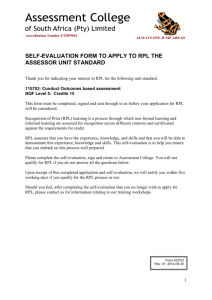

RPL Assessor Kit

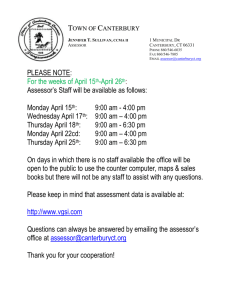

advertisement