Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

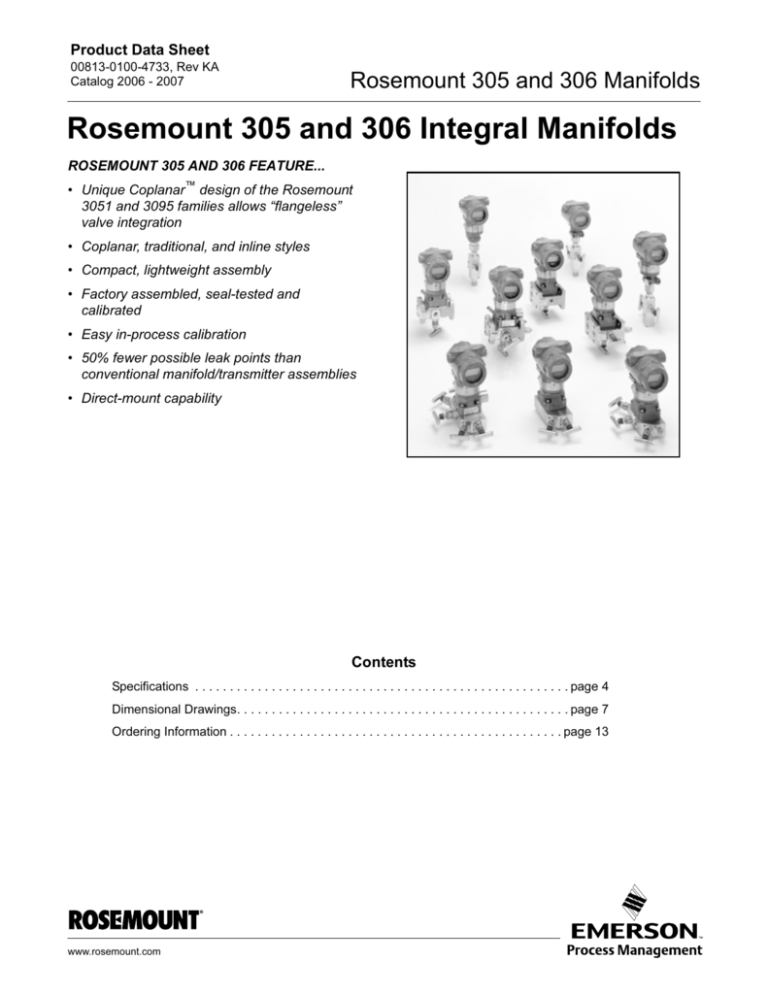

Rosemount 305 and 306 Integral Manifolds

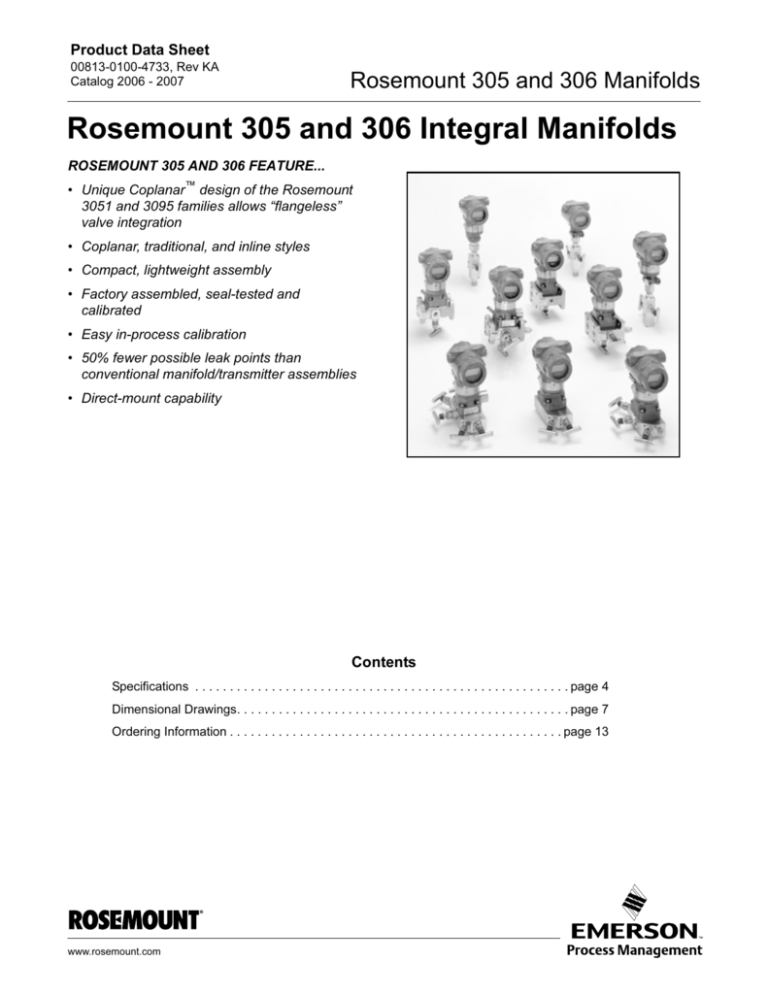

ROSEMOUNT 305 AND 306 FEATURE...

• Unique Coplanar™ design of the Rosemount

3051 and 3095 families allows “flangeless”

valve integration

• Coplanar, traditional, and inline styles

• Compact, lightweight assembly

• Factory assembled, seal-tested and

calibrated

• Easy in-process calibration

• 50% fewer possible leak points than

conventional manifold/transmitter assemblies

• Direct-mount capability

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

www.rosemount.com

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Rosemount 305R Coplanar Style Integral Manifolds

305R TWO-VALVE

ROSEMOUNT 305R FIVE-VALVE

This two-valve manifold is used with Rosemount

3051 gage and absolute pressure transmitters. The

first valve provides instrument isolation. The second

valve allows venting, draining, or calibration through

the test port.

This five-valve manifold is used with 3095 and 3051

differential pressure transmitters. It provides two

blocking valves, two test/vent valves, and one

equalizing valve. The two vent valves allow for 100%

capture of vented or drained process, and simplified

in-process calibration capability. We also offer a

five-valve integral manifold with a metering pattern

for Natural Gas installations.

•

305RC2

•

305RT2

•

305RM2

•

305RC7

Coplanar Transmitter

•

305RC5

•

305RC6

•

305RC9

•

305RM5

Coplanar Transmitter

Test/Vent

Test \

Vent Port

Test /

Vent Port

Isolate

Equalize

Process

Isolate

Isolate

Process

305R THREE-VALVE

This three-valve manifold is used with Rosemount

3095 and 3051 differential pressure transmitters. It

provides two blocking valves and one equalizing

valve. Two drain/vent valves are also installed at the

test ports.

•

305RC3

•

305RT3

•

305RM3

•

305RC8

FIVE-VALVE NATURAL GAS

Coplanar Transmitter

Coplanar Transmitter

Drain/

Vent

Valve

NOTE

Standard two-valve and standard 5-valve manifold

Test/Vents receive plastic caps to protect threaded

connections.

Equalize

Test

(Plugged)

Drain/

Vent

Valve

Equalize

Isolate

Process

Isolate

Isolate

Test/Vent

Process

Isolate

Process

2

Equalize

Test

(Plugged)

NOTE

Five-valve Natural Gas Test (Plugged) connections

receive 1/4-in. NPT plug.

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

306RT TWO-VALVE MANIFOLDS

306RT BLOCK-AND-BLEED MANIFOLDS

This two-valve pressure manifold is used with 3051

and 2088 gage and absolute pressure transmitters.

The first valve provides instrument isolation. The

second valve allows venting, draining, or calibration

through the test port. Available in 1/2–14 NPT male or

female process connections.

This pressure manifold is used with 3051 and 2088

gage and absolute pressure transmitters. It provides

a single block valve for instrument isolation. There is

also a plug for drain/vent capabilities. Available in

1

/2–14 NPT male process connection.

•

•

306RT1

306RT2

Pressure Transmitter

Pressure Transmitter

Test/Vent

Isolate

Bleed Screw

Isolate

Process

3

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Specifications

FIGURE 1. 305R integral Manifolds - Pressure vs. Temperature

PTFE Packed, Integral Seat

Graphite Packed, Integral Seal

Graphite Packed, (ASME B31.1), Integral Seat

6092

(420)

Pressure psig (bar)

6000

(414)

5000

(345)

4000

(276)

3000

(207)

2000

(138)

1000

(69)

0

0

(-18)

100

(38)

200

(93)

300

(149)

400

(204)

500

(260)

600

(316)

700

(371)

800

(427)

900

(482)

Temperature °F (°C)

TABLE 1. 305R Integral manifolds - pressure and temperature ratings(1)

Packing

Seat

Pressure and Temperature Ratings

PTFE

Integral

Graphite

Integral

Graphite (ASME B31.1)

Integral

6092 psi @ 200°F (420 bar @ 93°C)

4000 psi @ 400°F (276 bar @ 204°C)

6092 psi @ 200°F (420 bar @ 93°C)

1500 psi @ 750°F (103 bar @ 399°C)

6092 psi @ 100°F (420 bar @ 38°C)

2915 psi @ 1000°F (201 bar @ 538°C)

(1) Except option HK:

PTFE, Integral seat: 2324 psi @ 200°F (160 bar @ 93°C), 1680 psi @ 400°F (116 bar @ 204°C)

Graphite, Integral seat: 2324 psi @ 200°F (160 bar @ 93°C), 1125 psi @ 750°F (78 bar @ 399°C)

4

1000

(538)

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

FIGURE 2. 306R integral Manifolds - Pressure vs. Temperature

PTFE Packed, Integral Seat

Graphite Packed, Integral Seal

Graphite Packed, (ASME B31.1), Integral Seat

Pressure psig (bar)

10000

(689)

8000

(552)

6000

(414)

4000

(276)

2000

(138)

0

0

(-18)

100

(38)

200

(93)

300

(149)

400

(204)

500

(260)

600

(316)

700

(371)

800

(427)

900

(482)

1000

(538)

Temperature °F (°C)

TABLE 2. 306R Integral manifolds - pressure and temperature ratings

Packing

Seat

Pressure and Temperature Ratings

PTFE

Integral

Graphite

Integral

Graphite (ASME B31.1)

Integral

10000 psi @ 85°F (689 bar @ 29°C)

4000 psi @ 400°F (276 bar @ 204°C)

6000 psi @ 200°F (414 bar @ 93°C)

1500 psi @ 750°F (103 bar @ 399°C)

6000 psi @ 100°F (414 bar @ 38°C)

2915 psi @ 1000°F (201 bar @ 538°C)

TABLE 3. Process Wetted Materials of Construction - Typical(1)

Component

(2)

Body

Ball / Tip

Stem

Packing

Bonnet

Pipe Plug

Bleed Screw

Drain / Vent Valve

316SST

Hastelloy C

Monel

316 SST with SG option

316 SST

316 SST /316Ti SST

316 SST

PTFE / Graphite

316 SST

316 SST

316 SST / 316Ti SST

316 SST

Hastelloy C-276

Hastelloy C-276

Hastelloy C-276

PTFE / Graphite

Hastelloy C-276

Hastelloy C-276

Hastelloy C-276

Hastelloy C-276

Monel 400

Monel 400 / K500

Monel 400 / R-405

PTFE / Graphite

Monel 400 / R-405

Monel 400 / R-405

Monel 400 / R-405 / K500

Monel 400

316 SST

Hastelloy C-276

Hastelloy C-276

PTFE / Graphite

316 SST

316 SST

Hastelloy C-276

Hastelloy C-276

(1) Non-wetted parts are 300 series SST.

(2) Body may be supplied as appropriate cast equivalent.

5

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Shipping Weights

ISOLATION VALVE

TABLE 4. 305 Manifold Weights Without Options, lb (kg)

Bonnet

Stem

Body

Packing

Model

Approximate

Manifold

Weight

Manifold

with

3051C

Manifold

Manifold

3051S_C (1) with 3095

0305_C2

0305_C3

0305_C5

0305_C6

0305_C7

0305_C8

0305_C9

0305_T2

0305_T3

0305_T7

0305_T8

4.5 (2,0)

4.7 (2,1)

6.5 (3,0)

6.4 (2,9)

4.7 (2,1)

5.0 (2,3)

6.3(2,85)

6.0 (2,7)

6.0 (2,7)

6.2 (2,8)

6.2 (2,8)

9.4 (4,3)

9.6 (4,4)

11.4 (5,17)

11.3 (5,1)

9.6 (4,4)

9.9 (4,5)

11.2 (5,1)

10.9 (4,9)

10.9 (4,9)

11.1 (5,0)

11.1 (5,0)

7.6 (3,4)

7.8 (3,5)

9.6 (4,4)

9.5 (4,3)

7.8 (3,5)

8.1 (3,7)

9.4 (4,25)

9.1 (4,1)

9.1 (4,1)

9.3 (4,2)

9.3 (4,2)

9.9 (4,5)

10.1 (4,6)

11.9 (5,4)

11.8 (5,35)

10.1 (4,6)

10.4 (4,8)

11.7 (5,3)

–

–

–

–

(1) 3051S Module only; see Rosemount product data sheet

00813-0100-4801 for additional information.

Ball / Tip

Note: “Typical” Valve

TABLE 5. 306 Manifold Weights Without Options, lb (kg)

Model

Approximately

Manifold

Manifold

Manifold

Manifold

with 3051T 3051S_T(1) with 2088

Weight

0306_T1

0306_T2

0306_T3

1.1 (0,5)

2.5 (1,1)

2.5 (1,1)

4.1 (1,9)

5.5 (2,5)

5.5 (2,5)

2.5 (1,1)

3.9 (1,7)

3.9 (1,7)

3.1 (1,4)

4.5 (2,0)

4.5 (2,0)

(1) 3051S Module only; see Rosemount product data sheet

00813-0100-4801 for additional information.

Test Connections

1

/4-18 NPT

Adapters

DF option, CF-8M (Cast version of 316 SST, material

per ASTM-A743)

Bolts for Manifolds

Standard material is plated carbon steel per ASTM A449, Type 1

Alternative bolt materials offered through Option Codes

• L4 Austenitic 316 Stainless Steel Bolts

• L5 ASTM-A-193, Grade B7M Bolts

• L8 ASTM-A-193, Class 2, Grade B8M Bolts

6

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Dimensional Drawings

Rosemount 305R Two-Valve Coplanar Style Manifold

5.21 (132)

4.20 (107)

4.55 (116)

7.70

(196)

4.30 (108)

Max Open

7.2 (183)

Max Open

1

/2-14 NPT on Manifold for Process Connection

/4-18 NPT for test/vent connection.

1

3051-3031E06Q

9.00

(229)

Dimensions are in inches (millimeters)

Rosemount 305R Three-Valve Coplanar Style Manifolds

5.21 (132)

4.20 (107)

4.55 (116)

7.70

(196)

Drain/Vent

Valve

5.50 (140)

Max Open

10.60 (270)

Max Open

1

/2-14 NPT on Manifold for Process Connections, 2.125 inch center-to-center

3051-3031E06Q

9.00

(229)

Dimensions are in inches (millimeters)

7

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Rosemount 305R Five-Valve Coplanar Style Manifold

5.21 (132)

4.20 (107)

4.55 (116)

7.70

(196)

5.50 (140)

Max Open

11.50 (292)

Max Open

1

/2-14 NPT on Manifold for Process Connections, 2.125 inch center-to-center

/4-18 NPT for test/vent connection.

1

3051-3031E06Z

9.00

(229)

Dimensions are in inches (millimeters)

Rosemount 305RT Two-Valve Traditional Style Manifold

5.21 (132)

4.20 (107)

4.55 (116)

7.70

(196)

1/2-14

NPT on optional

Process Adapter*

1.63 (41)

3.75 (95)

Max Open

3.42 (87)

NPT on traditional

manifold for process

connection without the

use of a process adapter

1.10 (28)

2.125

(54)

6.40 (163) Max Open

Dimensions are in inches (millimeters)

8

3051-3031F30A

1/4-18

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Rosemount 305RT Three-Valve Traditional Style Manifold

5.21 (132)

4.55 (116)

4.20 (107)

7.70

(196)

1

/2-14 NPT on optional

Process Adapter*

Drain/Vent Valve

1.63 (41)

3.75 (95)

Max Open

3.5 (87)

/4-18 NPT on traditional

manifold for process

connections without the

use of process adapters

1.10 (28)

* Adapters can be rotated to give adapter connection

centers of 2.0 (51), 2.125 (54), or 2.25 (57).

2.125

(54)

6.20 (158) Max Open

2.70 (69)

2.70

(69)

Max

Max

Open

8.90 (226) Max Open

3051-3031G30B

1.05 (27)

1

Dimensions are in inches (millimeters)

Rosemount 305RM Two-Valve Traditional Style Manifold

5.21 (132)

4.20 (107)

4.55 (116)

7.70

(196)

1/2-14 NPT on optional

Process Adapter*

1.63 (41)

1/4-18 NPT on traditional

manifold for process

connection without the

use of a process adapter

3.42 (87)

1.10 (28)

1/4-18

NPT Vent

Connection

2.125

(54)

6.5 (165) Max Open

3051-3031RM2

3.75 (95)

Max Open

Dimensions are in inches (millimeters)

9

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Rosemount 305RM Three-Valve Traditional Style Manifold

5.21 (132)

4.55 (116)

4.20 (107)

0.75 (19) Clearance

for Cover Removal

7.70

(196)

1/2-14 NPT on optional

Process Adapter*

Drain/Vent

Valve

1.63 (41)

/4-18 NPT on traditional

manifold for process

connections without the

use of process adapters

3.5 (87)

1.05 (27)

1.10 (28)

* Adapters can be rotated to give adapter connection

centers of 2.0 (51), 2.125 (54), or 2.25 (57).

2.125

(54)

6.5 (165) Max Open

3051-305-3031F30B;

1

3.75 (95)

Max Open

2.5

(63)

Max

Open

9.0 (229) Max Open

Dimensions are in inches (millimeters)

Rosemount 305RM Five-Valve Traditional Style Manifold

5.21 (132)

4.20 (107)

4.55 (116)

7.70

(196)

1

/2-14 NPT on optional

Process Adapter*

1.63 (41)

/4-18 NPT on traditional

manifold for process

connections without the

use of process adapters

4.2 (107)

Max Open

2.6

(66)

Max Open

4.1 (104)

1.10 (28)

* Adapters can be rotated to give adapter connection

centers of 2.0 (51), 2.125 (54), or 2.25 (57).

2.125

(54)

6.5 (165) Max Open

9.0 (229) Max Open

Dimensions are in inches (millimeters)

10

2.5

(63)

Max

Open

3051-305-3031F30C

1

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Rosemount 306R Pressure Style Manifold (3051T Shown)

BLOCK AND BLEED STYLE

TWO-VALVE STYLE

4.55 (116)

4.20 (107)

8.00

(203)

4.85

(123)

NPT on traditional

vent connection

(pipe plug shown)

4.10 (105)

Bleed Screw

3.63

(92)

1

/2-14 NPT Female NPT

Process Connection (code BA)

3051-305-303D06B

1/4-18

Dimensions are in inches (millimeters)

Installations for Rosemount 3051T and 3051S_T Transmitters for 2-in. Pipe Mounting

6.25 (159)

ROSEMOUNT 3051S_T

3.13 (79)

NOTE: Dimensions are in inches (millimeters).

6.25 (159)

3.13 (79)

3051-305-3051D04B, 3031D06F

ROSEMOUNT 3051T

Dimensions are in inches (millimeters)

11

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Coplanar Manifold with Optional Bracket for 2-in. Pipe Mounting

OPTION CODE B4

7.68

(195)

3051-305-3031E04C; F04B; 3051-3031J04A

2-inch U-Bolt for

Pipe Mounting

4.9

(125)

3.54

(90)

6.25 (159)

Dimensions are in inches (millimeters)

Traditional Manifold with Optional Brackets for 2-in. Pipe Mounting

8.18 (208)

3.56

(90)

1.1 (28)

B3/B9/BC MOUNTING BRACKET

3.42

3.42(86.9)

(87)

2.62 (66)

7.7

(196)

1.94

(49.2)

13.03

(331)

0.93 (24)

B1/B7/BA MOUNTING BRACKET

3.56

(90)

5.32

(135)

3.42

(87)

Dimensions are in inches (millimeters)

12

4.85

(123)

1.1

(28)

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

Ordering Information

TABLE 6. Rosemount 305R Integral Manifolds

Model

0305

Code

R

Code

C

T

M

Code

2

3

5(1)

6(2)

7(2)(3)

8(2)(3)

9(2)(3)

Product Description

Integral Manifold

Manufacturer

Rosemount Inc.

Manifold Style

Coplanar

Traditional

Traditional (Rosemount 3095-compatible; DIN-compliant flange)

Manifold Type

2-valve

3-valve

5-valve

5-valve for natural gas/metering pattern

2-valve (per ASME B31.1[ANSI] power and piping code)

3-valve (per ASME B31.1[ANSI] power and piping code)

5-valve (per ASME B31.1[ANSI] power and piping code)

Materials of Construction

Code

Body

Bonnet

Stem and Tip / Ball

2

316 SST

316 SST

316 SST

3(4)(5)

Hastelloy® C

Hastelloy C

Hastelloy C

(4)

4

Monel®

Monel

Monel

Code

Process Connection

A

¼–18 NPT (Traditional manifold styles T and M)

1

B

/2–14 NPT (Coplanar manifold style only)

Code

Packing Material

1

Teflon

2(6)

Graphite-based

Code

Valve Seat

1

Integral

5

Soft delrin (only available with natural gas/ metering pattern)

Continued on Next Page

Drain/Vent

316 SST

Hastelloy C

Monel

13

Product Data Sheet

Rosemount 305 and 306 Manifolds

00813-0100-4733, Rev KA

Catalog 2006 - 2007

TABLE 6. Rosemount 305R Integral Manifolds

Code

305R Options

P2

Cleaning for special services (Not available with graphite-based packing)

SG(5)(7)

316 SST NACE option (316 SST body and bonnet; Hastelloy C drain/vent, stem and tip/ball) for H2S Service

L4(8)

Austenitic 316 SST bolts

L5

ASTM-A-193-B7M bolts

L8

ASTM-A-193, Class 2, Grade B8M bolts

Coplanar Options

B4

SST bracket for 2-in. pipe mount with series 300 SST bolts

Traditional Options

B1

Bracket for 2-in. pipe mounting, CS bolts

B3(9)

Flat bracket for 2-in. pipe mounting, CS bolts

B7

B1 bracket with series 300 SST bolts

B9(9)

B3 bracket with series 300 SST bolts

BA

SST B1 bracket with series 300 SST bolts

BC(9)

SST B3 bracket with series 300 SST bolts

BD

SST Bracket with Series 300 SST Bolts for 305RM5 Manifolds

1/2–14 NPT flange adapters, Material of construction; match body material and packing material

DF

(Not available with graphite-based packing or HK, HL options)

HK(10)

10mm (M10) process flange bolting connection

HL(10)

12mm (M12) process flange bolting connection

Typical Coplanar Integral Manifold Model Number: 305RC32B11B4

Typical Transmitter Model Number: 3051CD2A02A1AS5

(1) Not available with traditional manifold style T.

(2) Only available with Coplanar manifold style

(3) Only available with 316SST materials of construction and graphite-based packing.

(4) Not available with traditional manifold Style M.

(5) Materials of Construction comply with recommendations per NACE MR 0175/ISO 15156 for sour oil field production environments. Environmental limits

apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refining environments.

(6) Includes graphite tape on drain/vent valves and plugs.

(7) Only available with Materials of Construction Code 2: 316 SST body and bonnets; Hastelloy C stems, tip/balls, and drain/vents.

(8) Not available with manifold codes 7, 8, and 9.

(9) Not compatible with the Rosemount 3095 transmitter.

(10) Only available with traditional manifold style M.

14

Product Data Sheet

00813-0100-4733, Rev KA

Catalog 2006 - 2007

Rosemount 305 and 306 Manifolds

TABLE 7. Rosemount 306RT Integral Manifolds

Model

Product Description

0306

Code

Pressure Manifold

Manufacturer

R

Code

Rosemount Inc.

Manifold Style

T

Code

Threaded

Manifold Type

1

2

3(1)

Block-and-bleed

2-valve

2-valve (per ASME B31.1 [ANSI] power and piping code)

Materials of Construction

Code

Body

Bonnet

Stem and Tip / Ball

Drain/Vent Plug

2

3(2)(3)

Code

316 SST

Hastelloy C

Process Connection

316 SST

Hastelloy C

316 SST

Hastelloy C

316 SST

Hastelloy C

AA

BA(2)

Code

1

/2–14 male NPT

/2–14 female NPT

Packing Material

1

1

2(4)

Code

Teflon

Graphite-based

Valve Seat

1

Code

Integral

306RT Options

P2

Cleaning for special services (Not available with graphite-based packing)

SG(3)(5)

316 SST NACE option (316 SST body and bonnet; Hastelloy C stem and tip/ball). For H2S Service

Typical Integral Manifold Model Number: 3 0 6 R T 2 2 B A 1 1

Typical Transmitter Model Number: 3051TG3A2B21AS5B4

(1) Only available with 316SST materials of construction and graphite-based packing.

(2) Not available with block-and-bleed manifold type

(3) Materials of Construction comply with recommendations per NACE MR0175/ISO 15156 for sour oil field production environments. Environmental limits

apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refining environments.

(4) Includes graphite tape on plugs.

(5) Only available with material of construction code 2.

15

Product Data Sheet

Rosemount 305 and 306 Manifolds

00813-0100-4733, Rev KA

Catalog 2006 - 2007

OPTIONS

ASME B31.1 (ANSI)

Module Guard

The 305 and 306 Manifolds are available in

configurations that meet the requirements of ASME

B31.1(ANSI) Power and Piping Code. This code

specifies design criteria for most air, gas, steam,

water, and oil systems used in electric generating

systems, central and district heating systems,

industrial power plants and geothermal plants. ASME

B31.1(ANSI) includes requirements for manifolds,

valves, and piping. Transmitters and other measuring

devices do not fall within the scope of this code.

A sensor module guard is available to protect the

transmitter process isolating diaphragms. This guard

should be used whenever the transmitter is removed

from the integral manifold to avoid damage to the

isolating diaphragms.

•

Part number: 00305-1000-0001 (5/pack)

3051-3031C07F

Marking

P2 Cleaning for Special Services

Manifolds are tagged with a part number, schematic

drawing, temperature and pressure limits.

Other Publications

For additional information, go to

www.rosemount.com.

This option minimizes process contaminants by

cleaning wetted surfaces with a suitable detergent.

SG Sour Gas

Materials of Construction comply with

recommendations per NACE MR 0175/ISO 15156 for

sour oil field production environments. Environmental

limits apply to certain materials. Consult latest

standard for details. Selected materials also conform

to NACE MR0103 for sour refining environments.

Rosemount and the Rosemount logotype are registered trademarks of Rosemount Inc.

Coplanar is a trademark of Rosemount Inc.

Monel is a registered trademark of International Nickel Co.

Hastelloy is a registered trademark of Haynes International

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

Emerson Process Management

Emerson Process Management

Rosemount Inc.

Heath Place

8200 Market Boulevard

Bognor Regis

Chanhassen, MN 55317 USA

West Sussex PO22 9SH

T (U.S.) 1 800 999 9307

T (International) (952) 906 8888 England

T 44 (0) 1243 863121

F (952) 949 7001

F 44 (0) 1243 867554

www.rosemount.com

¢00813-0100-4733w¤

© 2006 Rosemount Inc. All rights reserved.

Emerson Process Management Asia

Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947

Enquiries@AP.EmersonProcess.com