StreamVane - Aerospace America

advertisement

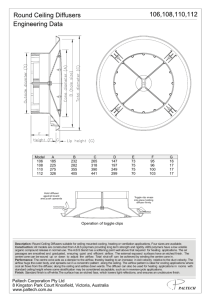

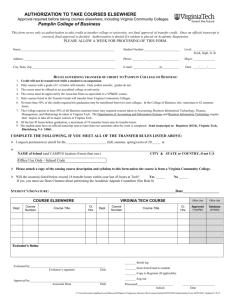

Distorting airflows on purpose Drawing up exotic, environmentally friendly airliner shapes won’t do much good if no one has an engine that can handle the distorted airflow. Henry Kenyon explains how a university team built a device that promises to expose such engine incompatibilities and save scarce research dollars in the process. NASA is researching designs for nextgeneration commercial aircraft through its Environmentally Responsible Aviation program, but there’s a catch: Some of the engineering models require inlets that are bent to match the shape of the plane’s wing or fuselage. Others are recessed into the fuselage or mounted above the aircraft’s wings. These engine and body configurations could improve fuel economy and reduce engine noise, but they come with a price. Serpentine or recessed inlets can cause airflow distortions. Mounting engines next to the Airflow distortion in a serpentine inlet is illustrated by a computational fluid dynamics simulation. As air flows through the duct, a counter-rotating twin swirl pattern develops near the top of the inlet. 10 AEROSPACE AMERICA/MARCH 2015 fuselage or over a wing can subject them to turbulent air. Engine designers need to know how these configurations will turn and swirl the air as it passes through the inlet to the engine turbine blades, so that they can predict whether these distortions are likely to result in reduced engine per- formance, unacceptable blade wear or proving that specific jet engines can Although advanced aircraft designs an increased risk of the blades failing tolerate the distortion produced by have been around for decades, there catastrophically. They can then get to the inlets of their host aircraft. Streamwas a missing technological compowork designing out these incompatiVanes also might replicate airflow nent — the ability to model airflow bilities or better yet finding a way to over propellers for fixed wing aircraft distortions for maximum perfortake advantage of the distortions to and helicopters. In fact, developers mance advantages, Lowe says. improve fuel efficiency. say requests for 3-D-printed StreamDeveloping StreamVane was not The trouble is, it would be costly Vanes are beginning to pour in. easy. For starters, the team needed to and time-consuming to build all these The devices allow engineers to digitally represent the airflow of a proposed inlets to scale and test them rapidly model new engine configuraspecific inlet in three dimensions, in wind tunnels with various engines, tions and modify them to either miticalled a profile. This would require make adjustments to the engines and gate or take advantage of any airflow precise measurements, which was test them again. Lowe’s specialty on the Engineers at Virginia StreamVane team. Virginia Tech set out in 2009 to solve Tech researchers used comthis problem with funds from putational fluid dynamics NASA as part of the ERA proand particle image velocimgram. The Virginia Tech enetry to track airflow and gineers saw that the ERA dedistortions. PIV measuresigns showed promise, but ments are made by seeding “there were certain enabling the flow with tiny liquid technologies that weren’t particles, explains O’Brien, there,” says K. Todd Lowe, an the principal researcher. assistant professor at Virginia These particles are usually a Tech’s Department of Aerotype of dye that can be space and Ocean Engineertracked visually. PIV meaing. One of the missing sures how clouds of these pieces was a low-cost way to particles move during very replicate airflow distortions. small time intervals and The Virginia Tech team then uses that data to create came up with a device called an airflow model. a StreamVane — a circular Researchers initially high-strength plastic screen plugged their real-world unthat can be fitted over an enderstanding of these swirlgine inlet to produce the ing, vortical airflows and same airflow profiles as spe- A StreamVane replicates airflow distortions of specific inlet designs in a wind tunnel. their related mathematics cific inlet designs. Each This one was made with a 3-D printer. into computer simulation StreamVane is made by an software such as MATLAB, industrial three-dimensional CFX and CFD to model airprinter according to a digital design. distortions. Money is saved that would flow and distortion dynamics. StreamVanes were developed and otherwise be spent building a series of A Virginia Tech mechanical engitested in Virginia Tech’s large wind physical prototypes. StreamVanes can neering masters student, Kevin Hoopes, tunnel. The devices were installed on also replace or be used together with devised a “push button” technique for the university’s PWC JT-15D jet turpressure screens, which have been the exporting the airflow profiles into a bine engines, which it maintains for standard airflow tool, explains Walter F. computer-aided design tool, says Lowe. research purposes. Because the O’Brien, a Virginia Tech professor of Each StreamVane is designed within StreamVanes are made in an industrial mechanical engineering and the prothat tool so it can be printed in three 3-D printer, they can be made of algram’s principal researcher. The key dimensions. At first, a small-scale most any material. Researchers hope difference is that pressure vanes do not StreamVane is printed and tested in a to make future StreamVanes from produce airflow distortions, which is small wind tunnel to make sure that it spray-deposited titanium. the main purpose of the StreamVane. creates the desired distortions and airIf the results of ongoing design The StreamVane team expects flow patterns. “It’s just like any sort of tests are good, ERA designers could the technology to be a key part of engineering program — there’s a layer soon have a new, low-cost method for designing next-generation aircraft. of experimentation and testing prior to AEROSPACE AMERICA/MARCH 2015 11 doing the full-blown applicathrusts, Lowe says. One is tion,” Lowe says. fundamental and applied reFor now, Virginia Tech search toward better turbine plans to use the StreamVane fans. The school is also being technology to focus on jet enapproached by industry and gine and inlet research. “We government to provide them actually are going to change with StreamVanes. For 2015, our engines here, based on the university has multiple what we think we should StreamVane orders from Boedo,” O’Brien says. ing and NASA. O’Brien contends that Virginia Tech has copythe StreamVane technology righted the StreamVane procould be very useful for cess. The university will build a StreamVane to order for labs companies developing new jet engines or airframes. For and universities wanting to example, if a company use the technology. Several of wanted to install or test a jet the devices have already been engine on a new airframe, a In a low-speed wind tunnel test, a StreamVane is mounted in a 6-inch-diameter built. In the future, it may be PVC pipe. An external motor can rotate the StreamVane to any angle. StreamVane could be applied possible that customers could craft’s performance, says O’Brien. to determine if there is distortion and acquire the software to make StreamBesides supporting research, the whether the engine will work with Vanes on their own printers, “but we StreamVane has turned out to be a that distortion. aren’t there yet,” O’Brien says. Henry Kenyon product that the university can supply Handled properly, inlet airflow hkenyon@hotmail.com to customers. There are currently two distortion can actually increase an air- Earn the Respect of your Peers and Colleagues Advance Your Membership The distinction you gain with each membership advancement earns the respect of your peers and employer – and bolsters your reputation throughout the industry. AIAA Members who have accomplished or been in charge of important engineering or scientific work and who have made notable valuable contributions to the arts, sciences, or technology of aeronautics or astronautics are encouraged to apply. ASSOCIATE FELLOW Accepting Nomination Packages: 15 December 2014 – 15 April 2015 FELLOW Accepting Nomination Packages: 1 January 2015 – 15 June 2015 HONORARY FELLOW Accepting Nominations Packages: 1 January 2015 – 15 June 2015 SENIOR MEMBER Accepting Online Nominations monthly For more information and requirements, please visit http://www.aiaa.org/Honors or contact Patricia A. Carr, Program Manager, Membership Advancement Program, at triciac@aiaa.org or 703.264.7523 12 AEROSPACE AMERICA/MARCH 2015