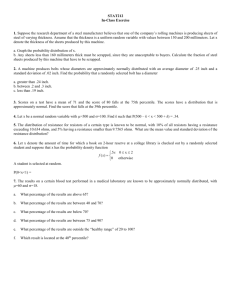

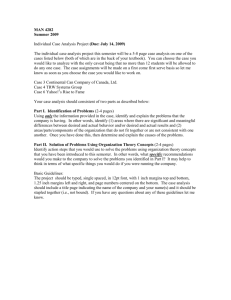

Division 15 – Mechanical

advertisement