Cleaning Specifications for Sure Klean 600 Detergent

advertisement

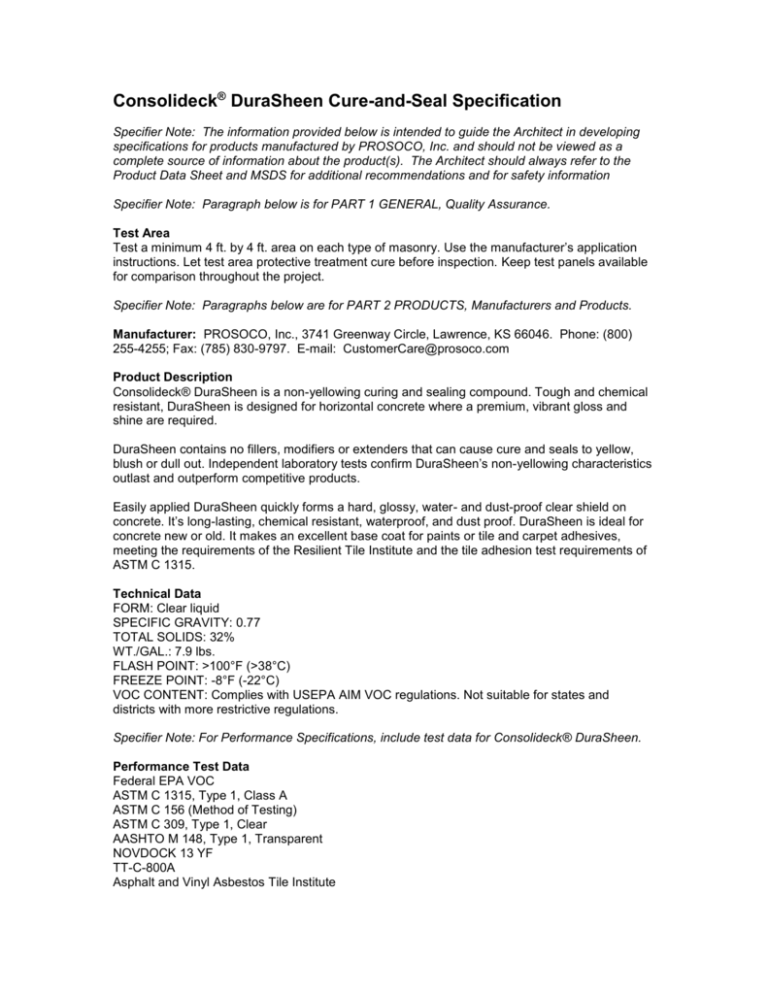

Consolideck® DuraSheen Cure-and-Seal Specification Specifier Note: The information provided below is intended to guide the Architect in developing specifications for products manufactured by PROSOCO, Inc. and should not be viewed as a complete source of information about the product(s). The Architect should always refer to the Product Data Sheet and MSDS for additional recommendations and for safety information Specifier Note: Paragraph below is for PART 1 GENERAL, Quality Assurance. Test Area Test a minimum 4 ft. by 4 ft. area on each type of masonry. Use the manufacturer’s application instructions. Let test area protective treatment cure before inspection. Keep test panels available for comparison throughout the project. Specifier Note: Paragraphs below are for PART 2 PRODUCTS, Manufacturers and Products. Manufacturer: PROSOCO, Inc., 3741 Greenway Circle, Lawrence, KS 66046. Phone: (800) 255-4255; Fax: (785) 830-9797. E-mail: CustomerCare@prosoco.com Product Description Consolideck® DuraSheen is a non-yellowing curing and sealing compound. Tough and chemical resistant, DuraSheen is designed for horizontal concrete where a premium, vibrant gloss and shine are required. DuraSheen contains no fillers, modifiers or extenders that can cause cure and seals to yellow, blush or dull out. Independent laboratory tests confirm DuraSheen’s non-yellowing characteristics outlast and outperform competitive products. Easily applied DuraSheen quickly forms a hard, glossy, water- and dust-proof clear shield on concrete. It’s long-lasting, chemical resistant, waterproof, and dust proof. DuraSheen is ideal for concrete new or old. It makes an excellent base coat for paints or tile and carpet adhesives, meeting the requirements of the Resilient Tile Institute and the tile adhesion test requirements of ASTM C 1315. Technical Data FORM: Clear liquid SPECIFIC GRAVITY: 0.77 TOTAL SOLIDS: 32% WT./GAL.: 7.9 lbs. FLASH POINT: >100°F (>38°C) FREEZE POINT: -8°F (-22°C) VOC CONTENT: Complies with USEPA AIM VOC regulations. Not suitable for states and districts with more restrictive regulations. Specifier Note: For Performance Specifications, include test data for Consolideck® DuraSheen. Performance Test Data6 Federal EPA VOC ASTM C 1315, Type 1, Class A ASTM C 156 (Method of Testing) ASTM C 309, Type 1, Clear AASHTO M 148, Type 1, Transparent NOVDOCK 13 YF TT-C-800A Asphalt and Vinyl Asbestos Tile Institute Code of Federal Regulations Title 40; Part 59 Limitations Will not bond to cementitious adhesives. Test for bondability to new products. Not for use around pools or fountains. Will not compensate for structural or surface defects. Not suitable for sale in states and districts with more restrictive AIM VOC regulations. Specifier Note: Paragraphs below are for PART 3 EXECUTION, Installation. Application Before applying, read “Preparation” and “Safety Information” sections in the Manufacturer’s Product Data Sheet for Consolideck ® DuraSheen. Do not dilute or alter. Mix well before use. Curing New Concrete Apply as soon as surface water has disappeared and slab can support the weight of an applicator. Apply at 300-400 ft2/gal (7-10 m2/L). Coverage may vary based on porosity and texture of surface. Sealing New & Existing Concrete Surfaces must be clean, dry and in good repair. On concrete already cured with DuraSheen, sealing with DuraSheen gives added protection. Apply after 28 days of curing. On concrete not cured with DuraSheen, apply two coats. Add the second coat four hours after the first. Coverage & Drying Times New concrete Older concrete 300 ft2/gal (7 ft2/L) 400-600 ft2/gal (7-10 ft2/L) At 80°F (27°C) treated surfaces dry as follows: To touch 25 minutes Light foot traffic 4 hours Normal traffic overnight Maximum hardness 7 days

![1 SECTION [03 30 00] [Cast-In-Place Concrete] Specifier Note: This](http://s2.studylib.net/store/data/018321747_1-a019eb82a5c1e918921b2259bc792a74-300x300.png)