Electricity Conservation On Ontario Farms - Envira

advertisement

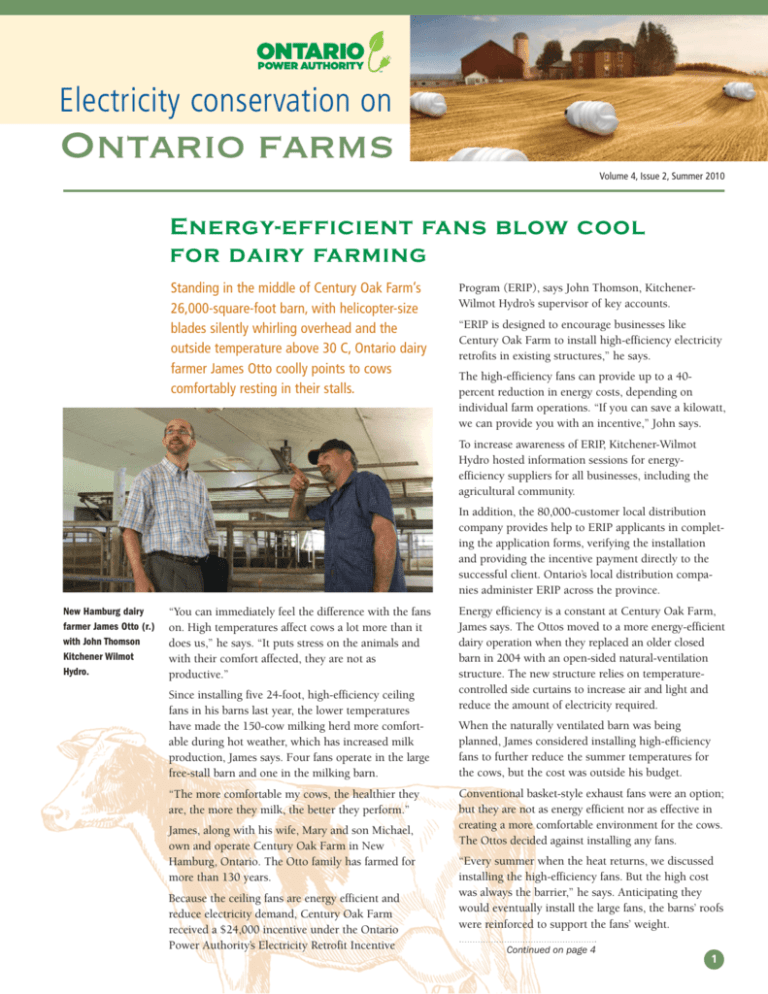

Electricity conservation on Ontario farms Volume 4, Issue 2, Summer 2010 Energy-efficient fans blow cool for dairy farming Standing in the middle of Century Oak Farm’s 26,000-square-foot barn, with helicopter-size blades silently whirling overhead and the outside temperature above 30 C, Ontario dairy farmer James Otto coolly points to cows comfortably resting in their stalls. Program (ERIP), says John Thomson, KitchenerWilmot Hydro’s supervisor of key accounts. “ERIP is designed to encourage businesses like Century Oak Farm to install high-efficiency electricity retrofits in existing structures,” he says. The high-efficiency fans can provide up to a 40percent reduction in energy costs, depending on individual farm operations. “If you can save a kilowatt, we can provide you with an incentive,” John says. To increase awareness of ERIP, Kitchener-Wilmot Hydro hosted information sessions for energyefficiency suppliers for all businesses, including the agricultural community. In addition, the 80,000-customer local distribution company provides help to ERIP applicants in completing the application forms, verifying the installation and providing the incentive payment directly to the successful client. Ontario’s local distribution companies administer ERIP across the province. New Hamburg dairy farmer James Otto (r.) with John Thomson Kitchener Wilmot Hydro. “You can immediately feel the difference with the fans on. High temperatures affect cows a lot more than it does us,” he says. “It puts stress on the animals and with their comfort affected, they are not as productive.” Since installing five 24-foot, high-efficiency ceiling fans in his barns last year, the lower temperatures have made the 150-cow milking herd more comfortable during hot weather, which has increased milk production, James says. Four fans operate in the large free-stall barn and one in the milking barn. “The more comfortable my cows, the healthier they are, the more they milk, the better they perform.” James, along with his wife, Mary and son Michael, own and operate Century Oak Farm in New Hamburg, Ontario. The Otto family has farmed for more than 130 years. Because the ceiling fans are energy efficient and reduce electricity demand, Century Oak Farm received a $24,000 incentive under the Ontario Power Authority’s Electricity Retrofit Incentive Energy efficiency is a constant at Century Oak Farm, James says. The Ottos moved to a more energy-efficient dairy operation when they replaced an older closed barn in 2004 with an open-sided natural-ventilation structure. The new structure relies on temperaturecontrolled side curtains to increase air and light and reduce the amount of electricity required. When the naturally ventilated barn was being planned, James considered installing high-efficiency fans to further reduce the summer temperatures for the cows, but the cost was outside his budget. Conventional basket-style exhaust fans were an option; but they are not as energy efficient nor as effective in creating a more comfortable environment for the cows. The Ottos decided against installing any fans. “Every summer when the heat returns, we discussed installing the high-efficiency fans. But the high cost was always the barrier,” he says. Anticipating they would eventually install the large fans, the barns’ roofs were reinforced to support the fans’ weight. Continued on page 4 1 Energy Efficient Fans take their cue from the Humpback Whale How can whales swimming in the ocean help generate more energy from natural, renewable sources such as wind? Two Ontario-based companies believe whales can help and have proven it. Toronto-based WhalePower Corp. has spent five years testing and gathering data to study whether a radically new type of turbine or fan blade modeled after the flippers of humpback whales – with rounded bumps known as tubercles along the leading edge – performs much more efficiently than conventional, flat, straight-edged blades. And Seaforth, Ont.-based Envira-North Systems Ltd., Canada’s largest supplier of industrial ceiling fans, has incorporated the new blades into a new line of fans that began shipment to customers in May 2009. Envira-North Systems has developed the energy-efficient Altra-Air industrial fan, which has blades modeled after the flippers of humpback whales. “We were approached by WhalePower with their tubercle-technology blade design and, after reviewing the test results, decided to take a chance,” says Envira-North chief executive officer Monica Bowden. “The result is our new HVLS – for high-volume, lowspeed – Altra-Air industrial fan, for use in large buildings such as factories, warehouses, arenas, swimming pools and dairy barns, where heating, cooling and air circulation are especially important for the health of the animals.” Customer interest in the new fan’s design has been strong, Bowden says, and will likely grow exponentially as early customers report improvements in efficiency and reductions in energy costs. “We estimate that the HLVS Altra-Air will pay for itself within six months – or sooner – from the reduction in electricity costs,” Bowden says. “In fact, one customer reduced energy costs by $100,000 in the first six months, which was more than twice the cost of the fans installed.” The market for industrial fans in North America is in the $100-million range, she adds. WhalePower says that the advantages of the HLVS fan design add up to a remarkable technological breakthrough. The largest model, 24 feet in diameter, uses five blades versus the conventional 10, yet the five blades are 25 percent more aerodynamically efficient than the traditional 10-blade configuration. And they not only circulate more air, but they also do it more quietly. Blade noise is reduced to less than 20 percent of that made by stock fans, with less vibration of the blades, which reduces blade failure from metal The fan blades feature tubercles along their leading edge, which dramatically increase their aerodynamic efficiency. fatigue and also less wear and tear on the fan motor and gearbox. And the lower number of blades reduces material and manufacturing costs, allowing Envira-North to price the new fans competitively with traditional models. HVLS fan also consume 20 percent less electricity than conventional types. HVLS fans for agricultural applications are eligible for incentives through the OPA’s Electricity Retrofit Incentive Program and the High Performance New Construction Program. Stephen Dewar, vice-president of business affairs, director of research and development and a co-founder of WhalePower, says that the company designed precisely formed versions of the “bumps” along the leading edges of the whales’ flippers, which combine the sciences of both fluid dynamics and biomechanics. According to Dewar, “the bumps or tubercles along the leading edge of their flippers dramatically increase their aerodynamic efficiency.” The OPA’s Technology Development Fund and the Ontario Centres of Excellence contributed $70,000 to windpower research using tubercle blades at the Wind Energy Institute of Canada. The results, Dewar says, showed a 20-percent increase in power generation and an 80-percent reduction in noise and vibration, which should translate into lower maintenance costs. These results, Dewar believes, will lead to dramatically increased efficiency of wind turbines and change the economics of wind-powered electricity generation on both a large and small scale. A number of technical, manufacturing, warranty and other issues will need to be resolved before tubercle blades for wind turbines, fans, compressors and other applications can achieve their maximum potential. Yet as they are adopted, the whale-inspired technology may be one of those breakthroughs the world needs, just when we need it. Note: The OPA does not endorse or guarantee any specific product or service. 2 Haldimand County Hydro knew the barn was too warm, and when I heard about these new fans, I thought they would be a better solution to buying more box fans. We wired them in last November, and when we had hot weather early in May, I saw how effective they are. I’m really happy with them.” Photo of the farmer, Howard Strobosser and Jane Albert, Haldimand County Hydro consumer services manager. Energy-efficient ventilation saves money, boosts production When hot weather arrived in early May, Howard Strobosser had 100 of the coolest Holstein cows in town, thanks to his decision to participate in an incentive program that helped him reduce electricity costs and increase milk production on his Jarvis, Ontario dairy farm. The Electricity Retrofit Incentive Program (ERIP) is designed to encourage agricultural businesses to conserve energy with the help of financial incentives. ERIP is funded by the Ontario Power Authority (OPA), delivered through participating local distribution companies (LDCs) across Ontario and is designed to encourage the replacement of old lighting, heating and cooling systems with energy-efficient technologies. In the agricultural sector, ERIP focuses on equipment such as lighting, heating, swine creep heat and controls, livestock waterers and ventilation. The program offers a set list of technologies that have a corresponding per-unit or performance-based savings and are ideal for equipment replacements or upgrades. The program also offers a custom-option track that allows farmers to select technologies based on their specific needs and calculates incentives based on how much they improve energy efficiency. For the nearly 5,000 dairy farmers in Ontario, keeping cows cool and comfortable year-round is a big part of a successful dairy operation. By applying for an ERIP incentive to offset the cost of new ventilation in his 18,000-square-foot, five-year-old barn, Strobosser was able to install three 24-inch energy efficient fans that move more air than dozens of smaller, less efficient fans. In fact, just one of these fans is equivalent to 56 24-inch highvelocity fans, or 30 36-inch ceiling fans. In addition to saving an estimated 60 kilowatts (kW) of electricity per year and recouping his initial investment in roughly two years, the cooler and more consistent temperatures in his barn will help optimize his herd’s milk production. And that’s the bottom line at Strodale Farms, where Howard, his wife, Amanda, and children Erin, age eleven, and Kyle, age nine, are a third-generation dairy farming family. “We have a lot of fun here,” says Amanda. While farmers know that keeping electricity costs down is integral to good farm management, many are unsure about the affordability or timing of efficiency retrofits – especially in challenging economic times. For Strobosser, the ERIP incentives available for his installation were a critical factor in his decision to install the high-volume, low-speed Altra-Air fan which utilizes some of the most innovative commercial ventilation technology on the market today. Like most other types of energy-efficient fans, the Altra-Air fan produces dramatically less noise and consumes much less energy than traditional models. Altra-Air is just one of the many kinds of energy-efficient fans that qualify for ERIP incentives. The Strobossers’ application was administered by Haldimand County Hydro, which works with farmers who are interested in participating in the ERIP program. Jane Albert, Haldimand County Hydro consumer services manager, visited their farm recently to deliver a cheque for $14,913. “Haldimand County Hydro is proud to support our agricultural customers’ efforts to increase their energy efficiency with the help of the Ontario Power Authority’s Electricity Retrofit Incentive Program,” she says. “Mr. Strobosser has made a significant investment in his dairy production with these fans and by doing so has demonstrated his commitment to energy conservation, as well as his desire to ensure his livestock are comfortable.” For more information about the ERIP program and to download application forms, visit www.business.everykilowattcounts.ca, or contact your local distribution company. “My grandparents came from Holland to start up this farm,” Howard adds. “My dad kept it going, and I’ve farmed all my life. I 3 Energy-efficient fans blow cool for dairy farming Continued from page 1 James then learned of the ERIP incentives for the high-efficiency ceiling fans through a vendor who had attended one of the Kitchener-Wilmot information sessions. Less than a week after making the application, KitchenerWilmot Hydro pre-approved the installation, Mr. Thomson says. “Without the incentive from ERIP, we would not have installed the fans,” James says. “The incentive was the solution to the problem.” The ceiling fans move more air using less electricity than conventional exhaust fans and as a result cost less to operate. Each of the fans has a two-horsepower motor and, working together, they move two million cubic feet of air per minute. As energy costs rise, farm businesses will become more focused on installing more efficient equipment, James says. “It’s getting more and more important as the price of energy goes up. If there is an incentive for choosing a more efficient energy technology over a less costly and less efficient one, we will choose the more energy-efficient equipment.” But the decision must be economically justifiable, James says, adding he normally expects a four- to five-year payback on equipment. “I am not going to pay twice as much to get the same thing because of a small energy savings. “As much as I am green, I still have to run a business. The incentive makes investing in more energy-efficient technology a realistic business decision.” For information about the Ontario Power Authority’s ERIP incentive program, see www.business.everykilowattcounts.ca. Planning to build a new livestock building? Build it green and reap the rewards. If you’re about to build a new livestock building, you owe it to yourself to check out the High Performance New Construction (HPNC) Program. It’s likely you could reap substantial benefits. Visit hpnc.ca to find out how you can make your project qualify. Download the agribusiness worksheet to instantly see your potential incentive amount. Not only is it easier than you think—it can make your new livestock building healthier and more profitable for years to come. If your building is in Ontario, contact us today. For more information call 1-888-OPA-HPNC or visit www.hpnc.ca Applications available online. Electricity conservation on Ontario farms is produced by the Ontario Power Authority to provide information about energy conservation and efficiency and innovative applications to help Ontario farmers better manage their electricity costs. This publication, available online at www.powerauthority.on.ca, examines a variety of technologies and best practices that improve farming operations and reduce energy costs. Your comments and suggestions are welcome. To have your name added to the mailing list, send an e-mail note to info@powerauthority.on.ca.