Reverse-Engineering the Engineering Curriculum: A Proposal

advertisement

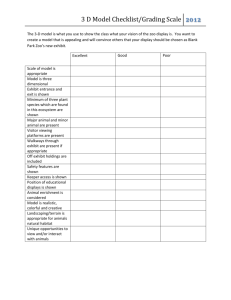

Reverse-Engineering the Engineering Curriculum: A Proposal Abstract The traditional approach to engineering education curriculum design is based on “basics first” principle. No doubt that physics, chemistry, mathematics (and even now biology) are essential in the understanding of engineering complex ill-defined problems in real practice. Unfortunately this approach does not necessarily motivate the new learners. We suggest a radical change in the engineering curriculum: starting from the “end product” continued by reconstructing -as in reverse engineering- the basic “components” –such as lenses, benzene- of the profession. We are aware of the difficulties in restructuring a rooted engineering program, but we feel the time for change is long due. Introduction Traditional engineering curricula will start with the basic science courses -including one introductory course to the profession- and continue with engineering sciences in the sophomore and junior years. Applications –including a capstone course- will be limited to the senior year. We claim that learners cannot see the importance of the basic courses –generally taught by field experts and not engineers- during the first years and soon get discouraged and start to think that engineering is not after all their vocation. Many start to look for alternative paths, the pains in learning pure sciences being overwhelming. Some engineering institutions –like Drexel- try to combine these basic courses in an integrated program to make learning more pleasant. None of the changes made in the engineering curriculum -that must nevertheless conform to strict traditional accreditation criteria- can provide the encouraging environment that the engineering candidate needs to be successful in her studies. Background “Concurrent engineering” has been for some decades now a fashionable expression to describe the need emerging from the need to shorten the “time to market” of a new product (see Exhibit 1.). Traditionally design was a sequential process starting from the need assessment followed by sketching phase down to the production line. Now-a-days all the stages are triggered at the same time including the potential user as part of the design process. This requires a different mindset and communication tools. Suppliers of elements and devices are invited to participate together with the production people in the whole process. An integrated view of the whole system is required in order to shorten the “product life-cycle”. In the meantime another approach reached the production environments. Although there is nothing new in this approach a whole branch developed around “reverse engineering” as the process of discovering the technological principles of a device or object or system through analysis of its structure, function and operation. It often involves taking something (e.g. a mechanical device, an electronic component, a software program) apart and analyzing its workings in detail, usually to try to make a new device or program that does the same thing without copying anything from the original1. Unfortunately these two approaches have not trickled into the educational system yet. Exhibit 1. Model of Concurrent Engineering design including all related components Ecology Sociology Concurrent Engineering Design Technology Philology Years / Products 1 Consumer 2 Construction 3 Industrial 4 Power Method We humbly propose in this paper the reverse-engineering of the engineering program so that the learners are presented from the beginning with the design courses that are traditionally offered in the senior year. As the learner becomes familiar with the design process will eventually see the relevance of the basic courses such as thermodynamics, strength and feel the need to go even deeper in the basic sciences –physics, chemistry and biology- with the help of mathematical tools. As an example to a reverse-engineering of the engineering program, we offer the topic of car design in mechanical engineering as the starting point. Knowledge of the basic components and the parametric design of the system will open the way to the other courses as they become relevant. In Exhibit 2., we show the relations between the car design and the three main areas of knowledge relevant to engineering, namely: basic, social and applied sciences. Just to get a flavor of what a reverse engineering approach note that “car design” is at the center of the model. Human engineering principles are the first requirements to be taken into consideration: ergonometric is the natural source for taking the necessary human measures which depend heavily on demographic considerations, thus the need for a social study. Similarly the design of the combustion chamber is a thermodynamic problem which is based on physical laws. Exhibit 2. Example of a “concurrent design model” for a car manufacturing enterprise BASIC SOCIAL Mathematics Geography Chemistry History Ergonometric Human design Physics (drawn by student using ACAD) CAR DESIGN Machine design Processes APPLIED Forming Materials Casting Thermal design Steel Plastic Rubber Results We are proposing a new approach to engineering education. It is not possible to give evidence of the positive results that such a change will make because it goes beyond the boarders of one course model. We are confident of the possible improvements in learners’ satisfaction from the results we get by implementing “reverse engineering” even from one single course. We expect that the learner should be immersed in the literature and catalogues of components that make the design. Eventual manufacture of prototype models in the coming years in a team work environment will help the learner acquire the professional skills she will need in the practice. It should be clear to the learner that technology is in constantly advancing Control engineering is at the crossroad of several disciplines. In Exhibit 3., we attempt to show how a control engineering undergraduate program could be designed to encompass all this disciplines showing at the same time the product life-cycle. Such a cycle starts with the product definition (customer needs, market expectation, time-to-market, etc). Basic sciences are shown in the left ready to be introduced as the component selection, product development followed by solution proposal ends the cycle. There is a sense of iteration as the product development takes shape and more details are revealed. We talk today of soft control, stressing the importance of the programming side of the product embedded in the product (also included in the model). Exhibit 3. Diagram showing all the components of a Control Engineering Program Table 1 Roadmap Proposal for a Control System Design Education Program Problem Definition Component Selection Pseudo Code System Mathematics Logics Pneumatic Equations Measuring Matrix Circuits Hydraulic Blocks Recording Differential Devices Mechanic Responses Actuating Probability Processes Numerical Program Validation Mechanics Conditioning Switch GET (variables) Drive DECIDE (rules) Motor ACT (variables) Electricity Basic Analog Optics Assembler I/O Functions Digital Thermo C Processor Diagrams Adaptive Physics Simulation PLC Controllers Robust Final Code Solution Proposal Control Product Development We acknowledge that this approach to education may sound confusing and somewhat chaotic. But engineers that have been on the ground now very well how the real world actually operates. We ought to introduce the realities of the “ground” in the educational system. Even the barriers between traditional freshmen-to-senior classes should be removed. Students with different learning experiences working simultaneously as in the real working environment can help to improve motivation. There are now evidences of cases where students join for competitions in the production of new cars or ships. In these cases, laboratory work has a real meaning by not just the repetition of test-benches having known results. Engineering is a challenging activity and the final results cannot necessarily be predicted before hand. Conclusion Dissatisfied with the state of engineering education –lagging behind the true needs of industrywe have ventured in this paper to propose a new approach to curriculum design. Leaving behind the traditional “basic science goes first” undergraduate program, we envisage one which starts with hands-on design applications and introduces sciences as it is relevant. Such an approach will require a whole re-structuring of the whole curriculum. We envisage a big resistance from basic science staff: they keep the doors closed to changes in the engineering world. Technology is developing fast. Everyday new products are coming to the market. The need for innovation and leadership in engineering is a new challenge. Education needs to fulfill the needs of the employers. There is no time for orientation and re-education in the working place. Engineers should graduate ready to “act”. A “situated learning environment” should be provided. It is the responsibility of the industry to demand change. We welcome the change in criteria we see in ABET 2000. It is not easy to assess “outcomes”, but we should definitely try. Acknowledgment We remain in debt to the former Director of the Biomedical Engineering Institute Prof.Yorgo Istefanopulos for his support in making this work possible. References 1. http://en.wikipedia.org/wiki/Reverse_engineering (last accessed July 2007)