Domain Expertise: Production/Assembly: Aggregate Production

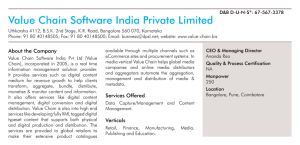

advertisement

Chandrashekar Thimmappa Domain Expertise: Production/Assembly: Aggregate Production planning, Indent creation, Process planning, Routing, Product assembly, In-process Inspection, Problem solving, Packing & Dispatch. ASME Y 14.5 (GD&T), Line balancing, Cell design, Poka Yoke, OEE, TPM. Lean Manufacturing: Identifying & Elimination of 8 deadly Muda, 5S, SOP, Value stream mapping, KanBan, Jidoka, SMED, Kaizen, Pull, Heijunka, Hoshin Kanri, Visual control, 3P, QCPC, JIT & VOC. Six Sigma: QFD, SIPOC, CpK, Force Field Analysis, ANOVA, Cost Benefit Analysis, DMAIC, PDPC, Affinity Diagram, PFMEA, Benchmarking, DOE, Fault Tree Analysis, DFSS, Hypothesis testing. QMS: SWI, CAPA, PPAP, APQP, SPC, Gauge R&R, ISO 9001:2008, PDCA, Run chart, ISO, Pareto chart, 7Qc, 8D,TUV, UL, 5 why, A3, TQM- Methodology, ISO-27001, Fault tree analysis etc. Strategic Execution: Principles of Execution (TAMMM), 7S FW, CSF, KPI, Balanced score card, SWOT, Metrics Chart, Dashboard. Training: Using “Toyota-TWI” framework, Employee engagement, Introducing “MFWTT”, Monitoring Skill Matrix & On job training. Address : No. 91, 17th Cross, 4th Stage, 4th Block, west of chord road, Bangalore -560079, India. Mobile : +91 9845239862 Landline : +91 8023409659 E-Mail : shekarprofession@gmail.com Professional Certification: - Quality Management System - Lean Six Sigma - Auto CAD - Microsoft Excel & Power point. - Minitab Quality Trainer - UL Inspection & Field Service Objective: Seeking an operations or management assignment as Executive in production, process excellence or quality assurance in a reputed firm PROFILE AT A GLANCE A result oriented, competent mechanical engineering professional with nearly 5.07 years’ experience, Including 3 months international experience in the USA, mainly in areas of production, operational excellence & Quality management in the Automotive and Industrial solutions industry KEY SKILLS SET Functional skills: Verifiable competence in driving, tracking, & improving quality, cost, delivery & safety parameters / performance indices of projects. Demonstrated skills in using Balanced Score Card frame work to keep track of line metrics and applying it to meet corporate strategic objectives. Proven capability in planning, control, maintenance, & trouble shooting, including preventive and corrective maintenance to curb machine downtime Expertise in foreseeing performance bottlenecks and taking corrective measures to avoid the same Ability to design & implement stringent systems and quality plans to ensure high quality standards at all the stages of production as well as redressing customer complaints. Technical Skills: A synergistic professional with cross functional exposure & ability to swiftly adapt to new environment Prowess in preparing & maintaining necessary documents required to comply with ISO norms & other statutory quality standards. Proven record in implementing lean & Six sigma tools. Developing methodology for inspections, tests, & analysis to ensure development of products in compliance with pre-set specifications. Good at presentation, freehand sketching and creative thinking People skills: Directing, leading & motivating workforce and imparting continuous on job training for accomplishing greater operational effectiveness/efficiency An effective communicator with excellent relationship management skills, strong analytical, problem solving & organizational abilities Résumé of Chandrashekar Thimmappa / Page 1 CAREER MILESTONES Current: Actively looking for an opportunity SAP-MM Training (July 2012 to Nov 2012) (SAP TAC Training Institute, Jayanagar 5th Block, Bangalore) TE Connectivity, Bangalore (A global company, involved in design & manufacture of products connecting & protecting the flow of power & data inside products used in consumer electronics, energy, healthcare, automotive, aerospace, & communication networks) Senior Engineer - Manufacturing Systems Development (July 2011 to July 2012) (Reporting to the Senior Manager-TEOA & leading a team of 6 members) (Ref: Sreekant Dhamle - 9880162164) Job Profile: As Senior Engineer- Manufacturing Systems Development, handling key tasks as lean practitioner and quality controller, & overseeing operational excellence initiatives with defined Key Performance Indices for F-74 plant: Monitoring, reviewing, & approving both process control and quality control in plant Using statistical tools & control charts to generate Cpk & Ppk values, to work on establishing 4.5 sigma standards on the RJ45 connector line. Identifying line issues, conducting PFMEA, Identifying root causes, Implementing containment & permanent corrective action, Monitoring sustainability program for Invertible & Enhanced Mod-jack line. Calculating efficiency parameters for assembly lines like productivity, overall equipment efficiency, defective parts per million, accident incident rates, process sigma, and inventory turns. Conducting periodic meetings with team & maintaining the operational parameters to achieve targets Handling replenishment & flow of smart card contacts through physical KanBan, including calculation of KanBan quantity, fixing pitch, and designing Heijunka board. Carrying out compressor installation, pressure regulation, & leak testing accompanied with regular maintenance activity. Conducting incoming inspection as per Acceptance Quality Level (AQL) norms. Coordinating continuous flow & establishing pull for connector contacts & housing material for RJ45 & Modjack connectors Handling kaizen activity & implementing Jidoka to facilitate automation Creating live templates in excel to calculate Economic Order Quantity, Safety Stock & Reorder Point for warehouse operations as per standards set by APICS. Responsible for implementing Multi-Functional Workers Training Template (MFWTT), to ease the process of training and monitoring employee skill matrix. Undertaking demand forecasting using Holt Winter Exponential Smoothing Technique Undergone training in Tyco Electronic Operating Advantage, including 6 foundation tools & 11 additional tools- 5S, QCPC, Mistake proofing, 3P, VSM, Cell Design, Pull, KanBan, FIFO & Supermarket Design, Waste identification and elimination, OEE, Quick change over, & Jidoka among others. Managing existing employee learning development & training framework by introducing ‘TWI System’ consisting of easing and gaining employee confidence, presenting the operation, trying out employee performance and follow up through facilitating tools including standardized work, job break down sheets, job instruction, and industry training based on Toyota Talent Hand Book. Résumé of Chandrashekar Thimmappa / Page 2 Tata Consultancy Services Ltd., Bangalore (A CMM Level 5 Indian IT services, business solutions and outsourcing giant) Systems Engineer - Quality Analyst (December 2010 – June 2011) (Reported to the Manager-Quality & led a team of 2) (Ref: John Bittel – 001-5127509762) Job Profile: As Systems Engineer- Quality Analyst, in-charge of first article inspection review, approval & quality management system for Client: Applied Materials India (AMIND). Was assigned responsibilities to achieve targets specified for Key Performance Parameters by global strategy formulation team Verified and validated FAI report submitted by worldwide vendors Accepted or rejected FAI submitted depending on quality of inspection documents submitted and its compliance with GMRM-2-60.1 document norms. Trained subordinates on implementation of Applied Material Quality System (AQS). Prepared Pareto charts using Excel on errors observed during the review. Read 2D & 3D drawing having familiarity of ASME Y 14.5M, GD&T standards. Carried out FAI review activities such as BOM verification, Vendor status verification, Receipt control adjustment in global document database, using applications like Team-center, Oracle & SAP. Generated monthly reports on FAI review progress rate for management review. Significantly increased the performance by applying quality management tools & techniques like QFD, matrix diagram, inter-relationship diagram, process design program chart, & activity network diagram to optimize management process involved in FAI review process using the ASQ, CQE Handbook. Achieved the KPI set for FAI review process Actively participated in value engineering group discussions on development of Function Analysis System Technique (FAST) and Functional cost worth analysis (FCWA). Dover India Pvt. Ltd., Chennai (An ISO 9001: 2008 & ISO14001:2004 certified global producer of innovative equipment, specialty systems and value-added services for the industrial products, fluid management, engineered systems and electronic technology markets) Senior Engineer - Production / Operation Excellence (October 2009– December 2010) (Reported to the Senior Manager- Operations & led a team of 8) (Ref: Krishna Kumar – 9940140569) Job Profile: As Senior Engineer- Production / Operation Excellence, in-charge of OPW FC cell in Chennai facility, handled Assembly line, Quality of products produced, Planning & Inventory management with defined Key Performance Metrics Coordinated daily production planning & control, met daily & monthly targets as well as quality objectives as per customer demands. Followed up machining & assembly activities to produce standard tools & fixture to ease production. Carried out installation & operation of machines for OPW Nozzle assembly line & CNG Receptacle/ Breakaway cell, using equipment’s- Yamato Vacuum Dryer, Bauer Compressor, EFD Performus III Fluid Dispenser, Edwards RV5 vacuum Pump, Ostling Laser marking machine and Flow tester. Setup incoming material inspection/rejection procedures using standards like AQL & ISO 9001 as well as process monitoring tools- 7QC. Conducted inspection of sampled parts using inspection tools such as Mitutoyo micrometer, Trimos height gauge, & Carl Zeiss CMM. Maintaining smooth function of nozzle line including OPW above ground dispensing products, nozzle building and rebuilding. Created & authorized indents in ERP for material removal from stores. Monitored individual assembly stages, final testing, packing, & transferred completed nozzles to finished goods stores. Résumé of Chandrashekar Thimmappa / Page 3 Conducted trouble shooting of day to day assembly problems using 8D, PDCA, 5 whys, Ishikawa diagram and PFMEA. Wrote SOP and test instructions for CNG and dispensing nozzle cell. Calculated and monitored OEE on monthly basis. Collected Kaizen suggestions from the team members, evaluated feasibility for implementation, & supported continuous improvement process Developed concepts for fixture design, including component drawing, orientation of component, number of stations, & considered cutting force. Created 2D and 3D models using AutoCAD Collaborated with procurement team to standardize the procurement process as per procedures Analyzed sales input to estimate safety stock level and established stock reorder point. Prepared live templates in Excel for calculating EOQ for effective inventory management As CNG Product Trainer for OPW FC line of products, trained staff on VSM and Lean Tools. As management representative driven ISO 9001-2008 certification & implementation. Undertook Pareto analysis as well as Cpk calculation to implement TQM principles on the shop floor. Prepared presentation on department performance & initiated PPAP. Created continuous flow in nozzle line by reducing seven deadly wastes & implemented 2 Kaizen results, thereby increasing production capacity from 24000 to 66000 nozzles/line/year, & contributed to increased profits by over $ 0.5 million/annum. GRE & TOEFL: Involved in University Submissions (May 2009 to Sep 2009) (IMS Training Institute, Sampige Road, Malleshwaram 8 th Cross, Bangalore) Kennametal India Ltd., Bangalore (An ISO 9001:2008 certified company, a pioneer and leader in the tooling solutions with services ranging from traditional single point carbide bits to complex helical toothed Milling cutter solutions) Executive – Production / Procurement (July 2007– May 2009) (Reported to the Deputy General Manager) (Ref: Nataraj.S.K - 9448041251) Job Profile: As Executive- Production / Procurement, was responsible for manufacture & assembly of fixtures and for stream lining procurement activities for MTB division. Monitored spindle assembly and RPM parameters as well as other quality parameters of machine parts. Prepared work break down structure and Gantt chart for manufacturing process. Analyzed defects in carbide inserts for PU5. Maintained necessary ISO 9001:2000 quality documentation like CMM inspection reports Captured CAPA for documentation. Conducted time and motion study to reduce machine building time by 30% for gun drilling machine. Monitored Special Purpose Machine (SPM) assembly starting from screw-rod assembly to work holding & cutting tool assembly. Trained staff on Project Procurement Management Framework (PMP) methodology & spearheaded implementation. Successfully completed Heat Treatment Standards for Bangalore plant & trained staff. Monitored & assembled guards on boring machine for IMTEX exhibition 2008. Used problem solving technique- A3 to prevent crack formation on guide ways during case hardening. Previous Employment: Mastercraft Engineers Pvt Ltd., Bangalore (An ISO 9001:2008 certified company, a pioneer and leader in specialized precision mold design & mold making) Résumé of Chandrashekar Thimmappa / Page 4 Inplant Trainee - Production / Quality (Jun 2003– Jun 2004) (Reported to the Manager- Shop floor) Job Profile: As Inplant Trainee- Production / Quality, was responsible for manufacturing of Injection molds for widely based customer base. Responsibilities included planning, part drawing, machining, assembly, try outs and vendor development. Coordinating with production planning & control team on daily material needs. Component Analysis: Study and analyze the need of the customer in terms of quality and precision. Production planning: Process planning of Injection mould assembly. Part drawing: Releasing part drawing for manufacturing. Sparking: Sparking of Core & Cavity inserts using MAKINO EDM. Grinding: Side core and Insert matching to the final assembly using OKAMATO grinding machine. Milling: Using Vertical Milling Machine for milling core and cavity inserts Turning: Turning of mould pillars for un-standard mould sets. Inspection: Inspection of the finished parts using CMM, Preparing Inspection charts, Monitoring Quality issues and Error identification. Assembly: Blue matching of Core and Cavity half. Coolant hole drilling and assembly of multiple cavity injection moulds Try Out: Ensuring that final products meet the customer requirements and Trouble shooting. Vendor Interaction: To ensure finished part for final assembly. EDUCATIONAL CREDENTIALS Bachelor’s Degree in Engineering– Mechanical, M.S. Ramaiah Institute of Technology, Bangalore, Visvesvaraya Technological University, 69% (2007) (Adjudged for 1st Prize in final year project in Mechanical Engineering) Diploma - Tool and Die Making, Government Tool Room and Training Center, Bangalore, 79% (2003) (Awarded 1st Rank in the 1st & 2nd year) Diploma - CET, Karnataka State,(2004) (85th Rank) TRAINING HISTORY Underwent “74” business management programs in Tyco Electronics-LMS. Completed training modules in UL inspection and field service program Underwent training for Lean Six Sigma and business management programs Attended workshop on heat treatment and error rectification in SPM. Participated in training programmes on production planning and inventory management. Successfully completed workshop on Press Tool design and manufacturing. Attended seminar on scope for hot runner moulds in current day mould making. PERSONAL DETAILS Date of Birth: 20th January 1983 Language Skills: English, Hindi, and Kannada Computer Proficiency: Win 7, Win XP, MS Office, Minitab & AutoCAD 2007 Nationality: Indian Pan Card: AFNPT3143F Passport No.: G 4738727, valid up to 26th August 2017 Visa: B1, USA, valid up to 25th October 2019 Résumé of Chandrashekar Thimmappa / Page 5