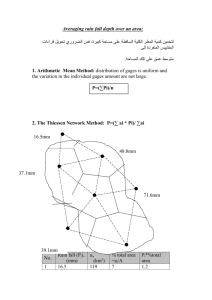

Hemco Catalog

advertisement