laboratory modul and template

advertisement

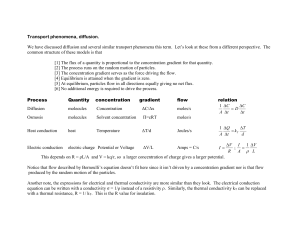

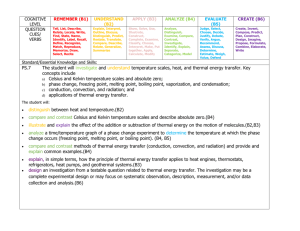

LABORATORY MODULE ERT 216/4 HEAT AND MASS TRANSFER SEMESTER 2 (2012/2013) LECTURER: MRS AZDUWIN KHASRI MISS MISMISURAYA MEOR AHMAD MR LEE BOON BENG PM DR KASSIM GRA: MR MOHYUDDIN MRS MAIZATUL SCHOOL OF BIOPROCESS ENGINEERING UNIVERSITI MALAYSIA PERLIS CONTENTS CONTENTS PREFACE LABORATORY SAFETY FORMAT OF LAB REPORT EXPERIMENT 1: Thermal Conductivity of Liquid and Gas EXPERIMENT 2: Linear and Radial Heat Conduction EXPERIMENT 3: Free and Force Convection Heat Exchanger EXPERIMENT 4: Plate Heat Exchanger EXPERIMENT 5: Liquid Diffusion Coefficient LAB REPORT TEMPLATE PREFACE This module is to serve as a guidance and reference material for students who are registering for Heat and mass transfer subject. It will be used by students for laboratory practices and it will help them to understand the subject in an effective manner. There are five (5) experiments that need to be performed by the students. All of the experiments are being designed to help student in comprehending the subject of Heat and Mass transfer. It is hoped the module is user friendly and that students would enjoy the laboratory work thereby increasing their awareness of the importance of the subject. LABORATORY SAFETY MANUAL Safety in the laboratory requires the same kind of continuing attention and effort that is given to research and teaching. The use of new and/or different techniques, chemicals, and equipment requires careful preparation. Reading, instruction, and supervision may be required, possibly in consultation with other people who have special knowledge or experience. Each individual who works in a laboratory has a responsibility to learn the health and safety hazards associated with the materials to be used or produced, and with the equipment to be employed. It is important for you to know what is expected of you and what your responsibilities are with regard to safety to yourself, your colleagues and our environment. In addition, there are safety practices and safety equipment with which you must be thoroughly familiar if you are to work safely in the laboratory. This manual should be used as a guide to the general types of hazards. Some of the more basic safety practices that you are expected to follow is: 1. Do not perform unauthorized experiments. 2. Upon entering the laboratory note the location of the closest fire extinguisher, first aid kit, eye wash station and chemical shower. Their location will be specified on the laboratory door. 3. DO NOT TOUCH MOVING COMPONENTS while the machine is in operation 4. Use a hood for hazardous, volatile, and noxious chemicals. 5. A laboratory coat or apron should be worn while working in the laboratory. In general, shorts, skirts, brief tops, and sandals are not safe. Further clarification of clothing requirements should be directed to the person(s) in charge of the laboratory in which you are working. Confine all loose clothing, ties, and long hair. Leave your jewellery at home. 6. Do not wear contact lenses in the laboratory. Fumes, gases, and vapors can easily be absorbed by the lens or trapped between the lens and eyes resulting in chemical burns or abrasive injury. 7. Do not work alone in a laboratory. It is unsafe and not recommended. FORMAT OF LABORATORY REPORT The purpose of the laboratory report is to provide information on the obtained results, analysis and interpretation and discussion of the results. The discussion and conclusions are definitely significant in a report because these sections deliver the knowledge you gained upon doing the experiments. For this particular laboratory, the following format is suggested: 1. Cover page 2. Objective 3. Introduction 4. Theory 5. Procedure 6. Results/Calculation 7. Discussion 8. Conclusion The template of the lab report is attached in the lab module. Detailed descriptions of every item are given below: 1. Cover page It should have the course name and number, the number and title of the experiment, group number and names of the team members and as well as the date of the report delivery. 2. Objective It should state main objective of this experiment. 3. Introduction Some of the background of this experiment needs to be stated. DO NOT REPEAT OR COPY INTRODUCTION FROM LAB MODULE. 4. Theory Complete analytical development of all important equations and concepts. DO NOT REPEAT OR COPY INTRODUCTION FROM LAB MODULE. 5. Procedure Schematic drawing of the experimental setup including all equipment. Outline step by step procedure how experiment was performed. 6. Results/Calculation This section deals with the management of data obtained after experiment. Data can be presented as a series of figures, tables, etc with descriptive text and numbered but no discussion. The best presentation of some data is graphical. Figures should be numbered. Each figure must have a caption following the number. ALL GRAPHS, BESIDE CAPTIONS, SHOULD HAVE CLEARLY LABELED AXES. 7. Discussion This section must emphasize on discussing the outcome of the experiment. It can be written in two ways: a) Compare the expected outcome of the experiment with theory or b) Make an appropriate graph on which the theory is represented and experimental data by points. A critical part of discussion is error analysis. In comparison of theory and experiment you may not get a perfect agreement. It does not necessarily mean that your experiment was failed. The results will be accepted, provided that you can account for discrepancy. Precision and accuracy of the instrument or your ability to read the scales may be one limitation. A part from this, data analysis requires you to open your mind and critical approach to your work and that routine methods may not be sufficient. 8. Conclusion The conclusions should contain several shorts statements closing the report. They should inform the reader if the experiments agreed with the theory. If there were differences between measured and expected results, explain possible reasons for these differences. You may also say what could have been done differently, how experiments may be improved, or make other comment on the laboratory report. EXPERIMENT 1 THERMAL CONDUCTIVITY OF LIQUID AND GAS 1.0 OBJECTIVE 1.1 To calibrate the unit by establishing the incidental heat transfer. 1.2 To determine the thermal conductivity of air and acetone. 2.0 INTRODUCTION The SOLTEQ® Thermal Conductivity of Liquid and Gas Unit (Model HE 156) has been designed for students to determine the thermal conductivity of various liquid and gas. Thermal conductivity data is of prime importance in designing heat exchangers. Heat transfer coefficients in these equipments are usually computed using correlations, which require thermal conductivity data. The thermal conductivity measurement unit for liquid and gas has been designed for student to determine the thermal conductivity of various liquid and gas by injecting the test fluid to the unit. 3.0 THEORY Conductivity is the ability of the given substance to transfer energy, in this case the thermal energy. Basically, the thermal conductivity can be measured by knowing the temperature difference between two known points of which heat flow is known. The basis of conduction heat transfer is Fourier’s Law. This law involves the idea that the heat flux, q, is proportional to the temperature gradient, ∂T in any direction, ∂n. Thermal conductivity, k, is the constant of proportionality; a property of materials that is temperature dependent, and A is the cross-sectional area normal to the heat flow, q kA T n (1) There are several experimental techniques used to determine the thermal conductivity of gas and liquid at steady state such as the hot wire method, the coaxial-cylinder method, the horizontal parallel flat-plate method, and the concentric sphere and sphere-cylinder method. The main principle of these methods is the employment of a thin layer of a test fluid enclosed between two surfaces that maintained at different temperatures. The apparatus is consists of two coaxial cylinders vertically placed and leaving a very small annular gap that is charged with the test fluid. The inner cylinder is heated with the electrical heater. As the thermal low across the gap is fairly radial, the governing equation is the Fourier equation, which relates heat output, Q, the inner cylinder temperature,T1, and outer cylinder temperature, T2 with the thermal conductivity, k, of test fluid : R ln 2 R1 Q k T1 T2 2L (2) where R1 and R2 are radius of the annulus, filled with the gas (R2> R1), and L is the length of cylinder. Figure 1: Heat conduction in coaxial cylinders method From the explanation, to find the thermal conductivity coefficient we must use Fourier’s Law as stated in equation (1). Solving for k we get, k qc dx A dT (3) For radial heat conduction in a cylinder, dx become dr , and area A , is the cross sectional area of a conducting path. At the steady state conditions across the small radial gap, dr become Δr, dT become ΔT and we get, k qc r A T (4) In order to find the heat by conduction (qc) we can use the conservation of energy equation. When we applied it to this system we will get, qc q gen qlost Q qlost (5) By substituting equation (4) into equation (5), we get the following expression for qlost T qlost q gen qc Q kA r (6) We may assume qlost to be proportional to the temperature difference between the plug and the jacket. This assumption will be tested with a linear regression analysis, and estimate qlost from the calibration graph of incidental heat transfer versus the plug and jacket temperature difference. This analysis used the known thermal conductivity of air,kair . The thermal conductivity coefficient can then be calculated for other fluids by the temperature difference across the fluid. 4.0 MATERIALS AND EQUIPMENTS 4.1 Thermal conductivity of liquid and gas unit Figure 2: Thermal Conductivity for Liquid and Gas Unit 1. Thermocouple Sensors 5. Cooling water intlet 2. Sample Port (Top) 6. Heater 3. Cooling water Control Valve 7. Sample Port (Bottom) 4. Cooling water outlet Figure 4 Figure 3: Construction of Thermal Conductivity of Liquid and Gas Unit 5.0 PROCEDURES 5.1 Experiment 1: Calibration of the thermal conductivity study unit 5.2.1 Use air as the sample for the calibration. 5.2 Experiment 2: Determination of thermal conductivity of liquids and gases 5.2.1 Use air as the sample of the experiment. 5.2.2 The power regulator to about 25 watt. 5.2.3 Record the power and temperature readings (T1 to T2) 5.2.4 Repeat the experiment by substituting the air with acetone with the heating power of 100 watt. 6.0 RESULTS AND CALCULATIONS 6.1 Plot a calibration graph of incidental heat loss, qlost versus temperature difference (Data of Experiment 1). Make sure to draw the straight line at zero intercept. 6.2 Use slope of the graph to calculate qlost in Experiment 1 for both air and acetone: 6.3 Calculate thermal conductivity of air and acetone and compare the value with the theoretical. 7.0 QUESTIONS 7.1 Explain why the gap between the two cylinders is small? 8.0 CONCLUSION 8.1 Based on the experimental procedure done and the results taken draw some conclusions to this experiment. EXPERIMENT 2 LINEAR AND RADIAL HEAT CONDUCTION 1.0 OBJECTIVES 1.1 To investigate the thermal conductivity and thermal contact resistance of brass in linear direction. 1.2 To investigate the thermal conductivity of brass in radial direction. 2.0 INTRODUCTION The Linear and Radial Heat Conduction Apparatus is designed for students to study the principles of conduction heat transfer. The student is able to determine the relationship between the rate of heat transfer and temperature gradient, the crosssectional area and length of the conducting path and thermal conductivity of the material. 3.0 THEORY 3.1 Heat Distribution in a Plane Wall The temperature distribution in the wall can be determined by solving the heat equation with the proper boundary conditions. For steady state conditions with no distributed source or sink within the wall, the form of the heat equation is: d dT kt 0 dx dx (1) For one-dimensional, steady-state conduction in a plane wall with no heat generation and constant thermal conductivity, the temperature varies linearly with x: q x kt A dT kt A TA TB dx L (2) Where; k - thermal conductivity A - cylindrical area of specimen L - heat traveling distance TA - temperature near heater TB - temperature further heater Thermal Resistance Thermal resistance for conduction in a plane wall is given as: Rt ,cond TA TB L qx kt A (3) Contact Resistance Although neglected until now, it is important to recognize that, in composite systems, the temperature drop across the interface between materials may be appreciable. This temperature change is attributed to what is known as the thermal contact resistance. Rt",c TA TB q"x (4) where q”x = qx/A (5) 3.2 LINEAR HEAT CONDUCTION The rate of linear conduction heat transfer for the system is shown in equation (2). 3.3 RADIAL HEAT CONDUCTION The rate of radial conduction heat transfer for this system ; qr 2Lkt TA TB l n rB / rA Where; L - specimen cylinder thickness rA - radius further heater rB - radius near heater (6) 4.0 EQUIPMENT AND SPECIFICATIONS 4.1 Equipment A L K B J C I D E F G H Figure 1 : Linear and Radial Heat Conduction Apparatus A = Extra 30mm test length B = Thermocouples C = Linear heat conduction tester D = Thermocouple ports E = Temperature meter F = Selector switch G = Power meter H = Power regulator I = ON/OFF switch J = Heater cable K = ON/OFF switch for linear or radial selection L = Radial heat conduction tester 4.2 Specifications 4.2.1 Linear Heat Conduction You might need this information for calculation: A = πD2/4, D = 0.0254 m Measuring Point Distance from Heater (mm) 1 15 2 25 3 35 4 45 5 55 6 65 4.2.2 Radial Heat Conduction You might need this information for calculation: L = 0.003 m Measuring Point Radius, (mm) 1 0 2 10 3 20 4 30 5 40 6 50 5.0 EXPERIMENTAL PROCEDURES 5.1 Experiment 1 :To investigate the thermal conductivity and thermal contact resistance of brass in linear direction. 5.1.1 Set the power of the heater to 15 W. 5.1.2 Wait for 25 to 30 minutes until the temperature achieved at every measuring point is stable. 5.1.3 Record the respective final temperature values at every point. 5.2 Experiment 2 : To investigate the thermal conductivity of brass in radial Direction. 5.2.1 Set the power of the heater to 15 W. 5.2.2 Wait for 25 to 30 minutes until the temperature achieved at every measuring point is stable. 5.2.3 Record the respective final temperature values at every point. 6.0 RESULTS AND CALCULATIONS 6.1 Determine the thermal conductivity of both experiments. 6.2 Determine the thermal contact resistance for experiment 1. 6.3 Show the temperature profile (graph) of both experiments. 7.0 CONCLUSIONS 7.1 Discuss /compare the thermal conductivity values obtained for linear and radial heat conduction. EXPERIMENT 3 FREE AND FORCE CONVECTION HEAT EXCHANGER 1.0 OBJECTIVES 2.1 To demonstrate the relationship between power input and surface temperature in free and force convection. 2.2 To demonstrate the use of extended surface to improve heat transfer from the surface. 2.0 INTRODUCTION Heat transfer by simultaneous conduction and convection, whether free or force, forms the basis of most industrial heat exchangers and related equipment. The measurement and prediction of heat transfer coefficients for such circumstances is achieved in the Free and Force Convection Heat Exchanger Apparatus by studying the temperature profiles and heat flux in an air duct with associated flat and extended transfer surfaces. The vertical duct is so constructed that the air temperature and velocity can be readily measured, and a variety of “plug-in” modules of heated solid surfaces of known dimensions can be presented to the air stream for detailed study. A fan situated at the top of the duct provides the air stream for forced convection experiments. Using the instrumentation provided, free and forced convective heat transfer coefficients may be determined for: 1. A flat surface 2. An array of cylinders (pinned heat sink) 3. An array of fins (finned heat sink) 3.0 THEORY 3.1 Free Convection A heated surface dissipates heat primarily through a process called convection. Heat is also dissipated by conduction and radiation, however these effects are not considered in this experiment. Air in contact with the hot surface is heated by the surface and rises due to a reduction in density. The heated air is replaced by cooler air which is in turn heated by the surface and rises. This process is called free convection. The hotter the temperature of the surface, the greater the convective currents and more heat (power) will be dissipated. If more power is supplied to a surface, the temperature of the surface must rise to dissipate this power. 3.2 Forced Convection In free convection the heat transfer rate from the surface is limited by the small movements of air generated by this heat. More heat is transferred if the air velocity is increased over the heated surface. This process of assisting the movement of air over the heated surface is called forced convection. Therefore a heated surface experiencing force convection will have a lower surface temperature than that of the same surface in free convection, for the same power input. 3.3 Extended Surface Heat transfer from an object can be improved by increasing the surface area in contact with the air. In practice it may be difficult to increase the size of the body to suit. In these circumstances the surface area in contact with the air may be increased by adding fins or pins normal to the surface. These features are called extended surfaces. A typical example is the use of fins on the cylinder and head of an air cooled petrol engine. The effect of extended surfaces can be demonstrated by comparing finned and pinned surfaces with a flat plate under the same conditions of power input and airflow. 4.0 MATERIALS AND EQUIPMENTS 4.1 DESCRIPTION OF APPARATUS Figure 1: Free and Force Convection Heat Exchanger Apparatus. 1. Fan 3. RTD sensors 5. Panel 2. Air flow column 4. Portable Anemometer 6. Exchangeable Heat Transfer System 5.0 PROCEDURES 5.1 Experiment 1: To demonstrate the relationship between power input and surface temperature in free convection. 5.1.1 Place the flat finned heat exchanger in to the duct. 5.1.2 Record the ambient air temperature (tA), 5.1.3 Set the heater power control to 20 Watts. Allow sufficient time to achieve steady state conditions before noting the heated plate temperature (tH). 5.1.4 Repeat the procedure at 40, 60 and 80 Watts. 5.2 Experiment 2 : To demonstrate the relationship between power input and surface temperature in force convection (finned heat exchanger) 5.2.1 Set the heater power control to 50 Watts. Allow sufficient time to achieve steady state conditions before noting the heated plate temperature (tH). 5.2.2 Set the fan speed control to give a reading of 0.5m/s on the thermal anemometer. Record the heated plate temperature (tH). 5.2.3 Repeat this procedure at 1.0m/s and 1.5m/s. 5.3 Experiment 3: To demonstrate the use of extended surface to improve heat transfer from the surface. 5.3.1 Place the tube bundle plate heat exchanger into the duct. 5.3.2 Set the heater power control to 75 Watts. Allow the temperature to rise to 80°C, and then adjust the heater power control to 15 Watts until a steady reading is obtained. Record heated plate temperature (tH). 5.3.3 Set the fan speed control to give 1m/s. 5.3.4 Repeat this procedure at 2.0 and 2.5m/s. 6.0 RESULTS AND CALCULATION 6.1 For experiment 1, based on the data recorded, plot the graph of power against temperature (tH – tA). 6.2 For experiment 2 and 3, based on data recorded, plot the graph of air velocity against temperature (tH – tA). 7.0 QUESTIONS 7.1 Why is it necessary to set the fan speed to maximum before switch OFF the apparatus? 7.2 How does the extended surface for the plate heat exchanger will improve the heat transfer process? 7.3 Differentiate between free and forced convection. 7.4 Discuss the relationship between air velocity and surface temperature. 7.5 Discuss the relationship between powers dissipated and surface temperature. 8.0 CONCLUSION 8.1 Based on the experimental procedure done and the results taken draw some conclusions to this experiment. EXPERIMENT 4 PLATE HEAT EXCHANGER 1.0 OBJECTIVE 1.1 To determine of the effect of the parallel flow and counter flow arrangement to the system efficiency. 1.2 To determine the effect of flow rate variation on the plate heat exchanger. 2.0 INTRODUCTION The SOLTEQ® Heat Transfer Service Unit (Plate Heat Exchanger) (Model: HE104-P & HE104-P-A) has been designed specifically to demonstrate the working principles of industrial heat exchangers in the most convenient way possible in the laboratory classroom. The equipment consists of a plate heat exchanger mounted on a support frame. The external surface of the piping is insulated. Two temperature measuring devices are installed in both the inside and outside tubes to measure the fluid temperatures accurately. The flow rates are measured using independent flowmeters installed in each line. 3.0 THEORY Plate heat exchangers are used extensively in the food and beverage industries due to the fact that they are easily taken apart for cleaning and inspection. The general equation for heat transfer across a surface is: Q = U A ∆Tm (1) where, Q U A ∆Tm = = = = heat transfer per unit time, W the overall heat transfer coefficient, W/m2°C heat transfer area, m2. the mean temperature difference, the temperature driving force, °C The mean temperature difference is normally expressed in terms of log-mean temperature difference, For counter-current flow: Tlm T1 t 2 T2 t1 T t ln 1 2 T2 t1 (2) For co-current flow: Tlm ∆Tlm T1 T2 t1 t2 = = = = = T1 t1 T2 t 2 T t ln 1 1 T2 t 2 log mean temperature difference inlet hot water temperature outlet hot water temperature inlet cold water temperature outlet cold water temperature From the energy balance principle: Power Emitted = Power Absorb + Power Loss Where, Power Emitted, WE QH H CpH (TH ,in TH ,out ) Power Absorbed, WA QC C CpC (TC ,out Tc,in ) Efficiency for the system can be calculated by applying the following equation: Power Absorbed 100% Power Emitted Overall heat transfer coefficient, U Power Absorbed t m Area Where, Area = surface of contact area = (width x length) x (number of plates – 1) (3) An example of schematic diagram for the flat plate heat exchanger, which is described in detail is shown as below: Figure 1: Counter Current Flow Figure 2: Parallel 4.0 EQUIPMENT AND SPECIFICATIONS 4.1 Equipment 8 9 8 7 6 1 2 3 5 4 7 8 Figure 3: Rear view of the Heat Transfer Service Unit 1. 2. 3. 4. 5. 6. 7. 8. Pump Circulation Valve, V2 Pump Inlet Valve, V1 Water Tank Heater Level Switch Drain Valve Water Tank Cover 21 15 23 14 16 9 10 20 18 25 11 19 24 22 17 Figure 4: Front view of the Heat Transfer Service Unit 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. Temperature Controller Temperature Selector Main Switch Water Outlet Water Inlet Temperature Indicator Flow Meter ,FI1 Flow Meter, FI2 Flow Meter Control Valve, V7 Flow Meter Control Valve, V8 Control Valve Plate Heat Exchanger Temperature Sensor, T1 Temperature Sensor, T2 Temperature Sensor, T3 Temperature Sensor, T4 Temperature Sensor, T5 12 5 13 4.2 Specifications Area = Surface of contact area = (width x length) x ( number of plates – 1) = (0.1245 x 0.3099) x (4-1) = 0.116 m2 5.0 EXPERIMENTAL PROCEDURES 5.1 General Start-up Procedures 5.1.1 Heat up the water in the storage tank. 5.1.2 Open pump inlet valve, V1 5.1.3 V2 should be open partially for the water circulation to the storage tank. ( Do not switch on the pump without water SUPPLY as it will damage the pump) 5.2 Experiment 1: Parallel Flow Arrangement 5.2.1 Set hot water inlet temperature on the temperature controller at 60 C. 5.2.2 Position of the valves for parallel flow. 5.2.3 The cold water flow rate is set constant at 3 LPM. 5.2.4 Vary the hot water flow rate QH at 3, 6,9,11 LPM. 5.2.5 Record the hot and cold water temperatures at inlet and outlet once conditions have stabilized. 5.3 Experiment 2: Counter Current Flow Arrangement 5.3.1 Set hot water inlet temperature on the temperature controller at 60 C. 5.3.2 Position of the valves for counter current flow. 5.3.3 The cold water flow rate is set constant at 3 LPM. 5.3.4 Vary the hot water flow rate QH at 3, 6,9,11 LPM. 5.3.5 Record the hot and cold water temperatures at inlet and outlet once conditions have stabilized. 6.0 RESULT AND CALCULATION 1. Determine the system efficiency of parallel and counter current flow arrangement. 2. Show your calculations. 7.0 CONCLUSION 1. Compare the system efficiency of parallel and counter current flow. 2. Discuss the effect of flow rate variation on the plate heat exchanger operating performance. 8.0 APPENDIX Table 1: Properties of water (saturated liquid) °C 21.11 26.67 30.00 31.00 32.00 32.22 34.00 34.30 34.65 35.15 35.65 35.90 36.20 36.40 37.25 47.20 48.89 50.00 51.50 54.44 54.65 55.00 55.05 55.50 56.50 57.00 57.25 59.70 60.00 65.00 65.55 Cp kJ/kg. K 4.179 4.179 4.176 4.175 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.174 4.175 4.176 4.179 4.179 4.179 4.179 4.179 4.180 4.180 4.180 4.181 4.179 4.183 4.183 ρ kg/m3 997.40 995.80 995.26 995.10 994.94 994.90 994.23 994.14 993.99 993.83 993.61 993.53 993.38 993.35 993.02 989.42 988.80 988.18 987.36 985.70 985.61 985.46 985.42 985.22 984.71 984.48 984.41 983.16 983.30 980.60 980.30 EXPERIMENT 5 LIQUID DIFFUSION COEFFICIENT 1.0 OBJECTIVE 1.1 To determine the liquid diffusion coefficient of NaCl solution in distilled / de-ionized water. 2.0 INTRODUCTION ® The SOLTEQ Liquid Diffusion Coefficient Apparatus (Model: BP 09) has been designed for students experiment on the technique of determining diffusivity of sodium chloride solution in distilled water. A known concentration of sodium chloride solution is placed in a diffusion cell immersed in distilled water. A magnetic stirrer and a conductivity meter are provided to monitor the progress of diffusion over time. A plot of conductivity against time will allow for the determination of the liquid diffusivity. 3.0 THEORY When a concentration gradient exists within a fluid consisting of two or more components, there is a tendency for each constituent to flow in such a direction as to reduce the concentration gradient. This is called mass transfer. Mass transfer takes place in either a gas phase or a liquid phase or in both simultaneously. The rate of diffusion is given by: The –ve sign indicates that flow is from high to low concentration. The appropriate units shall be: The concentration at the lower ends chosen and taken to be constant and the concentration at the top end is effectively zero during the experiment. Therefore, Where, The slope obtained from the plot of conductivity as a function of time can be used to calculate the diffusivity. 4.0 EQUIPMENT AND SPECIFICATIONS 4.1 Equipment Figure 1: Diagram for liquid diffusion coefficient apparatus 4.2 Description and Assembly Before operating the unit and running the experiments, students must familiarize themselves with every components of the unit. Please refer to Figure 1 to understand the process. 5.0 PROCEDURES PART A : LIQUID DIFFUSION COEFFICIENT 5.1 Experimental Procedure 5.1.1 Prepare 1M, 2M, and 4M NaCl solutions. 5.1.2 Fill the diffusion cell with 1M NaCl solution. 5.1.3 Immersed the cell into the distilled water. 5.1.4 Take readings every 5 minute intervals until 30 minutes. 5.1.5 Repeat steps 5.2.1 to 5.2.6 for 2M and 4M NaCl solutions. 6.0 RESULTS AND CALCULATIONS 6.1 Plot Conductivity against Time. 6.2 Determine the liquid diffusivity of sodium chloride solution from the obtained slope, s. You need the information below to calculate the diffusivity: Volume of water,V = volume of water in diffusion vessel, L Length of capillaries, x = 0.5 cm Diameter of capillaries, d = 0.1 cm Number of capillaries, N = 97 6.3 Show your calculations. 7.0 CONCLUSIONS 7.1 Based on the experimental procedure done and the results taken draw some conclusions to this experiment. SCHOOL OF BIOPROCESS ENGINEERING UNIVERSITY MALAYSIA PERLIS ERT216: HEAT AND MASS TRANSFER TITLE OF EXPERIMENT: NAME: ___________________________________ MATRIX NO.:___________________________________ GROUP MEMBERS: ___________________________ ____________________________ ____________________________ ____________________________ DATE OF EXPERIMENT: _______________________ DATE OF SUBMISSION: ________________________ 1.0 OBJECTIVES 2.0 INTRODUCTION (Not Repetition from Lab Module.) 3.0 THEORY (Not Repetition from Lab Module.) 4.0 PROCEDURE (Simplify In Schematic Drawing) 5.0 RESULTS/CALCULATION 6.0 DISCUSSION 7.0 QUESTION 8.0 CONCLUSION