130

TELECHELIC POLYMERS

Vol. 12

TEMPLATE POLYMERIZATION

Introduction

The term “replica” polymerization for polymerization of simple vinyl monomers

was first used by M. Szwarc (1) in 1954, and then displaced by “matrix” or “template” polymerization (2). Since this time, many articles and reviews have been

published (3–11). The concept of template polymerization originates from natural processes such as DNA replication and the biosynthesis of proteins. As we

know, the growth of living organisms is associated with very complicated processes of polymerization. Low molecular weight substrates—such as sugars, amino

acids, fats, water in animals, and carbon dioxide in plants—are precursors of

polymers (polypeptides, polynucleic acids, polysaccharides, etc.) (see POLYPEPTIDE

SYNTHESIS; POLYNUCLEOTIDES; POLYSACCHARIDES). They are organized in tissues

and are thus reproducible. In many biological reactions, such as DNA replication

Encyclopedia of Polymer Science and Technology. Copyright John Wiley & Sons, Inc. All rights reserved.

Vol. 12

TEMPLATE POLYMERIZATION

131

or polypeptide creation, not only are low molecular weight substrates and polymeric products present in the reaction medium, but also macromolecular compounds called matrices or templates which control the process. In spite of the fact

that only nonbiological systems are discussed here, the biological processes constitute an inimitable model for template polymerization of synthetic monomers. In

both cases, the process (synthetic or natural) is connected with the ability of two

polymers (template- and polymer-produced—often named the daughter polymer)

to form more or less stable interpolymer complexes.

Template polymerization is a particular case of a more general group of processes, such as polymerization in an organized system.

Many factors may affect the organization of monomer units during polymerization. For example, solid-state polymerization takes place when molecules of the

monomer are surrounded by molecules already organized in a crystal lattice. A

specific type of polymerization occurs on the surface of solids. Numerous monomers

with long hydrocarbon chains can form monolayers at the gas–water interface, and

are also oriented at the surface of the water. The polymerization of such organized

systems leads to the preparation of polymers with peculiar morphology and properties. It is the method for polymer synthesis in ultrathin films in different form.

Polymerization in the presence of minerals and clays is considered to have occurred on earth before life started. For instance, montmorillonite binds proteins so

strongly that they cannot be washed out without being destroyed. Another type of

polymerization of organized systems is polymerization in a liquid crystalline state.

However, in this article the term template polymerization will only be used

for one-phase systems. The template is usually a linear preformed polymer added

to the polymerization system.

When studying template systems, it is important to compare the template

process and products of the reaction with conventional polymerization carried out

under the same conditions but in a system in which the template is replaced by a

low molecular nonpolymerizable analogue (blank reaction). The influence of the

template on the process and on the product is usually called the template effect or

the chain effect (3–6). The template effects can be expressed as follows:

(1) Kinetic effect: usually an enhancement of the reaction rate and changes in

the kinetic equation;

(2) Molecular effect: the influence on the molecular weight and molecular

weight distribution of the daughter polymer. In the ideal case, the degree

of polymerization of the daughter polymer is the same as the degree of

polymerization of the template used, which is sometimes called replication;

(3) Effect on tacticity: the daughter polymer may have a complementary structure to the structure of the template used;

(4) in the case of template copolymerization, the template effect deals with the

change in reactivity ratios and the sequence distribution of units. This effect

is very important in biological synthesis, for instance in DNA replication.

The template processes can proceed as template polycondensation, polyaddition, ring-opening polymerisation (qv), and ionic or radical polymerization (qv)

(6,7) and the general rules characteristic for these processes can be applied.

132

TEMPLATE POLYMERIZATION

Vol. 12

Radical Template Polymerization

Much information and experimental data have been published about radical template polymerization. It is generally accepted (3–11) that template polymerization

can proceed according to two different mechanisms: type I (the “zip” mechanism)

or type II (the “pick-up” mechanism). In the case of type I, monomer units are

connected to a template by strong forces (electrostatic, hydrogen bridges, or even

covalent bonds). This is illustrated in the following scheme:

(1)

In the type II case, the monomer at the beginning of the reaction is “free”

and polymerization starts outside the template. When oligoradicals reach a critical

length, complexation with the template occurs, and propagation proceeds along

the template by adding monomer molecules from the surrounding solution. This

is illustrated in the following scheme:

(2)

Vol. 12

TEMPLATE POLYMERIZATION

133

Tan and Challa (3,4) proposed using the relationship between the relative

polymerization rate Rrel and concentration of monomer or template as a criterion

for distinguishing between type I and type II template polymerization.

The most popular method is to examine the initial rate or relative rate Rrel

as a function of base mole concentration of the template, [T], at constant monomer

concentration [M].

For type I mechanism, when strong interactions exist between the monomer

and the template, Rrel vs [T] shows a maximum for [T] = [M]0 .

For type II mechanism, Rrel increases with [T] to the critical concentration

of the template, c∗ (the concentration at which template macromolecules start to

overlap) and then remains stable. It is worth noting that c∗ (concentration in moles

per volume) depends on the molecular weight of the template. The most complete

kinetic model for radical-initiated template polymerization has been developed

and described by Tan and Alberda van Ekenstein (12).

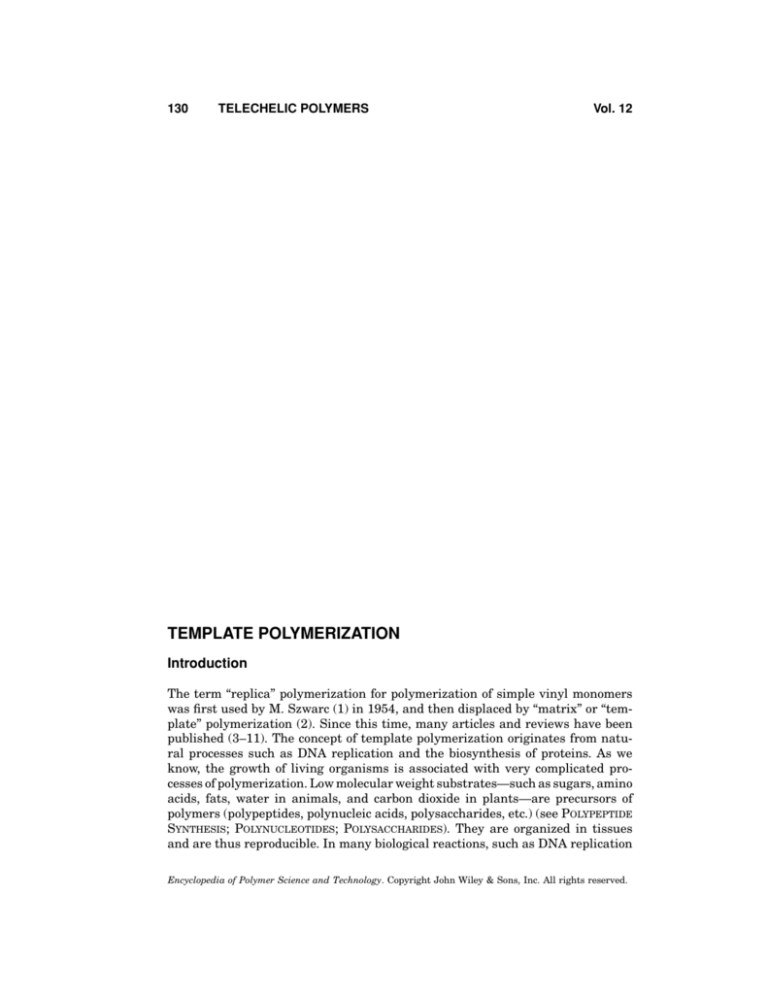

Typical examples of template polymerization systems are listed in Table 1.

The propagation and termination rate constants have been determined for

many systems (5,12,43–46). In most cases, the propagation rate constant is lower

than that for a reaction carried out in the same conditions but without a template.

The termination rate constant in the template polymerization is much lower in

comparison with the blank reaction. Retarded termination may be caused by retarded segmental diffusion of the template-bound radicals. This leads to the template increasing the overall rate of polymerization. Much experimental data from

the literature confirm this, and it is sometimes called the kinetic template effect.

It has been found that for many monomer–template–solvent systems, the

rate of reaction is proportional to the initiator concentration in power n and

monomer concentration in power m, as in simple radical polymerization (qv). However, exponents n and m in the presence of template are different in comparison

with the same system without the template.

An interesting case of template polymerization was described by Papisov and co-workers (47–49). The authors used two templates with different

strengths of interaction with respect to the daughter polymer. The first template

was poly(vinylpyrrolidinone) and the second, poly(ethylene glycol monolaurate).

Methacrylic acid was used as a monomer.

On the basis of kinetic measurements with various concentrations and ratios of both templates, the authors found that there are conditions in which

poly(methacrylic acid) molecules, in the course of growing, move from the strong,

but short poly(vinylpyrrolidinone) template to the weaker template—polyethylene

glycol monolaurate micelles. The circumstances of such a substitution reaction

(exchange reaction) are described by the equation

c1 K1ε1 = c2 K2ε

∗

(3)

where c1 and c2 are concentrations of template 1 [poly(vinylpyrrolidinone)] and

template 2 [poly(ethylene glycol monolaurate)], K 1 and K 2 are effective strength

constants for templates 1 and 2, and ε1 and ε ∗ are the corresponding degrees of

polymerization.

The template effect of tacticity has been shown by several authors (15,50–53).

These authors found that polymerization of methyl methacrylate in the presence

of isotactic poly(methyl methacrylate) proceeds as a template reaction. Extensive

Table 1. Typical Examples of Template Polymerization Systems

Monomer

Template

134

Acrylic acid

N-Vinylpyrrolidinone

Methyl methacrylate

Acrylic acid

Methacrylic acid

Methacrylic acid

Methacrylic acid

Poly(ethylene imine)

Poly(acrylic acid)

iso-Poly(methyl methacrylate)

Poly(ethylene glycol)

Poly(ethylene glycol)

Poly(4-vinylpyridine)

Poly(2-vinylpyridine)

Methacrylic acid

Poly(vinylpyrrolidinone)

Acrylic acid

p-Styrene sulfonic acid

Poly(vinyl pyrrolidinone-co-acrylamide)

Polybase ionenes

Vinyl sulfonic acid

Methacrylic acid, acrylic acid

Sodium acrylate

Sodium vinyl sulfonate

Acrylic acid, sodium styrenesulfonate

N-Vinylpyridine

N-Vinylimidazole

N-Dimethylaminoethyl methacrylate

Acrylic acid

Monomer with uracil groups

Polybase ionenes

Polybase ionenes

Poly(allylamine) hydrichloride

Poly(allylamine) hydrichloride

Chitosan

Poly(acrylic acid)

Poly(methacrylic acid)

Poly(acrylic acid)

Poly(acrylic acid)

Polymer with adenine groups

a Bis(p-tert-butyl

cyclohexyl) dipercarbonate.

acid.

c 2,2 -Azobis(2-amidopropane) · 2HCl.

b 4,4-Azobis-4-cyanovaleric

Solvent

H2 O

DMF

DMF

H2 O

H2 O

DMF, DMSO,

dioxane

H2 O

H2 O

H2 O/isopropyl

alcohol

H2 O

H2 O

H2 O

H2 O

H2 O

H2 O/acetone

Set of solvents

pyridine

Initiator

Reference

K 2 S2 O8

K2 S2 O8

TBCPa

K 2 S2 O8

K 2 S2 O8

AIBN

AIBN

13

14

15

16

16,17

18

19–21

Na2 S2 O8 or

UO2 SO4 +

photo.

K 2 S2 O8

AIBN

22–24

ACAb

K 2 S2 O8

K2 S2 O8 AIBN

K 2 S2 O8

K 2 S2 O8

None

ABIAPc

AIBN + UV

AIBN

AIBN

26,27

28

29

30

31

32–34

35–39

40

41

42

25

26,27

Vol. 12

TEMPLATE POLYMERIZATION

135

examination of the template polymerization process led the authors to general

and important conclusions about the influence of molecular weight, the tacticity

of the template, and the temperature and nature of the solvent. It was found that

stereoregular poly(methyl methacrylate) can influence the microstructure of the

daughter poly(methyl methacrylate).

The template molecular effect was observed by Ferguson (15), who found

that the degree of polymerization of poly(acrylic acid) obtained in template polymerization onto poly(vinylpyrrolidinone) is remarkably similar to the degree of

polymerization of the template. These results were surprising even to the authors, since they suggest that monomer radical propagation starts at one end of

the template and continues to the other end of the templates when termination

occurs. This was explained by the authors (15) in terms of the possibility of longer

propagation of growing molecule in the presence of the higher molecular weight

of the template and the interaction of the growing molecule with two or more

template molecules.

The case described was rather exceptional, and was induced by the advantageous selection of initiator concentration. The dependence of the degree of

polymerization of the template on the degree of polymerization of the daughter polymer was examined (11) for polymerization of methacrylic acid onto

poly(vinylpyrrolidinone) in ethyl alcohol. In these experiments, fractions of

poly(vinylpyrrolidinone) were used. The degree of polymerization of the daughter

polymer can differ substantially from the degree of polymerization of the template

used.

In type I template polymerization, in its most extreme case when monomer

units are connected with the template by covalent bonds, the Brownian motion

of the monomer units is replaced by conformational changes of the template

molecules. Moreover, the distance between two monomer units is virtually independent of the overall concentration, and cannot be changed by dilution of the

template solution.

For this type of polymerization, Kämmerer found (54–56) that for the

oligomeric template, with an excess of azobisisobutyronitrile (AIBN), the reaction takes place according to a scheme which can be called a replication:

(4)

136

TEMPLATE POLYMERIZATION

Vol. 12

The template in this case was rather stiff, and excess of an initiator leads

to termination by primary radicals. In this case the degree of polymerization of

the daughter polymer was exactly the same as the degree of polymerization of the

template (not taking end groups into account).

Another example is the synthesis of a ladder polymer as examined in Reference 57. Poly(vinyl alcohol) esterified by methacrylic chloride was used as a

template. Polymerization can be represented by the following reaction:

(5)

The polymerization can begin in any of the groups present and may proceed in any direction. In other words, since the reactive groups, are independent

of one another and initiation occurs randomly, polymerization leads to isolated

reactive groups, which are both potential cross-linking sites and breaks in the

ladder structure. Cross-linking as an intermolecular reaction can be minimized

by conducting the reaction at an appropriate dilution. If, however, initiation is

not random but starts at one end of the template, we might expect to obtain a

very regular ladder structure. Such a case was considered by Bamford (2), but has

never been checked experimentally. Active radicals in multimonomer—poly(vinyl

methacrylate)—can be created from CCl3 end groups, in the presence of manganese carbonyl, Mn2 (CO)10 , by irradiation with light. The radicals would be expected to initiate selectively at one end of the template according to the following

reaction:

(6)

Template polymerization of multi-acrylate and multi-methacrylate with

longer spacers has been studied (58–61). The reaction proceeds according to the

Vol. 12

TEMPLATE POLYMERIZATION

137

following scheme:

(7)

It was found that neither the average molecular weight nor the distribution of molecular weights change during polymerization, provided the molecular

weight is high enough and the concentration is low (60,61). For multi-acrylates,

it was found that distribution of molecular weights is the same up to more than

50% of conversion of double bonds. This means that under correct conditions,

intermolecular reaction can be neglected and the polymerization proceeds as a

template process. However, for high conversion and high monomer concentration,

an increase of molecular weight takes place, and eventually the product becomes

insoluble and cross-linked. Very similar behavior was observed for the photopolymerization of multi-methacrylate (62). The kinetics of template polymerization

of multi-methacrylates, poly(2-methacryloyloxyethyl methacrylate) and poly(2acryloyloxyethyl methacrylate), have been studied.

Template polymerization for polypeptide synthesis was reported by Ballard

and Bamford (63) and described in detail in Reference 2. The substrate for the

synthesis was N-carboxy-α-amino acid anhydride (NCA). The first step consists

in the reaction of NCA with secondary amine on the end of the polypeptide template. The ring-opening process and the elimination of CO2 then proceeds as a

chain reaction. Valuable experimental material concerning the polymerization

of many different N-carboxyanhydrides initiated by many different polypeptides

(64–66) as well as by poly(vinyl pyridine) (67,68) was collected by Imanishi and

co-workers.

Sugiyama and co-workers (69,70) report a very interesting template process

by the ring-opening polymerization induced by radicals. The polyethylene template was connected with 2,2-diphenyl-4-methylene-1,3-dioxolane groups by the

covalent bonds. The process can be illustrated by the following reaction:

(8)

138

TEMPLATE POLYMERIZATION

Vol. 12

In this case the daughter polymer is not connected to the template either by

hydrogen bonds or covalent bonds.

Template Radical Copolymerization

In the literature there is less information about template copolymerization than

about template homopolymerization. However, the process seems to be very interesting on account of the fact that the template can influence not only the molecular

weight and tacticity of the daughter polymer but also the composition and distribution of units in the copolymer macromolecule. Two different schema of template

copolymerization can be considered. First, the template can be a homopolymer and

one or both monomers can interact with the template. Second, the template can

be a copolymer, or in the system two different templates exist. Literature in the

field is not numerous.

It was found that the composition and the distribution of units in copolymerization is controlled mainly by the propagation process. From this point of

view, equations have been formulated (71) concerning how the reactivity ratios

depend on the template concentration and individual reactivity rate constants of

monomers taking part in the template copolymerization process. However, if long

critical length is necessary for the adsorption of the growing macroradical onto

the template, any template effect can be destroyed (72).

It seems that the template effect can be pronounced only if interactions between at least one of the monomers is sufficiently strong. Examples of the systems

in which one or both monomers were connected with the template by covalent

bonds have been described (73–78). Copolymerization of multimonomers similar

to the oligomers described by Kämmerer with styrene leads to semiladder copolymers, and after hydrolysis to short-block copolymers (73).

Step-Growth Template Polymerization

Template polycondensation or template polyaddition is much less elaborated

than the chain template reaction. However, many cases of homo- and heteropolycondensation have been considered (11).

Strong interaction between monomers and the template is a prerequisite

for the template process, while in simple polycondensation high temperature

and low pressure is applied. However, in mild conditions using the direct polycondensation method it was demonstrated that terephthalic acid connected with

poly(4-vinylpyridine) (79), poly(ethylene oxide) (80), poly(vinylpyrrolidinone) (81)

and activated by triphenyl phosphite reacts with hexamethylenediamine, giving

polyamides with high molecular weight.

Another example of template polycondensation was described by Ogata

and co-workers (82–85). Polycondensation of dimethyl tartrate or dimethyl

muconate with hexamethylenediamine was increased by the presence of

poly(vinylpyrrolidinone) and poly(vinyl alcohol). It was also found that polysaccharides increase the polycondensation rate. It seems that hydroxyl groups play

a substantial role in the absorption of monomers onto the template.

Vol. 12

TEMPLATE POLYMERIZATION

139

Polycondensation of various amino acids by means of triphenyl phosphite in

the presence of poly(vinylpyrrolidinone) was also reported (86).

A very interesting method of polycondensation of active esters containing

nucleic acid bases with diamines was described by Hattori and co-workers (87).

Di-p-nitrophenyl methylsuccinate with thymine or theophylline was condensed

with piperazine. The reaction was carried out in a pyridine/methylene chloride

mixture or dimethyl formamide (DMF) in the presence of a copolymer of styrene

and styrene derivatives with adenine groups as a template. The strong interaction between the complementary groups (adenine in the template and thymine in

the monomer) leads to the template effect. The maximum acceleration effect was

observed for copolymers with adenine content about 54% in the case of polycondensation with piperazine.

It was found that the rate of reaction differed depending on the percentage

of adenine groups in the copolymer.

A template polycondensation of urea with formaldehyde in the presence of

acrylic acid was published by Papisov and co-workers (88–92). The authors suggest

that a complex with polyacid is formed during the reaction. The complex has a

different structure than does urea–formaldehyde resin mixed with poly(acrylic

acid). The reaction can be written as follows:

(9)

The theoretical consideration and models for a kinetic description of the

template reaction in biological systems was published by Simha and co-workers

(93). The model was constructed on the basis of addition reaction in order to apply

to the synthesis of biological molecules, for instance DNA replication.

Potential Applications

The most promising applications of template polymerization seems to be the production of materials in which the daughter polymer and the template together

form a final product, because the synthesis of polymers requiring further separation of the product from the template is not acceptable for industry. The template

process can be applied in order to produce a set of new materials on the basis of

ladder-type polymers, semi-adder copolymers, the properties of which are not yet

well known.

Template polymerization is a convenient way to produce polycomplexes and

polycomplex composites, polymer blends, and interpenetrating networks or networks with nonrandom distribution of cross-linking points.

The polycomplexes obtained by template polymerization have been used for

spinning fibers (27).

140

TEMPLATE POLYMERIZATION

Vol. 12

The quite remarkable properties of composites obtained by template polycondensation of urea and formaldehyde are described by Papisov and co-workers

(92). The structure and properties of such composites can be widely varied by

changing initial composition and reacting conditions.

Rätzsch (94) reported an application of template polymerization similar in

technique to photolithography. However, up to this point template polymerization

has not found any industrial application.

BIBLIOGRAPHY

“Template Polymerization” in EPSE 2nd ed., Vol. 16, pp. 554–569, by Y. Yong Tan and

G. Challa, Groningen University.

1. M. Szwarc, J. Polym. Sci. 13, 317 (1954).

2. C. H. Bamford, in R. N. Haward, ed., Developments in Polymerization, Applied Science

Publishers, London, 1979, p. 215.

3. G. Challa and Y. Y. Tan, Pure Appl. Chem. 53, 627 (1981).

4. Y. Y. Tan, in G. Allen and J. C. Bevington, eds., Comprehensive Polymer Science, Vol. 3,

Pergamon Press, Oxford, 1989, p. 245.

5. Y. Y. Tan and G. Challa, Macromol. Chem. Macromol. Symp. 10/11, 215 (1987).

6. S. Polowiński, in D. Bloor, R. J. Brook, M. C. Flemings, and S. Mahajan, eds.,

The Encyclopaedia of Advanced Materials, Pergamon Press, New York, 1994,

p. 2784.

7. S. Polowiński, in J. C. Salamone, ed., Polymeric Materials Encyclopedia, Vol. 11, CRC

Press, Boca Raton, Fla., 1996, p. 8280.

8. S. Polowiński, Template Polymerization, ChemTec Publishers, Toronto, 1997.

9. I. M. Papisov, in J. C. Salamone, ed., Polymeric Materials Encyclopedia, Vol. 6, CRC

Press, Boca Raton, Fla., 1996, p. 4038.

10. Y. Y. Tan, Prog. Polym. Sci. 19, 561 (1994).

11. S. Polowiński, Prog. Polym. Sci. 27, 537 (2003).

12. Y. Y. Tan and G. O. R. Alberda van Ekenstein, Macromolecules 24, 1641 (1991).

13. J. Ferguson and S. A. O. Shah, Eur. Polym. J. 4, 611 (1968).

14. V. S. Rajan and J. Ferguson, Eur. Polym. J. 18, 633 (1982).

15. R. Buter, Y. Y. Tan, and G. Challa, J. Polym. Sci., Part A-1 10, 1031 (1972).

16. I. M. Papisov, V. A. Kabanov, E. Osada, M. Leskano-Brito, J. Reimont, and A. N. Gvozdetskii, Vysokomol. Soj. 14, 2462 (1972).

17. J. Matuszewska-Czerwik and S. Polowiński, Eur. Polym. J. 8, 791 (1988).

18. K. Fujimori, G. T. Trainor, and M. J. Costigan, J. Polym. Sci. 22, 2479 (1984).

19. J. Smid, Y. Y. Tan, and G. Challa, Eur. Polym. J. 20, 887 (1984).

20. J. Smid, J. C. Speelman, Y. Y. Tan, and G. Challa, Eur. Polym. J. 21, 2141 (1985).

21. J. Smid, Y. Y. Tan, and G. Challa, Eur. Polym. J. 19, 853 (1983).

22. J. Matuszewska-Czerwik and S. Polowiński, Eur. Polym. J. 26, 549 (1990).

23. J. Ferguson and S. A. O. Shah, Eur. Polym. J. 4, 343 (1968).

24. N. Shavit and J. Cohen, in H. G. Elias, ed., Polymerization in Organized Systems,

Gordon Breach, London, 1977, p. 213.

25. J. Ferguson and C. McLeod, Eur. Polym. J. 10, 1083 (1974).

26. A. Blumstein, S. R. Kakivaya, and J. C. Salamone, J. Polym. Sci., Polym. Lett. Ed. 12,

651 (1974).

27. A. Blumstein, S. R. Kakivaya, K. R. Shah, and D. J. Wilkins, J. Polym. Sci., Polym.

Symp. 45, 75 (1974).

28. E. Tsuchida and Y. Osada, J. Polym. Sci., Polym. Chem., Ed. 13, 559 (1975).

Vol. 12

TEMPLATE POLYMERIZATION

141

29. P. Cerrai, G. D. Guerra, S. Maltini, and M. Tricoli, Macromol Rapid Commun. 15, 983

(1994).

30. M. G. Cascone, L. Lazzeri, N. Barbani, C. Cristallini, and G. Polacco, Polym. Int. 41, 17

(1996).

31. P. Cerrai, G. D. Guerra, M. Tricoli, S. Maltini, N. Barbani, and L. Petarca, Macromol.

Chem. Phys. 197, 3567 (1996).

32. K. A. Kabanov, K. V. Aliev, O. V. Kargina, T. J. Patrikeeva, and V. A. Kargin, J. Polym.

Sci., Part C 16, 1079 (1967).

33. V. A. Kabanov, O. V. Kargina, and V. A. Petrovskaya, Vysokomol. Soj., Ser. A 13, 348

(1971).

34. V. A. Petrovskaya, V. A. Kabanov, and V. A. Kargin, Vysokomol. Soedin, Ser. A 12, 1645

(1970).

35. H. T. Van de Grampel, Y. Y. Tan, and G. Challa, Makromol. Chem. Makromol. Symp.

21/22, 83 (1988).

36. H. T. Van de Grampel, Y. Y. Tan, and G. Challa, Macromolecules 23, 5209 (1990).

37. H. T. Van de Grampel, Y. Y. Tan, and G. Challa, Macromolecules 24, 3767 (1991).

38. H. T. Van de Grampel and G. Challa, Macromolecules 24, 3773 (1991).

39. H. T. Van de Grampel, Y. Y. Tan, and G. Challa, Template. J. Polym. Sci., Polym. Chem.

Ed. 30, 787 (1992).

40. Z. H. Ellatif, Polym. Int. 28, 301 (1992).

41. A. Chapiro and J. Dulieu, Eur. Polym. J. 13, 563 (1977).

42. M. Akashi, H. Takeda, Y. Inaki, and K. Takemoto, J. Polym. Sci., Polym. Chem. Ed. 17,

747 (1979).

43. J. Gons, E. J. Vorekamp, and G. Challa, J. Polym. Sci., Chem. Ed. 15, 1699 (1977).

44. J. Gons, E. J. Vorekamp, and G. Challa, J. Polym. Sci., Chem. Ed. 15, 3031 (1977).

45. J. Matuszewska-Czerwik and S. Polowiński, Eur. Polym. J. 28, 1481 (1992).

46. J. Matuszewska-Czerwik and S. Polowiński, Eur. Polym. J. 34, 557 (1998).

47. I. M. Papisov, N. A. Nekrasova, V. D. Pautov, and V. A. Kabanov, Dokl. Acad. Nauk

SSSR 214, 861 (1974).

48. I. M. Papisov, T. I. Nedyalkova, N. K. Avramchyk, and V. A. Kabanov, Vysokomol. Soj.,

A 15, 2003 (1973).

49. V. Baranovskii, Yu., N. N. Gnatko, A. A. Litmanowich, and J. M. Papisov, Vysokomol.

Soj. 31, 984 (1989).

50. R. Buter, Y. Y. Tan, and G. Challa, J. Polym. Sci., Polym. Chem. Ed. 11, 989 (1973).

51. R. Buter, Y. Y. Tan, and G. Challa, J. Polym. Sci., Polym. Chem. Ed. 11, 1003 (1973).

52. R. Buter, Y. Y. Tan, and G. Challa, J. Polym. Sci., Polym. Chem. Ed. 11, 1013 (1973).

53. R. Buter, Y. Y. Tan, and G. Challa, J. Polym. Sci., Polym. Chem. Ed. 11, 2975 (1973).

54. H. Kämmerer and A. Jung, Makromol. Chem. 101, 284 (1966).

55. H. Kämmerer and S. Ozaki, Makromol. Chem. 91, 1 (1966).

56. H. Kämmerer, I. Shukla, N. Önder, and G. Schurmann, J. Polym. Sci., Polym. Symp.

22, 213 (1967); S. Polowiński and G. Janowska, Eur. Polym. J. 11, 183 (1975).

57. R. Jantas and S. Polowiński, J. Polym. Sci., Part A: Polym. Chem. 24, 1819 (1986).

58. R. Jantas, J. Polym. Sci., Part A: Polym. Chem. 28, 1973 (1990).

59. R. Jantas, J. Szumilewicz, G. Strobin, and S. Polowiński, J. Polym. Sci., Part A 32, 295

(1994).

60. R. Jantas, S. Polowiński, and G. Strobin, Polym. Int. 37, 315 (1995).

61. A. Blasińska, S. Polowiński, and R. Jantas, Polym. Int. 42, 436 (1997).

62. R. Jantas and S. Polowiński, J. Polym. Sci., Part A: Polym. Chem. 27, 475 (1989).

63. D. G. H. Ballard and C. H. Bamford, Proc. Roy. Soc. Ser. A 236, 384 (1956).

64. Y. Imanishi, T. Sugihara, and T. Higashimura, Biopolymers 12, 1505 (1973).

65. Y. Imanishi, K. Kugimiya, and T. Higashimura, Biopolymers 12, 2643 (1973).

66. Y. Imanishi, K. Kugimiya, and T. Higashimura, Biopolymers 13, 1205 (1974).

142

TEMPLATE POLYMERIZATION

Vol. 12

67. K. Suzuoki, Y. Imanishi, and K. T. Higashimura, Biopolymers 7, 925 (1969).

68. Y. Imanishi, S. Nagaoka, K. K. Suzuoki, and T. Higashimura, Biopolymers 12, 181

(1973).

69. J. Sugiyama, T. Yokozawa, and T. Endo, Macromolecules 27, 5536 (1994).

70. J. Sugiyama, T. Yokozawa, and T. Endo, J. Am. Chem. Soc. 115, 2041 (1993).

71. S. Polowiński, J. Polym. Sci., Polym. Chem. Ed. 22, 2887 (1984).

72. K. F. O’Driscoll and I. Capek, J. Polym. Sci., Polym. Lett. Ed. 19, 401 (1981).

73. S. Polowiński, in IUPAC Conference, Budapest, Vol. 3, 1969, p. 171.

74. S. Polowiński and G. Janowska, Eur. Polym. J. 11, 183 (1975).

75. S. Polowiński, Eur. Polym. J. 14, 563 (1978).

76. S. Polowiński, Polimery 17, 409 (1972).

77. R. Jantas, J. Polym. Sci., Part A: Polym. Chem. 28, 1973 (1990).

78. R. Jantas and J. M. S. Pure, Appl. Chem. A 29, 557 (1992).

79. F. Higashi, Y. Nakano, M. Goto, and H. Kakinoki, J. Polym. Sci., Polym. Chem. Ed. 18,

851 (1980).

80. F. Higashi, Y. Nakano, M. Goto, and H. Kakinoki, J. Polym. Sci., Polym. Chem. Ed. 18,

1099 (1980).

81. F. Higashi and Y. Taguchi, J. Polym, Sci., Polym. Chem. Ed. 18, 2875 (1980).

82. N. Ogata, K. Sanui, H. Nakamura, and H. Kishi, J. Polym. Sci., Polym. Chem. Ed. 18,

933 (1980).

83. N. Ogata, K. Sanui, H. Nakamura, and H. Kishi, J. Polym. Sci., Polym. Chem. Ed. 18,

939 (1980).

84. N. Ogata, K. Sanui, and M. Abe, J. Polym. Sci., Polym. Chem. Ed. 19, 1361 (1981).

85. N. Ogata, K. Sanui, H. Tanaka, H. Matsuto, and F. Iwaki, J. Polym. Sci., Polym. Chem.

Ed. 19, 2609 (1981).

86. N. Yamazaki and F. Higashi, Adv. Polym. Sci. 38, 1 (1981).

87. M. Hattori, H. Nagagawa, and M. Kinoshita, Makromol. Chem. 181, 2325 (1980).

88. I. M. Papisov and A. A. Litmanovich, Adv. Polym. Sci. 90, 139 (1989).

89. K. I. Boliachevskaya, A. A. Litmanovich, and I. M. Papisov, Polym. Sci. B 37, 424 (1995).

90. I. M. Papisov, O. E. Kuolvleva, S. V. Markov, and A. A. Litmanovich, Eur. Polym. J. 20,

195 (1984).

91. A. A. Litmanovich, S. V. Markov, and I. M. Papisov, Vysokomol. Soj. 28, 1271 (1986).

92. I. M. Papisov, A. A. Litmanovich, K. I. Boliachevskaya, Yu, S. Yablokov, I. A. Prokofiev,

O. Ya. Litmanovich, and S. V. Markov, Macromol. Symp. 106, 287 (1996).

93. R. Simha and J. M. Zimmerman, J. Moacanin, J. Chem. Phys. 39, 1239 (1963).

94. M. Rätzsch, in Abstracts 30th IUPAC Symposium on Macromolecules, The Hague, the

Netherlands, 1985, p. 37.

STEFAN POLOWIŃSKI

Technical University of Lódz

TEST METHODS.

See Volume 8.

TETRAFLUOROETHYLENE POLYMERS.

See PERFLUORINATED POLYMERS.

THERMAL ANALYSIS.

See ARTICLE ONLINE.