computational studies of the virginia tech hypersonic wind tunnel

advertisement

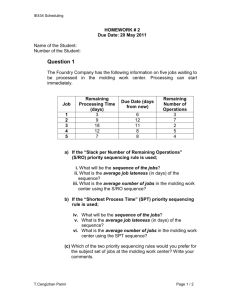

COMPUTATIONAL STUDIES OF THE VIRGINIA TECH HYPERSONIC WIND TUNNEL Rui Chen Department of Aerospace & Ocean Engineering, Virginia Tech, Blacksburg, VA Abstract Introduction This paper presents steady-state (viscous) and timeaccurate (inviscid) numerical solutions of the flowfield inside the Virginia Tech Hypersonic Wind Tunnel (VTHST) with a Mach 4 nozzle. The numerical solutions are obtained using a computational fluid dynamics (CFD) solver named GASP. Comparisons between the steady-state CFD solutions and available experimental data are also presented in this paper. The first objective of my research is to study the steadystate flowfield characteristics of the VTHST. The second objective of my research is to simulate the supersonic wind tunnel starting process, which has seldom been simulated using CFD. I was able to obtain reasonable Mach contours with my steady-state CFD calculations. However, I determined that steady-state CFD calculations cannot accurately predict the flowfield inside the VTHST because much higher pressure ratios (the total pressure in the settling chamber divided by the back pressure at the diffuser exit) are required to start the VTHST in steady-state CFD calculations than those required to start the actual tunnel. Currently, I am running time-accurate calculations for the VTHST with a Mach 4 nozzle. Although the calculations are still in progress, it seems that the VTHST can start at the correct pressure ratio in the time-accurate calculations. The Virginia Tech Hypersonic Wind Tunnel (VTHST) shown in Figure 1 is a unique intermittent blowdown tunnel designed and built by the Institute of Theoretical and Applied Mechanics (ITAM) in Novosibirsk, Russia. It is capable of creating Mach 2 to Mach 7 flow inside its test section for approximately 1.5 seconds per run. The VTHST has been used for researches related to direct-measuring skin friction gage and Scramjet. However, the ITAM only provided limited experimental and calculated flowfield data to researchers at Virginia Tech. Therefore, one objective of my research is to use a computational fluid dynamics (CFD) solver to calculate the characteristics of the flowfield inside the VTHST, such as the Mach number and pressure profiles inside the test section to help researchers design their experiments. Heater Settling Chamber Nozzle Test Chamber Diffuser Silencer Gas Storage Bottles Notation pb poc Q T Diffuser (movable) = pressure at the diffuser exit (atmospheric) Figure 1: The VT HST and Its Test Chamber = settling chamber total pressure CFD is an ideal tool to study the flowfield inside the VTHST since it enables one to obtain the flow properties at any position inside the tunnel. However, sometimes it can be difficult to get the CFD solution to converge. Even if the solution converges, it may not be the correct one. For example, although I was able to obtain steady-state solutions for the VTHST with Mach 4, 6 and 7 nozzles, the pressure ratios ( poc / pb ) = conservative variable = time required to start the tunnel are much higher in my steady-state CFD calculations than those required to start the real tunrrrnel. 1 time. This modification should not change the overall flow characteristics of the tunnel significantly. The diffuser is inside the test chamber, and it is 200mm from the nozzle exit. Figure 3 shows the grid of the test chamber for the steady-state calculation. The grid for the entire VTHST model for the steady-state calculation has 166400 cells. The supersonic wind tunnel starting process is a complex phenomenon. After the Mach number at the nozzle throat becomes 1.0, a nearly normal shockwave moves from the diverging part of the nozzle into the test chamber. Eventually, the diffuser will “swallow” the shock and the flow inside the test chamber achieves the designed conditions. Since the supersonic wind tunnel flow is inherently an unsteady process, another way to obtain the steady-state flowfield solution is to perform time accurate calculations. Although flowfield solutions take longer to obtain using time-accurate calculations than steady-state calculations, time accurate calculation should approximate more closely the physics of wind tunnel flow. In addition, the results of time-accurate calculations can be used to study the supersonic wind tunnel starting process, which has seldom been simulated using CFD. This paper presents the results of viscous steadystate CFD calculations for the VTHST with a Mach 4 nozzle, as well as some results of the inviscid timeaccurate calculation with the Mach 4 nozzle, which is still in progress Viscous effects are not included in the time-accurate calculation because it is believed that viscous effects do not play a significant role in the supersonic wind tunnel starting process. However, in my future studies, I would like to verify this assumption. The Mach number profile at the nozzle exits obtained using steady-state calculation is also compared with available experimental data. Nozzle Test Chamber Diffuser Figure 2: Boundary of the Grid for Steady-state Calculation Figure 3: Test Chamber Grid for Steady-state Calculation As shown in Figure 4, for the inviscid time-accurate calculation, a conical settling chamber is added in front of the axi-symmetrical Mach 4 nozzle, test chamber and diffuser assembly. The position of the diffuser is the same as that in the steady-state calculation. The real settling chamber consists of a constant area duct followed by a converging nozzle. However, since the exact geometry of the real settling chamber is not available, a conical settling camber with approximately the same volume is used in the CFD calculation. Figure 5 shows the grid of the test chamber for the timeaccurate calculation. The grid for the entire VTHST model for the time-accurate calculation has 10477 cells. The VTHST and Grid Generation Introduction to the VTHST The VTHST is an intermittent blowdown wind tunnel. The overall length of the VTHST is 13 feet, and it features a 14X7.9X8.9in. enclosed free-jet test chamber. All parts of the VTHST are axi-symmetric except for the test chamber. Before each run, the eight storage bottles (11.3ft.3) are filled with working gas to pressures ranging from 130 to 150atm. A time control device switches on the main valve, and gas enters the heater, and exhausts into the room. The VTHST also features six replaceable nozzles with an exit diameter of 3.9in. designed for Mach 2.0 to 7.0 flows. The diffuser can be moved back and forth inside the test chamber to accommodate a variety of model sizes. Settling Chamber Nozzle Test Chamber Diffuser Figure 4: Boundary of the Grid for Time-accurate Calculation Figure 5: Test Chamber Grid for Time-accurate Calculations Grid Generation The grids for my CFD calculations are generated using Pointwise’s Gridgen 15. For the viscous steadystate calculations, as shown in Figure 2, the grid consists of axi-symmetrical Mach 4 nozzle, test chamber and diffuser. The rectangular test chamber is modeled as axi-symmetric to reduce computational Flowfield Modeling The CFD calculations are performed using AeroSoft’s GASP (General Aerodynamic Simulation Program), which solves the Reynolds Averaged NavierStokes Equations (RANS). GASP has been used in a wide variety of applications such as Scramjet 2 contour). To make the calculation as realistic as possible, the boundary condition at the diffuser exit is set to “Pback Subsonic Outflow” before the working gas starts to exit the diffuser. Then the boundary condition is set to “1st Order Extrapolation”. As will be shown in the next section, the tunnel will not start if the “Pback Subsonic Outflow” boundary condition is used alone. In addition, “1st Order Extrapolation” cannot be used alone because the back pressure influences the flow properties inside the tunnel before the flow exits the diffuser. When the gas starts to exit the diffuser, exhaust plume near the boundary occurs outside of the computational domain, and thus may alter the boundary condition. Using “1st Order Extrapolation” will enable the calculation to continue realistically without having to model the exhaust plume. The inviscid flux scheme used in my calculation is Roe. First order spatial accuracy is used to make the solution converge faster and more easily. Implicit dual time stepping algorithm with 2nd order temporal accuracy is used to obtain the time-accurate solutions. Gauss Seidel is used for both implicit and inner iteration schemes. combustors and re-entry vehicle aerodynamics simulations. For my calculations, GASP was run on 8 processors in a SGI Origin 2000 parallel computer. In all the CFD calculations, the working gas is air, and it is assumed to be a perfect gas. Steady-state Calculation At the nozzle inlet, the Q (density, products of density and two components of velocity, and the internal energy) is fixed, but the turbulence variables are not fixed. This boundary condition at the inlet is referred to as “Fixed Q (not turbulence)” in GASP. This boundary condition requires the user to specify the pressure and Mach number at the boundary. Another boundary condition called “P0-T0 Subsonic Inflow” which fixes the total pressure and total temperature at the nozzle inlet could also have been used. But this boundary condition does not work well if the geometric contour near the boundary has large gradient such as that shown in Figure 2. The boundary condition at the tunnel walls are set to “no-slip and adiabatic”. Two boundary conditions are suitable for the diffuser exit. The first one is “Pback Subsonic Outflow”, which fixes the pressure at the diffuser exit at a user-specified value. This boundary condition can be used because the tunnel exhausts gas into the room atmosphere, and the flow inside the tunnel depends on the back pressure at the diffuser exit. The second option is to use “1st Order Extrapolation” boundary condition, which extrapolates the flow properties at the boundary from interior cells. By not enforcing a back pressure, the flow is not forced to slow down by adverse pressure gradient, thus the tunnel should be more likely to start. I have tried both boundary conditions in my calculations. The inviscid flux scheme used in my calculation is Roe, with 3rd order spatial accuracy and Van Albada limiter. The turbulence model used is Wilcox (1998) k − ω model. Gauss Seidel is used for both implicit and inner iteration schemes. Results and Discussions Steady-state calculation The back pressure is set to 94800Pa (0.93atm), the atmospheric pressure at Virginia Tech. The “Fixed Q (not turbulence)” boundary condition requires the user to input the pressure and the Mach number at the boundary. The Mach number at the nozzle inlet is set to 0.05 using the area-Mach number relation for quasi-1D flow. To start the tunnel, the pressure at the inlet is set to 27atm. This pressure is well above the settling chamber total pressure of 15atm, at which the real tunnel starts1. Figure 5 shows the Mach contour inside the test section when poc =15atm. Although the flow inside the nozzle achieves Mach 4, an oblique shock stands in the test chamber, and the tunnel is not started. Time-accurate Calculations Since disturbances can travel downstream of the diffuser exit before supersonic flow occurs in the nozzle, using the “P0-T0 Subsonic Inflow” boundary condition at the nozzle inlet should most closely approximate the physical situation. However, this boundary condition will not work with the geometry used for steady-state calculations as described in the previous section. So a conical settling chamber with a relatively small gradient in its contour is added in front of the nozzle inlet as shown in Figure 4. Since viscous effects are ignored in the time-accurate calculations, the boundary condition at the walls is set to “tangency” (the velocity vectors at the walls are tangent to the wall Figure 5: Test Chamber Mach Contour ( poc = 15 atm ) Figure 6 shows that the VTHST is still not started when poc is increased to 20atm. However, when the 3 VTHST to verify the Mach number profile at the nozzle exit. Poc is increased to 27atm, the tunnel is started as shown in Figure 7. The streamlines in Figure 7 shows that the flowfield is uniform in the Mach 4 region of the test section. The flow expands to Mach 6.0 after the Mach 4 region, and then slows down through an oblique shock at the diffuser inlet. Although the Mach contour in Figure 7 looks reasonable, the condition that produced the flow is far from the realistic condition. 5 Experimental Data (Ref. 1) CFD Prediction 4.5 4 3.5 y(cm) 3 2.5 2 1.5 1 0.5 0 2.5 3 3.5 4 4.5 5 Mach# Figure 6: Test Chamber Mach Contour ( Figure 8: Mach Number Profile at the Nozzle Exit for the Steady-state Calculation poc = 20atm ) T=0.0004sec. T=0.001sec. T=0.0018sec. Figure 7: Test Chamber Mach Contour and Streamlines ( T=0.0028sec. poc = 27 atm ) T=0.0038sec. To make the tunnel start, I also tried to set the diffuser exit boundary condition to “1st Order Extrapolation”, while leaving the nozzle inlet condition unchanged. However, the solution diverged before it reaches steady-state, and the Mach contour looked similar to that in Figure 5. The reason that the model tunnel cannot start at the correct poc may be caused by the fact that the tunnel T=0.004sec. T=0.0043sec. T=0.0083sec. starting process is inherently unsteady. A steady-state calculation cannot capture all the physics in the unsteady tunnel starting process, such as the moving shockwave, starting vortices and the change in boundary condition described in the flowfield modeling section. Figure 8 shows a comparison between experimental Mach number profile at the nozzle exit and the numerical prediction. As shown in Figure 8, the experimental and computed Mach number profiles outside of the boundary layer seem to agree. However, the measured boundary layer thickness is greater than that predicted by CFD. This discrepancy could either be due to errors in the experimental results presented in Ref. 1, or the turbulence model used in my CFD calculation. Experiments need to be performed in the T=0.015sec. T=0.020sec. T=0.0266sec. Figure 9: Flow Development in Time Time-accurate calculation The total pressure and total temperature for the “P0T0 Subsonic Inflow” boundary condition are set to 15atm (as in a real experiment) and 15oC respectively. The Mach number at the settling chamber inlet is set to 4 The time-accurate calculation is performed assuming inviscid flow because I believe that viscous effects do not play a significant role in wind tunnel starting process. However, in Ref. 3, Pope states that viscous effects are extremely important in the tunnel starting process. Thus, viscous effects will be modeled in my future studies to determine the importance of viscous effects in the supersonic wind tunnel starting process. 0.009 using the area-Mach number relation for quasi1D flow. The solution is saved every 0.0001 seconds. The flow reaches the diffuser exit at T=0.0031 seconds. Thus, the boundary condition from T=0.0001sec. to T=0.0031sec. is set to “Pback Subsonic Outflow”. “1st Order Extrapolation” boundary condition is used after T=0.0031sec. Figure 9 shows the Mach contour inside the VTHST from T=0.0008sec. to T=0.0266sec. As shown in Figure 9, the flow oscillates between the diverging section of the nozzle and the front of the test chamber from T=0.0018sec. to T=0.0043sec. After T=0.0043sec., the oblique shock starts to move toward the diffuser. At T=0.0266sec., the oblique shock is “swallowed” by the diffuser. But if the Mach contour at T=0.0266sec. is compared to Figure 7, one can see that the tunnel is still not started completely at T=0.0266sec. Experimental data from Ref. 1 shows that the timeaccurate calculation should be run until T=0.1sec. for the VTHST to achieve steady-state flow. Currently, the time-accurate solution diverges at T=0.0266sec. I am still trying to determine the cause of the divergence. One possible cause may be that the boundary conditions are still incorrect. There could also be some subtle problems with the grid. Figure 9 shows that, if the calculation is able to continue until T=0.1sec., time-accurate calculations may indeed make the VTHST start at a realistic pressure ratio. Before obtaining the solution shown in Figure 9, I run the time-accurate calculation with only the “Pback Subsonic Outflow” boundary condition, and 3rd order spatial accuracy instead of 1st order spatial accuracy. The solution diverged at T=0.026sec., and the Mach contour at T=0.026sec. is shown in Figure 10. From the time-accurate solution, the oblique shock seen in Figure 10 moves back and forth between the nozzle exit and its current position in Figure 10. As shown in Figure 10, if the “1st order Extrapolation” boundary condition is not used, there is little hope that the model tunnel can start. (a) 3rd Order Spatial Accuracy (b) 1st Order Spatial Accuracy Figure 11: Velocity Vector Near the Nozzle Inlet at T=0.0008sec. Conclusions Viscous steady-state and inviscid time-accurate CFD solutions of the flowfield inside the VTHST with a Mach 4 nozzle were presented in this paper. It is found that steady-state CFD calculations cannot accurately predict the flowfield inside the VTHST because much higher pressure ratios are required to start the VTHST in steady-state CFD calculations than those required to start the actual tunnel. Although currently the solution for the time-accurate calculation Figure 10: Mach Contour at T=0.026sec. Without using “1st Order Extrapolation” Boundary Condition Another interesting phenomenon associated with the tunnel starting process is starting vortex, which occurs when liquid or gas is starting to move around obstacles2. Figure 11 shows that one should use 3rd order spatial accuracy to capture starting vortices. 5 diverges at T=0.026sec., the time-accurate calculation seems to be able to make the tunnel start at the correct pressure ratio if the calculation could be run past T=0.026sec. It is also found that 3rd order spatial accuracy is needed to capture starting vortices near the nozzle inlet. Starting vortices do not occur in calculations with 1st order spatial accuracy. Currently, I am trying to make the time-accurate calculation run past T=0.026sec. Once I can get the inviscid and 1st order spatially accurate calculation to reach steady-state, I will add viscous effects into the computational model to investigate the importance of viscous effects in the supersonic wind tunnel starting process. In addition, 3rd order spatial accuracy will eventually be used to make my CFD simulation more realistic. Acknowledgement This research is supported by Virginia Space Grant Consortium (VSGC). I would like to thank my advisor Dr. Joseph Schetz for his help in my research, and Dr. Reece Neel of AeroSoft Inc. for his help in running GASP. References 1. 2. 3. ITAM, “Description and Specification of VT HST”, Novosibirsk, Russia, 2002. Luo, X and van Dongen M. E. H., “Strong Starting Vortices”, http://www.fluid.tue.nl/GDY/vortex/vortex.html. Pope, Alan and Goin, Kennith L., “High-Speed Wing Tunnel Testing”, John Wiley & Son Inc, 1965. 6