Hlinsko [CR] > Praha přes Pardubice

advertisement

![Hlinsko [CR] > Praha přes Pardubice](http://s3.studylib.net/store/data/008946157_1-1c034385b612dae591a6c90cf1135c97-768x994.png)

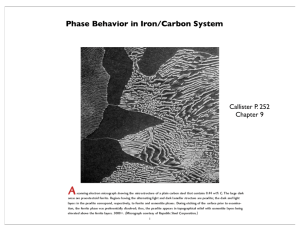

MATERIALS SCIENCE II. Nonmetallic Materials 1. Elements creating polymer molecules, electronegativity . 2. Scheme of addition and condensation polymerization reactions (an example). 3. Description of interatomic and intermolecular bonding in polymers (primary and secondary bonds), polarity. 4. Repeating structural unit for the PE, PP, PVC, PS, PTFE, POM, PPS, SI, PA6, PC. 5. Characterization of molecular size (length) in polymers. 6. Principles of thermoplastic and thermosetting polymers. 7. Polymer crystallinity, ability of polymers to crystallize. 8. Supermolecular structure of polymers. 9. Glass transition and melting of polymers. Dependance of specific volume and modulus of elasticity on temperature. 10. Viscoelasticity, explanation with the help of creep reological model. 11. Tensile properties of polymers. 12. Classification of composites. 13. Fibre reinforced composites. Types of reinforcing fibres, comparison of their properties. 14. Influence of fibre length, orientation and volume fraction on mechanical properties of composites. 15. Description of coordination geometry of cations and anions in ceramics. 16. Sintering of ceramic powders. Porosity and its influence on mechanical properties. 17. Brittlenes of ceramics and its explanation. 18. Basic types of structural ceramics and their properties. 19. Polymorphic forms of carbon and their properties. 20. Comparison of metals, polymers and ceramics (principal differences in structure, physical and mechanical properties). Metallic Materials Draw isomorphous phase diagram (e.g. Cu-Ni). Describe solidification and development of structure. Apply the lever rule. Draw the binary eutectic phase diagram and explain development of structure during cooling. Three phase reactions in phase diagrams-define eutectic, peritectic, eutectoid reactions. Draw schematically equilibrium diagram having intermediate phases. Demonstrate allotropy of pure iron during heating from room temperature to melting. Iron - carbon system - define ferrite, austenite, cementite, graphite. Draw and explain iron-iron carbide phase diagram. Apply Gibbs phase rule and lever rule. Classify the iron -carbon alloys by phase diagram (iron, steel, cast iron). Phase transformation in metals - classification, mechanism, kinetics (Avrami equation). Describe pearlite reaction in steel. Give main characteristics of martensite transformation. Bainite transformation in steel - mechanism, structure of lower and upper bainite. Draw T-T-T diagram for eutectoid (hypereutectoid, hypoeutectoid) iron carbon steel. Superimpose a critical cooling rate for martensite. Draw C-C-T diagram for 0,3 %C (0,8 %,1 %) steel. Superimpose critical cooling curve for quenching. Describe differences between isothermal and continuous cooling on construction of transformation diagram. Describe four stages of tempering of martensite. Explain purpose annealing in steels-stress relief, recrystallization, diffusion annealing, normalising, spheroiding. Hardening of steels-hardening temperature, hardening capacity. Hardenability - Jominy test, hardening curve. Hardening methods - demonstrate in T-T-T and C-C-T diagrams. Briefly explain formation of quench cracks during quenching. Surface hardening of steels - purpose, main methods. Surface treatment - cite treatments in which a hard structure is produced at the surface and briefly clarify principle. Thermomechanical treatment of steels-two basic methods, demonstrate in C-C-T diagram. Chemical heat treatment of steels - principal purpose, conditions of carburising and nitriding. Precipitation hardening -give conditions that must be satisfied for age-hardening response during heat treatment. Draw hypothetical phase diagram for precipitation hardenable alloy. Briefly explain three steps in the age-hardening treatment. Basic classification of ferrous alloys (steel, cast iron). Depict schematically microstructure of plain carbon steel with 0.4%C in normalising state. What is the function of alloys-elements in tool steel. Give the typical composition and typical heat treatment of high-speed steels. Draw the iron - chromium phase diagram and classify stainless steels according to this diagram. Explain chief differences between white and gray cast iron. Briefly describe malleablising process to obtain ferritic malleable iron. Illustrate in diagram temperature vs. time.