experiment p-8 uniaxial tensile test

advertisement

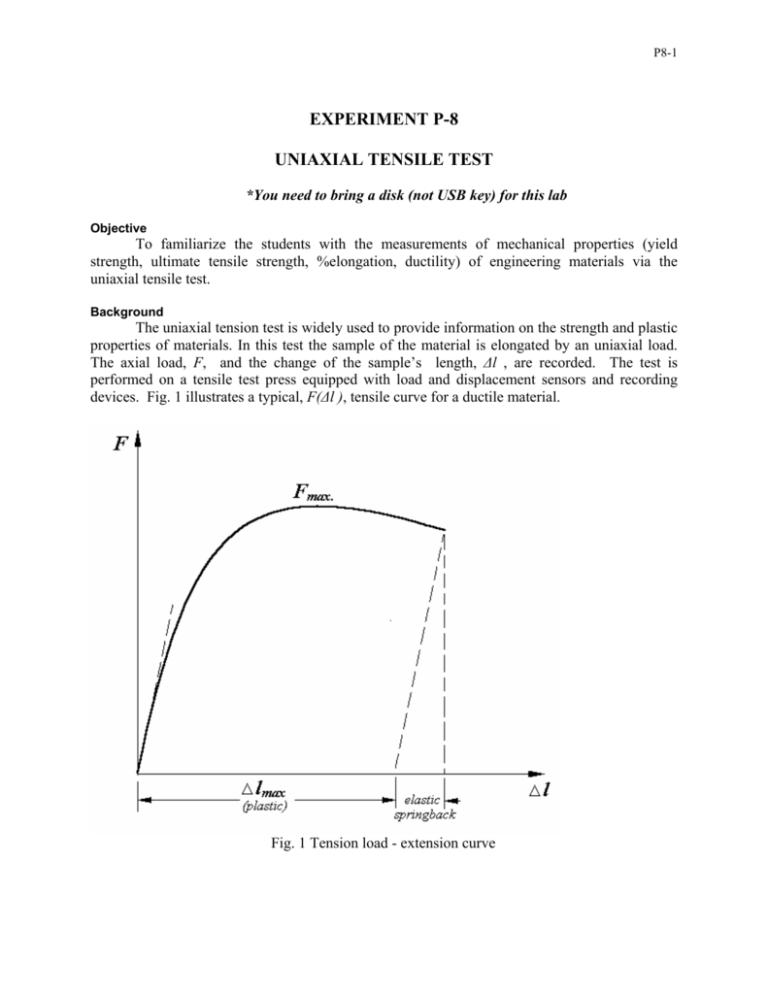

P8-1 EXPERIMENT P-8 UNIAXIAL TENSILE TEST *You need to bring a disk (not USB key) for this lab Objective To familiarize the students with the measurements of mechanical properties (yield strength, ultimate tensile strength, %elongation, ductility) of engineering materials via the uniaxial tensile test. Background The uniaxial tension test is widely used to provide information on the strength and plastic properties of materials. In this test the sample of the material is elongated by an uniaxial load. The axial load, F, and the change of the sample’s length, Δl , are recorded. The test is performed on a tensile test press equipped with load and displacement sensors and recording devices. Fig. 1 illustrates a typical, F(Δl ), tensile curve for a ductile material. Fig. 1 Tension load - extension curve ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-2 The actual range of the load and displacement depends on the material and dimensions of the sample. In order to compare different materials the effect of sample dimensions is eliminated by translating load into force per unit cross-sectional area - tensile stresses, σ, and displacement into relative elongation - tensile strain, ε. Fig. 2 illustrates a typical stress-strain curve, σ(ε), for an elastic plastic material. The basic mechanical properties pertaining to the strength and ductility of the materials are referred to in terms of stresses and strains. Particularly, so called effective stress and strain utilized in strength analysis, translate any general three dimensional stress-strain state to values equivalent to the uniaxial tensile test data, σ, and ε . The stress strain curve shown in fig. 2 contains several characteristic points usually listed in standard material data sheets. The slope of the initial linear portion of the curve, σ(ε), is referred to as Young’s modulus, E, which is the elastic stiffness of the material under normal stress. Upon unloading from a stress-strain state within this range of deformation, the sample fully recovers its initial dimensions, i.e the deformation is purely elastic, εel. Some materials may exhibit a non-linear elasticity, i.e. the value of Young’s modulus, E, may not be constant, yet there is full elastic shape recovery upon unloading. Fig. 2 Stress-strain curve, elastic-plastic material model If, during the loading stage the strain exceeds a specific limit, upon unloading the initial shape of the sample is not fully recovered, and some portion of the total loading strain, ε, becomes permanent. This permanent strain is referred to as plastic strain, εpl . The plastic strain, εpl, cannot be induced without being preceded by the elastic deformation, εel , The stress level at which the plastic deformation is initiated is referred to as the yield stress, Yo , of the material. Any structural application of a given material should insure that the maximum value of the effective stress remains below the yield stress, otherwise under the expected loading the shape of the structure would become permanently distorted due to plastic deformation. Most materials do ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-3 not exhibit the presence of a distinct point, Yo, on the curve, σ(ε). For materials without the distinct point, Yo , the yield stress is usually defined as the stress level at which the permanent, plastic, strain is 0.2%. In the material data sheets this kind of yield stress is referred to as R0.2. Different national standards also list other definitions of the yield stress such as R0.1, R0.02, etc., which refer to 0.1% and 0.02% plastic elongation at the yield point. Beyond the yield point the deformation is elastic-plastic. This range of deformation is of primary importance for forming technology applications in which different mechanical components are shaped by plastic strains. In the forming technology applications the plastic strain may become of two or more orders of magnitude greater than the elastic. Often, in the analysis of these applications, the elastic properties are neglected, and the material behavior is simplified by the so called rigid-plastic material model , for which the curve , σ(εpl), begins at the initial yield stress, Yo(εpl =0), and ignores the elastic strain, fig. 3. Fig. 3 Stress-strain curve, rigid plastic material model In the elastic-plastic range of deformation the level of stresses may increase with the magnitude of strains. This increase is referred to as strain hardening. The strain hardening indicates that the material is gaining strength with the amount of the induced plastic deformation. If a strain hardened material is unloaded from the elastic-plastic range of deformation and reloaded again, the plastic deformation will not resume at the stress level indicated by the initial yield point, Yo or R0.2, but at the stress level near or at the level, σ(εpl), reached just before the unloading. In the uniaxial tension test, only one from the triple, [σ1, σ2, σ3], of principal stress components is non-zero - the axial stress, σ = σ1, while the remaining two components associated with the planes orthogonal to the tension direction are zero, σ1=σ2 =0. The elongation of the sample is measured by the axial strain, ε =ε1. However, as the volume of the sample is conserved, while the sample is being elongated its width and thickness or in general its cross-sectional area decrease, and therefore, none of the principal strains is zero, ε1>0, ε2<0 and ε3<0. In the elasticplastic range a single stress component, σ1, results in six principal strain components, three elastic strains, [ε1, ε2, ε3]el , and three plastic strains, [ε1, ε2 ε3]pl . The axial stress and strain are ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-4 used as the reference, σ(ε), but in general the deformation in tensile test has all the same stress and strain characteristics as any other deformation process. The uniaxial tension stress-strain state exists as long as the sample is being deformed uniformly. The initial increase of the tension load, F(Δl ), shown in fig. 1 is due to the strain hardening (monotonic increase of the stress level of the, σ(ε), curve). However, the axial stresses, σ = σ1, are carried by the decreasing cross-section area, A, of the sample. At some point the effect of stress increase on the tension force becomes equal to the effect of the cross-section area decrease. At this point the force reaches a maximum value, Fmax.. Any further elongation of the sample results in the drop of force and elastic unloading of the previously stressed material with the exception of one zone, which due to micro-structural or dimensional defects has the lowest load carrying capacity. At this stage the overall extension of the sample length results in localization of the plastic deformation only in the weakest zone referred to as “the neck”. The stress state in the neck changes to a tri-axial tension, which is caused by the non-co-linearity of the neck profile with the sample axis. Essentially the stress state in the neck is undefined and only the portion of, σ(ε), within the uniform elongation range is considered valid. Stress and strain measures There are two basic stress and strain measures used in material data sheets: the engineering and the true measure. The engineering stress and strain measures are obsolete; nevertheless many national standards still utilize these traditional measures. The engineering stress, σeng , is defined as the ratio of the instantaneous tensile force, Fi , to the initial crosssection area of the sample, Ao, F σ eng = i , (1) Ao and the engineering percent strain, e%, as the % ratio of the length increase, Δl , to the initial length, lo, of the sample: e% = Δl 100% . lo (2) ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-5 Fig. 4 Engineering stress-strain curve However, during the tensile test the cross-section area, A, of the sample decreases due to elongation while each subsequent increase of sample length, dl , takes place over an already elongated sample length, l. It is evident that by neglecting the changes in the cross-section area, A, and sample length, l, the engineering measures are not representative of the actual strain and stress state of the material. The stress-stain curve expressed in the engineering measures is shown in fig. 4. Apparently, based on the engineering stress definition (1) the value of engineering stress decreases past the point marked with the symbol U.T.S . This is misleading; in reality the true stresses continuously increase. The so-called true stress and strain measures define the stress and strain state correctly. The true stress, σ, is defined as the ratio of the instantaneous applied force, Fi, to the instantaneous cross-section area, Ai: F σ= i (3) Ai and true strain, ε, is defined as the product of integration, given by: li dl ⎛l ⎞ (4) ε =∫ = ln⎜⎜ i ⎟⎟ , lo l ⎝ lo ⎠ where, lo, is the initial and, li, is the instantaneous length of the sample. The true strain is also often referred to as the logarithmic strain. Stress-strain curve for plastic deformation The relationship, σ(εpl), for true stress and strain measures is referred to as the stressstrain curve. For many materials the experimental, σ(εpl), data can be interpolated by an exponential function in the form: σ = K(εo + εpl) n (5) where K, εo and n are material constants. These constants are determined by fitting a curve expressed by equation (5) between experimental points obtained from the tensile test. Usually the curve-fitting algorithm neglects the small elastic deformation. The constant, K , is referred to as flow stress constant . It represents the stress level for εo + εpl = 1.0 and its value indicates the overall stress level at which the material is deformed plastically. The constant, εo , is referred to as initial strain offset. This constant shifts the exponential curve (5) to a position at which for, εpl=0, (the beginning of plastic deformation) the stress level is equal to the initial yield stress , σ = Yo.. The constant, n , is referred to as the strain hardening exponent. It indicates the rate of material strain hardening. On a logarithmic scale graph, fig. 5, the stress-strain curve, σ(εpl), represented by equation (5) becomes a straight line with the slope n, log( σ) = n log ( εo + εpl ) + log(K). (6) ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-6 Fig. 5 Stress-strain curve in logarithmic scale Coefficient of anisotropy, r. An isotropic material exhibits identical properties in all the directions in its volume. In general, an anisotropic material is characterized by different magnitude of its characteristic values such as Young’s modulus, yield stress, strain hardening etc. depending on the orientation of the loading direction in the material space. Particularly in the sheet forming technology applications (for example, forming automotive body panels) a desirable deformation behavior is such that the material resists deformation in its thickness direction but is easily deformable in its plane. This behavior promotes shaping of the surface over the localized thinning and ultimately, splitting, of the sheet during forming. The uniaxial tension test is used to evaluate this property of the sheet products by means of the coefficient of anisotropy, r, defined as the ratio of the true strain, ε2 = εw, measured in the direction of sample’s width over the strain, ε3 = εt, measured in the thickness direction: r = εw /εt . (7) The coefficient of anisotropy, r , is determined for three different directions 0o, 45o and 90o in the sheet plane with respect to the rolling direction of the sheet, r0, r45, r90 . Tensile test data sheet Standard tensile test data sheet provides the following data: Sample dimensions - National standards list several standard dimensions of the tensile test samples. They are different for flat, bar and wire products. The 4:1 gage length/width type sample used in the laboratory comply with the ISO/ASTM recommendations for flat (sheet) products with recommended gage length of 60mm (2.25 in) and width 12.5mm (0.5 in), ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-7 Young’s modulus, E, Yield stress ,Yo or R0.2 , - expressed as engineering stresses, Ultimate temsile strength U.T.S. - expressed as engineering stresses, U.T.S = Fmax / Ao, Total elongation, et%, - obtained by putting a fractured sample back together and measuring the % of total length change, ef% = Δlmax / lo. $ 100%, Reduction of area, q, A.R. or %At , - % of the area reduction of the fractured section Additional data : Plastic stress-strain curve parameters K, εo , n , ( true measures ), Uniform elongation, εu or %εu , - maximum elongation of the material outside the neck expressed in true or engineering strain measures, Coefficient of anisotropy, r0, r45, r90 (used for flat products only). Laboratory experiment The objective of the experiment is to generate a complete material data sheet for a flat product. The experiment will be performed on a standard tensile testing machine equipped with load cells, displacement and strain gages. The T.A. will give instructions pertaining to the testing machine and data acquisition system operations, but the students themselves will conduct the actual test. Prior to the experiment, the students should plan the steps of the experimental procedure. As part of the experimental procedure the students should perform full calibration of all the gages. A set of weights and a device equipped with micrometer screw will be provided to perform the calibration of the load and displacement sensors. The laboratory report should include: After lab, before write up session: 1. Create a graph of true stress/strain for each sample. Use extensometer data to calculate strain. 2. Create a graph showing both displacement versus time and extension versus time for one of the samples. Why did we measure both of these parameters? What is their significance? What does the graph tell you? 3. Complete the property calculations sheets 4. Complete the material data tables 5. Discuss the results of the labs. Were the yield strengths of the materials what were expected? Why or why not? Justify your results with other sources of information. Repeat for Young’s Modulus. Make sure to indicate your source. Do these values make sense according to the rolling directions of the samples? ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-8 6. Create an appendix of calibration data and graphs. Write Up Session: You will be given some questions based on what you did in the lab, the only preparation you need is to bring your brain, creativity and your completed pre lab. Good luck! Experiment safety The participants of the experiment must wear safety glasses. All participants of the this lab experiment must be familiar and follow the Standard Operating Procedure, (SOP), entitled “P5 Plastic properties of sheet metal (Instron 1140)”. The full text of the SOP is available in JHE 314. ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-9 Property Calculations (Sample Calculations): Sample Rolled in 0° Direction: Property Formula Young’s Modulus Ultimate Tensile Strength Note: Please indicate on graph also UTS = Fmax/Ao Total Elongation et% = (∆lo / lo) X 100% Reduction of Area Flow Stress Constant Strain Hardening Exponent Initial Strain Offset Uniform Elongation Coefficient of Anisotropy Calculation ME 3M02 – Experiment P8: Uniaxial Tensile Test Sample Rolled in 45° Direction: Property Formula Young’s Modulus Ultimate Tensile Strength Note: Please indicate on graph also UTS = Fmax/Ao Total Elongation et% = (∆lo / lo) X 100% Reduction of Area Flow Stress Constant Strain Hardening Exponent Initial Strain Offset Uniform Elongation Coefficient of Anisotropy P8-10 Calculation ME 3M02 – Experiment P8: Uniaxial Tensile Test Sample Rolled in 90° Direction: Property Formula Young’s Modulus Ultimate Tensile Strength Note: Please indicate on graph also UTS = Fmax/Ao Total Elongation et% = (∆lo / lo) X 100% Reduction of Area Flow Stress Constant Strain Hardening Exponent Initial Strain Offset Uniform Elongation Coefficient of Anisotropy P8-11 Calculation ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-12 Material Data Tables: Sample Rolled in 0° Direction: Parameter Sample Dimensions Initial Standard Material Data Sheet Final Additional Parameters Young’s Modulus Yield Stress Ultimate Tensile Strength Total Elongation Reduction of Area Flow Stress Constant Strain Hardening Exponent Initial Strain Offset Uniform Elongation Coefficient of Anisotropy Value Overall length Overall width Overall thickness Gage length Gage width Gage thickness Overall length Overall width Overall thickness Gage length Gage width Gage thickness E Yo or R0.2 UTS e t% q, AR or %At K n εo εu r 60 mm 12.5 mm ME 3M02 – Experiment P8: Uniaxial Tensile Test P8-13 Sample Rolled in 45° Direction: Standard Material Data Sheet Parameter Sample Dimensions Initial Final Additional Parameters Young’s Modulus Yield Stress Ultimate Tensile Strength Total Elongation Reduction of Area Flow Stress Constant Strain Hardening Exponent Initial Strain Offset Uniform Elongation Coefficient of Anisotropy Value Overall length Overall width Overall thickness Gage length Gage width Gage thickness Overall length Overall width Overall thickness Gage length Gage width Gage thickness E Yo or R0.2 UTS e t% q, AR or %At K n εo εu r 60 mm 12.5 mm ME 3M02 – Experiment P8: Uniaxial Tensile Test Sample Rolled in 90° Direction: Parameter Sample Dimensions Initial Standard Material Data Sheet Final Additional Parameters Young’s Modulus Yield Stress Ultimate Tensile Strength Total Elongation Reduction of Area Flow Stress Constant Strain Hardening Exponent Initial Strain Offset Uniform Elongation Coefficient of Anisotropy P8-14 Value Overall length Overall width Overall thickness Gage length Gage width Gage thickness Overall length Overall width Overall thickness Gage length Gage width Gage thickness E Yo or R0.2 UTS e t% q, AR or %At K n εo εu r 60 mm 12.5 mm