Team Delta

advertisement

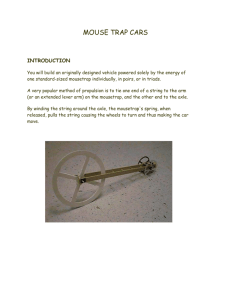

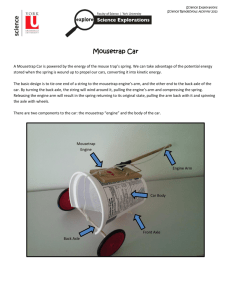

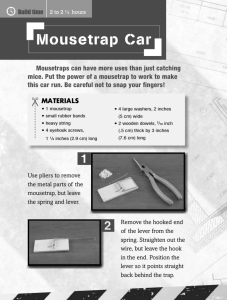

Team Delta Melissa Beyer Regina Corcoran Bryan Dreiling Mousetrap Vehicle: PHSY 102 Group Project Scientific Principles: This project revolves around Isaac Newton’s Third Law of Motion which states that “for every action there is an equal and opposite reaction”. The mousetrap is applying a force to the vehicle’s axle thus causing it to accelerate forward. Potential Energy is stored in the mousetrap’s spring – when loaded. In order to use that energy, it has to be transferred in a useable fashion to the wheels of the mousetrap car. This is done by attaching a string to the lever and to the axle. As the drive axel is turned – loaded – the mousetraps spring is wound. When the spring is released, the string is pulled off the drive axle causing the axle and the wheels to rotate, thus making the car move forward. Along with the core ideas of energy and Newton’s Third Law with the mousetrap, one must also take into account other forces acting on the car. This include the friction that occurring with the air, the rubbing of axels on the car, and the friction on the wheels. Procedure: Initially, our group spent a lot of time brainstorming about potential designs for this mousetrap vehicle. None of the group members had experience in constructing a vehicle of this nature, so this brainstorming process was a time consuming task. We talked about some type of pulley-system and some other nonworkable plans – in retrospect. The initial plan was to have the snapping action of the mousetrap pull a string that was wound up around the back axels of our vehicle. As you will see in the rest of our procedure, we had the correct concepts in our head, but the implementation of these concepts in practice was much more difficult that could have ever been expected. I hope everyone that reads this enjoys the trails and tribulations of Group Delta. The materials needed in this first design of our mousetrap vehicle included: Balsa Wood String Mouse Traps Wire Compact Disks (4) Wooden Dowels Straws (2) Hot Glue Staples The next major design step was to decide on the physical attributes of the vehicle’s body. We ended up deciding on box shape for our car. Even though there would be air resistance on this non-aero-dynamical shape we thought it would probably be the most sturdy to handle the snap of two mouse traps linked together. The body of the car was made with two different pieces of balsa wood. After the body of the car was completed, we measured where the holes for the axles would need to be in the balsa wood body. Bryan, not being very inclined to making exact measurements, had to re-drill a couple of holes in the body because the axels where not aligned perfectly straight. When this was completed we attached the wheels and axles to the vehicle. The wheels where made of compact disks. The axle was a piece of a wooden dowel that extended through the car and outside of the CD wheels. We attached the wheels to the axle by cutting out small pieces of our extra balsa wood and drilling a hole through it the same size as the axle. We then glued the balsa wood pieces to the wheels, slid the axle inside of those holes now attached to the wheels and glued them in place. We also had to look at what would allow the vehicles axles to spin the most freely. At first, we thought that having a straw covering the axle would help the spinning of the car the most. After experimenting with this, we found that the design with the least amount of friction was without any straws and just have the axle freely spinning around the holes in the balsa wood base of the vehicle. The straw was a little too small, and it also had more direct contact with the axle than the base alone. We believe these two factors caused the frictional deficiency of the straw/axle design. Next, we moved on to the power source of the vehicle. The initial thing that we did was to staple the 2 mousetraps together – side by side – with the bars aligned in the same direction. Next we wired the two bars together and tied a string in the middle of this dual mousetrap engine. A string was attached to the release mechanisms of each mouse trap so they would be released simultaneously. The next quandary was figuring out which direction the mousetrap needed to be orientated and what way the string had to be wrapped around the axel of the car. The mousetraps where glued in the front of our car and testing could begin. In the first tests, our string broke and the car went no where – actually in a couple of the experiments the car actually went upward. Unfortunately, vertical movement is not the criterion that we are being judged upon. If it was, our group would probably have won the competition. We believed that the force was what was snapping the string. In retrospect, it was probably a combination of the quick snap of the mousetraps and also that the string did not have anything to catch on attached to the axel. We did not have a spoke for it to turn with and as a result the string snapped. In our next tests, we where beginning to get on the right track. With just the mousetraps alone, the string that we were using was not going to get moved very far. So, we attempted to wire a piece of a wooden dowel to the levers of the mousetrap. In test the string did not break, but the dowel was very unstable. In the second test the dowel broke apart from the vehicle hitting one of the group members in the finger and also flying across the room at another group member. At this point, we opted for a new car and a new strategy. A step that was neglected in the first design plan was practical outside research. Newton’s Laws, book definitions, and an idea for the concepts proved to only take you so far in the practical applications of these pedagogies. Some helpful internet research showed us that we where all so close, but at the same time way off track in our first design. A few things we learned from this research. 1) The best way to construct this car is the have the winding of the string to take place in the center of the rear axel. 2) The lever used in the power supply can not extend past the rear axel of the car. If it does, the tendency will be for the car to go up. 3) The best design for our group might be the simplest design. It may not win the race, but it will sure be satisfying to see the car actually move forward. Our new design followed some of our thought from the old car, with a few modifications. First, we changed the style of the body. It became a single piece of wood rather than a box style racer. We cut out a notch of the wood. This is where we will load the axle with the wound up string. We screwed eye screws into the wood. These eye screws would hold the axel and give it only a minimal point of friction. The axles were salvaged from an old toy and modified so they would be the proper length of the piece of wood that we were working with. We cut four small pieces of a plastic straw to use as spacers so the wheels would not hit on the wood frame and cause more friction. Also, we glued CD’s to the back wheels. This is to allow more lateral movement with the same about of revolution of the axel. We let the front wheels in the original size to make the car more aerodynamical – allowing for less air resistance on the car. The biggest change actually took place with mousetrap. We decided that to keep this design simple and as a result, we only are using one mousetrap. We also used a principle we found in our research: the lever can not be longer than the axel. This was one – of many -- reasons our first design failed. We found a piece of hollow metal that after slight modification of the mousetrap, fit on to the spring to make a lever that was exactly as long as the axel. With the simple car put together, we tested it. To our surprise, it travels some distance. It by no means will be the class longest. But it moved! We where able to bridge the boundaries of philosophy and practice to actually get something workable to use the principles we outlined in the Scientific Principles section of the paper. Conclusion: This project was a lot harder than we expected it to be. It really forced us to look at the principles and apply them to get something that would meet the objectives that the project set out. For better or worse, our group now has a better understanding of Newton’s Laws of Motion with the completion of this project. Also, it gives us a greater appreciation of scientists and engineers that take these laws of science and apply them to make practical things that aid in the quality of individual’s lives.