Tutorial: M-Squared, The KPI (Key Performance Indicator) of Lasers

advertisement

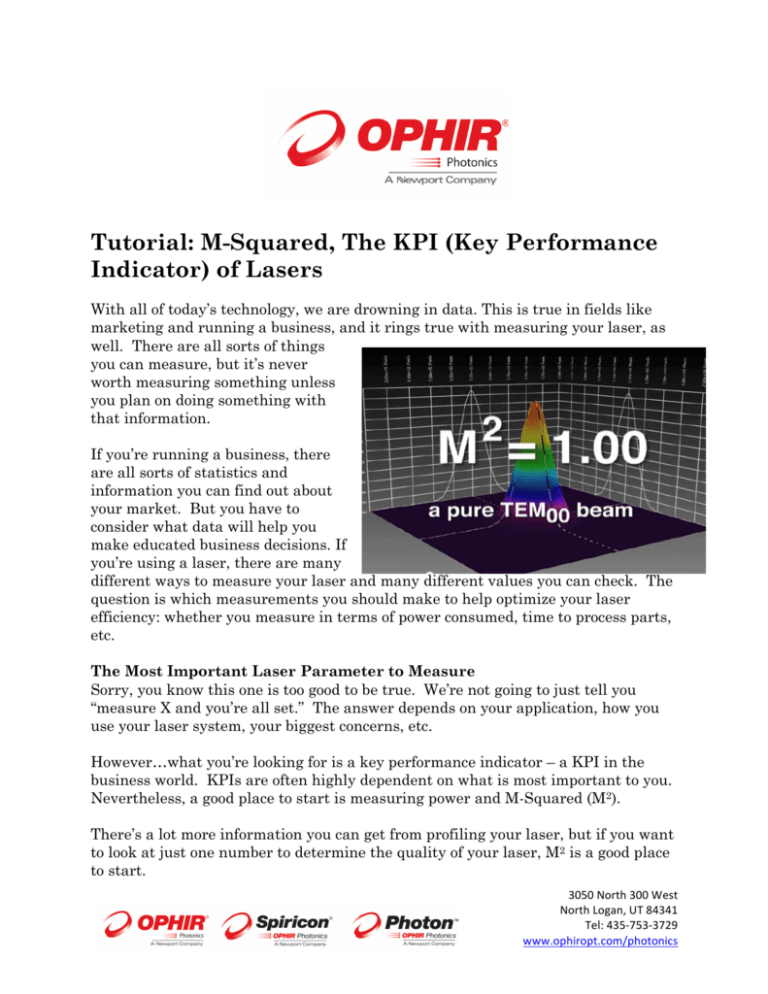

Tutorial: M-Squared, The KPI (Key Performance Indicator) of Lasers With all of today’s technology, we are drowning in data. This is true in fields like marketing and running a business, and it rings true with measuring your laser, as well. There are all sorts of things you can measure, but it’s never worth measuring something unless you plan on doing something with that information. If you’re running a business, there are all sorts of statistics and information you can find out about your market. But you have to consider what data will help you make educated business decisions. If you’re using a laser, there are many different ways to measure your laser and many different values you can check. The question is which measurements you should make to help optimize your laser efficiency: whether you measure in terms of power consumed, time to process parts, etc. The Most Important Laser Parameter to Measure Sorry, you know this one is too good to be true. We’re not going to just tell you “measure X and you’re all set.” The answer depends on your application, how you use your laser system, your biggest concerns, etc. However…what you’re looking for is a key performance indicator – a KPI in the business world. KPIs are often highly dependent on what is most important to you. Nevertheless, a good place to start is measuring power and M-Squared (M2). There’s a lot more information you can get from profiling your laser, but if you want to look at just one number to determine the quality of your laser, M2 is a good place to start. 3050 North 300 West North Logan, UT 84341 Tel: 435-­‐753-­‐3729 www.ophiropt.com/photonics What Is M2? Why? If you want a technical definition, you can find one in our M2 tutorial. But I want to focus not on how M2 is calculated, but why you should bother measuring it. If you are using a Gaussian-type laser, the closer your laser is to a perfect Gaussian, the better. M2 is a measure of how close the laser is to a Gaussian. If it were a perfect Gaussian beam, then M2 = 1. For any other laser beam, M2 > 1. Depending on the application and industry, M2 values of 1.1, 1.2, and even up to 1.5 may be considered high quality lasers. However, this is highly dependent on the power as well. For higher powers, M2 is usually higher (lower beam quality), even getting up to values of 5-10. Last Question: Why Is It So Important to Have a Near-Gaussian Laser? The closer your laser is to a perfect Gaussian shape, the tighter it can be focused. If you’re cutting steel, that means a smaller kerf, less wasted material. If you’re processing delicate medical devices, that means a more precise output. But the real kicker is that a more tightly focused beam at a lower power can give you a higher power density than a larger beam at higher power. That’s why we always stress to our material processing customers – if you want more power, don’t just raise the throttle. Check the beam profile. M2 is a good place to start. Ophir Photonics Group http://www.ophiropt.com/photonics Copyright © 2015, Ophir Photonics Group. 3050 North 300 West North Logan, UT 84341 Tel: 435-­‐753-­‐3729 www.ophiropt.com/photonics