ISO Training Program (CBSPD)

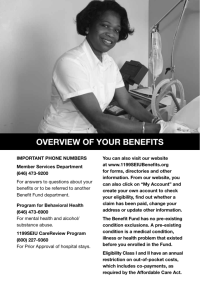

advertisement