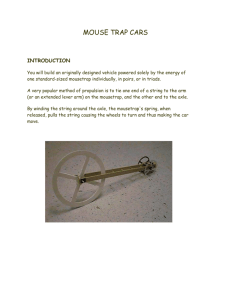

Mousetrap Cars Tips A mousetrap powered car is a vehicle that is

advertisement

Mousetrap Cars Tips A mousetrap powered car is a vehicle that is powered by the energy of a wound-up mouse trap's spring. The most basic design is to tie one end of a string to the tip of a mousetrap's snapper arm and then the other end of the string has a loop that is designed to "catch" a hook that is glued to a drive axle. Once the loop is placed over the axle hook, the string is wound around the drive axle by turning the wheels in the opposite direction to the vehicle intended motion. As the string is wound around the axle by the turning of the wheels, the snapper's lever arm is pulled closer to the drive axle causing the mousetrap's spring to "wind-up" and store energy. When the drive wheels are released, the string is pulled off the drive axle by the mousetrap causing the wheels to rotate. To wind the string around the axle, the wheels are turned in the direction opposite to the motion of the vehicle's travel. It is important that the string NOT be wound loosely or it will snag itself as it is pulled from the axle by the lever arm, the string should carefully be wound tight and uniform around the axle. Do not push on the mousetrap's lever arm during this process, you want the string to be tight and to pull the lever arm over. Once the car is released, the string is pulled off the axle it cause the wheels to rotate propelling the vehicle. If the mousetrap is located to close to the drive axle the wheels can spin at the start wasting energy. The first step to making a good mouse trap powered car is simple, put something together and find out how it works, it may not be pretty but it is a start. Once you have something working you can begin to isolate the variables that are affecting the performance and learn to adjust to improve your results. Building mousetrap cars is a simple process of design engineering, you build, you test and experiment, you change, and you do it all over again. Long lever arms decrease the pulling force and power output but increase the pulling distance. Short lever arms increase the pulling force and the power output by decrease the pulling distance but increasing the speed. If you are building a distance vehicle, you want to minimize the power output or the transfer of stored potential energy into kinetic energy of motion at the slowest possible rate. This usually means having a long lever arm and a large axle-to-wheel ratio. If you make the lever arm too long, you may not have enough torque through the entire pulling distance to keep the vehicle moving, in which case you will have to attach the string to a lower point or change the axle-to wheel ratio most important is reducing friction, the more you can reduce or eliminate friction, the farther your racer will travel. In a perfect universe, a mousetrap vehicle will travel forever, just like an object thrown in space should travel forever or until it hits something. This is the challenge that makes building mouse trap powered cars so much fun, seeing who can reduce friction the most Greater distance can be achieved by: • using a longer length lever arm • having a large axle to large wheel ratio. • eliminate friction Ideas for Increasing Distance Increase Axle-to-Wheel Ratio 1. Use a larger drive wheel. Try making a large wheel out of mat board. Mat board is stiff and light-weight. The larger your drive-wheel the greater the distance your mousetrap car will travel per turn of the wheel. 2. Use a smaller drive axle. The larger the ratio of drive wheel(s)-to-axles diameter, the farther you mousetrap car will go for each turn of the wheel and the greater the pulling distance will be.