Lipid Degrading Bacteria and Their Biotechnology Application

advertisement

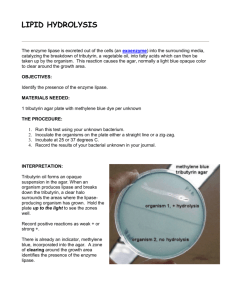

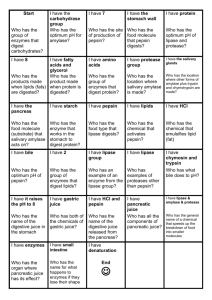

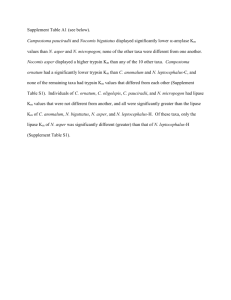

Lipid Degrading Bacteria and Their Biotechnology Application: Review of Present Scenario http://www.journals.elsevier.com/journal-of-bioscience-and-bioengineering/ Aqsad Rashda*, Tahir Iqbal, Muhammad Kaleem Sarwar, Muhammad Nadeem Abbas, Fareeha Azam, Iqra Azam and Waheed Iqbal. *Aqsad Rashda (Corresponding author) Department of Zoology, University of Gujrat Department of Zoology, University of Gujrat, Punjab, Pakistan Tel: 03068723540 E-mail: aqsadrashda@gmail.com Abstract Lipids are long chain fatty acids that offer wide applications for mankind. When released in environment, most of the forms of lipids undergo degradation. This review paper is intended to provide an overview about the microbial lipid degradation. Lipolytic enzymes mainly lipases have been explained here. Many microbial lipase-producing strains are reviewed along with the main substrates and factors affecting lipid biodegradation. Finally, some important applications of lipolytic bacteria and lipases have been discussed. Key words: Lipolytic Bacteria, Bacterial lipases, conditions for lipid biodegradation, lipase applications. 1. Introduction Lipids are long chain fatty acids that are bonded to glycerol, alcohols or other groups by an ester or ether linkage. These are classified into two main groups, Fats and oils that have the alcohol groups esterified with fatty acids, mostly in the form of triglycerides (Alves et al., 2009). Due to unique physiochemical properties, specific chemical composition and properties, lipids have been utilized as foods, fuels and lubricants. There are various sources of lipids such as vegetable, animal, and marine sources (Aluyor et al., 2009). But on the other hand lipids like fats, greases and oils are dominant organic matters present in municipal and some industrial wastewater, causing severe environmental pollution (Prasad and Manjunath, 2011). However, when discharged in the environment, lipids undergo degradation. One of the promising degradation methods - Microbial degradation - of oil wastewater is a major interest in recent years (WU Lanet al., 2009). Various microorganisms such as bacteria, yeasts and molds have been observed capable of degrading oil waste water completely (Ammar et al., 2005; Dhouib et al., 2006; Erguder et al., 2000; Ettayebi et al., 2003; Kissi et al., 2001). Microbial degradation and hydrolysis of lipids requires specific lipolytic enzymes which are called Lipases. Lipases are serine hydrolases of appreciable physiological significance and industrial potential to catalyze various reactions such as hydrolysis, esterification, interesterification, aminolysis and alcoholysis (Jaeger and Eggert, 2002). Microbial lipases have been produced by fungi, yeasts and bacteria as intracellular, extracellular and cell-bound enzyme (Bhumibhamon et al., 2002). The yeast, Candida deformans produces extracellular lipase of great biotechnological importance (Muderwa and Ratamahenina, 1985). microorganisms are inhabitants of different These lipase producing environmental niches. These microorganisms have been isolated from a variety of sources and degrading efficiency has been studied both as single culture and mixed culture formula (Bhumibhamon et al., 2002) This paper examines the biodegradation of lipids specifically by using bacterial lipase and the applications of these lipase-producing bacteria in environment as well as in industry processes. 2. General properties of lipids Lipids are essential to all living organisms, like other organic compounds they have specific properties due to their chemical composition. Fats and oils consist of mixtures of fatty acid esters of the trihydroxy alcohol or glycerol (Nwobiet al., 2006). Thus the physical properties of fats and oils depend on the nature of fatty acids involved in the ester formation (Aluyor et al., 2009). Triglyceride is an important component of natural oil or fat which can be hydrolyzed into diacylglycerol, monoacylglycerol, glycerol, and fatty acids. Glycerol and fatty acids are largely used as raw materials, for instance, monoacylglycerol is employed as an emulsifying agent in the cosmetics, food and pharmaceutical industries (Karigar and Rao, 2011). . 3. Lipases Enzymes are biological catalysts that are involved in the conversion of substrates into products by lowering the activation energy of the reaction (Karigar and Rao, 2011). Microbial enzymes are generally considered more useful than the enzymes derived from animals or plants due to the great variety of catalytic activities available, ease of genetic manipulation, high yields possibility, regular supply due to absence of seasonal fluctuations and rapid growth of microorganisms on inexpensive media (Iftikhar & Hussain, 2002; Iftikhar et al., 2003; Iftikhar et al., 2010b). Lipids are hydrolyzed or degraded by specific lipolytic enzymes. Lipases are the major lipolytic enzymes found in bacteria and offer wide range of applications. They catalyze both the hydrolysis and the production of poorly soluble or insoluble longchain triacylglycerols having an acyl chain length of ≥ 10 carbon atoms depending upon the availibility of water (Gupta et al., 2004). Thus generating free fatty acids, mono and diacylglycerols and glycerol (Lutz, 2004; Kempka et al., 2008) (Fig. 1). Lipases are produced by both prokaryotes such as bacteria and archaea and eukaryotes, including animals, plants and fungi (Wang et al., 2008). Among microbial lipases, bacterial lipases are most important. These are normally produced in the presence of oil or any other lipidic substrate, like fatty acids, fatty acid esters and glycerol, as carbon source along with the presence of any complex nitrogen source (Gupta et al., 2004). These are generally extracellular and are greatly affected by physicochemical and nutritional factors, such as temperature, pH, carbon and nitrogen sources, inorganic salts, dissolved oxygen concentration and agitation (Gupta et al., 2004). Filamentous fungi, especially Rhizopus, Aspergillus, Mucor, Fusarium ,Penicillium and Humicola, produce lipases with good lipolytic activities, besides bacterial sources ( Alves, 2002; Fuglsang, 2007). Lipase producing microorganisms have been isolated from various habitats and sources such as industrial wastes, dairy plants, vegetable oil processing factories and soil contaminated with oil (Sharma et al., 2001). 4. Lipases Producing Microorganisms Bacteria - Various species of bacteria showing lipolytic activity have been isolated and characterized. Table 1 shows source and lipid biodegradation activities of some recently identified bacterial strains. Matsumiya et al., (2007) reported the isolation of microorganisms that degrade lipids from a variety of environmental sources for the construction of waste water treatment system containing lipids. Among the isolated strains, Burkholderia sp. DW2-1 showed maximum rate of degradation of 1% (w/v) salad oils. Płaza et al., (2008) investigated biodegradation of crude oil and 7 diverse distillation products by Alcaligene spiechaudii SRS and Ralstonia picketti SRS. Crude oil degradation was above 80% after incubation of 20 days for both strains and their mixture. Čipinytė et al. (2009) screened grease wastes utilization microorganisms. Five strains (UP2, F2, E13, Kl1 and N3) showed lipolytic activity and rapidly degraded olive oil and sunflower oil, tallow and lard. Two of these strains identified as Enterobacter aerogenes E13 and Arthrobacter sp. N3 were found to have the highest lipase activity and the more intensive rates of the degradation of saturated (stearic and palmitic) and unsaturated (linoleic and oleic) fatty acids and triglycerides containing these fatty acids. Mixed culture of these strains E. aerogenes E13 and Arthrobacter sp. N3 grown on mineral medium containing 0.5% of sunflower oil produced monoglycerides, diglycerides and free fatty acids. According to this research, the mixed culture of strains E. aerogenes E13 and Arthrobacte rsp. N3 may be applicable for an effective grease waste reduction. Prasad and Manjunath (2011) carried out studies on biodegradation of high fat and oil wastewater by lipase producing bacteria such as Bacillus subtilis, B. licheniformis, B. amylo liquefaciens, Serratia marsescens, Pseudomonas aeruginosa and Staphylococcus aureus in wastewater released from palm oil mill, slaughter house, dairy, soap industry and domestic wastewater with both individual and mixed culture (consortia). After 12 d of BOD and lipid content was observed to be decreased in consortia (Table 1). Fungi - Most commercially valuable lipase-producing fungi belong to the genera Rhizopus sp., Penicillium sp., Aspergillus sp., Mucor sp., Geotrichum sp., and Rhizomucor sp. (Thakur, 2012). Vishnupriya et al. studied the lipase production by Sterptomyces grisesus and obtained maximum enzyme activity of 51.9U/ml. Fungal lipase production varies according to the strain, cultivation conditions, composition of the growth medium, temperature, pH, and the kind of carbon and nitrogen sources (Cihangir and Sarikaya, 2004). Due to increasing industrial demands of new lipases, isolation and identification of lipase producing fungi has also been reported in many studies. Kaushik et al. (2006) documented the production of an extracellular lipase from Aspergillus carneus. In another study WU Lanet al. (2008) checked the capability of Yarrowia lipolyticaW29 immobilized by calcium alginate to degrade oil, this species might be employed to a wastewater treatment system for the removal of oil. Further studies have reported other lipase producing fungal species such as Aspergillus niger (Ellaiah et al., 2004) Rhizopus arrhizus (Yang et al. 2005), Rhizopus sp. (Bapiraju et al., 2005), Penicillium restrictum (Azeredo et al., 2007), Penicillium simplicissimum (Vargas et al., 2008) and Sterptomyces grisesus (Vishnupriya et al., 2010) (Table 2). 5. Genes Encoding Lipases With the advancements of modern technologies, genes encoding lipases in various microorganisms have been identified. As lipase is considered as the key enzyme to degrade lipids, it is encoded by lipA gene. LipA gene has been reported in many studies. Long et al. (2007) detected lipA gene in Serratia marcescens ECUCU1010. Moreover, Sl LipA was isolated from Serratia liquefaciens S33 DB-1 which can degrade C18 of fatty acid (Yao et al., 2007).The lipase gene (LipA) and lipase chaperone-encoding genes (LipB) of strain Acinetobacter calcoaceticus RAG1has been cloned and sequenced (Sullivan et al., 1999). The gene coding for an extracellular lipase of genus Bacillus has been cloned using PCR techniques. The length of gene has been found to be 639 bp, encoding a peptide of 212 amino acids of molecular mass of 19353 Da, and pI 9.28 (Rabbani et al., 2009). The yeast Yarrowia lipolytica assimilates hydrophobic substrates, such as alkanes, fats, oils and fatty acids, by the activation of different enzymes such as lipases/esterases (LIP genes), peroxisomal acyl-CoA oxidases (POX genes) and cytochromes P450 (ALK genes) (Darvishi, 2012) . In this species, LIP2 gene (GenBank AJ012632) encodes extracellular lipase. Conditions for Lipid Degradation Various factors may tend to increase or the decrease the rate of lipid biodegradation. Most important factors are temperature and pH. Temperature has a significant role in controlling the nature and efficiency of microbial degradation of hydrocarbons (Leahy and Colwell, 1990). Degradation of long chain alkanes by mesophiles at temperatures between 25 and 28 °C has been extensively studied (Mishra et al. 2001). Bacillus cereus N-09 strain shows maximum degradation of lipids and detergents at temperature of 30 °C, pH 6.00, and agitation speed of 130rpm (Hidayat, 2011). Table 2 shows the optimized conditions for some lipolytic bacterial strains. Sugimori et al., (2013) investigated capability of soil bacterium, Raoultella planticola strain 232-2 for vegetable oil, lard, and beef tallow degradation under in acidic environment. Highly effective degradation rate was observed at 35 °C and pH 4.0, and the 24-h degradation rate was 62.5 ± 10.5 % for 3,000 ppm mixed lipids. Lipolytic activity of bacteria can be enhanced in the presence of exogenous surfactants. Karpenko et al. (2006) reported the acceleration of oil degradation by genus Rhodococcus in the presence of exogenous surfactants that has been produced by Pseudomonas sp. Various bacterial species capable of growing at high temperatures have also shown lipolytic activities such as a novel oil degrading bacteria identified as Pseudomonas aeruginosa has been isolated from hot spring, inhabiting at temperature ranges between 15°C and 55°C (Hasanuzzaman et al., 2004). At present, microorganisms such as Bacillus sp. strain 398 (Kim et al., 1994), Bacillus thermocatenulatus (Schmidt-Dannert et al., 1994), Bacillus sp. strain A30-1 (Wang et al., 1995), Bacillus thermoleovorans ID-1 (Lee et al., 1999), Bacillus sp. THL027 (Dharmsthiti and Luchai, 1999), Bacillus spp. (Handelsman et al., 1994; Llarch et al., 1997; Becker et al., 1997; Nawani et al., 1998), Bacillus sp. RSJ-1 (Sharma et al., 2001) have been reported as thermostable lipase producers. As thermophilic bacterial strains have an optimum growth temperature of 65–70°C, lipases isolated from such strains are good candidates for lipid modifications (Sigurgísladóttir et al., 1993) (Table 3). 6. Applications of lipids degrading bacteria Lipases are widely present in nature, but only microbial lipases are commercial significance (Kasra-Kermanshahiet al., 2011). Bacterial lipases are greatly utilized in food and dairy industry for milk fat hydrolysis, flavor enhancement, cheese ripening, and lipolysis of cream and butter fat (Falch, 1999). Lipases are also used in textile industry to enhance fabric absorbency (Sharma et al., 2001),in detergent industry as additive or supplement in washing powder (Fuji et al., 1986) , for various transesterification reactions ( Fariha et al., 2006) and for synthesis of biodegradable compounds or polymers ( Linko et al.,1998). Simultaneously, the enzyme is being employed in paper and pulp industry (Bajpai, 1999), as a catalyst for manufacturing various products used in cosmetic industry (Eugene, 1974), in biodiesel synthesis (Noureddini et al., 2005), in pharmaceutical industry (Higaki and Morohashi, 2003) and in degreasing of leather (Nakamura and Nasu, 1990). In recent years, microbial degradation of oil containing wastewater is an important concern (Lan et al., 2009). The utilization of lipase producing microorganisms into wastewater treatment system for the degradation of fat and oil is an interesting strategy (Bhumibhamon, 2002). Various microorganisms such as bacteria, yeasts and molds have been observed to be capable of completely degrading oil wastewater (Ammar et al., 2005; Dhouib et al., 2006; Erguder et al., 2000; Ettayebi et al., 2003; Kissi et al., 2001). These microorganisms can be applied on industrial as well as domestic wastewater lipids. containing lipids, in order to remove Mongkolthanaruk and Dharmsthiti (2002) formulated a mixed bacterial culture comprising of Pseudomonas aeruginosa LP602 and Acinetobacter calcoaceticus LP009, for use in treatment of lipid-rich wastewater. Oil spills are causing major hazards to the environment. Petroleum fuel spills from tank failure, pipeline ruptures, different production storage and transportation accidents are speculated as the most frequent organic pollutant of soil and aquatic environment and have been grouped as hazardous wastes due to their cytotoxic, carcinogenic and mutagenic effects on human (Margesin et al., 2003; Rahman et al., 2002). Oil degrading bacteria have been used to clear up oil spills. According to Kasra-Kermanshahi et al. (2011) lipase of P. aeruginosa KM110 is possibly an alkaline lipase and a candidate for various industrial applications such as leather, detergent and fine chemical industries. Extracellular lipase of Pseudomonas fluorescens KE38, is a candidate for industrial applications due to its high stability, wide substrate specificity and cold temperatures activity in the presence of organic solvents, and metal ions (Adan Gokbulut and Arslanoglu, 2013). Lipases have also found versatile applications in pharmaceutical industry. Specifically, preparation of homochiral compounds being used against HIV and synthesis of alkaloids, anti-tumor agents, vitamins and antibiotics are fundamental applications of lipases (Jaeger and Eggert, 2002). Furthermore, bacterial lipase treatment has been found to intensify the designing of cotton fabrics (Lange, 1997 and Buchert et al., 2000). Bacterial lipases have been analyzed for the efficiency as a scouring agent for raw cotton fabrics in order to eliminate the natural hydrophobic substances found in the fiber (Raja et al., 2012). Biodiesel has been considered the most effective energy alternative. At present biodiesel has been commercially carried out using alkaline catalyst. Lipases have been found to be active in transesterification process leading to production of biodiesel, which may be proved to be environmental friendly and economical. This involves use of immobilized lipases through various techniques (Jegannathan et al., 2008). Limitations of the industrial usage of these enzymes have chiefly been owing to their high production costs, which may be reduced by molecular technologies, thus enabling the production of these enzymes at high levels and in a virtually purified form (Houde et al., 2004) (Table 5). References ADAN GÖKBULUT, A. and ARSLANOĞLU. A. 2013. Purification and biochemical characterization of an extracellular lipase from psychrotolerant Pseudomonas fluorescens KE38.Turk. J. Biol.37:1-3 Aluyor, E.O., Obahiagbon, K. O. and Ori-jesu, M. 2009. Biodegradation of vegetable oils: A review. Sci.Res. and Essay.4(6): 543-548 http://www.academicjournals.org/SRE Alves, M. H., Takaki, G. M. C., Porto, A. L. F. &Milanez, A. I. 2002.Brazilian J Microbiol, 33: 325 – 330. Alves, M.M., Pereira, M. A., Sousa, D.Z., Cavaleiro, A. J., Picavet, M., Smidt, H. and Stams, A. J. M. .2009.Waste lipids to energy: how to optimize methane production from long-chain fatty acids (LCFA)Minireview. Microbial.Biotech.2(5): 538–550 Ammar, E., Nasri. M., and Medhioub, K. 2005.Isolation of phenol degrading Enterobacteria from the wastewater of olive oil extraction process.W. J Microbio. Biotech. 21(3): 253–259. Azeredo, L.A.I., P.M. Gomes, G., Sant’Anna, L.R. Jr. Castilho, D.G. Freire. 2007. Production and regulation of lipase activity from Penicilliumrestrictum in submerged and solid-state fermentations. Current Microbio.54: 361–365. Bajpai, P., 1999. Application of enzymes in the pulp and paper industry.Biotechnol Progr,15: 147-157. Bancerz, R., Ginalska, G.,Fiedurek, J. and Gromada, A. 2005. Cultivation conditions and properties of extracellular crude lipase from the psychrotrophic fungus Penicillium chrysogenum 9′. J. Ind. Microbio. Biotech. 32(6): 253-260 Bapiraju, K.V.V.S.N., P. Sujatha, P. Ellaiah, T. Ramana. 2005. Sequential parametric optimization of lipase production by a mutant strain Rhizopussp. BTNT-2”, Braz. J. Chem. Engin. 45(4):257–273. Becker, P., Reesh, I.A., Markossian, S., Antranikian, G., Märkl, H. 1997. Determination of the kinetic parameters during continuous cultivation of the lipaseproducing thermophile Bacillus sp. IHI-91 on olive oil. Appl. Microbiol. Biotechnol. 48:184-190. Bhumibhamon, O., Koprasertsak, A. and Funthong, S..2002. Biotreatment of High Fat and Oil Wastewater by Lipase Producing Microorganisms. Kasetsart. J. (Nat. Sci.) 36: 261 - 267 Bradoo, S., Saxena, R. K. and Gupta, R. 1999. Two acidothermotolerant lipases from new variants of Bacillus spp. World J. Microbio. Biotech.15(1): 87-91 Buchert, J., Peter, J., Puolakka, A. &Nousiainen, P.2000.Text Chem Color Am Dyest Rep, 32: 48 – 52. Cihangir, N. and E. Sarikaya. 2004. Investigation of lipase production by a new isolated of Aspergillus sp. W. J. Microbio. & Biotech.20:193–197. Čipinytė, V., Grigiškis, S. and Baškys,E. 2009.Selection of fat-degrading microorganisms for thestreatment of lipid-contaminated environment.BIOLOGIJA.55(3–4): 84–92 Colen, G., Junqueira, R. G. and Moraes-Santos, T. 2006. Isolation and Screening of Alkaline Lipase-producing Fungi from Brazilian Savanna Soil. World. J. Microbio. Biotech. 22(8): 881-885 Darvishi, F. 2012.Expression of native and mutant extracellular lipases fromYarrowialipolytica in Saccharomyces cerevisiae. Microbial.Biotech.5 (5): 634– 641 Dharmsthiti, S., Luchai, S. 1999. Production, purification and characterization of thermophilic lipase from Bacilus sp. THL027. FEMS Microbiol Lett. 179:241-246. Dhouib, A,.Ellouz, M,.Aloui, F,.andSayadi, S. 2006. Effect of bioaugmentation of activated sludge with white-rot fungi on olive mill wastewater detoxification. Letters in Appl. Microbio.42(4): 405–411. Ellaiah, P., T. Prabhakar, B. Ramakrishna, A.T. Taleb, K. Adinarayana. 2004. Production of lipase by immobilized cells of Aspergillusniger. Process Biochem. 39:525–528. Erguder, T. H., Guven, E., and Demirer, G. N. 2000.Anaerobic treatment of olive mill wastewaters in batch reactors.Process.Biochem.36(3): 243–248. Ettayebi, K., Errachidi, F., Jamai, L., Tahri-Jouti, A. M., Sendide, K., and Ettayebi, M. 2003. Biodegradation of polyphenols with immobilized Candida tropicalis under metabolic induction. FEMS Microbio.Letters.223(2): 215–219. Eugene, W.S. 1974. Industrial application of microbial lipases: A review. J. Am. Oil Chem. Soc., 51(2): 12-16. Fadile, A., Fatima Zahra el Hassani,.Aissam, H., Merzouki, M. and Benlemlih, M. 2011. Aerobic treatment of lipid-rich wastewater by a bacterial consortium. Afr. J. Microbiol. Res.5(30): 5333-5342 Falch, E.A. and E.A. Falch, 1991.Industrial enzymes developments in production and application.Biotechnol Adv. 9: 643-658. Fariha, H., Ali, A. and Hameed, A. 2006. Industrial applications of microbial lipases. Enzyme.Microbial. Tech.39(2): 235-251. Fickers, P. and Nicaud, J. M. 2013. Biotechnological Applications of Yarrowia lipolytica Lipases: An Overview. Microbio. Monographs. 25:121-136 Fuglsang, C. C., Okkels, J. S., Petersen, D. A., Patkar, S. A., Thellersen, M., Svendesen, A., Borch, K., Royer, J. C., Kretzchmac, T., Halkier, T., Vind, J. & Jorgensen, S. T., US Pat 7 157 262 (to Novozymes, Denmark), 2007. Fuji, T., T. Tatara and M. Minagawa, 1986.Studies on application of lipolytic enzyme in detergent industries.J. Am. Oil Chem. Soc. 63: 796-799. Gao, Y. and Breuil, C.1995. Extracellular lipase production by a sapwood-staining fungus, Ophiostoma piceae. World J. Microbio. Biotech. 11(6): 638-642 Godoy, M. G., Gutarra, M. L. E., Castro, A. M., Machado, O. L. T. and Freire, D. M. G. 2011. Adding value to a toxic residue from the biodiesel industry: production of two distinct pool of lipases from Penicillium simplicissimum in castor bean waste. J. Ind. Microbio. & Biotech. 38(8): 945-953 Gupta, R., Gupta, N. and Rathi, P. 2004. Bacterial lipases: an overview of production, purification and biotechnological properties. Appl. Microbiol. Biotechnol.64: 763781. Haas, M. J., Cichowicz, D. J. and Bailey, D. G. 1992. Purification and characterization of an extracellular lipase from the fungusRhizopus delemar. Lipids. 27(8): 571-576 Handelsman, T., Shoham, Y. 1994. Production and characterization of an extracellular thermostable lipase from a thermophilic Bacillus sp. J. Gen. Appl. Microbiol. 40:435-443. Hasanuzzaman, M. et al. 2004.Isolation, Identification, and Characterization of a Novel, Oil-Degrading Bacterium, Pseudomonas aeruginosa T1.Current Microbio.49(2): 108-114 Hidayat, N. 2011.Optimization of pH, Temperature and Agitation Rate on biodegradation of Lipids and Detergents in Food Wastewater by Bacillus sp N-09.J. Agric. Food. Tech.1(5):59-62 Higaki,S. and M. Morohashi, 2003. Propionibacterium acnes lipase in seborrheic dermatitis and other skin diseases and Unsei-in. Drugs Exp. Clin Res., 29: 157-9. Hoshino, T., Tronsmo, A. M., Matsumoto, N., Sakamoto, T., Ohgiya, S. and Ishizaki, K.1997. Purification and characterization of a lipolytic enzyme active at low temperature from Norwegian Typhula ishikariensis group III strain. Euro. J. Plant. Patho. 103(4): 357-361 Houde, A., Kademi, A. and Leblanc, D. 2004. Lipases and their industrial applications. Appl. Biochem. Biotech.118(1-3):155-170. Huang, J., Wang, T., Su, N. and Lee, M. 2009. A strategy for screening microbial strains with lipolytic specificity toward monoacylglycerols. World J. Microbio. Biotech. 25(9):1651-1658 Iftikhar, T. and A. Hussain. 2002. Effect of nutrients on the extracellular lipase production by the mutant strain of R. oligosporous Tuv-31. Biotech.,1(1): 15-20. Iftikhar, T., M. Niaz, Y. Hussain, S.Q. Abbas, I. Ashraf and M.A. Zia. 2010b. Improvement of selected strains through gamma Irradiation for enhanced lipolytic potential. Pak. J. Bot. 42(4): 2257-2267. Iftikhar, T., I.U. Haq and M.M. Javed. 2003. Optimization of cultural conditions for the production of lipase by submerged fermentation of RhizopusoligosporousTuv 31. Pak J. Bot., 35(4): 519-525. Jaeger, K. E. &Eggert, T. 2002.Lipases for biotechnology,Curr.Opin.Biotechnol.13 : 390-397. Jegannathan, K.r., Abang, S., Poncelet, D., Chan, E. S., Ravindra, P. 2008. Production of Biodiesel Using Immobilized Lipase, A Critical Review. 28 (4):253-264 Karpenko, E. V., Vil’danova-Martsishin, R., Scheglova, N.S., Pirog, T.P. and Voloshina, I. N. 2006.The prospects of using bacteria of the genus Rhodococcus and microbial surfactants for the degradation of oil pollutants.Appl. Biochem. Micro.42(2): 156-157 Karigar. C. S and Rao, S. S. 2011. Role of Microbial Enzymes in the Bioremediation of Pollutants: Review Article. Enzym. Res. 2011:1-11. http://dx.doi.org/10.4061/2011/805187 Kalyana, C. B. and Lakshmi, N. M. 2013.Screening, Isolation and Identification of Extracellular Lipase Producing Bacteria Bacillus TequilensisNrrl B-41771.J. Chem. Bio. Phy. Sci. 3 (1): 378-383. Kasra-Kermanshahi, R., Mobarak-Qamsari, E. and Moosavi-nejad, Z. 2011.Isolation and identification of a novel, lipase-producing bacterium, Pseudomnasaeruginosa KM110.IRAN. J. MICROBIOL.3 (2): 92-98 Kaushik, R.,S. Saran, J. Isar, R.K. Saxena. 2006. Statistical optimization of medium components and growth conditions by response surface methodology to enhance lipase production by Aspergilluscarneus. J. Mol. Catalysis. B. Enzymatic. 40:121–126 Kempka, A.P., N.L. Lipke, T.L.F. Pinheiro, S. Menoncin, H. Treichel, D.M.G. Freire, M.D. Luccio and D. Oliveira. 2008. Response surface method to optimize the production and characterization of lipase from Penicilliumverrucosum in solidstate fermentation. Biop.Biosys. Eng., 31: 119-125. Kim, H. K., Sung, M.H., Kim, H.K., Oh, T.K. 1994. Occurrence of thermostable lipase in thermophilic Bacilus sp. strain 398. Biosci. Biotechnol. Biochem. 58(5):961962. Kissi, M., Mountadar, M., Assobhei, O., Gargiulo, E., Palmieri, G. and Giardina, P. 2001. Roles of two white-rot basidiomycete fungi in decolorization and detoxification of olive mill wastewater.Appl. Microbio.Biotech.57(1-2): 221–226. Lange, N. K. 1997. AATCC Rev, 29: 23 – 26. Leahy JG & Colwell RR (1990) Microbial degradation of hydrocarbons in the environment. Microbiol.Rev. 54: 305–315. Lee, D.W., Koh, Y.S., Kim, K.J., Kim, B.C., Choi, H.J., Kim, D.S., Suhartono, M.T., Pyun, Y.R. 1999. Isolation and characterization of a thermophilic lipase from Bacillus thermoleovorans ID-1. FEMS Microbiol Lett.179:393-400. Lefebvre, X., Paul, E., Mauret, M., Baptiste, P., Capdeville, B., 1998. Kinetic characterization of saponified domestic lipid residues aerobic biodegradation.Water Res.32:3031–3038. Linko, Y.Y., M. Lamsa, X. Wu, E. Uosukainen, J. Seppala and P. Linko, 1998. Biodegradable products by lipase biocatalysis.J. Biotechnol.66(1): 41-50. Llarch, A., Logan, N.A., Castellví, J., Prieto, M.J., Guinea, J. 1997. Isolation and characterization of thermophilic Bacillus spp. from geothermal environments on deception island, south Shetlanh Archipelago. Microbiological Ecology. 34:58-65. Long, Z.D., Xu, J.H., Zhao, L.L., Pan, J., Yang, S. and Hua, L. 2007. Overexpression of Serratia marcescens lipase in Escherichia coli for efficient bioresolution of racemic ketoprofen. J. Mol. Catalysis. B: Enzymatic. 47: 105-110. doi:10.1016/j.molcatb.2007.04.004 Lu, Y., Lu, F., Wang, X., Bie, X., Sun, H., Wuyundalai. and Lu, Z. 2009. Identification of bacteria producing a thermophilic lipase with positional nonspecificity and characterization of the lipase. Annals. Microbio. 59(3): 565-571 López, E., Deive, F. J., Longo, M. A. and Sanromán, M. A. 2010. Strategies for utilisation of food-processing wastes to produce lipases in solid-state cultures of Rhizopus oryzae. Biopro. Biosys. Engin. 33(8):929-935 Lutz, S. 2004. Engineering lipase B from Candida antarctica.Tetrahedron Asymmetry., 15(18): 2743-2748. Ma, Q., Sun, X., Gong, S. and Zhang, J. 2010. Screening and identification of a highly lipolytic bacterial strain from barbecue sites in Hainan and characterization of its lipase. Annals. of Microbio. 60(3): 429-437 Margesin, R., D. 2003.Characterization Labbé, of F.W. Schinner, C. Hydrocarbon-Degrading Greer and Microbial L.G. Whyte, Populations in Contaminated and Pristine Alpine Soils.J. Appl.Environ. Microbiol.69: 3085-3092. Markossian, S., Becker, P. Märkl, H. and Antranikian, G. 2000. Isolation and characterization of lipid-degrading Bacillus thermoleovorans IHI-91 from an icelandic hot spring. Extremophiles. 4(6): 365-371 Matsumiya, Y., Wakita, D., Kimura, A., Sanpa, S. and Kubo, M. 2007. Isolation and Characterization of a Lipid-Degrading Bacterium and Its Application to LipidContaining Wastewater Treatment.J. BIOSC. BIOENG.103(4): 325–330. DOI: 10.1263/jbb.103.325 Mongkolthanaruk, W. And Dharmsthitia, S. 2002. Biodegradation of lipidrichwastewater by a mixed bacterial consortium. Internat.Biodet.&Biodeg.50:101105. Muderwa, J. M. and R. Ratamahenina. 1985. Purification and properties of the lipase from Candida deformansLangeron and Guerra. J. Amer. Oil. Chem. Soc. 62(6) : 10311036. Mukesh, K. DJ., Rejitha, R., Devika, S., Balakumaran, M. D., Rebecca, A. I. M. and Kalaichelvan, P. T. 2012.Production, optimization and purification of lipase from Bacillus sp. MPTK 912 isolated from oil mill effluent. Adv. Appl. Sci. Res. 3(2):930938 Muraoka, W., Nakashima, T., Tabira, Y., Eguchi, H., Imagawa, K., Mastumura, Y., Takeshita, S. and Takemasa, T. .2008. Characterization of Burkholderia sp. Y1 Isolated from Oil Polluted Soil. J. Environ. Biotech.8 (1): 43–47. Nakamura, K. and T. Nasu, 1990. Enzyme Containing Bleaching Composition, Japanese Patent,2: 208-400. Nawani, N., Dosanjh, N.S., Kaur, J. 1998. A novel thermostable lipase from a thermophilic Bacillus sp.: characterization and esterification studies. Biotechnol Lett. 20(10):997-1000. Noureddini, H., X. Gao and R.S. Philkana, 2005. Immobilized Pseudomonas cepacia lipase for biodiesel fuel production from soybean oil.Bioresour Technol., 96: 769-77. Nwobi BE, Ofoegbu O, Adesina OB (2006). Extraction and Qualitative Assessment of African Sweet Orange Seed Oil.Afr. J. Food Agric. Nutr.Dev. 6(2). Pollero, R. J., Gaspar, M. L. and Cabello, M. 2001. Extracellular lipolytic activity in Phoma glomerata. World. J. Microbio. Biotech. 17(8): 805-810 Prasad, M. P. and Manjunath, K. 2011. Comparative study on biodegradation of lipidrich wastewater using lipase producing bacterial species. Ind. J. Biotech.10:121 Rabbani, M., H. MirMohammadSadeghi., M. Ani., K. Goodarzv and Chegini., Z. Etemadifar.and F. Moazen. 2009. Cloning and nucleotide sequence of a lipase gene from a soil isolate. Res. Pharma. Sci. 4(1): 25-32 Rahman, K. S. M., Rahman, T., Lakshmanaperumalsamy, P., Samy, P. and Banat, I. M. 2002. Occurrence of crude oil degrading bacteria in gasoline and diesel stations.J. Microbiol.42: 286-293. Rahman, R. N. Z., Leow, T. C., Salleh. A. B. and Basri, M. 2007. Geobacillus zalihae sp. nov., a thermophilic lipolytic bacterium isolated from palm oil mill effluent in Malaysia. BMC Microbio. 7:77 doi: 10.1186/1471-2180-7-77 Raja, K.S., Vasanthi, N.S., Saravanan, D. and Ramachandran,T. 2012. Use of bacterial lipase for scouring of cotton fabrics.Ind. J. Fibre& Textile Res.37: 299-302 Romano, D., Gandolfi, R., Gualandris, R., Romano, A., Starace, F., Villa, R. and Molinari, F. 2007. Solid state fermentation for the production of lipolytic fungal enzyme. Annals. Microbio. 57(4): 561-564 Schmidt-Dannert, C., Sztajer, H., Stöcklein, W., Menge, U., Schmid, R.D. 1994. Screening, purification and properties of a thermophilic lipase from Bacillus thermocatenulatus. Biochim. Biophys. Acta.1214(1):43-53. Sharma, R., Y. Christi and U.C. Banerjee, 2001. Production, purification, characterization and application of lipases. Biotech Advances,19: 627-662. Sharma, R., Soni, S. K., Vohra, R. M., Gupta, L.K. and Gupta, J.K. 2001. Purification and characterization of a thermostable alkaline lipase from a new thermophilic Bacillus sp. RSJ-1. Process Biochem. 37:1075-1084. Sigurgísladóttir, S., Konráðsdóttir, M., Jónsson, A., Kristjánsson, J.K., Matthiasson, E.1993. Lipase activity of thermophilic bacteria from icelandic hot springs. Biotechnol Lett. 15(4):361-366. Sirisha, E., Rajasekar,N. and M. Lakshmi Narasu.2010. Isolation and Optimization of Lipase Producing Bacteria from Oil Contaminated Soils. Advan.in Bio. Res.4 (5): 249-252 Sugimori, D., Watanabe, M., and Utsue, M. 2013. Isolation and lipid degradation profile of Raoultellaplanticola strain 232-2 capable of efficiently catabolizing edible oils under acidic conditions. Appl.Microbiol. Biotech. 97(2): 871 Sullivan, E. R., Leahy, J.G. and Colwell, R. R. 1999. Cloning and sequence analysis of the lipase and lipase chaperone-encoding genes from Acinetobacter calcoaceticus RAG-1, and redefinition of a proteobacterial lipase family and an analogous lipase chaperone family. Gene. 230(2):277-86. Sztajer, H. and Maliszewska, I. 1989. The effect of culture conditions on lipolytic productivity of Penicillium citrinum. Biotech. Lett. 11(12): 895-898 Teles, F. R. R., Cabral, J. M. S. and Santos, J. A. L. 2001. Enzymatic degreasing of a solid waste from the leather industry by lipases. Biotech. Lett. 23(14): 1159-1163 Thakur, S. 2012. Lipases, its sources, Properties and Applications: A Review. Internat. J. Scien. & Engin.Res. 3(7):1-15 Vargas, G.D.L.P., H. Treichel, D. Oliveira, S.C. Beneti, D.M.G. Freire, M. Di Luccio. 2008. Optimization of lipase production by Penicilliumsimplicissimum in soybean meal. J. Chem. Tech. Biotech. 83: 47–54 Vishnupriya, B., C. Sundaramoorthi, M. Kalaivani, K., Selvam. 2010. Production of lipase from Streptomyces griseus and evaluation of bioparameters. Internat. J. ChemTech. Res.2(3):1380-1383. Wang, CH., Guo, R.F., Yu,H.W. and Jia, Y.M. 2008. Cloning and sequence analysis of a novel cold-adapted lipase gene from strain lip35 (Pseudomonas sp.). Agr. Sci. China.7: 1216–1221. Wang, Y., Srivastava, K.C., Shen, G.J., Wang, H.Y. 1995. Thermostable alkaline lipase from a newly isolated thermophilic Bacillus, strain A30-1 (ATCC 53841). J. Ferment. Bioeng. 79(5):433-438. WU, Lan., GE, Gang., WAN, Jinbao. 2009. Biodegradation of oil wastewater by free and immobilized YarrowialipolyticaW29. J. Environ. Sci.21:237–242 Yang, X., B. Wang, F. Cui, T. Tan. 2005. Production of lipase by repeated batch fermentation with immobilized Rhizopusarrhizus. Process Biochem. 40: 2095–2103 Yao, H., Yu, S., Zhang, L., Zuo, K., Ling, H., Zhang, F. and Tang, K. 2008. Isolation of a novel lipase gene from Serratia liquefaciensS33 DB-1, functional expression in Pichiapastoris and its properties. Mol. Biotech. 38: 99-107. doi:10.1007/s12033007-9007-6 Tables: Table 1. Sources and lipolytic activities of bacterial strains Source of Bacteria Bacterial Strain Sources of Carbon Bacillus stearothermophilus SB-1 Neem oil Bradoo et al. (1999) Bacillus licheniformis SB-3 Neem oil Bradoo et al.(1999) Icelandic hot spring Bacillus thermoleovorans IHI-91 Olive oil (triolein) Palm oil mill effluent Geobacillus zalihae T1T Olive oil Oil polluted soil Burkholderia sp. Y1 1% AlcaligenespiechaudiiSRS Salad oil Degree of degradation 93% Reference Markossian et al. (2000) Rahman et al. (2007) 83.1% Muraoka et al.(2008) Crude oil 80% Płaza et al. (2008) RalstoniapickettiSRS Crude oil 80% Płaza et al. (2008) Oil contaminated soil Enterobacteraerogenes E13 0.5% of sunflower oil Soil Burkholderia cepacia. S31 Oil contaminated soil Staphylococussps 1% olive oil Barbeque oilcontaminated soil Burkholderia cepacia Peanut oil 10.5 U mL−1 Ma et al. (2010) Slaughter house S. aureus Slaughter house 320 mg/L Prasad and Manjunath, (2011) Olive oil Čipinytė, (2009) 226.1 u/ml Lu et al. (2009) Sirishaet al. (2010) wastewater wastewater Food wastewater Bacillus sp N-09 Noodles soup+LAS 73.5% Hidayat, (2011) Palm oil effluent P. aeruginosa Palm oil effluent 325 mg/L Prasad and Manjunath, (2011) Dairy effluent S. marsescens Dairy effluent 280 Prasad and Manjunath, (2011) Oil processing plant Pseudomnasaeruginosa KM110 2 % Olive oil Kasra-Kermanshahi et al. (2011) Oil mill effluent Bacillus sp . Oil mill effluent Mukesh et al . (2012) Oil mill waste Bacillus tequilensisNRRL B- Oil mill waste 41771 Kalyana et al . (2013) Soil samples Pseudomonas fluorescens KE38 Adan and Arskanoglu, 2013 1% olive oil mg/L Table 2: Characteristics of Lipid degrading Fungi: Fungal species Medium Optimal Conditions Reference Penicillium citrinum 5% peptone, 2% starch and 22°C and pH 7.2 Sztajer and Maliszewska, (1989) Rapeseed oil Rhizopus delemar - 30°C and pH 8-8.5 Haas et al. (1992) Ophiostoma piceae Plant oils (Olive oil) 37°C and pH 5.5 Gao and Breuil, (1995) 30°C and pH 9 Hoshino et al. (1997) 40–50 °C and 1 h Pollero et al. (2001) 30°C and pH 5 Bancerz et al. (2005) Typhula ishikariensis group III, p-nitrophenyl palmitate strain 6-1-1 Phoma glomerata Triacylglycerol, Phosphoglyceride and Cholesterol ester Penicillium chrysogenum 9’ Natural oils Colletotrichum gloesporioides Natural oils Aspergillus oryzae Rice hulls,Tween 80 and - Colen et al. (2006) Romano et al. (2007) olive oil Paecilomyces nostocoides Monoacylglycerols Huang et al. (2009) NTU-FC-LP01 Penicillium simplicissimum Castor bean seeds waste 45°C and pH 6.5 Godoy et al. (2011) Table 3. Optimized conditions for some lipolytic bacterial strains: Strain Optimized Conditions Temperature pH References Bacillus stearothermophilus SB-1 50 °C 3 Bradoo et al., 1999 Bacillus licheniformis SB-3 50 °C 3 Bradoo et al., 1999 Bacillus thermoleovorans IHI-91 65°C 6 Markossian et al., 2000 Geobacillus zalihae T1T 70°C - Rahman et al. (2007) Burkholderia cepacia. S31 70 °C 9 Lu et al. (2009) Staphylococussps 36°C 7 Sirishaet al., 2010 Burkholderia cepacia 37°C 8 Ma et al. (2010) Pseudomnasaeruginosa KM110 45°C 7-10 Bacillus sp N-09 30°C 6 Hidayat, 2011 Bacillus sp . 35°C 8 Mukesh et al ., 2012 Bacillus tequilensisNRRL B-41771 34°C 7 Kalyana et al ., 2013 Pseudomonas fluorescens KE38 45 °C 8 Adan and Arskanoglu, 2013 Kasra-Kermanshahi et al., 2011 Table 5. Applications of lipid degrading fungi and bacteria Industry Chemical (waste) Leather industry Lipidic Fungal or bacterial strains used Saccharomyces cerevisiae Degree of degradation Reference 2749 U mg−1 Teles et al. (2001) concentrate of sheep fleshing Food-processing Rhizopus oryzae Petrobras Research Center Toxic and alkaline using castor bean seeds waste Leather, detergent and Penicillium simplicissimum P. aeruginosa KM110 chemical industries Oil mill wastewater López et al. (2010) 155.0 U/g after 96 h Godoy et al. (2011) Kasra-Kermanshahi et al. (2011) Fatty acids and Yarrowia lipolytica Fickers and Nicaud, 2013 Yarrowia lipolytica Fickers and Nicaud, 2013 triglycerides Food industry Grease Figures: Fig. 1. Hydrolytic and Synthetic Actions of Lipase (Source: Jaeger and Reetz 1998)