Wipes Market - John R. Starr Inc.

advertisement

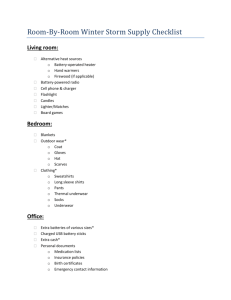

KEY FACTORS DRIVING AIRLAID DEMAND, SUPPLY AND PROFITABILITY By Pricie Hanna NTC 2002 John R. Starr, Inc. Resources for Decisions Nonwovens, Hygiene Absorbent Products & Key Raw Materials John R. Starr, Inc. u Management consulting firm u Specialists in nonwoven products, hygiene absorbent products and related industries u Confidential client engagements u Multi -client market and technology Multi-client publications Global Overview of Airlaid Nonwovens By Process and Application 2001 Demand for All Applications By Bonding Process By Product Application Wipes Latex Bonded Thermal & Multi Bonded Hydroentangled Airlaced Hydrogen Bonded K-C Coform Other Hygiene Cores & Sublayers Other: Tabletop Medical Food Packaging OUTLOOK FOR WIPES MARKETS Global Outlook for Nonwoven Consumption in Wipes 10 4.4% per year growth 1.5 billion m2 incremental demand 7.7 8 6.2 Billions of Square Meters 6 4 2 0 2001 2006 Spunlaced is emerging as the leading technology competing with airlaid for wipes applications. Technology Life Cycle for Nonwoven Wipes Sales Spunlaced Carded thermal bonded Airlaid Airlaced Laminates Needlepunched Introduction Advanced technologies Growth Time Mature Carded chemical bonded Decline Nonwoven Technology Competition in Global Wipes Market Product Specialization Spunlaced Airlaid Carded Other Scale Ovals represent approximations of volume present in wipes market Performance of Nonwoven Wipes Market – Price Versus Performance of Nonwovens Spunlaced All-Staple Airlaced & Spunlaced Pulp/Staple Composites Caustic Entangled Specialty Carded Cheese Cloth Airlaid Carded Wet Laid Apertured Film laminates Spunbonded Price/Yd2 Performance of Nonwoven Wipes Market – Price Versus Performance of Nonwovens in Selected Markets Clean Room Dry Floor Sweepers Baby Wipes General Purpose Wipes Personal Care Wipes Household Cleaner Cloths Food Service Wipes Price/Yd2 Surface Prep Printing Wipes Embalming Wipes Global Outlook for Nonwoven Consumption in Wipes Spunlaced and Airlaid – 2001 Billions of Square Meters Spunlaced Airlaid Global U.S. & Canada North American Airlaid Market Environment u Significant new airlaid capacity recently installed (with latex, thermal and hydrogen bonding capabilities) for advanced airlaid composite, flushable moist tissue and traditional applications. u New lines have excellent economics of scale when fully utilized. u Currently, supply exceeds demand. u No airlaced (hydroentangled airlaid) lines are in this region yet. North American Spunlaced Market Environment u Significant new capacity has been announced to the industry. u Continued import of low cost spunlaced substrate from Europe and Middle East will be needed to satisfy ongoing demand. u North American nonwovens producers and their major customers have not embraced airlaced concept for wipes. U.S. and Canada Market Dynamics Baby Wipes High Performance Attributes Key Drivers Airlaced Spunlaced Airlaid • Major consumer products competitor switching substrate technology • Excess European spunlaced and airlaced capacity entering market Low Low High Relative Cost U.S. and Canada Market Dynamics Home Care Wipes High Performance Attributes Key Drivers Airlaced Airlaid Carded Spunlaced Low Low High Relative Cost • Increased price competition at end product level as category matures • New market entrants drive demand for substrate differentiation U.S. and Canada Market Dynamics Personal Care Wipes High Performance Attributes Key Drivers Airlaced Spunlaced • Spunlaced is the traditionally preferred substrate for personal care wipes • New spunlaced/airlaced innovation occurring to reduce costs and increase differentiation Low Low High Relative Cost Airlaid Will Remain a Major Technology in the Global Wipes Markets but growth could be impacted by • a possible shift to spunlaced in the large North American baby wipes market, and • a shift to carded in the household wipes market Airlaid Versus Spunlaced in Global Wipes Market Airlaid could grow faster if the baby wipes shift does not occur Billions of Square Meters Latex/Thermal Bonded Airlaid 2001 2006 Spunlaced/Airlaced 2001 2006 Sources of Nonwoven Demand Growth For Global Wipes Markets 2001 – 2006 By Technology Millions of Square Meters Spunlaced Including Airlaced Latex & Thermal Bonded Airlaid Carded Other Additional Capacity Will Be Needed to Meet Future Spunlaced/Airlaced Demand WORLD SUPPLY AND DEMAND OUTLOOK SPUNLACED NONWOVENS 2001 - 2006 (1) ine Trend L y t i c a p rm Ca Long Te Thousands of Tonnes Demand 2001 2002 2003 2004 2005 91% of Nameplate Capacity (1) Capacity announcements to date only through 2003/2004. No additions assumed after that time in this figure. 2006 Wipes Will Account for Much of the Demand Growth for Spunlaced/Airlaced Nonwovens SOURCES OF GLOBAL DEMAND GROWTH SPUNLACED NONWOVENS BY END USE 2001 - 2006 Thousands of Tonnes Wet Wipes Medical Applications Dry Wipes Other Commercial Progress Will be Driven by a Number of Well Resourced Companies Consumer wipes: Procter & Gamble, Kimberly-Clark (baby and adult hygiene) Procter & Gamble, Reckitt Benckiser, Kao, Beiersdorf, Clorox, Unilever, SC Johnson, Kimberly-Clark, Henkel (personal care and household) Industrial wipes: Kimberly-Clark, Georgia-Pacific, SCA Hygiene, PGI, DuPont, others Nonwovens: DuPont, PGI, Buckeye, GeorgiaPacific, Suominen, others North American Examples of New Airlaid Wipes u P&G’s Swiffer Wet and Swiffer Wet Jet u Clorox’s ReadyMop u SC Johnson’s Pledge Grab -It Wet Floor Grab-It Wipes u K -C Splash ‘n Go hand and face wipes K-C u Playtex’s Personal Cleansing Cloths u K -C’s Cottonelle Fresh Roll Wipes K-C’s Recent John R. Starr, Inc. Reports on Wipes Markets and Nonwoven Technology Competition u World Outlook for Nonwoven Wipes 2001 – 2006 u World Demand and Supply Outlook for Spunlaced Nonwovens 2001 – 2006 u Personal Care Nonwovens Products – North America u The Evolving Markets for Nonwoven Home Care Products OUTLOOK FOR HYGIENE CORE AND SUBLAYER APPLICATIONS Airlaid Cores and Sublayers in Feminine Pads u Ultra thin sanitary napkins with airlaid cores are slowly and steadily penetrating in all global markets. u In developing markets, higher cost of ultra thins and women’s uncertainty about performance are barriers. u Leading brands have upgraded airlaid core and sublayer components. Trends in Airlaid Cores and Sublayers for Ultra Thin Feminine Pads Old Designs Most Recent Designs P&G Latex LatexBonded BondedAirlaid Airlaid Multi-Bonded Multi-Bonded Airlaid Airlaid K-C Coform Coform Thermal ThermalBonded Bonded Airlaid Airlaid Multi-Bonded Multi-Bonded Airlaid AirlaidSublayer Sublayer Multi-Bonded Multi-Bonded Airlaid AirlaidSublayer Sublayer Peat PeatMoss MossCore Core Hydrogen HydrogenBonded Bonded Airlaid Core Airlaid Core J&J Trends in Airlaid Cores and Sublayers for Ultra Thin Feminine Pads Old Designs SCA Hartmann Private Label Latex LatexBonded Bonded Airlaid Sublayer Airlaid Sublayer Hydrogen HydrogenBonded Bonded Airlaid Core Airlaid Core Conventional Conventional Fluff FluffPulp Pulp Conventional Conventional Fluff FluffPulp Pulp & Latex LatexBonded Bonded Airlaid Airlaid Most Recent Designs Multi-Bonded Multi-Bonded Airlaid AirlaidSublayer Sublayer Hydrogen HydrogenBonded Bonded Airlaid Core Airlaid Core Carded CardedTAB TAB Sublayer Sublayer Hydrogen HydrogenBonded Bonded Core Core Latex LatexBonded Bonded Airlaid Airlaid & Multi-Bonded Multi-Bonded Airlaid Airlaid Airlaid Composite Cores in Adult Incontinence Products and Diapers u u Within three to five years, significant penetration expected for light to moderate urinary incontinence pads. u u Specialty diapers, such as swim diapers, use airlaid cores. u u Product development work continues on cost effective applications for airlaid cores in diapers and training pants. Converting efficiency and cost barriers currently prevent use in high volume diapers/training pants. OUTLOOK FOR AIRLAID SUPPLY/DEMAND BALANCE AND PROFITABILITY Substantial New Airlaid Capacity Installed in 2001 in North America u u In North America, 5 new lines with capacity in excess of 100,000 tonnes were installed last year. Ø None of these lines are expected to be fully utilized in 2002 with incremental new volume. Ø Buckeye and Concert have shifted production from older lines to new lines causing significant unused capacity on older lines. Ø Demand for new airlaid composites and moist toilet tissue is growing at slower pace than expected. New Airlaced Capacity Available in Europe and Middle East Region u New airlaced (hydroentangled airlaid) nonwovens are becoming available to compete with all -staple spunlaced wipe applications. all-staple u u Cost competitive exports to North America are expected. Asia – New Capacity Driving Growth in Both Conventional and Composite Applications u Large scale capacity installed by BBA in China last year is filling up initially more on conventional applications than higher value composites. u A new Dan -Web airlaid line is planned for Dan-Web China. u u One or two other new lines expected in this region. Profitability Outlook u u Near term, airlaid producers’ profitability will continue to be depressed until the large capacities of the recently installed lines are filled. u Longer term, the companies that have invested in large capacity lines with significant economies of scale will achieve attractive profitability levels on those lines. Profitability Outlook u Profitability prospects for older, smaller capacity lines are dependent on successful development of specialty niche applications which command higher sales values. u Competition from spunlaced all -staple fabrics all-staple and airlaced substrates in the wipes markets will reduce the growth prospects and profitability of latex bonded airlaid producers.