Fire Protection Engineering Standards

advertisement

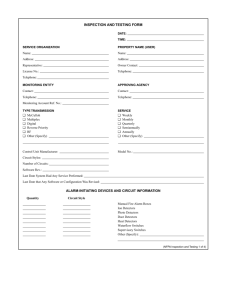

CHRYSLER LLC Chrysler Security Services Fire Protection Engineering Standards Standard 104 Fire Protection Equipment Maintenance Issued: 2/1/89 Revised: 12/99 Revised 3/01 Revised 12/01 6/11/2003 02/06 09/07 Table of Contents 1.0 Introduction 1.1 Purpose 1.2 User 1.3 Authorization 2.0 Definitions 2.1 General 3.0 References 3.1 General 3.2 National Fire Protection Association Standards and Factory Mutual Data Sheets 3.3 National Fire Protection Association 3.4 Fire Protection Handbook 3.5 Underwriters Laboratories 3.6 Factory Mutual Global 3.7 Industrial Risk Insurers 3.8 Canadian Standards/Codes 3.9 Building Codes 3.10 Occupational Safety & Health Administration 3.11 Chrysler LLC Corporate Fire Protection Standards 4.0 General 4.1 Introduction 4.2 Authority 4.3 Equipment Maintenance 4.4 Approvals 5.0 Water Supply 5.1 General 5.2 Isolation Valves 5.3 Hydrants 5.4 Flushing of Underground Connections 5.5 Water Storage Facilities 5.6 Centrifugal Fire Pumps 5.6.1 General 5.6.1.1 Summary of Fire Pump Testing and Maintenance 5.6.1.2 Summary of Water Storage Tank Testing and Maintenance 5.6.2 Measurements 5.6.3 Annual Flow Test Procedures Standard 104 2 5.6.4 Power Supply 5.6.4.1 Over-current Protection 5.6.4.1.1 Fire Pump Controller 5.6.4.1.2 Fire Pump Feeder Circuit 5.6.5 Motor and Diesel Engine 5.6.5.1 Electric Motor 5.6.5.2 Diesel Engine 5.6.6 Accessories 5.6.7 Control Panel Functions 5.6.8 Suction 5.6.9 Jockey (Pressure Maintenance) Pump 5.6.10 Additional Criteria 6.0 Sprinkler Systems 6.1 General 6.2 Flushing 6.3 System Waterflow Tests 6.4 Sprinklers and Piping 6.5 Dry Pipe Sprinkler Systems 6.6 Pre-action/Deluge Sprinkler Systems 7.0 High-Speed Water Spray (Deluge) Systems 7.1 General 7.2 Flushing 7.3 Fire Detection Systems 7.4 System Waterflow Tests 7.5 Water Spray Nozzles and Piping 7.6 Protected Areas 7.7 Propriety Products 7.7.1 Material Legend for Cla-Valves 8.0 Foam Water Sprinkler Systems (AFFF) 8.1 General 8.2 Flushing 8.3 System Waterflow Tests 8.4 Sprinklers and Piping 9.0 Fixed and Gaseous Agent Fire Systems 9.1 General 9.1.1 Additional Equipment 9.1.2 Protected Areas 9.2 Gaseous Agent Standard 104 3 9.2.1 General 9.2.2 Inspection 9.2.3 System Operations 9.3 Carbon Dioxide 9.3.1 General 9.3.2 Inspection 9.3.3 System Operations 9.3.4 High Pressure Storage 9.3.5 Low Pressure Storage 9.3.6 Extended Discharge 9.3.7 Hand Held Hose Lines 9.4 Wet/Dry Chemical Systems 9.4.1 General 9.4.2 Functional Tests 9.4.3 Manual Release 10.0 Detection Systems 10.1 General 10.2 Fire Alarm Control Panel 10.3 Detectors 10.3.1 Smoke Detectors 10.3.2 Heat Detectors 10.3.3 UV or UV/IR or IR/IR Flame Detection Systems 10.3.4 Beam Smoke Detection Systems 10.4 Initiating Devices 10.4.1 Manual Pull Stations 10.4.2 Alarm Signaling Appliances 10.4.3 Voice Alarm Systems 10.4.4 Power Supply 10.4.5 Electrically Supervised Circuits 10.4.6 Auxiliary Equipment 11.0 Fire Doors 11.1 General 12.0 Standpipe and Hose Systems 12.1 General 12.2 Classifications 13.0 Test Intervals 13.1 General Standard 104 4 1.0 1.1 Introduction Purpose The purpose of this standard is to provide guidelines for the maintenance on Fire Protection Systems. The Chrysler LLC Book of Knowledge (BOK) Standard Operating Practices’ shall be followed. The purpose of this standard shall not take the place of, but shall be in addition to federal, state, province or local fire safety requirements. The Authority Having Jurisdiction (AHJ) shall also be consulted. This Standard shall not be construed as detailed design criteria for the installation of new fire protection equipment or modification of existing fire protection systems, nor shall these standards be used in place of equipment manufacturers’ specifications or test procedures. They are general guidelines, which can be used by qualified Chrysler LLC authorized personnel to assist in conducting maintenance of fire protection systems/equipment. In no case shall unqualified persons attempt to use these guidelines in lieu of proper training. 1.2 User This Standard has been developed for use by the Corporate, GRC, and Wackenhut Site Security Manager’s in the performance of work associated with maintenance on fire protection systems. Local management shall be responsible to assure that equipment maintenance tests are performed in accordance with these guidelines, and that records accurately monitoring the tests are filed. Records will be susceptible to Chrysler LLC or GRC audit or inspection. Also, system tests and record keeping are subject to requirements of the federal law, the Federal Registry, Title 29 OSHA, Part 1910, Subpart L, Sections 1910.155-163 (Industrial Safety for General Industry) requirements. The applicable forms found in the Chrysler LLC BOK CFS No. 104 section shall be utilized for maintenance 1.3 Authorization This Standard is issued from Chrysler Security Services. Only personnel from Corporate shall revise this Standard. Suggestions shall be submitted to this department for review and possible action. Standard 104 5 2.0 2.1 Definitions General For the purpose of this standard, terminology is applied with definitions as follows: Approved: Acceptable to the “Authority Having Jurisdiction (AHJ)”. Audible Alarm: A fire alarm device which produces a distinctive audible signal and is effectively heard above the ambient noise level per NFPA No. 72, “Proprietary Protective Signaling Systems”. Authority Having Jurisdiction (AHJ): The organization, office or individual responsible for “approving” equipment, an installation, or a procedure to meet statutory requirements. For insurance underwriting purposes only, the insurance carrier representative may be the AHJ. Bypass Switch: A control switch that electrically bypasses normal actuating components and allows the system to function (in by-pass mode) for testing or maintenance. Contractor: The party/persons contracted (including Plant Maintenance) for the design and installation of fire protection systems. Corporate: Chrysler LLC Corporate Security and Fire Prevention Department and its’ members. Control Cabinet/Unit: The cabinets that contain detection control units, system release panels and standby batteries for special systems. Cross-Tie: Connection between two adjacent sprinkler systems that adds reliability to a sprinkler system by providing a second water supply (source) in the event of primary water supply shutdown. Cross-Tie valves are usually 2.5-inch normally closed valves. Valves shall not be locked or monitored. “Deluge” Sprinkler System: A system employing automatic sprinklers with open orifices attached to a piping system with a supplemental detection system installed in the same area as the sprinklers. Actuation of the detection system opens a valve that permits water to flow into the piping system and out the open sprinklers. “Dry” Pipe Sprinkler System: A system employing automatic sprinklers attached to a piping system containing either pressurized air or nitrogen, the release of which permits the water pressure below the valve to open the dry pipe valve, allowing water to flow into the piping system and out of the fused (open) sprinklers. This system is commonly used for below freezing temperature environments. Grid piping arrangements shall not be permitted for dry pipe system. GRC - Global Risk Consulting. High Speed Water Spray (Deluge) System: A suppression system for the high explosion hazard areas designed to rapidly detect fire (by infrared detectors) and subsequently provide water to the protected area through special nozzles. Infrared Detection (IR): A device that is responsive to radiant energy outside the range of human vision (above 7700 Angstroms) to sense the presence of flame as manufactured by a licensed and qualified fire detection contractor. Manual Pull Station: A wall mounted device that enables a suppression and/or alarm system to be manually activated. Operating Facility: A plant building or site where materials are handled, manufactured, or stored. Pilot Line: The hydraulic line that initiates the functions of the High Speed Water Spray Systems. Standard 104 6 “Pre-Action” Sprinkler System: A system employing automatic sprinklers attached to a piping system containing air (pressurized or not) with a supplemental fire detection system installed in the same area as the sprinklers. Actuation of the detection system opens a valve that permits water to flow into the piping and out any fused (open) sprinklers. Proprietary Protection Signaling System: A signaling system that serves properties (all buildings at a site) under-one-ownership from a central “on site” constantly attended supervising station. Special System: A Fire Protection System designed to protect special hazard areas i.e. Carbon Dioxide, Ecaro, HFC-227ea (FM200), AFFF, Water Spray, and Water Mist. Standard shall mean this Corporate Security and Fire Prevention Standard. Temperature Rating: Pre-determined melting point (temperature) at which the fusible link (metal alloy) of the sprinkler head fuses (operates). Also, predetermined temperature at which the glass bulb breaks causing Glass Bulb sprinkler head to operate. Ultraviolet Detection (UV): A device that is responsive to radiant energy outside the range of human vision (below 4,000 Angstroms) to sense the presence of flame as manufactured by a licensed and qualified fire detection contractor. Ultraviolet/Infrared Detection (UV/IR): A device that uses the ultraviolet and infrared detection principles to sense the presence of flame (both UV and IR sensors must be activated to release the suppression agent) as manufactured by a licensed and qualified detection contractor. Wackenhut Site Security Manager: The plant Security Manager Water Hammer: The effect of pressure rise (pipe rupture) that may accompany a sudden change in the velocity of the water flowing in a pipe. “Wet” Pipe Sprinkler System: A system employing automatic sprinklers attached to a piping system containing water and connected to a water supply so that water discharges immediately from any fused (open) sprinklers. Standard 104 7 3.0 3.1 References General The following references provide fire protection standards and code requirements that shall be used in conjunction with the established guidelines of this standard and GRC. These codes shall be applied where they have been adopted as law by a particular state government or authority and where they supersede listed references. 3.2 National Fire Protection Association (NFPA) Standards and Factory Mutual (FM) Data Sheets. (Latest editions shall be followed) NFPA 10 & FM 4-5 Portable Fire Extinguishers NFPA 12 & FM 4-11N Installation of Carbon Dioxide Fire Protection Systems NFPA 2001 Clean Agent Fire Extinguishing Systems including HFC-227ea (FM200), Ecaro Fire Protection Systems NFPA 13 & Installation of Sprinkler Systems FM 2-8N & 8-9 (includes protection of various storage arrangements) NFPA 13A & DS 2-81 Inspection, Testing, and Maintenance of Sprinkler Systems NFPA 14 Installation of Standpipe & Hose Systems NFPA 15 & FM 4-1N Water Spray Fixed Systems for Fire Protection NFPA 16A & DS 4-7N Installation of Closed Head Foam Water Sprinkler Systems NFPA 17 & FM 4-10 Dry Chemical Extinguishing Systems NFPA 17A Wet Chemical Extinguishing Systems NFPA 20 & FM 3-7N Installation of Centrifugal Fire Pumps NFPA 22 & DS 3-2 Water Tanks for Private Fire Protection NFPA 24 & FM 3-10 Installation of private Fire Service Mains & their Appurtenances NFPA 26 Supervision of Valves Controlling Water Supplies NFPA 30 Flammable & Combustible Liquids Code NFPA 70 National Electric Code NFPA 72 & Fire Detection and Alarm Systems Standard 104 8 FM 5-2 & 5- 5 3.3 NFPA 80 Standard for Fire Doors & Windows NFPA 750 Water Mist Fire Protection Systems National Fire Protection Association (NFPA) Fire Protection Systems - Inspection, Test and Maintenance Manual (NFPA) Industrial Fire Hazards Handbook - NFPA 3.4 Fire Protection Handbook (NFPA) 3.5 Underwriters Laboratories (U.L.), Inc. Fire Protection Equipment List 3.6 Factory Mutual Global Approval Guides Data Sheets 3.7 Industrial Risk Insurers (known as GE Solutions) Interpretive Guides 3.8 Canadian Standards/Codes Canadian Standards/Codes associated with items covered in this Standard shall be adhered to by Canadian operations where they supersede the references listed above. 3.9 Building Codes BOCA Basic/National Building Code Uniform Building Code (UBC) Southern Building Code (SBC) International Fire Code International Building Code These codes shall be applied where they have been adopted as law by a particular state government or authority and where they supersede the reference above. 3.10 Occupational Safety & Health Administration Federal Registry, Title 29, Part 1910, Subpart L. 3.11 Chrysler LLC Corporate Fire Protection Standards 101 – Paint Spray Operations 102 – Material Storage 103 – Fire Protection Acceptance Test Standards 105 – Fire Protection New Construction Standards Standard 104 9 4.0 4.1 General Introduction This Standard is intended to provide guidelines for Equipment Maintenance of fire protection systems. This Standard provides guidance on required equipment maintenance and frequency of fire protection systems. Equipment Maintenance inspection forms are provided in the Fire BOK under section CFS 104 and shall be used or referenced when conducting or observing Equipment Maintenance procedures. Forms showing satisfactory test results (provided by the installing contractor) and record drawings shall be obtained as a reference for each test that is conducted by the plant (on-site) fire prevention department. 4.2 Authority Equipment Maintenance shall be performed on all installed equipment/systems in accordance with this Standard. Contractors shall be authorized by system manufacturers and shall be trained to perform maintenance of the fire protection systems. Maintenance of all fire protection systems shall be performed in accordance with applicable standards and Authority Having Jurisdiction (AHJ) requirements. Equipment Maintenance shall be coordinated with the following: - 4.3 Corporate Wackenhut Site Security Manager GRC Authority Having Jurisdiction Equipment Maintenance Wackenhut site Security Manager shall be responsible for the scheduling, witnessing, follow-up and maintaining the written results 4.4 Approvals The Wackenhut Site Security Manager shall maintain a PDCA (database) of the maintenance items that need follow-up. Standard 104 10 5.0 5.1 Water Supply General Equipment maintenance shall be performed for all water supply system components. Satisfactory test results shall be recorded by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. 5.2 Isolation Valves Isolation valves shall be inspected to verify that they are in the operating position. Valves shall also be inspected for water leakage. Valves shall be operated and lubricated annually. 5.3 Hydrants Hydrants shall be inspected to verify that they are in operating mode. They shall be inspected to verify that they drain properly and do not leak on a semi-annual basis. Hydrants shall be operated and lubricated. Operation of hydrants is appropriately implemented during flushing operations of underground piping. Hydrants shall be restored to operating condition upon completion of hydrant flushing operations. Hydrants (where applicable) shall be winterized by draining. Hydrant water flow tests shall be conducted to verify that an adequate water supply is available for a designated water demand (sprinkler system). This test involves only the two hydrants closest to the water demand (sprinkler system tie-in). These tests are done at most facilities by GRC on an annual basis. 5.4 Flushing of Underground Connections All underground supply mains and lead-in connections shall be flushed to remove foreign materials before connection is made to sprinkler piping. Flushing shall continue until the water flows clear. Care shall be exercised during the flushing operation to assure that water flow will adequately drain without producing damage to surroundings. Flow rates, in accordance with the latest edition of NFPA No. 13, Table10.10.2.1.3 shall be used. They are as follows: Flow Rate required to produce a Velocity of 10-fps (3 m/s) in pipes Pipe Size (in inches) Pipe Size (mm) Gallons/Minute 5.5 Liters/Minute 4 102 390 1476 6 152 880 3331 8 203 1560 5905 10 254 2440 9235 12 305 3520 13323 Water Storage Facilities Flow tests shall be conducted for water storage systems to verify that the tank and joints are not rusted and that the material and equipment are operating properly. Valves shall be inspected to verify that they are in the operating position. For elevated gravity fed and pressure tanks, this test consists of opening a two-inch main drain at the storage tank or at any sprinkler system that, in turn, causes operation of the Standard 104 11 water supply and the pumping system. Valves between the water supply and the distribution system shall be inspected to verify that they are fully open. For ground gravity fed and underground storage tanks, the flow test is conducted in conjunction with fire pump flow tests. Water level of storage tanks shall be observed and filled, if required. Tank overflow shall be conducted annually. Heating systems shall be tested to verify that they are in operating condition. 5.6 Centrifugal Fire Pumps (contractor conducted) 5.6.1 General Equipment maintenance shall be performed for all fire pump installations. The purpose of the fire pump maintenance is to: - Determine that the fire pump will perform in accordance with or in excess of the manufacturer’s certified characteristic curve. Verify that the fire pump will operate properly when needed. Determine that the supplemental features are operable as follows: a. Power supply (electricity, fuel) b. Controllers c. Drivers (motors, engines) Accessories (relief valves, priming sources, flexible coupling, alarms, interlocks, ect. d. Suction supplies and strainers e. Fire pump house (construction, heat, lighting, access, ventilation, sprinkler protection, etc.) Manufacturer’s procedure manuals and NFPA No. 20 shall be reviewed prior to each test. The fire pump manufacturer’s representative in conjunction with the installing contractor is responsible for conducting equipment maintenance tests and to demonstrate that the installation is satisfactory. Insurance carrier representatives shall be available for all fire pump flow tests. Fire pump results shall be compared step-by-step with the certified fire pump curve during the test and discrepancies noted. Owner representatives shall be informally advised of the fire pump test results when the test is performed. 5.6.1.1 Summary of Fire Pump Testing and Maintenance ITEM Pump System Lubricate pump bearings Check pump shaft end play Check accuracy of pressure gauges and sensors Check pump coupling alignment Mechanical Transmission Lubricate coupling Lubricate right-angle gear drive Electrical System Exercise isolating switch and circuit breaker Trip circuit breaker (if mechanism provided) Operate manual starting means (electrical) Inspect and operate emergency manual starting means (without power) Tighten electrical connections as necessary Lubricate mechanical moving parts (excluding starters and relays) Standard 104 ACTIVITY FREQUENCY Change Check Check Check Annually Semiannually Semiannually Semiannually Change Change Annually Annually Test Test Test Semiannually Annually Semiannually Visual Inspection Test Check Annually Annually Check Annually 12 Calibrate pressure switch settings Grease motor bearings Diesel Engine System Fuel Tank Level Tank float switch Solenoids valve operation Strainer, filter, or dirt leg, or combination thereof Water and foreign material in tank Water in system Flexible hoses and connectors Tank vents and overflow piping unobstructed Piping Lubrication System Oil level Oil change Oil filter(s) Lube oil heater Crankcase breather Cooling System Level Antifreeze protection level Antifreeze Adequate cooling water to heat exchanger Rod out heat exchanger Water pump(s) Condition of flexible hoses and connections Jacket water heater Inspect duct work, clean louvers (combustion air) Water Strainer Exhaust System Leakage Drain condensate trap Insulation and fire hazards Excessive back pressure Exhaust system hangers and supports Flexible exhaust section Battery System Remove corrosion, case exterior clean and cry Specific gravity or state of charge Charger and charge rate Equalize charge Electrical System General Inspection Tighten control and power wiring connections Wire chafing where subject to movement Operation of safeties and alarms Boxes, panels and cabinets Circuit breakers or fuses Circuit breakers or fuses Check Change Annually Annually Check gauge operation Visual Inspection Test Visual Inspection Test Clean Clean Check/Clean Visual Inspection Check/Test Visual Inspection Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Visual Inspection/Check Change Change Check Visual Inspection/Change/Test Semiannually Semiannually Semiannually Semiannually Semiannually Visual Inspection/Check Test Change Check Clean Visual Inspection Visual Inspection/Check Check Visual Inspection/Check/Change Clean Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Visual Inspection/Check Check Visual Inspection Test Visual Inspection Visual Inspection Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Visual Inspection/Change Test Visual Inspection Check Semiannually Semiannually Semiannually Semiannually Visual Inspection Check Visual Inspection/Check Check/Test Clean Visual Inspection/Check Clean Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually 5.6.1.2 Summary of Water Storage Tank Testing and Maintenance ITEM Water Storage Tank Condition of water in tank Water temperature Heating system Control valves Water - level Air pressure Standard 104 ACTIVITY FREQUENCY Check Check Check Check Check Check Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually 13 Tank - exterior Check valves Temperature alarms High-temperature limit switches Water level alarms Level indicators Pressure gauges Thermostats Cathodic protection 5.6.2 Check Check Check Check Check Check Check Check Check Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Semiannually Measurements Fire pump speed shall be measured with an accurate speed indicator. Direct reading digital tachometers or stroboscopic speed indicators can be used to record fire pump speed. If a contact-type speed indicator is used, a plug or cap is removed from the end of the fire pump casing so that the speed indicator can contact the end of the fire pump shaft. Any oil or grease on the end of the shaft shall be removed before the speed device is inserted. When using a revolution-counter (for fire pumps 2,500 RPM and over) take a reading for two minutes and divide by two to determine the oneminute measurement. This minimizes starting and stopping timing errors. Calibrated pressure gauges shall be used during the test and shall be checked against the gauges that are installed on the fire pump. Test headers are provided for fire pump tests. A separate 2½-inch outlet is required for every 250 GPM rating of the fire pump. Lengths of 2½-inch hose with straight bore nozzles (Underwriters’ Play Pipes) are attached and firmly supported. It may be feasible to attach the straight bore nozzle directly to each outlet of the test header if water damage can be prevented. Water is flowed through nozzles and measured by use of a Pitot gauge. Pitot pressure, size of outlet, outlet coefficient, fire pump intake pressure, fire pump outlet pressure and fire pump speed shall be tested and recorded. These tests are repeated and recorded for each of the flows. Results of the tests are plotted on a special graph commonly known as N 1.85 paper and compared with the manufacturer’s fire pump test curve and the requirements of NFPA No. 20, “Standard for the Installation of Centrifugal Fire Pumps.” 5.6.3 Annual Flow Test Procedures Flow tests shall be conducted from the fire pump test header with the discharge valve to the site underground fire main piping being closed. This arrangement will prevent unwanted conditions such as blowing-out of pipe in the site underground fire main. Impairment procedures shall be followed in accordance with insurance company policy. It is critical that the alignment of the flexible coupling between the fire pump and the driver be checked annually. Discharge and suction pressure for a horizontal fire pump shall be read at gauges located at the centerline of the fire pump on the casing. Vertical turbine fire pump discharge pressure is recorded from a gauge located at the discharge head fitting. 5.6.4 Power Supply 5.6.4.1 Over-current Protection Standard 104 14 5.6.4.1.1 Fire Pump Controller The circuit breaker shall be inspected to verify that the breaker meets the following specifications: - The continuous current rating shall be at least 115 percent of the fire pump motor’s rated fullload current as shown on the nameplate of the over-current device. The interrupting capacity shall be equal to or greater than the maximum fault-current possible at the location of the breaker, as determined by the manufacturer. The instantaneous trip setting shall be at least 12 times the full-load current rating of the fire pump motor. This setting is shown on the nameplate of the over-current device. An instantaneous trip setting as high as this is necessary because of the “spike” or current surge when the motor attempts to start at the peak of the current cycle. - The overload trip mechanism shall be set at 300 percent of the motor full-load current. At locked-rotor current (about 600 percent of the motor full-load current), the circuit breaker must trip in 8 to 20 seconds. This setting is shown on the nameplate of the over-current device. Direct current motors shall have circuit breakers that will trip instantaneously at or above 400 percent of the motor full-load current. This protects the motor insulation against heat generated in an extended lock-rotor condition. 5.6.4.1.2 Fire Pump Feeder Circuit Fuses, if used, shall have: - - A continuous current rating equal to or greater than the sum of the full-load current of the fire pump room accessories and the rated lock-rotor current(s) of the fire pump motor(s) (600 percent of the full-load current) if they operate off the same feed. Interrupting capacity equal to or greater than the maximum fault current possible at the location of the fuses as determined by a qualified electrical engineer. A locked panel door to ensure non-tampering by unauthorized persons. A circuit breaker, if used, shall have: - - 5.6.5 The breaker shall have an instantaneous trip only. It shall not have an “over-load” trip mechanism. The continuous current rating equal to or greater than the sum of the full-load current of the fire pump room accessories and the rated lock-rotor current(s) of the fire pump motor(s) (600 percent of the full-load current) if they operate off the same feed. Interrupting capacity equal to or greater than the maximum fault current possible at the location of the breaker. The instantaneous trip setting shall be at least 12 times the full load current rating of the fire pump motor. An instantaneous trip setting as high as this is necessary because “spikes” or current surges may occur if the motor(s) attempts to start at the peak of the current cycle. This is considerably above the calculated trip setting, but is accessible because it is intended for short circuit protection on the feeder conductors where a short circuit can draw current in excess of this value. This setting is shown on the nameplate of the over-current device. A locked panel door to ensure non-tampering by unauthorized persons. Any manual disconnect switches shall be in a locked box or locked in the closed position Motor and Diesel Engine 5.6.5.1 Electric Motor Motors shall operate smoothly without excessive vibration. Voltage shall not exceed 110 percent of the motor’s rated voltage and shall not drop more than 5 percent below the motor’s rated voltage when the fire pumps are being driven at rated conditions while the conductors between the power station(s) and motors are carrying peak loads. Standard 104 15 The “running” timer shall be set for approximately one-minute per ten horsepower to allow the motor windings to cool. When operating at peak electrical load (about 140 to 150 percent of the flow capacity) the fire pump shall be shut down and then restarted. The “in-rush” motor current will be the same as when cold, but be of greater duration since the fire pump will come up to speed more slowly. Motors used above an altitude of 3,300 feet shall be de-rated according to altitude. manufacturer for information. Consult the 5.6.5.2 Diesel Engine The flow of the fire pump may not adequately test the engine. After the fire pump has been flow-tested satisfactorily, water flow shall be adjusted for peak power requirement (about 140 to 150 percent capacity), and allowed to run for 15 to 20 minutes to demonstrate that the engine will not overheat under this condition. Cooling water shall be arranged to discharge to a safe location with no possibility of flooding the fire pump room even during a power failure. After the engine has operated for approximately 30 minutes (for the flow test), it shall be started and stopped 10 times in succession to test both manual and automatic operation. The engine-speed governor shall be adjusted and secured to maintain fire pump load, or approximately 140 to 150 percent of the rated fire pump capacity. The governor must control the speed with no more than a 10 percent variation between maximum fire pump load and shut-off condition (churn). The overspeed governor shall be set at approximately 120 percent of the rated fire pump speed. When possible, check this setting by operating the engine above rated speed. It is important that the setting is high enough to prevent shutdown of the engine during start-up. This device must be reset manually after each over-speed shutdown. Diesel engines shall be wired to not shut down automatically when they over-heat or when the lubricating oil pressure is low. Warning alarms indicating these conditions shall be provided. Fuel supply tanks shall have a capacity at least equal to one (1) gallon per horsepower, plus five (5) percent for volume expansion and shall be dedicated to the fire pump diesel engine. Tanks shall be inspected for leaks and to verify that the diesel fuel level is full. Multiple diesel fire pump installations shall have individual fuel tank supplies. 5.6.6 Accessories The installation and setting of the main relief valve shall conform to NFPA No. 20. To prevent overheating, a circulation relief valve adjusted to open at approximately 5 PSI below the minimum shutoff (churn) pressure, or suction at the lowest point, is needed to provide a small water flow through the fire pump when it is operating with no other discharge. A horizontal fire pump and driver require a flexible coupling and safety guard in the shaft between them to compensate for any slight misalignment, and to provide shaft-end clearance to compensate for heat induced shaft expansion. This is usually a simple loose pin coupling. NOTE: It is very important that the alignment of this coupling be checked before conducting the annual flow test. The fire pump shall be subject to at least one full hour of continuous operation to prove that bearings and packing boxes are in good condition, and will not over-heat. Packing glands on horizontal fire pump shafts shall be adjusted so that water drips freely or “runs” in a thin stream to cool, lubricate and provide an air seal. A fire pump shall not be operated when dry or unprimed, nor shall it be allowed to “churn” for more than three to five minutes without water circulation. The closely fitted seal rings can overheat, and cause damage to the fire pump. Standard 104 16 Other accessories include: 5.6.7 Suction and discharge pressure gauges Flanged type waste cone Capacity nameplate Control Panel Functions All control panel functions shall be tested. If the fire pump house is not constantly attended, alarms shall be transmitted to the on-site central supervision station (proprietary signaling system). Typical alarms indicate: - - Fire pump “running” (started) Loss of operating electric power Phase reversal on line side of the motor Low fuel supply Controller main switch in “off” or “manual” position Engine trouble such as Low lubricating oil pressure High engine temperature Failure of engine to start (over-crank) Engine over-speed shutdown High water temperature Battery failure Control valve tampering Relief valve open Fire pump room trouble (unauthorized entry) Low temperature in fire pump room Suction supply water level below normal Suction supply water level near depletion If these alarms have a common audible signal, each condition shall be visually shown (individually) at the fire pump house controller, and at the on-site central supervision station. 5.6.8 Suction Multiple fire pumps taking suction from a single water source shall be operated simultaneously at maximum flow to verify that the fill pipes are unobstructed, and properly sized to maintain an adequate water level. 5.6.9 Jockey (Pressure Maintenance) Pump Jockey pumps are used to maintain a uniformly high pressure on the fire protection system to: - Assure high pressure on initially fused sprinklers. Permit the fire pump to start at a high system pressure so that water hammer will be less likely to occur. Avoid frequent and unnecessary starting of fire pumps because of minor fluctuations in the system pressure. Prevent false alarms caused by surges in the public water supply. Jockey pumps can be used for applications as small as an individual sprinkler system, or for an entire underground system. The jockey pump shall be rated (capacity and pressure) to provide a flow approximately twice the rate of anticipated or experienced leakage in the system at the pressure corresponding to the “off” setting of the controller for the fire pump. The jockey pump and controls arrangement shall be designed in accordance with NFPA No. 20. Jockey pumps may be of either the centrifugal or positive displacement type. Standard 104 17 To prevent over-pressurizing and damage the system, the maximum possible discharge pressure of the jockey pump shall be less than the pressure rating of the system. A positive-displacement jockey pump shall have a relief valve bypass (internal or external) that is set to prevent a pressure in excess of the system rating. 5.6.10 Additional Criteria - - Standard 104 Pressure shall not exceed the pressure rating of the system (usually 150-PSI). The fire pump shall be arranged to start at a pressure close to its maximum possible discharge pressure (as installed) to avoid water hammer. The fire pump shall be arranged to start before sprinkler system pressure drops below designed operating pressure. The fire pump shall be arranged for automatic start and manual stop. The jockey pump shall be arranged to start at a pressure above the starting pressure setting of the fire pump (approximately 10-PSI) to prevent false starts of the fire pump. A pressure differential between the “start” and “stop” settings of the jockey pump (10 to 15 PSI) is required to prevent unwanted fire pump motor/engine starts. The controller for the jockey pump shall incorporate a running-period timer (set for approximately 1 minute per 10 horsepower) to allow for cooling of the electric motors, unless it can be determined that the normal “running” cycle will equal or exceed that period. Weekly “run” criteria for fire pumps is Ten (10) minutes – electric motor driven (normally fire pump is operated for one minute per 10 horsepower rating of the motor. Thirty (30) minutes – diesel engine driven 18 6.0 6.1 Sprinkler Systems General Equipment maintenance shall be conducted in the form of flow and pressure tests. A flow test involves testing of all system components of a sprinkler system. Satisfactory test results shall be recorded by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. 6.2 Flushing (as required) All sprinkler system piping and lead-in connections shall be flushed to remove foreign material from supply mains and branch lines. Flushing shall continue until the water flows clear. Care shall be exercised during the flushing operation to assure that water flow will adequately drain without producing water damage to property. Flow rates, in accordance with the 2002 edition with NFPA No. 13, Table 10.10.2.1.3 are: Flow Rate Required to Produce a Velocity of 10-fps (3 m/s) in Pipes Pipe Size (in inches) 6.3 Pipe Size (mm) Gallons/Minute Liters/Minute 4 102 390 1476 6 152 880 3331 8 203 1560 5905 10 254 2440 9235 12 305 3520 13323 System Waterflow Tests (annually) Water flow tests shall be conducted for each sprinkler system to verify that the water supply and sprinkler system piping are in operating condition. A two-inch main drain at the sprinkler riser acts as a water supply test pipe by activating the system (opening the alarm or check valve). System pressure shall be recorded by observing the system pressure gauge at the alarm or check valve. Pressure on the system side of the alarm or check valve may be higher than that of the water supply because any momentary high pressure on the supply will be transmitted to the system and retained by the check valve. This excess pressure is relieved when a water flow test is conducted. Residual pressure (below static pressure) shall be recorded by opening the two-inch main drain and observing the system pressure gauge at the valve. A flow test shall be conducted for each system. Water supplies and systems shall be returned to service after testing is satisfactorily completed. 6.4 Sprinklers and Piping A visual inspection shall be conducted of all sprinkler heads and piping to assure that they are properly installed, not obstructed and that proper clearances from structural members are maintained per the 2002 edition of NFPA No. 13. Piping shall be visually inspected to verify that nothing is supported from it. Standard 104 19 Sprinklers shall not be obstructed by high piled stock storage, other materials, by partitions, or walls that might prevent free and proper water distribution. A clear space of 18 inches is required between the topof-storage and sprinkler deflectors for storage up and equal to 12 feet. For storage above 12 feet and for ESFR and Large Drop sprinkler systems, the minimum clear space shall be 36 inches. Only new sprinklers shall be used for installation installed in accordance with this Standard. Ensure that previously installed sprinklers are not re-used for new installations. Observe the type of sprinkler, year manufactured and date of installation. Verify that all sprinklers are of the proper temperature rating and type for their intended use. Replace upright sprinklers with upright sprinklers and pendent sprinklers with pendent sprinklers. Also, verify orifice size and not just thread size. Sprinklers shall be protected against coating of paint, excessive deposits or incrustations or corrosive conditions should any of these conditions exist. Optional methods are: Do not use thin bags over sprinklers in spray paint booths where high pressure water is used to clean the booths. Plastic Bags over sprinklers - 0.003-inch (0.076-mm) cellophane secured with rubber bands. NFPA No. 13, (2002 edition) “Standard for Installation of Sprinkler Systems”, requires that hydraulically designed sprinkler systems each have a permanent non-corrosive sign attached to the given sprinkler riser that states the design criteria and system demand. Permanently marked on these signs will be the location of the design area, discharge density and remote area, required flow and residual pressure at BOR, occupancy class or commodity class, and hose demand system demand. 6.5 Dry Pipe Sprinkler Systems (conducted yearly by a contractor) Maintenance tests for dry pipe systems consist of system operation (water-flow test) through use of the inspector’s test connections. Water flow tests shall be conducted for each dry pipe sprinkler system to verify that the water supply and sprinkler system piping are in operating condition. System pressure shall be observed at the alarm valve pressure gauge. Verify that the proprietary signaling station is notified within 60 seconds. Silence alarms when tests are completed. Water supplies and systems shall be returned to service after testing is satisfactorily completed. Quick opening devices shall be provided and shall be functional to boost air release from system piping to lessen time between valve trip and water discharging from the inspector’s test connection. These are usually required for dry pipe system with an interior pipe capacity (volume) of 500 gallons or more. 6.6 Pre-action/Deluge Sprinkler Systems (contractor) Pre-action and deluge systems are designed to protect properties where danger of water damage exists as a result of automatic sprinkler system damage. Deluge systems are used when high water volume sprinkler system is required. Deluge systems differ from pre-action systems in that deluge systems have open sprinkler heads, and pre-action systems have closed sprinklers heads. Both types of systems are operated by an automatic detection system. The principle difference between a pre-action and a standard dry pipe system is that in a pre-action system, the water supply valve is actuated not by air release, but actuated independently by operation of an automatic fire detection system. The valve can also be operated manually. Maintenance tests for pre-action and deluge systems consist of testing the detection system, valve solenoid, flushing, and main drain test. Standard 104 20 Water flow tests shall be conducted for each pre-action/deluge sprinkler system to verify that the water supply and sprinkler system piping are in operating condition. System pressure shall be observed at the alarm valve pressure gauge. Verify that the proprietary signaling station is notified. Silence alarms when tests are completed. Water supplies and systems shall be returned to service after testing is satisfactorily completed. Standard 104 21 7.0 7.1 High Speed Water Spray (Deluge) Systems General (conducted annually by contractor) High Speed Water Spray systems are used for high volume water-flow requirements in high hazard areas. Water Spray systems are used to protect spray paint booth operations where large quantities of water are needed for fire suppression. NOTE: Water Spray systems are also used at openings in firewalls where fire doors can not be installed. High Speed Water Spray nozzles are open and water flows from all nozzles when the control valve is opened. The control valve is opened as a result of a fire detection system. CFS No. 101 requirement is to use optical infrared detectors (IR3) instead of ultraviolet (UV) detection. Water is applied in a designated pattern, velocity, particle size and density, using special nozzles that generally provide a solid cone of water to a precisely defined area. High-Speed Water Spray (Deluge) systems differ from a standard deluge sprinkler systems. High Speed Water Spray systems have open, high volume, nozzles that distribute water in a denser water curtain pattern and standard deluge sprinkler systems have open sprinkler heads that distribute water in a more conventional pattern, satisfying other design criteria. Both types of systems are operated by an automatic fire (or smoke) detection system. Functional and flow tests shall be performed on all operating systems including the detection system, valve solenoid, automatic shutdown of equipment, flushing, and main drain test. A flow test shall be conducted to flush the system using down commers. When more than one system operates in the event of fire in a given fire zone, all systems shall be simultaneously flow tested. Satisfactory test results shall be provided by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. 7.2 Flushing (as required) All sprinkler system underground piping and lead-in connections shall be flushed to remove foreign material from supply mains and branch lines. Flushing shall continue until the water flows clear. Care shall be exercised during the flushing operation to assure that water flow will adequately drain without producing water damage to property. Flow rates, in accordance with the 2002 edition of NFPA No. 13, Table 10.10.2.1.3 are: Flow Rate required to produce a velocity of 10 fps (3 m/s) in pipes Pipe Size (in inches) 7.3 Pipe Size (mm) Gallons/Minute Liters/Minute 4 102 390 1476 6 152 880 3331 8 203 1560 5905 10 254 2440 9235 12 305 3520 13323 Fire Detection Systems (conducted semi annually by contractor) Ultraviolet (UV) and Infrared (IR) detectors are flame detectors that sense UV or IR radiation (wavelengths) from a fire source. Standard 104 22 A functional test shall be performed on all Fire Detection systems and shall be comprised of the Detection System Checkout Procedure and testing of Optical Integrity and Detection Module Response to UV and IR Radiation. 7.4 System Water flow Tests Water flow tests shall be conducted for each High-Speed Water Spray (Deluge) system to verify that the water supply, and High-Speed Water Spray system piping are in operating condition using down commers. The proprietary signaling station shall be notified and all alarms silenced when tests are conducted. Water supplies and systems shall be returned to service after testing is satisfactorily completed. 7.5 Water Spray Nozzles and Piping A visual inspection shall be conducted of all (Bete) nozzles and piping to assure that they are properly installed, not obstructed, and proper clearances from structural members are maintained in accordance with latest edition of NFPA No. 13. Piping shall be visually inspected to verify that nothing is supported from it. Hangers shall be properly supported in accordance with the latest edition of NFPA No. 13. Observe whether sprinkler piping is used to support stock, clothing, etc. Fire protection piping shall not be used for such purposes. Observe nozzles to be certain they are positioned in accordance with their intended use. 7.6 Protected Areas Paint spray booth zones are protected by IR 3 optical fire detectors connected to High-Speed Water Spray (Deluge) systems and a gaseous agent system such as carbon dioxide or HFC-227ea (FM-200). 7.7 Proprietary Products The following products shall be exclusively used for their respective services in accordance with this Standard: Equipment Manufacturer Cla-Valve Model #7100KH Cla-Val Company Bete Nozzle TF Series Bete Nozzle, Inc. IR3 Detector X-3301A21W1 Model FS-10CS, X3301A Detector Electronics/Detronics (Preferred Unit) Fire Sentry, Detector Electronics IR Fiber Optical Detector Model PM9-SBE Detector Electronics/Dual Spectrum Detector Control Panel Eagle Quantum Intelliscan III/Cheetah/Cheetah Xi Fenwalnet 2000 AFP 400 Standard 104 Detector Electronics/Detronics (Preferred Unit) Fike Corporation Fenwall Corporation Notifier Corporation 23 7.7.1 Material Legend for Cla-Valves Removed Standard 104 24 8.0 8.1 Foam Water Sprinkler Systems (AFFF) General Aqueous Film-Forming Foam (AFFF) water sprinkler systems are used to provide fire suppression for flammable liquids operation and storage areas. Standard sprinkler heads are used with AFFF systems, as aspiration of air to form bubbles is not required, unlike mechanical foam. A foam proportioning system is used to inject the foam concentrate into the water supply. For a specified period of time (10 minutes), after the supply of foam concentrate is exhausted, the system will continue to discharge water. Heat detectors generally activate systems, but other types of detectors or manual activation can be used. Foam-water sprinkler systems are used principally for protecting flammable liquid hazards, such as flammable liquid handling and storage, and spray paint operations. Equipment maintenance shall be conducted in the form of flow and pressure tests. Satisfactory test results shall be recorded by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. A Test Form is provided in this Standard. 8.2 Flushing (as required) All sprinkler system piping and lead-in connections shall be flushed to remove foreign material from supply mains and branch lines. Flushing shall continue until the water “runs” clear. Care shall be exercised during the flushing operation to assure that water flow will adequately drain without producing water damage to property. Flow rates, in accordance with the latest edition of NFPA No. 13, Table 10.10.2.1.3, are: Flow Rate required to produce a velocity of 10 fps (3 m/s) in pipes Pipe Size (in inches) 8.3 Pipe Size (mm) Gallons/Minute Liters/Minute 4 102 390 1476 6 152 880 3331 8 203 1560 5905 10 254 2440 9235 12 305 3520 13323 System Waterflow Tests Water flow tests shall be conducted for each AFFF sprinkler system to verify that the water supply and sprinkler system piping are in operating condition. System pressure shall be recorded by observing the system pressure gauge at the alarm or check valve. A flow test shall be conducted for each system. The proprietary signaling station shall be notified and all alarms silenced when tests are conducted. Water supplies and systems shall be returned to service after testing is satisfactorily completed. Standard 104 25 8.4 Sprinklers and Piping A visual inspection shall be conducted of all sprinkler heads and piping to assure that they are properly installed, not obstructed and that proper clearances from structural members are maintained per NFPA #13. Piping shall be visually inspected to verify that nothing is supported from it. Sprinklers shall not be obstructed by high piled stock storage, other materials, by partitions, or walls that might prevent free and proper water distribution. A clear space of 18 inches is required between the topof-storage and sprinkler deflectors for storage up and equal to 12 feet. A supply of extra sprinklers in a sprinkler cabinet shall be provided so that any sprinkler that has operated (fused) or has been damaged may be promptly replaced. Sprinkler shall correspond in type and temperature rating to the sprinklers in the protected area. Proportioning devices and strainers shall be inspected after operation of AFFF systems. Foam concentrate shall be tested to verify the quality of concentration in solution. Standard 104 26 9.0 9.1 Gaseous Agent Fixed Fire Systems General (contractor) Equipment maintenance shall be performed in the form of a functional test for all HFC-227ea (FM-200), ECARO, Carbon Dioxide (high and low-pressure) systems and Wet/Dry Chemical systems including all kitchen systems. Functional testing involves testing of all system components, i.e. system control panel, power supply, emergency power, detectors, time delay devices, alarm devices, selector valves, release devices for doors and dampers, equipment shutdown and manual releases, without discharging the suppression agent (control heads are removed prior to test). The functional test also includes an examination of the system piping, nozzles, and storage cylinders. 9.1.1 Additional Equipment A gaseous agent system abort station may be located inside the main door. HFC-227ea (FM-200) discharge may be delayed by pushing in and HOLDING the “dead-person” abort button. Pushing in the abort button recycles the time delay period (30 to 60 seconds) is obtained once the push button is released. The near by telephone shall be tested. Manual pull station operation (electric) causes the system to discharge immediately, and activates the “Manual Activated” and “Discharged” lights. The pulsed horn signal will sound indicating a gaseous agent discharge. Manual pull stations shall be inspected to be readily accessible and accurately identified. Manual pull stations shall always over-ride abort switches. A pressure operated switch for manual shutdown of computer power and HVAC is located at cylinder bank and connected to system piping. The stem on top of the switch shall be pushed up to operate and pushed down to the normal position to restore power. 9.1.2 Protected Areas Gaseous agent fire protection shall be provided in the following areas: - Paint Mix Room(s) Paint Conveyor Control Room Computer Control Room – Paint Mix Room Flammable Liquid Storage Room High Voltage Paint Change Cabinets Turbo-Bells Dyno cells Engine Test Cells Pits containing hydraulic oil under pressure Machining operations requiring secondary protection Wet/Dry Chemical fire protection shall be provided in the following areas: Kitchen Cooking Hoods Kitchen Cooking ductwork Kitchen Cooking surfaces The installed systems shall meet UL300 Standards and be so listed. Standard 104 27 9.2 Gaseous Agent 9.2.1 General Equipment Maintenance shall be conducted in the form of a functional test for all gaseous agent systems. A functional test involves testing all functions of all systems, i.e. the system control panel, power supply, emergency power, detectors, time delay devices, alarm devices, selector valves, release devices for doors and dampers, equipment shutdown and manual releases without discharging gaseous agent. The functional test also includes an examination of the system piping, nozzles, and agent storage cylinders. Personnel trained in the function of the system shall perform all functional tests. One detector places the gaseous agent system into the alarm mode (without agent discharge). Two detectors on a separate zone (cross-zone or counting zone) or a manual pull station operate to actuate system discharge. Cross-zone is when two detectors, each on a separate circuit, operate to actuate agent discharge. Counting zone is when two detectors, on the same circuit, operate to actuate agent discharge. Detectors or manual pull stations initiate a signal to the control panel. The control panel sends a discharge signal to the discharge control valves (heads) Satisfactory test results shall be provided by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. 9.2.2 Inspection The protected enclosure shall be inspected as follows: - The room and openings that are automatically closed upon system actuation shall be in normal operating condition. Ceiling tiles must be installed and clipped in-place. Agent and containers shall be inspected as follows: - Storage material shall not obstruct access to agent storage containers Containers and mounting brackets shall be securely fastened in accordance with manufacturer’s requirements. The amount of agent in storage containers shall be determined. The electrical system shall be inspected as follows: - - Wiring systems shall be installed in compliance with local codes, insurance agencies, and system design drawings. Field circuitry shall be tested for ground fault and “short” circuit condition. All auxiliary functions, including sounding of an alarm, damper and door closer actuation, remote annunciation, HVAC shutdown and equipment shutdown, shall be inspected for proper operation in accordance with system requirements. Manual pull operation and protective cover For systems with a main/reserve cylinder bank, the main/reserve switch shall be tested, readily accessible and clearly identified. A door fan test is needed whenever modifications are made to the room such that the integrity of the sealing is disturbed. NOTE: Specifications shall state which contractor shall be responsible for making repairs to the room if the door fan test fails. 9.2.3 System Operations System operation shall be performed in the form of a functional test (without release of gaseous agent) into the area). Standard 104 28 Activation of any one (1) detector on the ceiling or in the under-floor of the protected area will cause the following to occur: - The pre-alarm bell (horn) will ring (sound) and signal the building fire alarm system. The “First zone” lamp on the control panel will illuminate. The auxiliary first detector relay will activate. Door holders will release doors. The activated smoke detector has its L.E.D. lit bright red (steady). The corresponding light on the graphic annunciator that the detector is in alarm. Upon verifying the cause of the alarm, the audible alarm may be silenced by momentarily operating the “System Alarm Silence” switch. After an alarm test, the system shall be reset. Activation of a second detector or “Second Zone” detector on the ceiling or in the under-floor of the protected area will cause the following to occur: - The alarm bell (horn) will ring (sound) and the warning strobe lights will activate (unless previously silenced during the first alarm) and signal the building fire alarm system. The “Second Zone” alarm light will illuminate. Control/Computer equipment will shutdown. HVAC will shutdown. Dampers will close. The gaseous agent will discharge after a preset time delay of 15-20 seconds 9.3 Carbon Dioxide 9.3.1 General (contractor) Equipment Maintenance shall be conducted in the form of a functional test for all Carbon Dioxide systems. A functional test involves testing all functions of all systems, i.e. the system control panel, power supply, emergency power, detectors, time delay devices, alarm devices, selector valves, release devices for doors and dampers, equipment shutdown and manual releases without discharging Carbon Dioxide (control heads are removed prior to test). ). The functional test also includes an examination of the system piping, nozzles, and Carbon Dioxide storage cylinders, pneumatic time delay and sirens. Personnel trained in the function of the system shall perform all functional tests. Satisfactory test results shall be provided by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. Contractor will be responsible for providing and using any exhaust equipment needed to exhaust or dilute carbon dioxide gas after the test. 9.3.2 Inspection The protected enclosure shall be inspected as follows: - The room and openings that are automatically closed upon system actuation shall be in normal operating condition. Ceiling tiles must be installed and clipped in-place. Agent and containers shall be inspected as follows: - Storage material shall not obstruct access to agent storage containers Containers and mounting brackets shall be securely fastened in accordance with manufacturer’s requirements. The amount of agent in storage containers shall be determined. The electrical system shall be inspected as follows: Standard 104 Wiring systems shall be installed in compliance with local codes, insurance agencies, and system design drawings. Field circuitry shall be tested for ground fault and “short” circuit condition. 29 - 9.3.3 All auxiliary functions, including sounding of an alarm, damper and door closer actuation, remote annunciation, HVAC shutdown and equipment shutdown, shall be inspected for proper operation in accordance with system requirements. For systems with a main/reserve cylinder bank, the main/reserve switch shall be tested, readily accessible and clearly identified. Manual pull operation and protective cover System Operations System operation shall be performed in the form of a functional test (without release of Carbon Dioxide into the area). Cylinder heads shall be removed prior to this test. Activation of any one (1) detector on the ceiling or in the under-floor of the protected area will cause the following to occur: - 9.3.4 The pre-alarm bell (horn) will ring (sound) and signal the building fire alarm system. The “Zone” lamp on the control panel will illuminate. Door holders will release doors. HVAC will shutdown. Dampers will close. Equipment/fuel supply will shut down. The indicating light for the activated detector will illuminate at the control panel The corresponding light on the graphic annunciator, if applicable, will light indicating that the detector is in alarm mode After a pre-determined time delay (30 to 60 seconds), the system (zoned selector valve if low pressure carbon dioxide) will discharge. Upon verifying the cause of the alarm, the audible alarm may be silenced by momentarily operating the “System Alarm Silence” switch. After an alarm test, the system shall be reset. High Pressure Storage High-pressure containers (cylinders) are designed to store liquid carbon dioxide at atmospheric temperature. Since maximum pressure in the cylinder is 800 to 1,000 PSI for carbon dioxide at ambient temperature, the container shall be designed to withstand maximum expected pressure. Storage cylinders are designed, tested and filled to U.S. Department of Transportation (DOT) specifications. The maximum permitted filling density is equal to 68% of the weight of water that the container can hold at 60 degree Fahrenheit. Cylinders are fitted with an internal dip tube so that liquid will be discharged from the bottom when the cylinder is upright and the valve is opened. Abnormally low storage temperatures would adversely affect the rate of discharge. For this reason, storage temperature below 0°F for total flooding systems or below 32°F for local application systems are not permitted. 9.3.5 Low Pressure Storage Low-pressure storage tanks are pressure vessels with a designed working pressure of approximately 300PSI. Storage tanks are maintained at a temperature of approximately 0°F by use of insulation and mechanical refrigeration. At this temperature, the pressure is approximately 300 PSI. A compressor, controlled by a pressure switch in the tank, circulates refrigerant through the coils near the top of the tank. Tank pressure is controlled by condensation of carbon dioxide vapors by the coils. In the event refrigeration fails, pressure relief valves bleed off some vapors to keep the pressure within safe limits. This permits some of the liquid to evaporate; creating a self-refrigerating effect that keeps the emergency loss rate at a low level. With low-pressure storage, it is common practice to protect multiple hazards from one central storage tank. Opening and closing the discharge (selector) valves using a preset timed sequence controls the quantity of carbon dioxide discharged in a protected area. Central storage tanks may have capacities ranging from less than one ton to one hundred tons. For large protected areas, the distance between the hazard and storage could be as much as several hundred feet. Standard 104 30 9.3.6 Extended Discharge An extended discharge of carbon dioxide is used when an enclosure is not tight enough to retain an extinguishing concentration as long as it is needed. The extended discharge is discharged at a reduced rate following the initial discharge used to develop the extinguishing concentration (within a two-minute time frame). The reduced rate of discharge shall be a function of the leakage rate (calculated by leakage area), or the flow rate, through ventilation ducts that cannot be shut down. Extended discharge is particularly applicable to enclosed rotating electrical equipment such as generators, where it is difficult to prevent leakage until rotation stops. Extended discharge can be applied to ordinary total flooding systems as well as to local application systems where a small spot may require prolonged cooling. 9.3.7 Hand Held Hose Lines Chrysler LLC does not utilize hand held lines at any US facility. 9.4 Wet/Dry Chemical Systems (contractor) 9.4.1 General Wet chemical systems shall meet the new UL 300 Standard. Equipment Maintenance shall be performed in the form of a functional test for all Wet/Dry Chemical systems (without release of the wet/dry chemical into the area). Cylinder heads shall be removed prior to this test. A functional test involves testing of all system components of the chemical system. Satisfactory test results shall be provided by the testing contractor and shall be maintained by Wackenhut Site Security Manager. 9.4.2 Functional Tests Functional testing and inspection shall be performed on all system components without discharging chemical agent. Shut-off valves and switches shall be tested to ensure their operability in conjunction with system operation. Piping and nozzles shall be inspected to assure proper types and location. Operate pressure switches and auxiliary equipment that is connected to the system control panel/box and the cooking equipment power supply shutoff. Auxiliary equipment includes: - 9.4.3 Remote Manual Pull Station Mechanical Gas shut-off Valve(s) Electric Gas shut-off Valve(s) Electrical Switch(s) Pressure Switch(s) Building Fire Alarm Manual Release dual action` A “STRIKE” button is a manual release device and is located on the face of the mechanical release mechanism. A remote manual pull station allows the system to be manually operated at some point distant from the release mechanism. The manual pull station shall be installed at a height convenient for the manual operation and located in the exit path. The manual pull station becomes either a primary or secondary source of manual actuation depending on accessibility of the “STRIKE” button on the face of the release mechanism (which is sometimes acceptably inaccessible). Standard 104 31 Manual pull stations shall be located within 25 feet of the release mechanism. The maximum number of pulley elbows that may be used per system is twelve. (NOTE: There is a new class of fire known as a Class ‘K’. The agent is electrically conductive and therefore, it is critical that the total flooding agent discharge (and shut off electrical power) before anyone discharges a portable Class ‘K’ extinguisher. A Class ‘K’ unit shall be provided in the kitchen area only if required by the local AHJ) Standard 104 32 10.0 10.1 Detection Systems General (contractor) Equipment maintenance shall be performed in the form of a functional test on all fire detection and alarm systems. A functional test involves testing of all system components of a detection system. The testing contractor shall certify that all tests have been successfully completed. Satisfactory test results shall be provided by the testing contractor and shall be maintained by the Wackenhut Site Security Manager. 10.2 Fire Alarm Control Panel All control equipment shall be tested to verify operability of its intended function. - - A visual inspection on all cable terminals, plug interconnections, plug-in circuit components, lamps, sockets and controls to establish that their mechanical and electrical connections and mounting are as required for intended function and where applicable, to confirm the electrical supervision of the equipment. All control unit functions shall be operated to verify appropriate response. All lamps and indicators shall be tested. Simulation of open circuits, short circuits and ground faults shall be performed on all relevant circuits in order to confirm the appropriate electrical supervisory responses. 10.3 Detectors 10.3.1 Smoke Detectors Smoke detectors are of two types; i.e., ionization and photoelectric. The only difference between the two detectors is their method of operation (ionization detects an ionized atmosphere and photoelectric detects a clouded photoelectric cell). Testing method is identical for both types of smoke detectors. All smoke detectors are tested in the same manner. This test consists of spraying a smoke detector test aerosol into the detector chamber. Each detector has a self-contained light that illuminates flashes or loses illumination when the detector operates. 10.3.2 Heat Detectors Heat detectors are of three types; i.e., fixed temperature, rate-of-rise, and rate compensated. Fixed temperature detectors operate when the temperature of the operating element reaches a specified point. Rate-of-Rise detectors operate when the rate of temperature increase exceeds a pre-determined level. Rate compensated detectors operate when the temperature of the surrounding air reaches a predetermined level, regardless of the rate of temperature rise. Heat detectors are tested by the application of heat (hair dryer) or by being “short” circuited. Rate-of –Rise and rate compensation (heat) detectors can be tested using a hair dryer or shielded heat lamp. The following inspections shall be conducted on all installed equipment: - Standard 104 For damage or tampering that may interfere with its intended operation. For functionality to ensure that it will function as intended under emergency operating conditions. 33 10.3.3 UV or UV/IR or IR/IR Flame Detection Systems Ultraviolet (UV) and Infrared (IR) detectors are flame detectors that sense UV or IR radiation (wavelengths) from a fire source. A functional test shall be performed on all UV and UV/IR and IR/IR detection systems. The functional test shall be comprised of the detection system checkout procedure and testing of optical integrity and detector module responses to UV and IR radiation. The Automatic Optical Integrity feature checks the controller and all detectors in all zones approximately once every second. This monitors the system for faults that may occur, including wiring between detectors and the controller. 10.3.4 Beam Smoke Detection Systems A beam detector detects smoke through a transmitter that sends a beam of infrared light to a receiver. The received signal is analyzed for loss of strength caused by smoke obscuration when smoke obscuration exceeds a pre-set level. A functional test shall be performed on all beam detection systems. 10.4 Initiating Devices 10.4.1 Manual Pull Stations dual action Functional testing of manual pull stations consists of activating the station in the manner indicated on the device. Movement of the switch causes a fire alarm to be transmitted to the fire alarm control panel. Manual stations can have a pull/push mechanism or “break glass” feature that consists of a piece of glass rod within the station. Upon activation of the device, it shall be reset. Protective covers must be provided on all manual pulls. 10.4.2 Alarm Signaling Appliances Alarm signaling appliances shall be activated to ensure that they function properly. Audible Signal Appliances – The fire alarm system shall be tested on main power supply and standby power supply with the maximum expected load on the system. Audible signal appliances shall operate and shall be audible throughout the building with normal background noise present. Visual Signal Appliances – the visual signal appliances shall function as intended and shall be clearly visible from all points within the visual alarm area. 10.4.3 Voice Alarm Systems The voice alarm system consists of a power supply, pre-amplifier, amplifier, loudspeakers, tape player, tape and interconnecting wiring. Upon actuation of a fire alarm within the building, the tape player sends a pre-recorded message over the voice fire alarm circuit. The message is amplified and given to occupants through individual loudspeakers. Some voice alarm systems use a live voice message spoken into a microphone at a central location instead of tape player. Voice messages sometimes have pre-alert tones for drawing attention to the message that is to follow. 10.4.4 Power Supply The primary and secondary power supply to the detection system shall be inspected to verify that: - Standard 104 Power supply is properly protected (fused). Power supply is not vulnerable to unauthorized interruption. Power supply is designed adequately to meet the code requirements of the system. 34 - - Power for auxiliary devices is taken from a source separate from the fire alarm system control panel source in such a way that a fault of an auxiliary device circuit shall not detrimentally affect the fire alarm system power supply. The breaker lock is inspected Standby Power Supply (Batteries) shall be inspected to verify that they are: - Not damaged Protected from accidental damage Terminals are clean and lubricated Terminals clamps are clean and tight Provided with adequate ventilation Connected to a properly fused charging circuit Electrolyte (water) level and specific gravity are as specified by the manufacturer Standby batteries of the rechargeable type shall be capable of operating the fire alarm system with the charger input disconnected for one rated load cycle. A rated load cycle means the total energy consumed by the maximum electrical supervisory current plus the trouble signal current for 24 hours followed by the general alarm load for fifteen minutes. The batteries are checked for 3 year replacement date If engine driven generators act as the standby power supply, an inspection and test shall be made to establish that the transfer to standby power functions properly and that the generator starts and exercises itself without applying unacceptable voltages to control equipment. Initiating devices shall be activated with the main power supply disconnected to verify operation of the backup power supply. 10.4.5 Electrically Supervised Circuits Electrical connections for each device shall be tested to ensure that disconnection of the device from the circuit or improper wiring will activate the required electrical supervisory signals. 10.4.6 Auxiliary Equipment Auxiliary equipment shall be inspected to verify that faults in the auxiliary equipment o no interfere with the normal operation of the fire alarm system. Operate manual pull stations and protective covers. Operate every audible and visual signal appliance to verify proper operation and supervision. The fire alarm system control panel shall be visually inspected to ensure that the control panel has not been altered from its designed intent. . Standard 104 35 11.0 11.1 Fire Doors General (contractor) Fire barriers, including doors, are passive fire protection elements installed to prevent exposure fires from damaging equipment or structures in adjacent areas. For the barrier to be effective, all components of the barrier must operate as designed. Failure of a fire door in a barrier will result in failure of the barrier and, therefore, fire doors must operate properly. In addition, the door must be rated by U.L. and/or FM, and labeled for the specific doorway in which it is installed. Fire doors are of the overhead and swinging types. Overhead fire doors are used for large openings that go beyond the practical limits of a swinging door. Each fire door shall comply with the following criteria: - Standard 104 Fire doors and frames shall be labeled. Fire door closer devices shall be labeled. Fire doors shall be operational at all times. Fire doors shall be closed and arranged for automatic operation (in operating condition) and supervised. Fire doors and frames shall not have any un-authorized holes. Fire doors with automatic hardware shall be tested to verify that it is operable. Fire doors shall be unobstructed so that they may open to gain access or egress from a zone. Fire doors shall also be able to close and latch to maintain the intended fire barrier rating. Fire doors shall be fully opened and allowed to be fully close and latch to verify that they are operable. Clearances between swinging fire doors and the frame or sill shall satisfy the following criteria: - ¾” between door and non-combustible floor - 1/8” between door and frame or between door and door - 3/8” between floor and frame A list of all fire rated doors shall be recorded and used for identification purposes during inspections. An inspection label shall be attached to the door frame for roll up and sliding fire doors. 36 12.0 12.1 Standpipe and Hose Systems General Standpipe systems provide fire hose connections located throughout a facility. A supply pipe (often referred to as a riser) feeds standpipe connections. For Class I standpipes, there is no attached fire hose. The 2½-inch valve shall be checked to make sure it is not damaged, that it is readily accessible and that the protective caps are in place. For Class II and III systems, hose cabinets are equipped with 2½-inch hose and nozzle. The hose shall be visually inspected for damage. Hose shall be properly racked in the cabinet with the nozzle attached. Hand tools to connect and disconnect fire hoses and nozzles shall be maintained within each cabinet. Fire department connections shall be inspected to verify that they are readily accessible, that the inlets are unobstructed and that the protective caps are in place. Confirm that main water supply valves are locked . Inspect piping of dry pipe systems for damage and corrosion. Check nozzles on Class II and III standpipes to be sure that they can be easily opened and closed. All hose connections shall be visually inspected to make sure no obstructions prevent attaching a hose and to operating the valve. Hose threads shall be inspected for damage. Hose (1 ½ inch) for Class II and III standpipes shall be removed and re-racked so that it will not deteriorate at the bends. Different parts of the hose shall be located at the bends. Gaskets at the hose connection shall also be checked for deterioration and replaced if necessary. Lubricate the swing-out hose racks and/or hose reels so that they operate easily. An inspection tag shall be attached to each Class II and III hose cabinet or information shall be recorded on an inspection form, indicating the date of visual inspection and the date the hose was last re-racked. A conspicuous sign shall be posted at each hose station indicating a fire hose station. If any pressure reducing devices are used on the hose system they must be maintained per the manufacturer recommendations. Dry standpipes shall be hydrostatically tested every 5 years. 12.2 Classifications Standpipe and fire hose systems have three classifications, based on intended use, as follows: Class I - for use by fire department and those trained in handling heavy fire streams. Standpipes for Class I service shall be provided with 2 ½ inch hose connections. Class II - for use by building occupants. Standpipes for Class II service shall be provided with 1 ½ inch hose connections and fire hose. Class III - for use by either fire department or building occupants. Standpipes for Class III service shall be provided with both a 2-½ inch and a 1-½ inch hose connection (reducer outlet) and fire hose. Standard 104 37 13.0 13.1 Test Intervals General Fire Pumps Dry Valve Special Systems Heat/Smoke Detection Supply Tank Fire Doors Standard 104 Semi-Annual Service Yearly Trip Test Semi-Annual Service Yearly Testing Yearly Overflow Annually 38