Code Case Expiration Dates and Annulments

advertisement

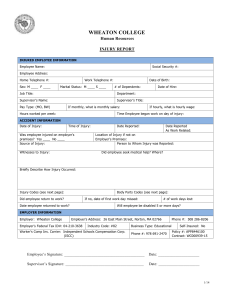

Code Case Expiration Dates and Annulments The ASME Boiler and Pressure Vessel Standards Committee took action to eliminate Code Case expiration dates, effective March 11, 2005. This means that all Code Cases listed in Supplement 3 and beyond will remain available for use until annulled by the ASME Boiler and Pressure Vessel Standard Committee. The following non-nuclear Code Cases for the 2004 Edition have been annulled to date as of Supplement Number 10: Case Number 1939 Code Section(s) VIII-1 1973-2 1983 VIII-2 VIII-1 2010-5 I 2019-1 VIII-1 2033-2 I 2042 I 2053-1 I, IV, VIII-1, VIII-2 2083 I 2097-1 VIII-1 2121-1 VIII-1 2184-1 IV 2186-1 VIII-1 2191 I title SA-395 Class 60-4018 Welded Ferritic Ductile (Nodular) Cast Iron 9Cr-1Mo-V Material Alloy UNS N08810 Up to 1800F Fe-22Cr-21Ni18.5Co-La Alloy, UNS R30556 for Code Construction Aluminum Alloy 3003-H24 for Code Construction 21Cr-11Ni-N Alloy (UNS S30815) for Code Construction Use of Welded Pipe as the Shell of a Boiler For Materials in Inventory Alloy UNS N06690 Up to 1200F Ni-Fe-Cr-Mo Alloy UNS N08932 Plates Co-26Cr-9Ni-5Mo3Fe-2W Alloy (UNS R31233) Use of UNS C90300 Material for Copper Alloy Sand Castings Use of UNS S31803 Plates and Bars in Dimpled or Embossed Assemblies Exemption for Attachment Strength Calculations annulled date 2-22-05 1-1-05 1-1-05 2-22-05 1-1-06 1-1-06 1-1-05 2-20-04 6-23-05 10-27-05 1-1-05 1-1-05 1-1-05 8-11-04 2198-1 VIII-1 2206 VIII-2 2208 VIII-1 2240-2 VIII-1 2242-1 VIII-1, VIII-2 2255 I 2258 IV 2278 II, VIII-1 2289 VIII-1 2292 I 2294-1 IV 2303 X Austenitic Ni-Cr-MoW Alloy (UNS N06686) PrecipitationHardening Nickel Alloy (UNS N07718) Used as Bolting Material Corrosion Resistant Coating of Pressure Relief Valves by Assemblers Ni-23Cr-16Mo-1.6Cu Alloy (UNS N06200) SA-765 Grade IV Forgings Minimum Metal Temperatures of PMB Pressure Vessels During Hydrostatic Testing Use of Flared Tubing Fittings for Attachment of Watertubes Alternative Method for Calculating Maximum Allowable Stresses Based on a Factor of 3.5 on Tensile Strrength Copper Alloy Tube Conforming to SB-75 UNS C12200 Temper O50 for External Pressure Use Up To and Including 400F Welding of NonPressure Parts After Hydrostatic Test Alternative Attachments of Fire Tubes to Tube Sheets Greater than 5/16 in. Thick Alternative Quality Control Test Frequency, Class 1 Fiber Reinforced Plastic Pressure Vessels 1-1-05 2-22-05 1-1-07 1-1-05 1-1-05 1-1-06 4-25-06 8-3-05 8-3-05 8-11-04 1-1-05 1-1-05 2319-2 VIII-1 2325 VIII-1 2332 I 2342 I 2355 VIII-2 2365 I 2368 I 2370 VIII-3 2371 VIII-1 2372 VIII-3 2374 I 2384 VIII-1 2391 I 2417 VIII-1 2429 VIII-1 Ni-25Mo-8Cr-2Fe Alloy UNS N10242 for Code Construction Titanium-Ruthenium Alloys (Ti-0.1Ru), UNS R52404 and UNS 52254 Alternative Rules for the Postweld Heat Treatment of Tubeto-Vessel Welds Use of SA/EN 10028-2, Grade P295GH 59Ni-16Mo LowCarbon Alloy (UNS N06059) Stamping and Data Reports for Boilers Assembled by Multiple Assemblers Demonstration of Safety Valve Performance SA-738, Grade B Plates Manhole Assemblies in Inventory for Construction to UG-46(g)(1) SA-516, Grades 60, 65, and 70 Plate Material Alternative Safety Valve Mounting Ni-22Cr-14W-2MoLa Alloy (UNS N06230) Use of Carbon Steel Plate Material (JIS G3118, Grade SGV 480) Nickel-IronChromiumMolybdenum-Copper Alloy SB-564 UNS N08825 Forgings Alternative Rules for the Design of Tubesheets 1-1-07 1-1-05 1-1-05 2-20-04 1-1-05 1-1-05 2-20-04 2-22-05 1-1-05 2-22-05 1-1-06 1-1-07 8-11-04 1-1-05 1-1-05 2431 II 2436 VIII-1 2444 I 2452-2 VIII-1 2462 IX 2466 VIII-1 2472 VIII-1 2488-2 I 2536 I 2550 I 57Ni-22Cr-14W2Mo-La Alloy (UNS N06230) [external pressure chart] Use of Forged Nickel Alloys (ASTM B 46202) under UNS N06022, N06030, N10276, N10655, and N10675 Alternative Requirements for Piping Connections and Valves SA-182, SA-240, 25Cr-7Ni-4Mo Modified With Nitrogen (UNS S32750) AusteniticFerritic Duplex Stainless Steel Use of Flash Welding for Joining Materials With Other Than Tubular CrossSections Use of Submerged Arc Welding (SAW) in Low Temperature Applications Nickel Tube Conforming to SB161 N02200 Stress Relieved for External Pressure Use Up To And Including 400F UNS S31803 Plates and Seamless and Welded Pipe and Tube and Forgings and Fittings and Bar SA-53 Type F Grade A Furnace Butt Welded Carbon Steel Pipe Exemption from Postweld Heat Treatment for Corrosion Resistant Weld Overlay of PNo.5A Tube and Pipe 1-1-05 1-1-05 1-1-06 1-1-06 1-1-06 1-1-06 1-1-06 1-1-07 1-1-07 1-1-07