Me 462 Machine Design Design Project 1: Shaft Design

advertisement

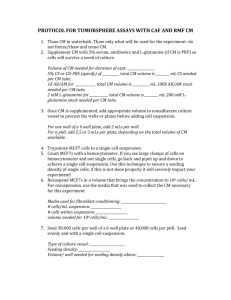

ME 462 Machine Design Automotive Suspension Reverse Engineering Page 1 of 3 F03 Reverse Engineering Reverse Engineering is "the process of analyzing a subject system to identify the system's components and their interrelationships and create representations of the system in another form or at a higher level of abstraction." (Source: Chikofsky and Cross). In the process, we learn how the “form” of a product actually “functions.” We use engineering principles and models to attempt to predict the behavior of the product, and to learn why various design decisions were made. Additionally, if the final goal is “re-engineering” …. we then try to redesign the form to improve its function. Design Project Problem The average automobile has many subsystems, which can be used to conduct reverse engineering activities. In this design project we will examine suspensions systems. Your task is to reverse engineer portions of the front or rear suspension subsystem of a motor vehicle that you drive. Project Worktasks 1. Define the suspension system (USE English Units!) 1.1. Select a car, truck, ATV, motorcycle or trailer. Describe your vehicle: make, model, year, and weight. 1.2. Select either the front or rear suspension subsystem. 1.3. Obtain pictorial drawings of the suspension subsystem from a repair manual, owners manual, product literature and or off the web. 1.4. Determine or estimate pertinent problem definition parameters for the spring (such as shear modulus of elasticity, yield strength, setting strength, and number of active coils/leaves). 1.5. Measure significant design variables for the spring such as coil diameter, wire diameter and or leaf section sizes, leaf lengths. 1.6. Describe how the suspension subsystem works (use engineering terminology); discuss the sketch or annotated figure (published). Label or annotate photocopies, cite the source, add your name and date. 2. Analyze spring performance 2.1. Prepare a static force analysis of the suspension linkage that supports the wheel. Starting with one or more free body diagrams. Measure relevant dimensions directly from the vehicle. Assume that ¼ vehicle weight is supported by the wheel. Discuss the static force analysis. Cite calculated/measured numbers in your sentences. 2.2. Experimentally determine the spring constant. Sit on the “corner” of your vehicle, directly over the spring and measuring the deflection. Then have another person of different weight sit on the corner, measure the deflection. Note that the linkage may cause a mechanical advantage, which needs to be factored in the spring constant calculations. 2.3. Analytically predict (i.e. calculate) the spring constant using the Machine Design text formula using N, d, D found in step 1.5 etc. 2.4. Compare the predicted and measured values. Compare your vehicle’s spring performance with someone else in the class who has a similar type spring and or vehicle. Discuss your findings in your report. 2.5. Determine the deflection to solid height (or the deflection when snubber engages). Estimate the force at this deflection. Estimate the maximum working stresses. Determine whether the spring will set at this deflection? ME 462 Machine Design Automotive Suspension Reverse Engineering Page 2 of 3 F03 2.6. Include and discuss a summary table of your predicted performance versus measured performance for the spring. Discuss in your narrative using numbers. 3. Analyze suspension performance 3.1. Determine the spring force/wheel force ratio. Compare this to the ratio of kmeasured/kpredicted . Discuss if, and how, mechanical advantage of the suspension (linkage) plays a role. 3.2. Estimate the height from which the vehicle would need to be dropped, to fully compress the spring during an impact. Use basic form of the conservation of energy equation (chapter 7). 3.3. For helical compression springs, estimate the tendency to buckle. 3.4. Calculate the frequency at which the spring & suspended mass would resonate. Assume no damping. Note that k / m for an undamped system. How do spring constant and the amount of sprung mass affect ride performance? 3.5. Calculate the number of cycles to fatigue failure (assume each cycle Fs). 3.6. Estimate the equivalent number of “washboard” miles before fatigue failure. 3.7. Discuss each of these analyses in your report, citing numbers in your sentences. 4. Design an ATV spring. 4.1. Determine d, D, N for a steel, helical coil compression spring to be used on an ATV suspension system shown on the attached figure. 4.2. The vehicle must not permit clash when dropped from a height of 8 feet. 4.3. Prepare a spreadsheet to facilitate your design. 4.4. Select and use two or more criteria for best (optimal) designs. Establish satisfaction curves (without horizontal flat spots). 4.5. Calculate total satisfaction for each design iteration. Optimize! 5. Prepare five minute oral report 5.1. Prepare 5 to 10 overhead transparencies using PowerPoint. 5.2. Photocopy sketches onto transparencies (Do not scan. Scanning will not project well.) Deliverables Prepare a typewritten report describing your reverse engineering worktasks. Format using 1.5 line spacing. The report will approximate 7-10 pages not including charts, performance tables, graphs, summary tables, and figures). Attach engineering analyses on 8 ½ x 11 engineering paper to support your findings and to prove your spreadsheet calculations. Neatly draw and fully label your diagrams. Specify all units and state assumptions. Show all calculations. The following sections are recommended. Introduction Suspension System Description Spring Performance Suspension Performance ATV Suspension Spring Design Appendices Due Date Thursday, October 16, 2003 ME 462 Machine Design Automotive Suspension Reverse Engineering ATV Suspension Spring Design A Upper arm Wheel E B Vehicle frame C D Lower arm Wheel width Upper arm EB Lower arm DC Vehicle Weight Spindle link ED AB length Droop Total travel 8 in 10 in 15 in 600 lbs 5 in 10 in 5 in 20 in Page 3 of 3 F03