IT210 - SharePoint - Erie Community College

advertisement

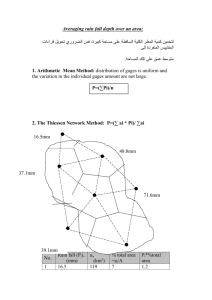

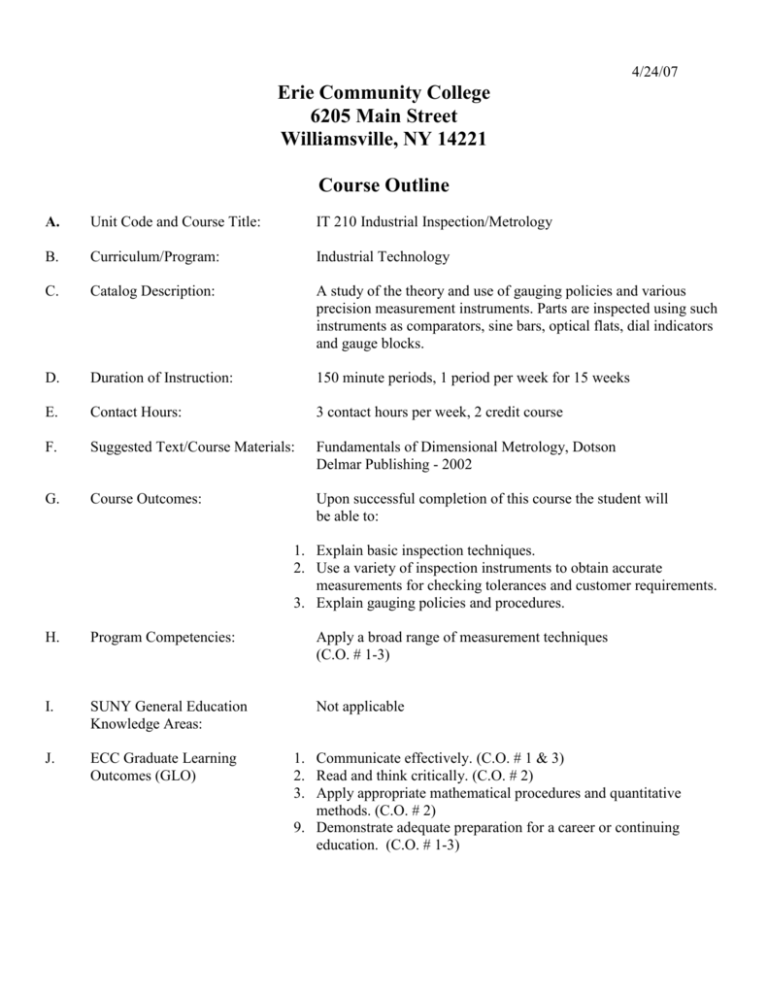

4/24/07 Erie Community College 6205 Main Street Williamsville, NY 14221 Course Outline A. Unit Code and Course Title: IT 210 Industrial Inspection/Metrology B. Curriculum/Program: Industrial Technology C. Catalog Description: A study of the theory and use of gauging policies and various precision measurement instruments. Parts are inspected using such instruments as comparators, sine bars, optical flats, dial indicators and gauge blocks. D. Duration of Instruction: 150 minute periods, 1 period per week for 15 weeks E. Contact Hours: 3 contact hours per week, 2 credit course F. Suggested Text/Course Materials: Fundamentals of Dimensional Metrology, Dotson Delmar Publishing - 2002 G. Course Outcomes: Upon successful completion of this course the student will be able to: 1. Explain basic inspection techniques. 2. Use a variety of inspection instruments to obtain accurate measurements for checking tolerances and customer requirements. 3. Explain gauging policies and procedures. H. Program Competencies: Apply a broad range of measurement techniques (C.O. # 1-3) I. SUNY General Education Knowledge Areas: Not applicable J. ECC Graduate Learning Outcomes (GLO) 1. Communicate effectively. (C.O. # 1 & 3) 2. Read and think critically. (C.O. # 2) 3. Apply appropriate mathematical procedures and quantitative methods. (C.O. # 2) 9. Demonstrate adequate preparation for a career or continuing education. (C.O. # 1-3) Industrial Inspection/Metrology Page 2 K. Assessment of Student Learning: Two exams, lathe project and mill project. L. Library Resources: M. Topical Outline: I Introduction A. Basic Concepts B. Origin and Need C. Dimensions, Tolerance, Basic Size Limits D. Clearance and Allowance E. Interference F. Selective Assembly G. Classes of Fit H. Interchangeable Fits 1. Basic Hole System 2. Basic Shaft System I Zoning Assembly II III Machinery’s Handbook-27th Edition, Industrial Press, 2004 Machining and Metalworking Handbook-3rd Edition, McGraw-Hill, 2006 Dimensional Control A. Units of Length 1. Yard and Meter 2. Inch and Fraction 3. Inch and Decimal B. Sight and Touch C. Measurement 1. Direct measurement 2. Indirect measurement 3. Direct check measurement Non-Precision Measurement A. Definition B. Steel Rules 1. Classifications 2. Applications 3. Care and use C. Calipers 1. Types 2. Applications 3. General rules for using D. Dividers 3 periods 1 period 3 periods Industrial Inspection/Metrology Page 3 Topical Outline Continued E. Combination Set 1. Application of squaring head and scale 2. Plain protractor F. Radius Gages G. Universal Surface Gage – Applications IV Micrometers A. Principle of micrometer B. Outside micrometers 1. Component parts 2. How to read 3. Check for accuracy 4. Inspection of parts C. Inside micrometer – Uses and applications D. Depth micrometer – Uses and applications E. Care, calibration and adjustment V Vernier Instruments A. Principle of vernier scale B. Vernier caliper 1. Reading the vernier caliper 2. Use on outside dimensions 3. Use on inside dimensions 4. Care and adjustment C. Vernier height gage – Uses D. Vernier micrometer 3 periods VI Plug, Ring and Snap Gages A. Termonology B. Characteristics C. Plug Gages 1. Theory of limit plug gages 2. Types 3. Variations and special plug gages 4. Use of plug gages 5. Accuracy of plug gages 6. Care of plug gages D. Ring Gages 1. Standard ring gages 2. Special ring gages 3. Applications 4. Care of ring gages 3 periods Industrial Inspection/Metrology Page 4 Topical Outline Continued E. Snap Gages 1. 2. 3. 4. Types Applications Setting and adjustable snap gages Care of snap gages VII Gaging Policy A. Need B. Basic factors C. Gage makers tolerances D. Unilateral and Bilateral Gage Tolerances E. Wear Allowance F. Ordnance practice G. Human error 3 periods VIII Precision Gage Blocks A. Industrial functions B. Gage block design C. Classifications and tolerances D. Selecting gage blocks for a required dimension E. “Wringing” F. Applications G. Care and use 1 period IX Dial Indicators A. Introduction B. Advantages C. Working Mechanism 1. Range of travel 2. “Nine o’clock” setting 3. Indicator parts D. Types of Dial Indicators and Uses 1. Plain dial indicator 2. Universal test indicator 3. Height measurements E. Dial Indicating Gages – Types and uses F Care and adjustment 3 periods X Precision Angle Measurement A. Units of measurement B. Bevel Protractor 1. Reading 2. Setting 3. Applications C. Universal Angle Gages D. Bevel Gages 3 periods Industrial Inspection/Metrology Page 5 Topical Outline Continued E. F. Sine Bar 1. Theory 2. Use 3. Checking unknown angles 4. Care Plain Index Centers XI Comparators and Automatic Gaging A. Mechanical comparators B. Mechanical – Optical Comparators 1. Principle 2. Applications C. Electrical and Electronic Comparators 1. Electricheck D. Air Comparitors 1. Advantages 2. Mechanism 3. Applications E. Multicheck Comparators F. Automatic Gaging 6 periods XII Optical Instruments in Industrial Inspection A. Measuring Micrometer 1. Advantages 2. Types B. Tool Maker Microscope 1. Description 2. Applications C. Optical Comparator 1. Optical system 2. Floor type 3. Bench comparators D. Measurement by Light Wave Interference 1. Basic equipment 2. Principles 3. Gage block inspection 6 periods XIII Screw Threads and Thread Gages A. Elements of Screw Threads 1. Thread terminology 2. Standards 3. Thread fits 4. Control of threaded products 3 periods Industrial Inspection/Metrology Page 6 Topical Outline Continued B. Thread Gages and Gaging Methods 1. Thread gage theory 2. Thread plug gages 3. Thread ring gages 4. Tri-roll gages 5. Thread snap gages XIV Surface Plates and Toolroom Specialties A. Surface Plates B. Bench Block C. Toolmaker Flat D. Angle Irons E. Parallesl F. V Blocks G. Squares 1 period XV Typical Inspection Problems A. Tapers B. Dovetails C. Concentricity and Eccentricity 3 periods XVI Surface Inspection A. Definitions B. Comparison Methods C. Direct Instrument Measurement D. Applications XVIII Final Exam N. Prepared by: Sam Kassab, 1996