To Whom it may concern, - Business and Computer Science

advertisement

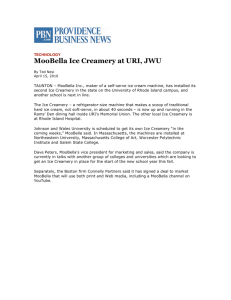

To whom it may concern, This document is our business plan for the Solano Creamery. The address of the business will be: 123 Lopes Rd Cordelia, CA 94534 Phone: 707-444-1234 The Solano Creamery is designed as a partnership between the following: Charles XXXXXXXX Tom XXXXXXXX Chris XXXXXXXX Brenda XXXXXXXX TABLE OF CONTENT 1.0 Executive Summary 3 1.1 Objective 5 1.2 Mission 5 1.3 Keys to Success 5 2.0 Company Background 5 2.1 History of Ice Cream 6 2.2 Company Location and Facility 6 2.3 Company Competition 6 3.0 Management Team (Organization Chart) 7 3.1 Board of Directors 7 3.2 Key Position Descriptions 7 3.3 Staffing 8 4.0 Financial Plan 9 5.0 Capital Required 15 6.0 Marketing Plan 15 7.0 Location Analysis 16 8.0 Manufacturing Plan 17 9.0 Appendix 18 2 1. Executive Summary The Solano Creamery is a high end Ice Creamery and it is the first Ice Creamery of this class to be located in the heart of the city of Cordelia, California. Its location is adjacent to highway 80 and highway 680. Solano Creamery will be located in a 5000 square foot building that will be leased from a privately owned commercial property. The Solano Creamery will sell Homemade Ice Cream as its primary product. In addition, homemade Lemonade, other soft drinks, and Italian Sodas will be available. Ice cream is an American tradition. Ice cream comprises approximately 60% of the market share among frozen desserts. The advantage and disadvantages are that some people get what they want and some don’t, but in this business we aim to please every customer by at least putting forth the effort of developing a flavor that is suitable for the customer. The four partners have been making homemade ice cream for several years and have sold some flavors at the Solano County Fair and have given to friends. The ice cream was met with favorable comments so we decided to open our own business. Three of the partners have past experiences with entrepreneurship with small businesses in baking, T-Shirts and Beer Brewing. Each partner has experience in various vital roles needed to make a small business successful. References are provided in the Appendix. Our partner Brenda XXXXXXXX has experience in owning her own Bakery which is an asset to this company; it will allow her to express her skills that she has acquired as a baker. It will benefit the company in her knowledge of the food industry operations. Thomas XXXXXXXX posses the skills of 10 years experience as a Brew Master in manufacturing beer his expertise in manufacturing will benefit this business tremendously. Chris XXXXXXXX has owned a T-Shirt company and has been a senior Accountant for AMS with his expertise in accounting, the Solano Creamery will benefit in utilizing his knowledge of accounting in the companies accounting department. Charles XXXXXXXX has experience in modern technology along with managerial skills that is a very big asset to our company. He will enable our company to keep up with the current technology that is available in the food industries and because of his background in repairing computers this will allow this company to keep it repair cost on all of its computer based equipment to a minimum. Each partner will invest $50,000.00 and will require a small business loan in the amount of $300,000.00 for a total startup cost of $500,000.00. The startup cost is sufficient to purchase used manufacturing equipment, build out of the leased building, materials and ingredients and hire staff. We will start off manufacturing and selling our tried and true recipes that have been loved by family and friends for years and then expand to customer requests if we feel that they can be profitable. 3 Our target market is all age groups and income brackets. We will sell premium ice cream at affordable prices that will undercut our competitors. Our commitment to creating the best products and our customers will set us apart. 4 1.1 Objectives a. b. c. To produce a net profit of at least 20% of profits by the fourth year operation. To sell as many flavors as our customer can create. To sell other products such as: homemade lemonade, soft drinks and Italian sodas 1.2 Mission The mission of Solano Creamery is to provide delectable gourmet ice creams at reasonable prices with enough varieties of flavors to satisfy the whole family. 1.3 Keys to Success The keys to success are: a. b. c. Lack of Competition: Will be the first business of its kind in the city of Cordelia, California. Quality: Product quality will include a major variety of flavored Ice Creams and other custom additives. Seasonally Appropriate: The city of Cordelia experiences warm to hot weather approximately seven months of the year. 2. Company Background The Solano Creamery is a new startup business. This business will be in an area that currently has no Ice Cream shops. The Solano Creamery will use bank loans and limited partners for startup cash. We have been making homemade gourmet ice cream. We started making ice cream in 1995 or so as a way to hang out and do something that we all liked to do, that was eating ice cream; on hot summer days and swimming. We found that we could make ice cream at home. Then we took it one step further and came up with our own flavors and recipes. We entered the ice cream in the Solano county fair and lots of people liked it and asked how they could buy some. We thought we should try to start up the Solano Creamery in an area that currently has no Ice Cream shops. Homemade Ice Cream is much different than commercial Ice Cream in that it is made by using all natural ingredients and made in small batches per day, rather than big batches that a lot of commercial Ice Cream companies produce. Ice cream Company’s use’s a 100% of over run which is nothing but air bubbles in which the volume is increased from the initial mixture to the final product. We will manufacture our ice cream using as little as 10% - 15% of overrun, which will result in a creamier, better tasting ice cream. Because Homemade Ice Cream is so rich and creamy and it is produced by making small batches, it can be customized by each customer. Adults and children of all ages and ethnic background prefer it. 5 2.1 History of Ice Cream The earliest forms of ice cream date back to the Romans and the Chinese, thousands of years ago. Marco Polo brought back fruit-flavored ices from Asia, during his famous expedition. During the 1500’s, the fruit flavored ices were popular in France among royalty. Over the next few centuries, the process of making them evolved from hauling mountain ice to salt/ice freezing methods. Cream was introduced as an ingredient, and by 1700s, people were enjoying a dessert that was similar to today’s ice cream. Over the next few decades, the ice cream business slowly evolved. Manufacturing methods and ingredients improved, while refrigeration technology became cheaper and more efficient by the 1920s, home refrigerators and freezers became more common, which gave the ice cream industry another boost. Sugar was rationed in the U.S. during World War I, but the ice cream industry convinced the government that ice cream was an “essential food. Ice cream factories were allotted sugar rations and production continued according to How stuff works Internet site (http://www.howstuffworks.com). Retail sales of ice cream in the U.S. topped $4 billion in 1999. The U.S. was the worldwide leader in ice cream production. In 2002, more than $20 billion was spent on frozen desserts. California, Indiana, Pennsylvania, Texas and New York are the leading states in ice cream consumption. Americans ate on an average of 2.1 quarts of ice cream per person in 2004. (http://www.howstuffworks.com) 2.2 Company Location and Facility Solano Creamery will be located adjacent to Highway 80 and Highway 680 in Cordelia, California, which experiences a high volume of traffic on a daily basis. According to a study by Cal Trans (Traffic Volumes, 2004), approximately 16,000 vehicles pass through this location each weekday. The number of vehicles that pass through this area is expected to grow substantially over the next 25-30 years. The average annual traffic growth rate of approximately 2 percent that is project over the next 30 year is consistent with the historic growth rate over last twenty years. The resulting projected growth in traffic within the project area range from nearly 23,000 vehicles in the morning peak hours to 26,000 in the afternoon peak hour, by 2035. These peak hour forecast correspond to an estimate of more than 250,000 vehicles traveling through the interchange each weekday by 2035. A 5000 square foot facility will be leased commercial property, which also includes parking facilities, landscaping, and small sitting area. Other major businesses located adjacent to Highway 80 includes Costco, L & L Hawaiian Barbecue, Sticky Rice Bristol, Subway, Pelayo’s Mexican Food, Happy Garden, Round Table, Sushi King, and Jack In The Box, gas stations, and several motel/hotels. 2.3 Company Competition 6 a. Baskin Robbins Baskin Robbins is located at 2121 N Texas St in Fairfield (approximately 8 miles & 6 freeway exits from our location). The store was purchased in 2002 and has estimated annual sales of $250,000.00 and has 9 employees. b. Cold Stone Creamery Cold Stone Creamery is located at 1586 Gateway Blvd, Ste C-9 in Fairfield (approximately 7 miles and 4 freeway exits from our location). The store has estimated annual sales of $322,000.00. 3 Management Team The management of Solano Creamery will consist of the 4 full Partners. The organization chart is shown below. Each of the partners has experience in the areas of assignment. See Appendix A through D for resume′s. Solano Creamery Accounting Chris XXXXXXXX Manufacturing Tom XXXXXXXX Shift Manager/Operations Brenda XXXXXXXX Shift Manager/Operations Charles XXXXXXXX Manufacturing Assistant Counter Staff Counter Staff Manufacturing Assistant Counter Staff Counter Staff Manufacturing Assistant Counter Staff Counter Staff Manufacturing Assistant 3.1 Board of Directors The Board of Directors will consist of the 4 partners. Decisions will be made by a majority vote. In the event of a tie vote, the partners will seek outside advice from either an Attorney or Technical Expert in the field of the decision. Board meetings will be held on the first Thursday of each month. An impromptu meeting can be called outside of the normal monthly meeting if an urgent decision is required to be made. 3.2 Key Position Descriptions 7 Chief Financial Officer: Manage the day to day financial obligations of the Solano Creamery to include accounts receivable and accounts payable. Managing and balancing cash flow and making future predictions. Prepare payrolls, financial statements and financial reports. Advise the other partners on all financial matters and make recommendations to improve cash flow. The Chief Financial Officer will also advise and seek an Insurance Agent to provide the proper liability coverage for the business. This position is an equal member of the Management Team and will have full voting authority. Manufacturing Supervisor: Research and recommend ice cream manufacturing equipment. Research and prepare recipes that are compliant with all State and Federal regulations. Train the manufacturing staff on proper ice cream preparation procedures, how to clean and maintain all equipment and equipment safety requirements and procedures. This position is an equal member of the Management Team and will have full voting authority. See App Shift and Operations Managers: Manage the day to day operations of the Solano Creamery. This will include supervising the counter staff, ensuring the cleanliness of the business, proper customer service techniques, prevention of loss or theft of goods and money and that the business is sufficiently staffed during peak hours. This position is an equal member of the Management Team and will have full voting authority. See Appendix B & D for the Shift and Operations Managers resume 3.3 Staffing Staffing will consist of the following: Manufacturing: Manufacturing of the ice cream will consist of 2 teams of 2 members each supervised by the Manufacturing Manager. Duties will include making the homemade ice cream and cleaning the production area. Counter Staff: 8 The counter staff will consist of 2 teams of 3 members each supervised by the Shift Managers. Duties will include taking order from customers, preparing the ice cream dish or fountain drink, taking payment for the product using a cash register and cleaning the work area as well as the customer tables. 4 Financial Plan The 3 year profit projection is included in the business plan. Profit sharing will be equal between all general partners. Our profit outlook is estimated to be 20 percent. The company plans to raise $500,000.00 for startup costs. This will accomplished through partner investments and bank loans. Each partner will contribute $50,000.00 totaling $200,000.00. We plan to borrow $300,000.00 from a bank. Our ice cream will be of high quality and unique in the business area that we have selected. 9 3 Year Profit and Loss Projection Profit and Loss Projection (3 Years) Solano Creamery 2009 % 2010 % 2011 % Sales Cost/ Goods Sold (COGS) Gross Profit $250,000 106,023 $ 143,977 100.00% 35.00% 57.59% $ 360,068 126,023 $ 234,045 100.00% 35.00% 65.00% $ 420,068 140,098 $ 279,970 100.00% 33.35% 66.65% Operating Expenses Salary (Office & Overhead) Payroll (taxes etc.) Outside Services Supplies (off and operation) Repairs/ Maintenance Advertising Car, Delivery and Travel Accounting and Legal Rent Telephone Utilities Insurance Taxes (real estate etc.) Interest Depreciation Other expense (specify) Other expense (specify) Total Expenses $ 64,512 6,451 1,100 12,054 24,000 480 11,400 30,000 $ 149,997 25.80% 2.58% 0.00% 0.00% 0.44% 4.82% 0.00% 0.00% 9.60% 0.19% 4.56% 12.00% 0.00% 0.00% 0.00% 0.00% 0.00% 60.00% $ 64,512 6,451 1,100 12,044 24,000 480 11,400 30,000 $ 149,987 17.92% 1.79% 0.00% 0.00% 0.31% 3.34% 0.00% 0.00% 6.67% 0.13% 3.17% 8.33% 0.00% 0.00% 0.00% 0.00% 0.00% 41.66% $ 64,512 6,451 1,100 13,000 24,000 480 11,400 30,000 $ 150,943 15.36% 1.54% 0.00% 0.00% 0.26% 3.09% 0.00% 0.00% 5.71% 0.11% 2.71% 7.14% 0.00% 0.00% 0.00% 0.00% 0.00% 35.93% Net Profit Before Tax Income Taxes Net Profit After Tax Owner Draw/ Dividends Adj. to Retained Earnings (6,020) (6,020) $ (6,020) 84,059 84,059 $ 84,059 129,027 129,027 $ 129,027 10 12 Months Sales Forecast Sales Forecast (12 Months) Solano Creamery Fiscal Year Begins Jun-09 12-month Sales Forecast Jun-09 7800 Ice cream units sold 1.50 Sale price @ unit 11,700 Ice Cream TOTAL 2128 Sundae units sold 2.75 Sale price @ unit 5,852 Sundae TOTAL Jul-09 7800 1.50 11,700 Aug-09 7800 1.50 11,700 Sep-09 7800 1.50 11,700 Oct-09 7000 1.50 10,500 Nov-09 6250 1.50 9,375 Dec-09 6100 1.50 9,150 Jan-10 6050 1.50 9,075 Feb-10 6050 1.50 9,075 Mar-10 6500 1.50 9,750 Apr-10 7800 1.50 11,700 May-10 7800 1.50 11,700 2128 2.75 5,852 2128 2.75 5,852 2128 2.75 5,852 1978 2.75 5,440 1800 2.75 4,950 1725 2.75 4,744 1715 2.75 4,716 1700 2.75 4,675 1900 2.75 5,225 2128 2.75 5,852 2128 2.75 5,852 Shake units sold Sale price @ unit Shake TOTAL 710 2.75 1,953 710 2.75 1,953 710 2.75 1,953 710 2.75 1,953 650 2.75 1,788 625 2.75 1,719 605 2.75 1,664 600 2.75 1,650 600 2.75 1,650 650 2.75 1,788 710 2.75 1,953 710 2.75 1,953 Pint units sold Sale price @ unit Pint TOTAL 375 8.00 3,000 375 8.00 3,000 375 8.00 3,000 375 8.00 3,000 325 8.00 2,600 300 8.00 2,400 300 8.00 2,400 290 8.00 2,320 290 8.00 2,320 335 8.00 2,680 375 8.00 3,000 375 8.00 3,000 Fountain Drink units price sold @ unit Sale Fountain Drink TOTAL Cat 6 units sold Sale price @ unit Cat 6 TOTAL 5358 1.40 7,501 5358 1.40 7,501 5358 1.40 7,501 5358 1.40 7,501 5100 1.40 7,140 5100 1.40 7,140 5100 1.40 7,140 5100 1.40 7,140 5100 1.40 7,140 5250 1.40 7,350 5358 1.40 7,501 5358 1.40 7,501 Cat 7 units sold Sale price @ unit Cat 7 TOTAL Monthly totals: All Categories Annual Totals 84750 127,125 23586 64,862 7990 21,973 4090 32,720 62898 88,057 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 30,006 30,006 30,006 30,006 27,467 25,584 25,098 24,901 24,860 26,793 30,006 30,006 334736 11 Startup Expenses Startup Expenses Solano Creamery Sources of Capital Owners' Investment (name and percent ownership) Chris XXXXXXXX 25% Charles XXXXXXXX 25% Tom XXXXXXXX 25% Brenda XXXXXXXX 25% Total Investment $ $ Bank Loans Bank of America Bank 2 Bank 3 Bank 4 Total Bank Loans $ N/A N/A N/A $ Other Loans Source 1 Source 2 Total Other Loans N/A N/A $ 50,000 50,000 50,000 50,000 200,000 300,000 300,000 - Startup Expenses Buildings/Real Estate Purchase Construction Remodeling Design Total Buildings/Real Estate Leasehold Improvements Item 1 Item 2 Item 3 Item 4 Total Leasehold Improvements Capital Equipment List Furniture Equipment $ $ $ $ $ 120,000 10,000 2,500 132,500 - 1,164 9,170 12 Fixtures Machinery Other Total Capital Equipment $ Location and Admin Expenses Rental Utility deposits Legal and accounting fees Prepaid insurance Pre-opening salaries Other Total Location and Admin Expenses Opening Inventory Ice Cream Fountain Drinks Pints Cones Category 5 Total Inventory Advertising and Promotional Expenses Advertising Signage Printing Travel/entertainment Other/additional categories Total Advertising/Promotional Expenses $ $ $ 5,550 2,500 - $ 2,950 $ $ - Reserve for Contingencies $ - Working Capital $ 334,311 $ 200,000 300,000 500,000 Other Expenses Other expense 1 Other expense 2 Total Other Expenses 1,000 6,805 18,139 2,000 5,000 7,000 Summary Statement Sources of Capital Owners' and other investments Bank loans Other loans Total Source of Funds Startup Expenses Buildings/real estate Leasehold improvements Capital equipment $ $ 132,500 18,139 13 Location/administration expenses Opening inventory Advertising/promotional expenses Other expenses Contingency fund Working capital Total Startup Expenses $ 7,000 2,950 500,000 14 5. Capital Required The partners have determined that they will need $500,000.00 in startup costs. The startup will include the building rent, equipment purchase, insurance, permits and initial marketing. This startup cost will also include any staff hired. Cost of used ice cream equipment Channel sign-100.00 Dipping cabinets-600.00 Reach in freezer-500.00 Batch freezer-4000.00 2 door hardening cabinet-3000.00 Soda machine-500.00 Waffle cone iron-5.00 Microwave-250.00 Shake mixer w/4cap-600.00 Fudge warmer-175.00 4 hold cone holder-35.00 Topping bin-70.00 Cash register-50.00 Fax machine(4 in one)-200.00 Elec. Scale-30.00 Credit card machine-100.00 Sst. prep table(96”)-350.00 5 quart mixer & 3 bowls-180.00 Walk in storage freezer & shelves(8x10)-4600.00 Mop & Hand sink with faucet-1200.00 Dishwashing sink, wash bords-1100.00 Inside & outside 20 chairs.(@35.00EA X 20=)-700.00 Inside tables (@80.00EA X 4 =)-320.00 Outside tables (@72.00EA x 2=)-144.00 Store art- 1000.00 Total $18,139.00 6. Marketing Plan Our plan is to market to all ethnic and socio-economic groups as ice cream is loved by everyone. We will place adds the local newspaper in each of the cities in Solano County as well buy time on the local radio stations and flyers will be distributed. We will capitalize on the fact that 15 Solano County has only a few gourmet ice cream shops and only one that makes it’s own ice cream. The local newspapers that will we target for advertisement space are: o The Daily Republic o The Vallejo Times-Herald o The Reporter None of the newspapers responded with advertising cost, but we did find that a banner for our business on the bottom of the Daily Republic website will cost $10.00 per day for a monthly cost of $300.00. Our intent is to advertise daily for the first 30 days and then twice weekly for the next 6 months. We will also be listed in each newspaper Service Directly weekly on a continuous basis. The Solano Creamery will buy 30 second air times on the following radio stations: o KUIC 95.3 FM o KASK 91.5 FM The cost of 30 seconds air time is $37.50 per commercial. We will 3 commercials per day for both radio stations for the first 14 days for a cost of $3150.00. We will then run 2 commercials per day per radio station for the remaining 16 days for a total of $2400.00. The first month would cost $5550.00 and each subsequent month would be $4500.00 for the second month. After the second month, we would only rely on radio for special events. Additionally the Solano Creamery will place weekly ads in the listed classified papers as well as there online version: o Solano Direct o Penny Saver (San Francisco) o Penny Saver (Sacramento) The average Penny Saver ad is $4.75 for 2 weeks. Web ads are free. And finally we plan to hire staff to stand on the nearest corner drawing attention with a sign pointing to our location at a cost of $10.00 per hour for 8 hours each Saturday and Sunday. 7. Location Analysis Much thought was given to the location we have chosen for the Solano Creamery. Cordelia is a growing community that does not have an ice cream shop. We consult and expert for the area’s demographics. Demographic, Traffic and Pedestrian pattern for Cordelia /Fairfield Ca. Zip 94534 16 a. The 2007 Cordelia / Fairfield. (Zip 94534), CA, population is 32,818. There are 355 people per square mile b. The average household size is 2.96 people. 35.58% of people are married, with children. 6.29% have children, but are single.10988 household are located in Cordelia / Fairfield. c. The income per capita is $36,780, which includes all adults and children. The median household income is $92,087 d. Overall, Cordelia/Fairfield (zip 94534), CA cost of living is 140.99. (Our cost of living indices are based on a US average of 100. An amount below 100 means Cordelia/Fairfield (zip 94534), CA is cheaper than the US average. A cost of living index above 100 means Cordelia/Fairfield (zip 94534), CA is more expensive.) e. Traffic and Pedestrian pattern at the intersection of Green valley and Business center drive going into the Business Center Mall. As of 4/05/09 10:00am-12:00pm averaged 504 cars And 20 Pedestrian. 12:00pm-2:00pm averaged 756 cars And 28 Pedestrian 2:00pm-4:00pm averaged 657cars And 25 Pedestrian 4:00pm-8:00pm averaged 573 cars And 15 Pedestrian 8. Manufacturing Plan The business size of 5000 square feet will include manufacturing, sales and customer seating. The Solano Creamery will use an automated Point of Sales system which will integrated inventory control. Ice cream will be manufactured in the business and sold directly to our customers. Our Ice cream will be homemade gourmet flavors. Since we are a small business, we are flexible in the ice cream flavors that will be sold. Our customers will influence the ice cream flavors sold that are reasonable and profitable. See appendix E for recipes of our two top selling flavors and appendix F and G for recipes on the Italian Soda and Lemonade. 17 9. Appendix A. Tom XXXXXXXX Resume B. Charles XXXXXXXX Resume C. Chris XXXXXXXX Resume D. Brenda XXXXXXXX Resume E. Ice Cream Recipes F. Italian Soda Recipe G. Homemade Lemonade Recipe H. Solano Creamery Menu I. Confidentiality Agreement 18 THOMAS CARY XXXXXXXX XXX Georgia Street Vallejo, CA 94590 Phone: home 707/XXXXXX; cell 925/XXXXXXX Email: XXXXX@yahoo.com Functional Summary I have 28 years total experience in the Mechanical Assembly field and 20 years experience in the Mechanical Assembly of vacuum systems both large and small. (Assembles: Flat Glass Coater, Curved Glass Coater, Roll Coater, E-Beam, ILS and small vacuum System). I have the ability to work with minimal supervision to accomplish tasks, as demonstrated by my employer's willingness to send me to job sites around the world to Install Large Flat Glass Coaters and Roll Coaters. I have also participated in the R&D lab process as a Roll Coater Operator. Additionally, I have over 10 years experience as a Brew Master in manufacturing beer for public sales and consumption. I have experience in all aspects of professional brewing, from development of the recipe to production and distribution of the beer. Employment Sr. Mechanical Vacuum Technician July, 15 1990 – Present Vacuum Coating Technologies, Inc. 2700 Maxwell Way Fairfield, CA 94533 Job duties include, but are not limited to: Assembly: Roots blower / Lock pump package assembly and servicing, mechanical and booster pump installation and servicing, assemble and install and test slit valve assembly, assemble and install conveyor and drive systems, troubleshooting, assemble and install all type of gauging (Capacitance manometer, I-on and Thin film), assemble and install and test and service poppets and cyclinoid assembly, assemble and install and test vacuum feed through and responsibly for the mechanical shipping of large coaters parts. Planar Magnetron Assembly: including use of gauss meter to gauss and degauss magnets and probes to check magnetic field. Assembly of source covers. Coater Operation: operation and maintenance including leak checking with helium (Mass Spectrometer), changing sources, shields, roll, tunnels, etc. soldering, brazing, bead blasting, all cleaning and all modifications. Certifications: overhead crane, forklift. I do all the pre shift inspection of all forklifts and tugger. High Vacuum Practices and Applications, Class 10 k clean room certification. 19 Maintenance of Production Equipment: troubleshooting downed equipment during test and production runs. Perform routine preventive maintenance to the coater. Tools: All hand tool used, soldering cutting, welding (soft and Acetylene), band saw, grinders, pneumatic, tools, transit and leveling jacks, Hovair heavy moving equipment, sanders, polishers, tubing benders and cutter, etc. Responsible for the work of up to 6 junior mechanics / temps at a given time. Part of the B.O.C. Safety committee for 3 years. Follow the B.O.C. ISO-9003 processes. Computer: Microsoft (95, 98,ME, 2000), Word 2002, Excel 2002, Access 2002, PowerPoint 2002, Job scope. (I can look up part numbers, P.O. numbers, due date, part description, quantities, locations, shipping document), E-mail and Internet skills. Owner, Vice President of Manufacturing, and Brew Master 1994 2004 White Water Brewing Company 560 Hwy 12, Unit D Rio Vista Ca. 94571 Job duties included, but were not limited to: Day-to-Day Operation of the Brewery: Set up of production schedule, keeping track of all batch information (Brew dates, Quantity of beer brewed, Original & Terminal specific gravity, Fermentation temperature, Bottling dates, Kegging dates, Quantity of bottles on hand, Quantity of kegs on hand and keeping track of all taxable information for B.A.T.F., cleaning of all equipment, fixtures hoses and test equipment), all ordering for manufacturing (malt & barley, hops, yeast, adjuncts, filters, Co2, bottles, caps, responsible for all quality controls. Equipment Operation: Brew on and maintain a 15-barrel brew house, four 15-barrel fermenter, plate & frame filter. Average batch produced 300 gallons for bottling & kegging. As a home brewer for 4 years I learned the old step methods for brewing a Light Ale, Ale, I.P.A., October fest and Stout. Awards: As the Brew Master for White Water Brewing Company, I have received two 2nd place ribbons at the California state fair. Received one in 1999 for our Jalapeno ale and a notable mention for our Stout beer. In 2000, I received a notable mention for my light blond ale. In 1993, we won 1st place in the state of California Home Brewer contest in the spice category with our Jalapeno Ale, and subsequently won 2nd place wit h the same ale in the national competition. Education 1982 - Antioch High School 510 G St. Antioch, Ca.94509 1996-1998 - Brew it up 1411 W. Covell Blvd. Davis CA 95616 Fermentation Science (Brewing Beer as Professional Brew Master) Areas of study included infusion-brewing methods at 1 bbl. Batch. I have developed recipes for Light Ale, Ale, I.P.A., October fest and Stout beers, starting from 5 gallon to 300-gallon batches. 2002-2003- Pittsburgh Adult Education Microsoft Office XP (Word 2002, Excel 2002, Access 2002, PowerPoint 2002) 20 References Jorge A. XXXXX Traffic & Inventory Manager VON ARDENNE Coating Technology XXXXX Maxwell Way Fairfield, CA 94533 Robert E. XXXXXX XXXX Mountainview Rd. Antioch CA.94509 Jim TXXXX (510) XXXXXX John XXXXXXXX (775) XXXXXXXX Appendix A 21 Charles J. XXXXXXXX Jr. XXXXXXX Lane Fairfield, CA 94533 Phone: home 707-XXXXXXX Email: XXXXXX@att.net Objective Work in highly technical fast pace environment. Be given the opportunity to excel and help the Company grow. I have many technical, supervisory and management skills that will benefit any organization. Experience United States Marine Corps January 1977 to January 1997 Personal Financial Records clerk. This job included maintaining personal financial records of Marines ensuring they received accurate pay by evaluating financial documents that affected pay with either credits or checkages. Prepared bi-monthly payrolls for cash or check payment. Disbursing Chief. Supervising younger Marines and auditing military pay records for accuracy. Drill Instructor. Training recruits to be Marines in a 12-week training cycle by instilling Espirit de Corps, teaching Marine Corps history, customs and courtesies and basic drill movements. After the training evolution, recruits will be basically trained Marines. Operations Officer. Prepared Marines for deployment by ensuring that they were familiar with local customs, proper liberty etiquette, proper technical training and that they had the proper equipment to accomplish the assigned mission. Information Technology Specialist 2005 November 1996 to September Troubleshoot hardware and software problems by using industry standard methods and tools. Install hardware, software and peripherals. Troubleshoot both wired and wireless network problems. Create network and Virtual Private Network (VPN) accounts Participate in PC lease refresh of 3000 computers Create Symantec Ghost images to readily reimage PC’s that are experiencing Operating System problems. Supervisory Information Technology Specialist September 2005 to Present Supervise the PC, Server and Customer Support Sections with a technical staff of 18 Project manager for all new initiatives that involve PC’s and Servers. 22 Manage the PC lease that refreshes 3000 computers every 3 years Recommend the purchase of laptops, printers and other peripherals. Manage the help desk and oversee the completion of all user tickets generated Commodity Purchase Committee of equipment for the entire West Coast. Education Altus High School, Altus Oklahoma January 1977 Graduated High School mid-term with a 3.9 GPA. Certifications Comptia A+ hardware and software March 2000 Microsoft Certified Professional March 2000 Scuba Schools International Open Water Dive Certified January 1990 Skills Microsoft Office, able to set up both wired and wireless networks, am capable of building and repairing computers and repairing printers. Appendix B 23 Chris XXXXXXXX Chief Financial Officer Chris XXXXXXXX is the Chief Financial Officer of Solano Creamery, a position he has held since the company opened. He is currently responsible for all financial matters for Solano Creamery, including Accounting, Internal Audit and Controls, Facilities, Tax, Treasury and Investor Relations. Prior to joining Solano Creamery, Chris was a senior accountant for AMS, a staffing agency, also located in Fairfield where he served as a payroll manager. Mr. XXXXXXXX is an alumnus of University of Miami, in Miami, FL. He is also a member of the American Payroll Association and American Institute of Certified Public Accountants. Appendix C 24 XXXXXXXX CT., VACAVILLE, CA 95687 916-XXXXXXXXX Brenda.j.XXXXXXXX@usps.gov BRENDA XXXXXXXX Experience: Work History 1987-Present US POSTAL SERVICE SACRAMENTO, CA Purchasing Agent I purchase parts for the Mail Processing Equipment Purchase tools for the Maintenance Technicians I also purchase Safety wear for the Maintenance Employee’s 1988-1990 HOME COOKING BAKERY Owner of Baking Company This was a short lived business; I was working out of my home baking cake & pies on a daily basis. 1985-1987 US POSTAL SERVICE SACRAMENTO, CA Motor Vehicle Truck Driver I would be dispatched out to different Post Office to pick up or Deliver Mail 1978-1985 UNITED STATES AIR FORCE KEESLER AFB, MS Safety Inspector I investigated all type of mishaps from Airplanes to Vehicle Accidents Prepared report for the media and official reports for military eye’s only I investigated employee accidents, and conducted safety inspection from flight line to offices. 1976-1978 UNITED STATES AIR FORCE CARSWELL AFB, TX Dental Assistance I practice four handed dentistry, that is were you manipulate using both hand of the dental assistance and the doctor. 1974-1976 UNITED STATES NAVY MARE ISLAND NAVAL SHIPYARD VALLEJO, CA Student Aide Metrology Lab In the Metrology Lab is where the testing and measuring of electronic instrument is done I was the receptionist. Education 2004-Present 1986-1987 FAIRFIELD, CA AMERICAN RIVER COLLEGE SACRAMENTO, CA Attended to earn a degree in culinary arts 1978-1980 SOLANO COMMUNITY COLLEGE Attending Solano Community College to obtain a degree in Business YUBA CITY COLLEGE MARYSVILLE, CA Attended to earn a degree in Computer Programming Appendix D 25 Manufacturing Process for Recipe #1 Gourmet Vanilla Ice Cream Ingredients: 2400 egg yolks 37.5 gallons milk 37.5 gallons double/heavy cream 150 pounds sugar or caster sugar 600 vanilla pods (sliced down the middle) Pour the milk into a saucepan and bring the pan slowly up to boiling point. Place the vanilla pods into it and leave to infuse for about 20 minutes. In a 40-quart mixer, beat and mix together the egg yolks and sugar until thick. Carefully remove the vanilla pods from the pan of milk and scrape out the seeds into the milk. Pour the milk into the mixture of egg yolks and sugar whilst stirring. Pour the mixture back into the pan and heat gently, stirring until the custard thickens – DO NOT BRING TO THE BOIL OR IT WILL PROBALY CURDLE. When you can see a film form over the back of your spoon it’s time to remove the saucepan from the heat. Leave to cool. When the custard base is cold stir in the cream. Transfer the whole mixture into an ice cream maker and freeze for 10 hours. Manufacturing Process for Recipe #2 Gourmet Chocolate Ice Cream Ingredients: 150 gallons unsweetened chocolate 10.5 gallons dry unsweetened cocoa powder 1200 large eggs 112.5 gallons milk 7.5 gallons whipping cream 75 gallons sugar 45 cups vanilla extract 1. Melt the unsweetened chocolate on top of a double boiler over hot, not boiling, water. Gradually whisk in the cocoa and heat, stirring constantly, until smooth. (The chocolate may "seize" or clump together. Don't worry, the milk will dissolve it.) Whisk in the milk, a little at a time, and heat until completely blended. Remove from the heat and let cool. 2. Whisk the eggs in a mixing bowl until light and fluffy, 1 to 2 minutes. Whisk in the sugar, a little at a time, and then continue whisking until completely blended, about 1 minute more. Pour in the cream and vanilla and whisk to blend. 26 3. Pour the chocolate mixture into the cream mixture and blend. Cover and refrigerate until cold, about 1 to 2 hours, depending on your refrigerator. 4. Transfer the mixture to an ice cream maker and freeze for 10 hours. Appendix E 27 Manufacturing Process for Recipe Italian Soda Make 5 gal. 1. water 2. 1.5 gal half and half 3. 8 oz of any flavored syrup 4. ice 5. whipped cream 6. CO2 thank 7. 5ga Soda keg Measure syrup into a 5 gallon Soda keg. Add ice, Pour in half and half. Add water. Stir well. Then carbonated Serve topped with whipped cream Appendix F 28 Manufacturing Process for Recipe Homemade Lemonade Make 5 gal. 1. .5 lbs granulated sugar 5gal.cold water 20 lemons 2. In addition, you will need: Big pitcher 3. Pour the sugar and gal. of the water into a 1 gal.pot. Over medium heat, bring to a boil. Reduce heat, and stir until all the sugar has dissolved. 4. Now you have a simple syrup. Cool to room temperature, then refrigerate while you juice the lemons. 5. Roll the lemons to warm them and get the juices flowing. Cut in half. And juice all the lemons into 1 gal pot 6. Mix the refrigerated simple syrup and the remaining cold water. Add the fresh lemon juice. Mix well. 7. Enjoy your lemonade! For variety, try garnishing with fresh mint, fresh lemon slices or a fresh strawberry Appendix G 29 Single scoop Ice Cream cone $1.50 Ice Cream Sundae $2.75 Italian Soda $2.75 Small Shake $2.75 Large Shake $3.50 Fountain drinks $1.40 Pint of Ice Cream $8.00 Appendix H 30 CONFIDENTIALITY AGREEMENT The undersigned reader acknowledges that the information provided by the Solano Creamery in this business plan is confidential; therefore, reader agrees not to disclose it without the express written permission of the Solano Creamery owners. It is acknowledged by reader that information to be furnished in this business plan is in all respects confidential in nature, other than information which is in the public domain through other means and that any disclosure or use of same by eader may cause serious harm or damage to the Solano Creamery. Upon request, this document is to be immediately returned to the owners of the Solano Creamery. _____________________ Signature _____________________ Name (typed or printed) _____________________ Date This is a business plan. It does not imply an offering of securities Appendix I 31