Identification

advertisement

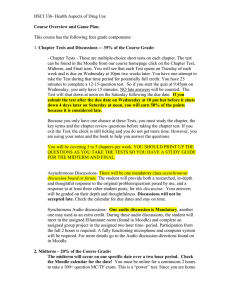

SYLLABUS Economics and Management Department Undergraduate Program MGT 440 – Production Operations Management – 3KU credits (6 ECTS credits) Subject Spring, 2015 Term Antony Jose - tony73@gmail.com Instructor 122 Bashir Safaroglu str. (Downtown campus) THU 18:30-21:00 room 13 Classroom/hours MGT 310 Management and Organization Prerequisites English Language Compulsory/Elective Compulsory Textbook: Jay Heizer, Barry Render [1] Text books and course materials Principles of Operations Management, 8th edition, 2011 ISBN-10 : 0136114466 ISBN-13 : 9780136114468 Identification Supplementary materials: Book handouts cases This course is carrying out by using Blended learning methods that combine traditional face-to-face classes with online learning. The course management platform Moodle is used to provide a wide range of resources to support learning. And all course related materials including, but not limited to, syllabus, supplementary readings, course announcements, cases and assignments are available only at the course website http://www.khazar.org/moodle. Grades will also be posted on Moodle. The students are expected to check it in a regular basis and communicate with the lecturer only via Moodle. x Teaching methods Case analysis x Group discussion x Experiential exercise x Lecture Course paper Others Evaluation Criteria Methods Date/deadlines Percentage (%) 25 Midterm Exam 10 Class Participation 10 Activity 20 Home-assignment 35 Final Exam 100 Total To understand potential issues managers must foresee and address when designing and managing Course objectives operating systems that are aimed at maximizing effectiveness and efficiency while satisfying customers needs. Course website Course outline Course objective is to provide students with concepts, techniques and tools to design, analyze and improve operational capabilities of an organization. In this course, student will learn the fundamentals of operations management as they apply to both production and service-based operations. Successful completion of this course will empower the student to implement the concepts he or she have learned in their place of business. Even if the student does not plan to work in operations, every department of every company has processes that must be completed; someone savvy with operations management will be able to improve just about any process. Learning Outcomes Upon successful completion of this course, students will be able to: - Explain the role of operations and its relationship with the other functional areas of a business organization; - Analyze operation processes from a variety of perspectives such as productivity, workflow, and quality; -- Apply the “Transformation Model” as a construct for understanding the relationship between the inputs, processes, and outputs of an organization; Explain techniques and methodologies for managing an organization’s productive resources; - Apply basic design principles to determine appropriate facility location and layout; - Explain quality management and apply quality management principles to continuous improvement in operations management; - Discuss the goal of Supply Chain Management and its application in a variety of organizational settings; - Identify the critical factors involved in inventory control systems; and - Identify the operational processes in the student’s own organization. Week 1 2 Date (tentative) January 29, 2015 Topics Textbook/Assignments Introduction and Production Operation Management February 05, 2015 The global Environment and Operations strategy / Managing Projects Chapters 2 & 3 3 February 12, 2015 Forecasting Demand /Product design Chapters 4 & 5 4 February 19, 2015 Quality Management and International Standards/ Statistical Process Control Chapter 6 5 February 26, 2015 Process Design/Capacity Planning Chapter 7 6 March 05, 2015 Location Strategies Chapter 8 7 March 12, 2015 Layout Strategies ; 8 March 19, 2015 Midterm 9 March 26, 2015 Novruz Holidays 10 April 02, 2015 Supply chain Management / Outsourcing as a Supply chain strategy 11 April 09, 2015 12 April 16, 2015 Aggregate Scheduling, Material Requirements Planning Chapter 13 13 April 23, 2015 ERP Chapter 14 14 April 30, 2015 Short Term Scheduling Chapter 15 15 May 07, 2015 JIT, Lean operations and the Toyota Production System; Maintenance and Reliability 16 TBD Final Job Design and Work Measurement Inventory Management Chapter 1 Chapters 9 &10 Chapter 11 Chapter 12 Chapters 16 & 17