respectively. Thermal conductivity of the ceramic-metal composites will be calculated by using these data. Impedance method will be used to measure electrical conductivity of the produced composites. Keywords: thermal conductivity, electrical conductivity, ceramic-metal composite, particle size,composition MLZ-12 PROJE FUARI 2009 APPROACHES FOR NANO-SIZE PARTICLES AND THEIR SAFE USAGE Fatih PİŞKİN Advisor: Assoc. Prof. Dr. Ender SUVACI Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Titanium dioxide (TiO2) has high absorbance behaviour, especially for the lower wavelengths of solar light (290-320 nm) and since the usage of nanosized particles; it shows great cosmetic compatibility and higher absorbance values. That’s why it is the main physical barrier component for sunscreens which have high sun protection factor. However, combining the skin penetration with photocatalytic behaviour of TiO2 which caused by absorbing the energy from solar light, TiO2 may cause skin cancer by damaging human via cells and DNA. Considering the higher photocatalytic behaviour of nanosized particles, it is required to examine the photocatalytic activity and the skin penetration of TiO2 which have limited study in literature, to provide safe usage of nanosized TiO2 in sunscreens. In this study, it is aimed to eliminate or reduce the potential skin penetration of TiO2, which makes the resultants of photocatalytic activitiy of TiO2 insignificant; micron sized controlled agglomerates that are still consisting of nanosized TiO2 particles would be produced to provide safe usage of TiO2 in sunscreens. Preventing the skin penetration of TiO2 would be the approach that avoids the potential hazardous effects on via cells and DNA. For this study, it was tried to provide control agglomeration by heat treatment with certain organics. In order to characterize and get information about phase composition of particles which exposed to heat treatment, Fourier Transform Infrared (FTIR) and X-ray diffraction (XRD) method was used. For the morphological information, scanning electron microscope (SEM) was utilized. MLZ-13 Keywords: TiO₂, sunscreen, agglomeration, photocatalytic activity PROJE FUARI 2009 _________________________________________________________________________ THE EFFECT OF COMPACT THICKNESS ON NITRIDATION OF SILICON Melih ÖZÇATAL Yiğit ATTİLA Supervisor Prof. Dr. Ferhat KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir SiAlON ceramics have a high potential for structural applications due to their good mechanical, chemical and thermal properties. SiAlON ceramics are used in applications such as cutting tools, refractory materials and ball bearings. In this study reaction bonding process was used to produce dense sialon ceramics with a relatively low cost. A mixture of Si and Si3N4 powder was used to prepare the compositions. Powders were pelletized with uniaxial pressing and cold isostatic pressing. Two different nitridation processes is applied. The first one is nitridation at 1350 0C, by keeping the temperature constant about 2 hours. The second one is nitridation beginning at 1150 0C, then slowly increasing the temperature (first 100 0C then 50 0C about 30 minutes) until 1350 0C. The efficiency of these two techniques was compared. Nitridation is followed by a sintering process at 1950 0C under 5 bar pressure and 1990 0C under 10 bar pressure. At the end of the study XRD and SEM techniques were applied to decide optimum processing parameters. Keywords: SiAlON, Si and Si3N4 powder, Reaction Bonding MLZ-14 PROJE FUARI 2009 _________________________________________________________________________ TEXTURE EVOLUTİON IN DEFORMATİON OF MAGNESİUM ALLOYS AND ITS ASSESSMENT USİNG X-RAYS Murat EROĞLU Supervisor Prof. Dr. Ferhat KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Magnesium alloys have a great potential in automotive industries, compared to steel and aluminium (Al), Magnesium (Mg) is much lighter and this weight reduction improves fuel efficiency and lowers green gas emission. Due to its hexagonal crystal structure, magnesium has poor ductility at room temperature. Magnesium's ductility improves significantly above about 200°C due to thermal activation of additional slip systems. In this study, texture evolution of magnesium alloy sheets in different deformation processes were researched by X-ray pole figure technique. It is observed that the texture of magnesium alloy sheets prefers the basal texture, and other compositions of texture are relatively weak MLZ-15 PROJE FUARI 2009 ________________________________________________________________________ THE USAGE OF ISTANBUL COALED CLAYS IN PORCELAIN TILE PRODUCTION Murat TARCAN Advisor: Assoc. Prof. Dr. Alpagut KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir It is well known that clays are important constituents of ceramic tile bodies. An optimum combination of various clays provide plasticity and green strength during forming stages and contribute substantially to the colour of the fired products depending upon the impurity oxides present. With the increased production rate in ceramic tile manufacturing, new alternative clays are needed in the whole ceramic sector. Due to this, new clays deposits and their investigation had become and important issue for the producers. In this study, the clay deposits near Şile region were investigated. Firstly, the clay samples were characterised using with XRF and XRD. In order to study the thermal properties of the clay samples, TGA/DTG measurements were carried out. Finally standard tests were applied to the porcelain tiles obtained from the experimental bodies incorporated with varying amounts of clay samples after single fast-firing under industrial conditions. The results showed that, it was possible to use of İstanbul coaled clays into porcelain tile formulations Keywords: Coaled clay, Porcelain tile, Characterisation MLZ-16 PROJE FUARI 2009 _________________________________________________________________________ EXPERIMENTAL SETUP FOR GIANT MAGNETORESISTANCE MEASUREMENTS Okan DENİZ Assoc. Prof. Dr. R. Mustafa ÖKSÜZOĞLU Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Giant magnetoresistance (GMR) is an effect which is observed in thin film multilayer structures composed of two ferromagnetic material and a metal between them. The idea of GMR is basically providing an extra electrical resistivity by changing the magnetic orientation of the spins of the electrons. An increase electrical resistivity can be provided when the spin of the electrons which is passing through the material by current is opposite to the spin direction of spin of the material’s electrons. The magnetic orientation of spin can be changed by applying an external magnetic field. By changing the magnetic orientation of the materials electrons we gather a difference between the resistivities from one applied magnetic field direction to another, called Magnetoresistance Effect. For understanding the GMR effect measurement the electrical characterization is important. For the thin film structures, “four point probe” technique is common to measure the sheet resistance. In this project, the experimental setup consisting self made FPP and Helmholtz Coil was utilized for GMR effect measurements. The specifications, parameters, problems, especially the integration of four point probe technique into the Helmholtz coil (magnetic field provider) and the possible solution suggestions will be considered and discussed. MLZ-17 PROJE FUARI 2009 OPTICAL PROPERTIES OF OXYNITRIDE GLASS Orçun PEŞKİRCİ Advisor: Asst. Prof. Dr. Emrah DÖLEKÇEKİÇ Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Oxynitride glass is found at the intergranular phases in the Si3N4 based ceramics in which oxygen atoms replaced by the nitrogen atoms. Glass network is more strength than the other glass due to the nitrogen makes 3 bonds instead of the oxygen makes the 2 bonds. Due to that, oxynitride glass has high mechanical properties. Also, oxynitride glass has high thermal properties, high chemical durability and electrical insulator properties with respect to glass batch. In these days, special glasses which have not high mechanical properties corresponding to the oxynitride glass are used for optical and electrical systems. According to the mechanical properties, oxynitride glass can be appropriate candidate materials especially for optical and various systems. Experiments are done by using the different amount of nitrogen and rare-earth elements with the same rare-earth element (Er). After the sintering process, samples cuts off the 1.2 mm thickness and samples get 80% infrared transmission between 6000 cm-1 and 3000 cm-1. Also, process parameters such as sintering temperature and cooling temperature, affects the transparency of oxynitride glass in the visible light region. Keywords: Oxynitride glass, Infrared, optical properties, transparency MLZ-18 PROJE FUARI 2009 SPARK PLASMA SINTERING OF ELECTRICALLY CONDUCTIVE ZrO2 – Ti(C,N) COMPOSITES İbrahim Erdem İRTEM Supervisor: Assoc. Prof. Alpagut KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In the aerospace, automotive and tool field, advanced ultra hard materials are needed. However, these advanced ceramics materials are difficult to machine with traditional methods due to their high cost diamond and cubic boron nitride grinding tools. Consequently alternative methods are needed such as EDM. Electrical discharge machining (EDM) is a nonmechanical contact machining technology, which allows machining of complicated parts, is widely used for electrically conductive materials despite of their hardness. However, engineering ceramics such as ZrO2, Al2O3 or Si3N4 cannot be machined by EDM due to their too high electrical resistivity. In order to use the advantages of the EDM process, a secondary electrically conductive phase, such as WC, Ti(C,N) can be added to obtain a composite that is electrically conductive enough to allow EDM machining. In this project, yttria-doped zirconia (YSZ) powder is used as matrix material. YSZ powder is mixed with Ti(C,N) powder to acquire a preferable system. Ti(C,N)-YSZ powder are sintered under pre-defined conditions by spark plasma sintering and conventional pressureless sintering. The physical properties of sintered samples are carried out with; Archimedes method, Scanning electron microscope (SEM), X-ray diffraction system (XRD) and Vickers hardness indentation measurements. For electrical conductivity sample surfaces are polished and coated for creating an electrolyte surface. Thus impedance and two point probe techniques are employed. MLZ-19 The experimental results revealed a strong influence of the secondary electroconductive phase to a high surface hardness and good electrical conductivity of the ZrO2based composites for EDM behavior. MLZ-20 PROJE FUARI 2009 CHARACTERİZATİON ON NANO SCALE THİN FİLMS USİNG X-RAY REFLECTİVİTY AND ROCKİNG CURVE TECHNİQUE Özgün Başkan TAŞTAN Supervisor: Assoc. Prof. Ramis Mustafa ÖKSÜZOĞLU Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Recent progress in growth techniques has made it possible to fabricate different kinds of thin films and multilayer structures. Optimisation of the fabrication process and a physical understanding of the samples require non-destructive methods to study the samples produced. X-ray reflectivity (XRR) is conveniently applied for surface-interface roughness, density and thickness determinations. XRR is nowadays used for the characterisation of coating layers for optics and surface hardening, and different layers used in micro- and optoelectronics. Rocking Curve (RC) technique is important for deriving the texture profile and determination of the crystalline quality of the film. MLZ-21 PROJE FUARI 2009 ________________________________________________________________________ THE INVESTIGATION OF COLLOIDAL STABILITY OF COAl2O4 CERAMIC PIGMENT Serhan KARABIYIKOĞLU Supervisor: Assist. Prof. Dr. Emel ÖZEL Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Ceramic inks prepared with inorganic pigments are widely used for decoration of ceramics. Coloured inks are prepared by dispersing of inorganic pigment in water and organic solvent mixture. Ceramic inks, used in screen printing, are called as paste because of their high viscosity. The stability of inks and rheological properties are affected by physical and chemical interactions between pigment particle and solvent. To reduce decoration problems and use new decoration techniques successfully, colloidal properties of inks and physicalchemical interactions between pigment particle and solvent should be well known. On the other hand, there are only few related studies about these topic exist. For this reason, the colloidal properties and stability of Co-Aluminate inorganic pigment suspension in water was investigated. In this project, firstly, Co-aluminates blue pigments which are industrially available were ground to about 1 µm and pigment particles dispersed in different pH values. The zeta potential, pH/conductivity and Inductive Coupled Plasma (ICP-OES), measurement was performed. Obtained results showed that the pigment particles dissolve in water and the ion concentration increase with increasing time. Also, the value of the conductivity increase with ion concentration of suspension. Keywords: Co-Aluminate, cake, stability MLZ-22 PROJE FUARI 2009 ________________________________________________________________________ DİFFUSION BONDİNG OF MAGNESIUM AND TITANIUM FOR BİOMEDICAL APPLICATION Tuğçe YILDIZ Supervisor Prof. Dr. Ali Arslan KAYA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Degrading metal alloys are used for future biomedical applications as implant material such as hip joint, stents and to make medical equipment. Magnesyum has good biocompability and facilitates new bone formation and accelerates healing of bone by forming hidroxiapatite on bone crystalline structure. Ti-6Al-4V alloy has high machanical properties such as high strength, high corrosion and wear resistance and also good biocompability and presently, it is used for many biomedical applications due to their excellent properties. Therefore, this study aim is joining titanium and magnesium alloys by diffusion bonding. Diffusion bonding requires mutual solubility and/or intermetallic compound formation between the joining metals. Magnesium and titanium do not show either in their binary phase diagram. However, zirconium can be used as a transition agent between magnesium and titanium. İn this study vacuum hot pressing (VHP) technique is used for forming Tİ-Zr-Mg structure by diffusion bonding. SEM, TEM and optic microscope are used for analysing morfology and thickness of diffusion zone. MLZ-23 PROJE FUARI 2009 _________________________________________________________________________ α - β SiALON/SiC COMPOSITES BY PARTIAL NITRIDATION İsmail İŞÇİ Supervisor: Prof. Dr. Ferhat KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Silicon nitride (Si3N4) and silicon carbide (SiC) are ceramics extensively investigated, because of their excellent mechanical properties, such as, high hardness, high strength at high temperatures as well creep and oxidation resistance. These properties turn these ceramics, candidates and also composite materials for structural applications such as cutting tools, engine components and aerospace devices. For this purpose Si3N4, Al/AlN, Si, SiC, Al2O3, Yb2O3, Sm2O3, CaCO3 powder batches were mixed by planetary milling, for 2 h, in isopropilic alcohol. The powders were dried in the rotary evaporator. After drying, the powder batches were sieved and compacted in two-step: (1) uniaxial pressing, under 30MPa; (2) cold isostatic pressing under 300MPa. Sintering was done gas pressure sintering at 1990 ◦C with an isothermal holding time of 2 h under 2,2MPa-N2. The sintered samples were characterized by X-ray diffraction. In this study the results will be presented. Keywords: SiALON, SiC, Composites, Nitridation MLZ-24 PROJE FUARI 2009 INVESTIGATION OF HOT WORKED MICROALLOYED PLATE STEELS AND EFFECTS OF THERMOMECHANICAL PROCESSES Güneş GÜNGÖR Supervisor: Prof. Dr. Ali Arslan KAYA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir HSLA steels (microalloyed) known as high-strength low-alloy steels provide increased strength-to-weight ratios over conventional low-carbon steels for only a modest price premium. Due to the fact that HSLA alloys are stronger, they can be used in thinner sections, making them particularly attractive for transportation-equipment components where weight reduction is important and these steels are available in all standard wrought forms such as sheet, strip, plate, structural shapes, bar-size shapes, and special shapes. HSLA steels are lowcarbon steels with up to 1.5% Manganese, strengthened by small additions of elements, such as Niobium, Vanadium or Titanium and sometimes by special rolling and cooling techniques. Improved-formability HSLA steels contain additions such as Zirconium, Calcium, or rareearth elements for inclusion control. With this study, the structure, production methods and processes of hot-worked microalloyed plate steels were investigated and how the mechanical properties of them had changed was researched. Keywords: Microalloy, Thermomechanic, Steel, Hsla, Hot Work Deformation MLZ-25 PROJE FUARI 2009 ________________________________________________________________________ OPTİMİZATİON OF THE PASSİVATİON HEAT - TREATEMENT APPLİED TO B4C POWDERS TO PRODUCE B4C - AL COMPOSİTES Umut T. SANLI Supervisor: Doç.Dr. Gürsoy ARSLAN Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Passivation heat treatment is a process that reduces the reactivity of the powders by changing their surface chemistry. The optimization of passivation time and temperature of boron carbide (B4C) powders was studied in this work. The B4C powders that were hours were used to find the optimum passivation temperature and time combination. Besides passivated powders, as-received B4C powders were also used to investigate the effect of passivation heat treatment on the mechanical properties of the composites. It was observed that passivation helps reducing the amount of the reaction products namely Al3BC and improving the mechanical properties. The phases present in the produced composites were determined by using X-ray diffraction technique. After the passivation heat treatment, B4C pellets were pressureless melt infiltrated under an argon gas atmosphere with an 2024 Al alloy light-weight (< 2.65 g/cm3) B4C–Al composites. Microstructure of the produced composites were characterised by scanning electron microscopy (SEM). Keywords: Passivation, Boron Carbide, Ceramic Matrix Composites, Al3BC. MLZ-26 PROJE FUARI 2009 ________________________________________________________________________ EFFECT OF THE PARTICLE SIZE OF NON-PLASTIC RAW MATERIALS ON THE PYROPLASTIC DEFORMATION OF SANITARYWARE Ömer EKER Supervisor: Assist. Prof. Dr. Emel ÖZEL Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In sanitaryware industry, the pyroplastic deformation, commonly observed in big and flat shape products can be modified with particle size of non-plastic raw materials, amount of glassy phase and its viscosity. In this study, the effect of particle size of non plastic raw materials on pyroplastic deformation was investigated. Additionally, green strength, water absorption and shrinkage values of sanitaryware products were measured. As a result of experimental studies, it was determined that pyroplastic deformation reduces as 5 % ratio with decreasing particle size of non-plastic raw materials. Also the lower water absorption values were obtained than the standard sanitaryware body formulation, especially 0 % water absorption was obtained with grounded powder for 50 minutes. Keywords: Sanitaryware, pyroplastic deformation, particle size distribution. MLZ-27 PROJE FUARI 2009 _______________________________________________________________________ THE REDUCTION OF PORCELAIN TILE THICKNESS Selda NAYİR Assoc. Prof. Dr. Alpagut KARA Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Porcelain tile is basically made from clays, kaolin, feldspars, and quartz. Clays and kaolins provide plasticity and dry mechanical strength and form mullite and glassy phase during firing; feldspars are low-temperature glassy phase formers; and quartz contributes to thermal and dimensional stability, because it is the most refractory constituent. Porcelain is characterized by high technological properties, especially regarding water absorption, chemical and frost resistance, bending strength and abrasion resistance. Due to its excellent functional, mechanical and aesthetical properties it is selected as a thesis study and the main aim of the study is that reducing the thickness of the porcelain tile without loses from its mechanical properties. Because It is believed that the thin porcelain tile would have a definite advantage where transportation is an important factor and in the erection of prefabricated units. Shorter firing periods and the use of less material may be further advantages. [3] For this purpose, four different samples that are STD, 5.5 h, 6.0 h and 14.0 h, are used. Even though, their compositions same and contain standard porcelain raw material, their milling times are make the differences. Besides, 90 bar, 100 bar, 110 bar, 120 bar and 130 bar pressures are exposed to the each sample that are at 5x10 cm size and 70 g weight. The mean of the pressure and particle size differences, to show the effect of them on the strength. After pressing they are subjected to the three point bending test and they show different strength values. At the result of the tests maximum strength is observed from 5.5 h sample at 130 bars. The main problem is that loosing the strength when the tiles is heated to kiln, it can not carry its own weight due to pyroplastic effect. By reason of, the deformation occurs more frequently in highly vitrified pastes like porcelain tiles. The deformation highly depends on MLZ-28 thermal work, composition and thickness of the tile and it develops as a function of vitrification during firing. MLZ-29 PROJE FUARI 2009 _________________________________________________________________________ INFLUENCE OF SURFACE PREPARATİON ON NANO SCALE THİN FİLM GROWTH AND INDUSTRİAL MANUFACTURİNG Barış ÇELTİKÇİ Supervisior: Doç. Dr. R. Mustafa ÖKSÜZOĞLU Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In today’s thin film growth processes is seen in all applications which is used commonly. Especially this process is used in electronic and nanotechnology applications and will be more favorable in the future. Primary requirements on thin film growth (surface crystal structure, surface cleaning on atomic scale and etc.) determine growth thermodynamic and structural and functional properties. The first question on nano scale thin film growth is that the providing of requirements is done or not. This study contains preparing of an wafer to growth a thin film. In today’s the preparing of an wafer is done in 2 ways; physical and chemical procedure. This study is about effects of chemical methods on wafer surfaces. In addition the light and atomic force microscopies were used for characterizing of the wafers MLZ-30 PROJE FUARI 2009 _________________________________________________________________________ NOVEL APPLICATION OF TEXTURED CERAMICS Umut SAVACI Superviser : Assoc. Prof. Dr. Ender SUVACI Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Piezoelectric ceramics are widely used in broad range of applications such as medical imaging, microscopes, microphones and etc. Piezoelectric effect was first discovered by Curie brother while they induce stress to quartz, it produced current. After that during the World War huge researches were done in the piezoelectric ceramics. During researches now it is well known lead zirconate titanate (PZT) composition was showed high piezoelectric properties. Its’ good piezoelectric properties make PZT useful for wide range of applications. Due to the toxicity of PZT because of lead, most researches started to investigate other lead-free piezoelectric ceramics. BaTiO3 (BT), (K,Na)NbO3 (KNN) and (Bi,Na)TiO3 (BNT) were candidates of lead based piezoelectric ceramics but they not have piezoelectric properties as high as PZT. Binary compositions of these compositions investigated for better piezoelectric properties. According to these researches binary solid solutions possess higher piezoelectric properties but not good enough. Ternary compositions were tried and showed better piezoelectric properties. Piezoelectric properties can be increased with some applications such as hot pressing and many other methods. In this project first grain growth attempts were tried for ternary composition, and in the case of success grains are oriented by using templates with appropriate heat treatment methods. MLZ-31 PROJE FUARI 2009 ________________________________________________________________________ EFFECTS OF SEPIOLITE ADDITION ON WALL TILE BODY Okan ANDIRIN Danışman: Yrd. Doç. Dr. İrfan TÖRE Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir In this study, raw material of sepiolite was analyzed availability for wall tile body and variation of physical properties on body due to sepiolite ratio. Russian clay, kaolen, quartz and Na-feldispat including mixture was prapered as main recipe. Sepiolite was added to obtained mixture %5, %10, %15, %20 ratio weight of mixture. Ratio of Na-feldispat was decreased due to additional ratio of sepiolite. This mixture was grinded below to 63 µm. Granules was obtained which has %5 moisture after slurry has dried. Obtained these granule was shaped at 5x10 cm sizes by pressing at 75 bar with hand press and was fired at 10500C, 1100 0C, 1125 0C, 1150 0C with nabertherm roller (laboratory vintage) furnace. Physical and mechanical behaviour as firing shrinkage, firing strength, water absorbtion, density, color, porosity of obtained ceramic materials was done characterization analyses. Physical property of porous body strructure as wall tile was seen improve according to obtained results by addition of sepiolite. MLZ-32 PROJE FUARI 2009 ________________________________________________________________________ PRODUCTION AND APPLICATION OF RED PHOSPHORESCENT PIGMENTS Mehmet Tümerkan KESİM Danışman: Prof. Dr. Bekir KARASU Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir Phosphorescence is the re-emission of the absorbed radiation after a specific period of time. It differs from luminescence in a way that emission continues after the cessation of the excitation for several minutes to hours. Phosphorescent pigments are utilized in many areas including military applications, security signs, and lightening devices. Satisfactory results have been acquired in blue-green, and yellow phosphor systems. On the other hand, red phosphorescent pigments cannot be improved as much as blue-green, and yellow, thus cannot find many application areas. Over 5 hours of red afterglow can be acquired in red phosphorescent systems, however they are not chemically stable and harmful by-products are produced. For that reason, in the scope of this thesis, production of red phosphorescent systems and their application on traditional ceramics were investigated. Sintering regime and compositions of the systems were changed in order to observe the afterglow time and intensity of phosphorescence. MLZ-33 PROJE FUARI 2009 _________________________________________________________________________ ZNO ESASLI VARİSTÖR ÜRETİMİNDE YENİ BİR YAKLAŞIM Hakan YAVAŞ Danışman: Doç. Dr. Ender SUVACI Malzeme Bilimi Ve Mühendisliği Mühendislik-Mimarlık Fakültesi, Anadolu Üniversitesi İki Eylül Kampusu, 26555, Eskişehir Bu çalışmada, varistör uygulamalarında kullanılmak üzere hazırlanan çinko oksit ve bizmut oksit tozlarının kolloidal sistemlerde ki kaplanma karakteristiği incelenmiştir. Çalışmanın ilk aşamasında kolloidal kaplamada önemli olan parametreler belirlenmiş ve bizmut oksitin su içerindeki zeta potansiyeli ölçülmüştür. Seyreltik olan hazırlanan bizmut oksit çözeltisinin pH 1.0, 1.5, 3.0, 5.0, 6.0, 7.0, 8.3, 9.0, 10.0, 11.0 değerlerinde zeta potansiyeli zetametre ile ölçülmüş ve izoelektrik noktası da pH 1.4 olarak bulunmuştur. Bu aşamadan sonra kaplama yapılması planlanan pH 10 değeri için çinko oksitin su içerisindeki zeta potansiyeli zetametre ile ölçülmüştür. Çalışmanın ikinci aşamasında birbirinden bağımsız ve seyreltik olarak pH 10’da hazırlanan çinko oksit ve bismut oksit çözeltileri kontrollü olarak karıştırılmıştır. Yapılmış olan kaplamanın karakterizasyonu için SEM analizleri yapılmıştır. MLZ-34 PROJE FUARI 2009 ___________________________________________________________________________ BORTEK 11’İN METAL DÖKÜM MAÇALARINDA KULLANIMININ İNCELENMESİ Abdullah GÜLEÇ Özkan KIDAK Prof. Dr. Nuran AY Malzeme Bilimi ve Mühendisliği Mühendislik-Mimarlık Fakültesi, Anadolu Üniversitesi İki Eylül Kampusu, 26555, Eskişehir Metal döküm sanayi her gecen gün kendisini yenilemekte, en ucuz maliyetle en kaliteli ürünü elde etme amacı ile üretim yöntemleri gözden geçirilmektedir. Üretim yöntemlerinde ve kullanılan malzemelerde yenilikler yapılmaya çalışılmaktadır. Döküm yöntemi, ilk çağlardan beri kullanılan bir şekillendirme yöntemidir. Döküm işlemlerinde kalıp malzemeleri, ergitme cihazları, yardımcı malzemeler üzerinde sürekli çalışılmaktadır. Bu çalışmada, içi boş döküm parçası üretmek için yararlanılan maçaların özelliklerine BORTEK 11 ilavesinin etkisi incelenmiştir. Maçalar, maça kumu, bağlayıcı ve BORTEK 11 karışımının şekillendirilmesiyle hazırlanmıştır. Hazırlanan numuneler (D1, D2, D3, D4 kodları ile üretilmiştir) kalıp içine yerleştirilerek döküm yapılmıştır. Döküm işlemi sonucunda metal parçalar temizlenmiş ve yüzeyleri incelenmiştir. Elde edilen sonuçlara göre BORTEK 11’ in maçalarda kullanımı daha az hata oluşumuna olduğu bulunmuştur. MLZ-35 PROJE FUARI 2009 ________________________________________________________________ CHARACTERIZATION OF SiAlON-SiC COMPOSITE SYSTEM BY USING TRANSMISSION ELECTRON MICROSCOPY Berke ÖKSÜZ Supervisor : Prof. Dr. Servet TURAN Material Science and Engineering Faculty of Engineering and Architecture, Anadolu University İki Eylül Kampusu, 26555, Eskişehir Silicon aluminium oxynitrides (SiAlONs) have superior mechanical and thermal properties which are the reason of the usage in high temperature applications that are ideal engineering materials. The mechanical properties can be adjusted over a wide range by modifying the type and quantity of the additives. Due to having complex crystal structure of SiAlON, their microstructure had to be investigated to improve the final product properties and identify effective parameters on microstructure. Therefore, the parameters which are compositional variation, grain boundary phase, microstructure and secondary phase addition had to be investigated. In this study, SiAlON- SiC (Silicon carbide) and SiAlON- ZrO2 (Zirconia) composite system were utilized for characterization. Samples were prepared by Cross Section Polisher (CP) for Scanning Electron Microscope (SEM). Samples were into electron transparent by cutting, grinding, ultrasonic disc cutter, parallel polishing and ionbeam processes for Transmission Electron Microscope (TEM) investigations. And then, these samples were characterized by utilizing Energy Filtering (EFTEM), parallel electron energy loss spectrometer (PEELS), High angle Annular Dark Field (HAADF) Scanning Transmission Electron Microscope (STEM) detector and Energy-Dispersive X-Ray (EDX) spectrometer attached to TEM. Keywords: SiAlON, SiC, ZrO2, characterization, TEM MLZ-36 PROJE FUARI 2009 ___________________________________________________________________________ MECHANICAL PROPERTIES OF SiC-B4C-Al COMPOSITES Fatma KARANFİL Supervisor : Assist. Prof. Dr. Gürsoy ARSLAN Department Of Materıals Scıence And Engıneerıng Faculty of Engineering and Architecture, Anadolu University Iki Eylül Campus, 26555, Eskisehir B4C-Al composites are the most favorable material to use in the ballistic applications. SiC is the ceramic material which are similar mechanical properties with B4C and cheaper than B4C. In this thesis, it was aimed to investigate mechanical behaviour of SiC-B4C-Al ceramic-metal composites to use multiple impact resistance armour materials. The passivated B4C and SiC were mixed and Al was infiltrated at 973C and 1h via pressureless infiltration method. Passivation condition of B4C was 1400C and 2h. The microstructure of the composites were investigated using a scanning electron microscope (SEM) and the phases quantity were determined by using X-ray diffraction (XRD) analysis. Vicker microhardness and compression test will be done to investigate mechanical properties of composites. The result of the XRD was the reaction product of Al4C3 that affect the mechanical properties negatively was not exist in the system. Keywords: SiC-B4C-Al Composites, Mechanical Properties, Balistic Application. MLZ-37 PROJE FUARI 2009 ________________________________________________________________ PORSELEN KARO SIRI UYGULAMALARI İÇİN OKSİNİTRÜR CAMLAR Suna AVCIOĞLU Danışman: Prof. Dr. Hasan MANDAL Malzeme Bilimi ve Mühendisliği Mühendislik-Mimarlık Fakültesi, Anadolu Üniversitesi İki Eylül Kampusu, 26555, Eskişehir Bu çalışmanın amacı, genel kullanıma açık alanlarda tercih edilen porselen karoların aşınma direncini arttırmak için porselen karo sırlarında oksinitrür camların kullanılabilirliğinin araştırılmasıdır. İlk olarak oksinitrür camların potansiyeli hakkında fikir sahibi olmak amacı ile literatür incelemesi yürütülmüştür. Ardından oksinitrür camların sır olarak uygulanabilirliği ve porselen karo pişirim rejimi ile oksinitrür camların sentezlenme davranışları ilişkilendirilmeye çalışılmış, aralarında sağlanabilecek uyum araştırılmıştır. Daha sonra sırlı porselen karoların yüzey özelliklerini (örneğin; aşınmaya karşı direnç ve sertlik) etkileyen faktörler ve iyileştirilmeleri için kullanılan genel yöntemler araştırılmıştır. Bu çalışmada üç farklı ticari frit ile çalışılmıştır. Kompozisyonlarına farklı oranlarda çeşitli azot kaynağı hammaddeler eklenerek porselen karo üretim koşullarında cam ağı içerisine girmesi amaçlanmış, etkileri gözlenmiştir. Her sistem için benzer öğütme ve pişirim koşulları sağlanmıştır. Tüm kompozisyonlar bir saat jet değirmende öğütülmüş ve öğütme işleminin son 5 dakikasında nitrojen içerikli hammadde kompozisyona dahil edilmiştir. Elde edilen sırlar karo yüzeyine uygulanıp kurutulduktan sonra 20 ºC/dk hızla 1200ºC’de hızlı pişirim fırınında pişirilmiştir. Numunelerin yüzeyinde pişirim esnasında sistemdeki nitrojen kaynağının oksitlenmesi nedeniyle gaz çıkışı problemi meydana gelmiş, kabarma ve kaynama gözlenmiştir. Ancak meydana gelen yüzey hatalarının kompozisyon farklılıklarına göre değişim gösterdiği söylenebilmektedir MLZ-38 PROJE FUARI 2009 ________________________________________________________________ BOR NİTRÜR (BN) OKSİDASYONU Cem KARAKÖYLÜ Danışman: Yrd. Doç. Dr. İrfan TÖRE Malzeme Bilimi ve Mühendisliği Bölümü Mühendislik-Mimarlık Fakültesi, Anadolu Üniversitesi İki Eylül Kampusu, 26555, Eskişehir Bu çalışmada bor nitrür (BN) tozunun çeşitli sıcaklık değerlerindeki oksidasyon davranışı incelenmiştir. Oksidasyon davranışları uygulanan sıcaklık değerlerinde kuru hava atmosferinde gerçekleştirilmiş olup, yapılan deneysel çalışmalarda bor nitrür (BN) tozunun oksidasyon davranışları sırasıyla 500 oC, 600 oC, 700 oC, 800 oC, 900 oC, 1000 oC, 1100 oC sıcaklıklarında incelenmiş ve uygulanan her bir sıcaklık değerinden sonra bor nitrür tozunun oksidasyon davranışının sıcaklık değişimlerine göre gösterdiği değişiklikler hassas tartımlar ve XRD analizleriyle desteklenilmeye çalışılmıştır. MLZ-39 PROJE FUARI 2009 ________________________________________________________________ HEGZAGONAL BOR NİTRÜRÜN YAŞ ORTAMDAKİ ÖGÜTME PARAMETRELERİNİN İNCELENMESİ Ahmet Serter KARABIYIK Danışman: Prof. Dr. Nuran AY Malzeme Bilimi ve Mühendisliği Mühendislik-Mimarlık Fakültesi, Anadolu Üniversitesi İki Eylül Kampusu, 26555, Eskişehir Üretilen parçacıkların en büyük boyutunun yaklaşık 5mm’den daha az olduğu hallerdeki yüzey büyültme işlemine öğütme adı verilir. Öğütme işlemi, öğütülecek maddenin özelliklerine ve kullanılan değirmene bağlı olarak kuru ve yaş olarak yapılmaktadır. Öğütmenin su, alkol ve heptan gibi bir sıvı içinde yapılması hem öğütme süresini kısaltır, hem de ince tozlar üretilmesini sağlar. Bir öğütücünün verimliliğini öğütme ortamının çarpışma hızı ve öğütücü içindeki malzemenin hareketliliği belirler. Tüm seramik ürünler tozlardan elde edilmekte ve ürünün bazı özellikleri (ör. mukavemet, kırılma tokluğu ve ısıl iletkenlik) tozun tane boyutu ve tane boyut dağılımı ile ilgilidir. Üretilecek ürünün özelliklerinin istenilen derecede olması için tane boyutunun ve tane boyut dağılımının mümkün olduğunca optimum değerlerde olmalıdır. Bu çalışmada faktöriyel deney tasarımı ile 300 µm üstünde ki h-BN numunesinin bilyalı değirmende öğütülmesi sonucunda, tane boyutunun uygulanan öğütme ortamına (su, alkol) ve dönme hızına göre nasıl değiştiği incelenmiştir. Numunelerin XRD, SEM, tane boyut analizi yapılmıştır. Anahtar kelimeler: h-Bn, yaş öğütme, bilyalı değirmen, MLZ-40