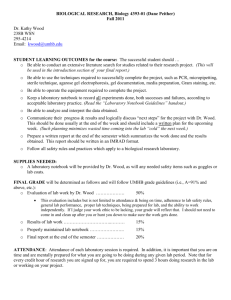

nolengerkeWoodlab

advertisement

Materials Lab Compression and Structural Bending of Wood Nolen Gerke February 14, 2006 February 21, 2006 Dr. Jim Brenner Introduction: The wood lab is conducted in order to get a general idea of what range of pressures wood will be capable of withstanding. Wood is a material that is widely used in the construction of buildings, bridges, and other structures. This lab will use a load apparatus machine (see picture 1) and apply a force to different types and geometries of wood until they break. After breakage or shearing, the location of the break will be recorded along with the load pressure. By measuring and comparing these values, we will be able to better understand the properties of wood such as the modulus of elasticity and the modulus of rupture. The modulus of elasticity (MOE) measures the stiffness of the wood and the modulus of rupture (MOR) refers to the strength of the wood under bending. The wood lab will consist of 3 different samples being pressed until breaking occurs. One sample will have knots, one sample will not have knots, and one sample will be cylindrical in shape and a different type of wood. The 4th sample will be a piece of long wood with 4 pressures applied, basically breaking the wood in half (see picture 3). Some Expectations/Assumptions may include: Breaking along the grain of the wood. Breakage should be around the knot if present. Data should roughly follow the given standards for wood. Air conditioning unit in room may cause electrical fluctuations. Extensometer (measures the length that the wood changes) does not reach its maximum (2 inches) before end of test. Machine is properly calibrated for use and operator is fully trained. The cut of the wood is proper (for flexural bending test). Moisture content in wood is normal. Experimental Procedure: Beginning this lab, Dr. Brenner Set up the load apparatus. The Load apparatus was set to take the first 3 samples of wood and apply a pressure to them. Dr. Brenner provided the samples of wood and his assistant made all the dimension calculations using a vernier caliper (see picture 2). For all physical attributes, view Wood Lab Data Sheet. For all data recorded see Data Sheets, Data Fit Graph, Fit Information and Data table. Four samples of wood were tested over 2 types of test. For the compression test, 2 blocks of wood (one with point deflects (knots), one without) were pressed perpendicular to the grain, and 1 cylinder of wood was pressed parallel to the grain. For the 4th sample, a 4 point roller was used to bend the long wood until it fails. (see figure 1) Figure 1 Each piece of wood is loaded into the load apparatus and then force is applied until the wood breaks. The breakage point on all of the specimens is based off of the audible loud “crack” the wood makes, not the splintering. For the first test, a sample of wood with no knots was placed into the load apparatus. The wood was lain so that the longest part of the wood was horizontal. The load apparatus was turned on and set to apply pressure until failure. The second test was the same as the first using a block of wood with nearly the same dimensions and grain as the first. However, this block had point defects in the center, which caused the failure directly down the center of the wood, through and around the point defect. The third test included a cylindrical piece of Brazilian wood, which was placed into the load apparatus with the longest dimension in the vertical stance. This caused the wood to be compressed parallel to the grain seeing as how the grain follows it’s longest axis. The fourth test was somewhat different from the rest of the tests because it used what is referred to as a 4-point roller test. This test means that the applied force was condensed down into 2 rollers that were positioned at equal lengths from the center of the wood. Rather then the wood being on a flat surface, it was elevated by 2 more rollers. This distance between the rollers is recorded on the WoodlabDataSheet. The wood was loaded into the load apparatus with the longest axis horizontally. Results: During the first three experiments, only the rupture load was recorded rather then the stresses at each 100 lb interval like experiment four. Here is a comparison of actual data of the first three experiments to the textbook solutions: Type Ex. Strength Pine With Knots (Perpendicular) 4100 psi Pine Without Knots (Perpendicular) 4598 psi Pine Dowel (Parallel) 7270 psi Text Strengths (theoretical) N/A N/A 5,370 psi Some errors involved in the recordings may have to do with the certain type of wood used (seeing as how we are not exactly sure it is pine), moisture content of the wood may be out of specs and the load apparatus may not be calculated correctly. For the fourth experiment, modulus of elasticity and rupture are shown: MOE: MOE = ((S) x (L^3/4))/ (12I) L = length between the supports = 16 1/8 S = slope of graph of load versus deflection (elastic region) = P/ changeX I = moment of inertia = (1/12) x W x h^3 I = (1/12) x (1.491) x (1.486^3)= 0.408 MOE = (3300 x 1048.188)/ (12 x .408) = 7.06x10^6 MOR: σfs = (4Ff)/ (2Wh3) Ff = load at failure W = width of sample h = height of sample σfs = (4 x 1390)/ (2 x 1.491 x 1.486^3) = 5.68x10^2 For all experiments view Figures A-H in the Appendix: Picture Listing. Discussion: By comparing the differences in the loads that wood could take, I found that compression parallel to the grain was much more complicated and took more effort to split the wood. One can conclude that if using a material such as wood, they should build using the grain as a directional. The first three tests showed how brittle (MOE) the object was when compressed perpendicular to the grain vs. parallel to the grain. These results were confirmed by the book that wood would take more of a load when compressed parallel to the grain. The fourth experiment tested the wood’s ductility (ability to bend without breaking). Wood has a very low ductility (MOR) and would not be suggested for use when something needs to bend. A graph of Load Vs Stress of the long wood is included in appendix 2, which confirms how the wood broke (Figure Z). However, wood does flex and should not be taken lightly because the experiment shows that the wood becomes weaker the more it bends. Wood is also a composite of layers, which is where the grain comes from. These experiments tested the wood’s delaminating failure, which is the separation between those layers. Some plausible sources of error include the electrical error in calculation of course, which has proved a problem in earlier experiments. Moisture in the wood can cause the wood’s properties to change. Also, before experiment four was started, all students pointed out that the wood sample was slightly warped (within an 1/8 of an inch at the center). I believe Dr. Brenner set it in the machine so that this was negligible. Appendix 1: Picture Listing Figure A – Brazilian Wood with Cracks Labeled Figure B – Long Wood cracked in center with labeled lines for 4 roller points. Figure C – Long Wood (side) cracked in center with labeled lines for 4 roller points. Figure D – Close up of fracture from Long Wood test. Figure E – Side View of Block of Wood with No Knots Figure F – Close up of labeled fracture on “No Knots” wood block Figure G – Side view with labeled cracks of wood with knots Figure H – Close-up of fracture on wood with knots Picture 1 – Load Apparatus (With a sample of dowel wood) Picture 2 – Venier Caliper Used for measurement Picture 3 – Example of a 4 point roller test on Long Wood. Appendix 2: Data Visual DataFit version 6.1.10 Results from project "Untitled1" Equation ID: a*x+b Number of observations = 15 Number of missing observations = 0 Solver type: Nonlinear Nonlinear iteration limit = 250 Diverging nonlinear iteration limit =10 Number of nonlinear iterations performed = 11 Residual tolerance = 0.0000000001 Sum of Residuals = 3.97903932025656E-13 Average Residual = 2.65269288017104E-14 Residual Sum of Squares (Absolute) = 25866.2061236236 Residual Sum of Squares (Relative) = 25866.2061236236 Standard Error of the Estimate = 44.6061449057825 Coefficient of Multiple Determination (R^2) = 0.9907159585 Proportion of Variance Explained = 99.07159585% Adjusted coefficient of multiple determination (Ra^2) = 0.9900018015 Durbin-Watson statistic = 0.64456609131857 Regression Variable Results Variable Value Standard Error a 4921.23193 132.1283812 b 19.5471626 21.58143632 t-ratio 37.24583534 0.90573965 68% Confidence Intervals Variable Value 68% (+/-) a 4921.23193 136.6207462 b 19.5471626 22.31520516 Lower Limit Upper Limit 4784.611185 5057.85268 -2.768042585 41.8623677 90% Confidence Intervals Variable Value 90% (+/-) a 4921.23193 233.9861503 b 19.5471626 38.21856558 Lower Limit Upper Limit 4687.245781 5155.21808 -18.67140301 57.7657282 95% Confidence Intervals Variable Value 95% (+/-) a 4921.23193 285.4501548 b 19.5471626 46.62453503 Lower Limit Upper Limit 4635.781776 5206.68209 -27.07737246 66.1716976 Prob(t) 0.0 0.38155 99% Confidence Intervals Variable Value 99% (+/-) a 4921.23193 398.0103228 b 19.5471626 65.00976063 Variance Analysis Source DF Regression 1 Error 13 Total 14 Sum of Squares 2760227.127 25866.20612 2786093.333 Lower Limit Upper Limit 4523.221608 5319.24225 -45.46259806 84.5569232 Mean Square F Ratio Prob(F) 2760227.127 1387.25225 0 1989.708163 Figure Z – Graph of Load Vs Stress of Long Wood. Last Point is fracture of wood. The drop off is visible. Appendix 3: Woodlab Data Sheet 1st sample: Wood Type: Unknown – Assumed Idaho Timber or Pine Length – 6.125 inches Width – 1.493 inches Height – 1.515 inches Wblock – 4.961 inches Cross Sectional area – Width X Wblock – 7.407 Note: Error in lengths – 0.001 Weight – 100.3 grams Rupture load - 4,598 lb (+-) 1 lb By visible inspection of the rings in the wood, this sample was close to the center of the tree and the grain travels along the longest axis. There is a small knot on one end, which was taken as negligible. 2nd sample Wood Type: Unknown – Assumed Idaho Timber or Pine Length – 6.05 inches Width – 1.495 inches Height – 1.482 inches Wblock – 4.961 inches Note: Error in lengths – 0.001 Cross Sectional Area – Width X Wblock – 7.417 inches ^2 Weight – 98.9 grams Rupture load – 4100 (+-) 1 lb By visible inspection of the rings in the wood, this sample was close to the center of the tree and the grain travels along the longest axis. This sample has a knot in the middle of the wood. 3rd sample Wood Type: Brazilian Wood – Dowel Form Length – 3.057 inches Diameter – 0.884 inches Note: Error In Lengths – 0.001 Cross Sectional area – (pi)(Diamter)^2/4 – 1.928 Weight – 25.30 Grams Rupture load – 7270 lb By visible inspection, no knots are visible in the wood and the grain travels along its longest axis. 4th sample Wood Type: Unknown – Assumed Idaho Timber or Pine Length – 25.75 (+-) .125 inches Width – 1.491 inches Height –1.486 inches Weight – 462.8 grams Actual Length where breakage may occur – 16.125 Rupture load – 1390 lb 4th Sample Load Vs. Deflection Load (lb) Deflection (in) 0 0 100 0.019 200 0.040 300 0.061 400 0.089 500 0.096 600 0.114 700 0.133 800 900 1000 1100 1200 1300 1390 0.151 0.172 0.190 0.209 0.233 0.265 0.300 <<<Breaking Point Appendix 4: Sample Calculations – taken from Mohammed Alamri’s Lab Report Flexural Modulus of Elasticity: MOE = ((S) x (L3/4))/ (12I) L = length between the supports = 16 1/8 S = slope of graph of load versus deflection (elastic region) = P/ΔX I = moment of inertia = (1/12) x W x h3 I = (1 x 1.523 x 1.5193)/12 = 0.445 MOE = (3300 x 16.1253)/ (12 x 4 x 0.445) = 6.6 x 105psi Flexural Strength/ Modulus of Rupture (σfs) σfs = (4Ff)/ (2Wh3) Ff = load at failure W = width of sample h = height of sample σfs = (4 x 1290)/ (2 x 1.523 x 1.5192) = 1.11 x 103 Density = Mass/ Volume Density = 420.2/ (1.523 x 1.519 x 26) = 6.99g/in3 = 0.43g/cm3 Units = g/cm3 (39.37)3 = (100)3cm3 (Using dimensions for flexural bending test wood sample) Ultimate Compressive Strength: UCS = Failure load/ (C/S Area) Sample calculation using wooden dowel: 5420/ (3.1416 x 0.8472/4) = 9619.3psi Appendix 5: Sources Alamri, Mohammed Lab report fall 2003 Callister, William D. Materials in Science and Engineering an Introduction Fifth Edition. DataFit software. Provided by Dr. Brenner. Experimental photographs. Email from Dr. Brenner. Leahy, Edward Lab report spring Microsoft excel. Graphs and tables. New York. John Wiley and Sons, Inc. Copyright 2000. 2002 WWW3265 CD. Course CD. Given by prof. J Brenner