Sun City - Energy load shifting and shedding

advertisement

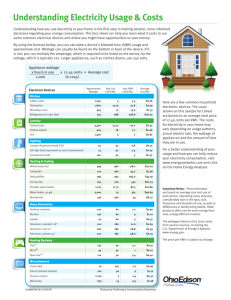

Case Study SA-SUN LOAD SHEDDING AND LOAD SHIFTING IN OPTIMISING WATER AND ENERGY EFFICIENCY This case study considers how a holiday resort with on-site water and sanitation services identified specific areas to shift- and shed electricity loads through demand management and a multi-phased energy optimisation project. Load Shedding and Load Shifting in Optimising Water and Energy Efficiency Description of Process: Sun City is a world renowned resort that caters for up to 6058 daily visitors and > 2 million guests each year. Water and electricity is provided on demand and often difficult to plan within a 10% confidence span. Onsite water and sanitation infrastructure and electricity supply amount to significant portion of the total budget. The responsible practice of the Resort offset the increased environmental impact of this business, as part of an integrated strategy to reduce the carbon footprint, as well as the water footprint. The energy management strategy involves the upgrading of the electrical infrastructure grid in order to consolidate Eskom feed to the substations which equated to significant savings from the lower tariff applied to the bulk supply. The new metering system enables the accurate monitoring of all business units on the site, and assists to identify areas for load reduction projects. From the demand circle, the Resort electricians shift the main power consuming processes through 2 interventions: Load shedding: actual saving of electricity via new technology and electrical consumption drives Load shifting: saving via the sequencing of the high demand processes The main water supply units that have been identified to equate to high energy demand include: the boilers that supply hot water to the hotels, swimming pool heaters and water pump stations. Cognisance is also taken of the energy consumption by the wastewater treatment plant for the mechanical surface aeration of the activated sludge processes for future optimisation. Potential Interventions Adoption of an Energy Management Strategy that link water, energy and other areas of facility management into an integrated approach Upgrading of electricity grid and installation of consumption metering in real time, and a management system. Identify units with high energy consumption during maximum demand periods when high tariffs apply. Shifting of work periods of identified equipment to time spans when lower tariffs apply Maintaining supply MVA against setpoint MVA, revert to load shedding when exceeding set point. Replacement of electrical geysers with solar geysers. Upgrade of technology for pool heating and boiler to improve performance and save energy. Range of potential savings 3% of total load shifted from peak to off peak time, 4% of standard time shifted to off peak time – resulting in savings of 2.34% and 1.63% on total consumption. This saving amount to R604 000 on a >R4.14million bill per month which equate to 990 000 kWh saving/month Further savings were recorded through projects not directly linked to the water balance. Case Study SA-SUN LOAD SHEDDING AND LOAD SHIFTING IN OPTIMISING WATER AND ENERGY EFFICIENCY Ref Case Study SA-SUN Response information, description and remarks Location: South Africa, Sun City Resort, North West Province. Sector: Drinking water and electricity supply Works Owner or Operator: The supply system is owned and operated by Sun City, a private tourism resort. Regulated under the SA legislation and the municipal bylaws. Size: 1683 rooms, 6085 visitors each day/night with > 2 million guests per year, as well as >6000 staff and contractors per month. Water supplied estimated at 150 kL/c/day and sewage at 0.75 kl/c/day. Energy Provider: Power is in form of electricity, provider by the national electricity agency, ESKOM. Sun City buys electricity at R0-29/kWh during off peak, R0-55/kWh during standard time and R2-11/kW during peak time. The energy tariff is made up of various levies and taxes (www.Eskom.com) Process: The project involves a management and technical intervention, by way of a tripartite partnership between the energy provider, the facility owner and National Power agency. Component: Water supply inefficiencies addressed as part of a bigger energy optimisation project as part of a multi-phased project over > 3 years. Motivation for the case study: The increasing electricity in addition to the increased carbon and water footprint triggered the intervention. Monthly bill is > R4.14 million per month. Details pertaining to wastewater treatment: i) 361 000 kWh /month average (167,000 to R 325,016); 2013 projection 369,000 and for 2014: 373,000 kWh; unit cost R 3-90/m3 wastewater treated = equal 1.52 kWh/ML/day). This latter phase will be addressed in future projects. Process/Plant changes: Upgrade electricity grid, install meters and BMS management system, replace electricity based technology with solar and mechanical energy technologies. Apply load shedding and shifting against set targets. Civil/Physical Changes Changes in equipment by replacing identified electrical equipment with solar or mechanical driven equipment. Changes mostly in management approach and management support systems, adding intelligence and real time monitoring equipment. Water quality complies to SANS 0241 no changes, effluent complies to Water Affairs standards (with some exception). Operational Changes: Engineering oversight and project management was done by electricians and engineers from Sun City. Software installation and operations took place by the services providers, as part of the electricity monitoring and management system. Risks and Dependencies: The difficulty to plan for a demand driven approach with varying guest’s numbers posed a low risk to optimal planning. Some risk was involved in applying new technology and setting up maintenance team to ensure optimal m&O&r for equipment. No major risk elements identified. 1 2 3 4 5 6 7 8 9 10 11 12 13 Implementation: The project was executed by the three partners: Sun city, Eskom and the National Energy agent. Service providers were used for equipment and installation thereof. Energy Efficiency gains: This saving amount to R604 000 on a >R4.14million bill per month (low season) which equate to 990 000 kWh saving/month. Cost / Benefit analysis: The project cost benefit analysis indicates a return on investment of 4 to 12 months for interventions on the water supply side of the business (year 2011 - 2012). For interventions on solar geysers and lighting optimisation, up to 44 months ROI is recorded. Project review: The Sun City project is in early days, but already efforts are recognised and data recorded and published. Sun City’s efforts in bringing the water and energy nexus closer through a focused strategy is acknowledge by the Department of Water Affairs through the Green Drop Certification process. Confidence grade High confidence, data focus on financial aspects with supportive data and information regarding the energy consumption before and after interventions. The energy savings are based on real time monitoring and transparent tariff recording and calculations. The corresponding energy and water footprint could receive further attention. 14 15 16 17 Sun City is a world renowned resort nestled in the hart of the South African bushveld in the North West Province and accommodate >2 millions guests each year, and a staff compliment of >6000 persons. The responsible care to energy and water footprint reduction, compounded by the increased electricity tariffs made for a strong business decision to upgrade the electrical infrastructure grid via a tripartite agreement between Eskom, National power and Sun, which included upgrades to the substations to consolidate the Eskom feed into one centralised substation. This resulted in meaningful savings to the facility by the lower tariff received on the bulk supply. In addition, a metering project has been implemented to enable accurate reading of all the business units’ consumptions on site on a monthly basis and to identify various areas for load reduction projects. Description of Process A key motivator to project approval has been the rising cost of electricity and the impact on the facility’s carbon footprint – which subsequently stimulated good practice through energy and water efficiency measures. The following schematic shows the Eskom tariff charges during off-, standard- and peak electricity consumption period, as well as the associated charges during the usage periods. Figure: Eskom Demand Tariff charges 2012: Colour code Tariff period description Cents/kWh (Sept-May 2011) Cents/kWh (June-August 2012) Off Peak R 0.25/kWh R 0.29/kWh Standard R 0.36/kWh R 0.55/kWh Peak R 0.58/kWh R 2.11/kWh The project commenced with the establishment of a sophisticated metering system to monitor existing business units and account for electricity consumption. The project included various phases, some of which are outside the water supply balance, but part of the overall (integrated) strategy: Load shedding: actual saving of electricity via new technology and electrical consumption drives Load shifting: saving via the sequencing of the high demand processes An early intervention (over 4 years implemented) as part of the overall project involved the consolidation of the various Eskom feed supplies into one substation. The allowed for the elimination of the various and separate customer charges demand charges, network charges and electrical rate charges. The project resulted in R 200 000 saving /month. Potential Interventions Upgrade of electricity grid / supply system Installation of meters to monitor consumption Installation of metering and management system to allow for real time monitoring Identification of equipment with high usage that operated in peak- or standard time at higher tariffs Shifting of load to ensure equipment operate in lower tariff periods Replacement of electricity driven geysers, boilers and water pumps with solar and mechanical energy drivers Design of water shedding programme to reduce the operation of the water equipment within the maximum demand period / tariff levels and shifting the operation of high consumption equipment to more favourable times and tariffs. The BMS monitoring & management systems were recorded (monthly) with a max MVA value, followed by subtraction of 1MVA from the max MVA. This set MVA point are used to monitor and compare the incomer measurements to the set point at which time the BMS will systemically start to switch of the processes described above in the load shedding process until the value decrease below the monthly prescribed set point. The DSM Phase 2 project was launched in the 1st quarter of 2012 in conjunction with Eskom and National Power (ESCO). This project effectively changes the method to heat the water in the pools and hotels. The use of 21 electric boilers and 3 pool water heaters result in the heat energy generated by mechanical energy (which is normally lost), however is now used to heat the water instead of electric elements. The efficiency of the performance of a heat pump compared to the standard electric boiler system is 3 : 1. The expected reduction in electricity usage for water heating purposes on the Resort following a measurement and verification exercise is in the order of 60%. A survey by the University of Pretoria confirmed that implementation of the heat pump project would show a saving of 8MW per annum. The current heat pump project will be completed in phases towards early 2013 and is expected to culminate in 27 units being installed throughout the Resort. Benefits derived from case study: The most significant benefits from the project (as captured by the case study) include: The approach to energy saving linked to the water supply and equipment on the site as an integrated approach. The importance of monitoring and measurement systems to support decision making and inform project priorities for future implementation The results can be converted into kWh savings, as well as cost benefits per business unit. Estimated energy saving of 15.4 million kWh per annum A saving of 11,76 million kWh per annum translate to 11,210 annual GHG emissions avoided of 13,700 metric tonnes of (equivalent) CO2. Cost Saving 3% of total load shifted from peak to off peak time, 4% of standard time shifted to off peak time – resulting in savings of 2.34% and 1.63% on total consumption. This saving amount to R604 000 per month which equate to 990 000 kWh saving/month. Further savings were recorded through projects not directly linked to the water balance. Figure: Electricity consumption profile for i) March 2012 and ii) April 2012 In financial terms, the savings translated to the following energy, cost and ROI figures: kWh saving / month Rand (ZAR) value saving /month ROI (months) 340 000 R 204 000 29 to 44 Electrical feed consolidation N/A R 200 000 5 Electrical meter network (42 installations) N/A N/A N/A Optic fibre installation N/A N/A N/A BMS upgrade N/A N/A N/A Mimic panels upgrade N/A N/A N/A VSD drives installation N/A N/A N/A Heat pumps to replace boilers(7 locations) 65 000 R 400 000 12 Load shifting on boilers, pump stations and pool heaters N/A N/A N/A 990 000 R 604 000 5 (min) to 44 (max) Project Element Solar geyser at 6 locations TOTAL Note: Solar lighting devises also implemented and savings recorded – not included as part of this case study as it falls outside the water balance. Acknowledgement: Vernon Victor: Energy and maintenance optimization technician, Electrical engineering Department - Sun City Resort.