2012 Corporate Responsibility Report

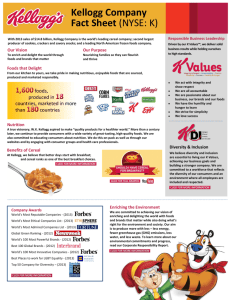

advertisement