Chinese factories plead for help Is Obama giving up on

advertisement

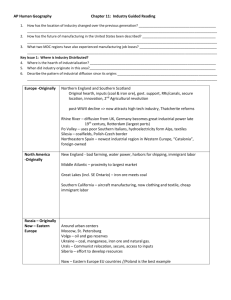

Textile and Apparel Weekly September 25, 2009 EXTRACT Content: Chinese factories plead for help d Is Obama giving up on free trade? China's textile industry once again stands on the cusp Zhejiang: Textile Factory Price Down 3.3% Jinzhou Plan to Become Largest Textile Industry Base in North China Cotton stocks in third consecutive season of decline in 2009/10 Opportunities for UK fashion companies in China New textile e-book offers invaluable resource China Textile and Apparel Exports Tumbled 11.12% in Jan.-Jul. Chinese factories plead for help DATE: 2009-09-25 During the first half of this year, Yang Zongfu's blue jean factory had few customers. Now, as his business picks up, he can't find enough workers. Clutching a chalkboard with a long list of job openings, Mr. Yang joined about 30 other factory owners who have been spending their mornings at a street employment fair in the southern town of Xintang, the jean-manufacturing hub of China. "I've been out here for two days and haven't found anyone," said Mr. Yang, as the scorching late morning sun beamed down on his sweaty, bald head. The dearth of workers is a surprising turn in an economy where millions were laid off just months ago, and the government worried the jobless would riot. Back then, it was the workers roaming the streets looking for jobs. The labor crunch is another sign that the Chinese economy - the world's third largest - is bouncing back from the global downturn, invigorated by government stimulus spending and a flood of cheap bank loans. But experts say the shortage is also the result of a wariness among migrant workers - whom the government discouraged from traveling to cities when jobs were scarce - of returning before they are sure the economy has fully recovered. China's economy has certainly begun to heat up, contributing to the increased demand for labor. The nation's economic growth hit 7.9 percent in the second quarter, up from 6.1 percent the previous quarter, the government said. Exports, retail sales and factory output also improved in July, according to official statistics. In Xintang, Mr. Yang said his business started improving in August when domestic buyers started placing orders. His factory - which has received few overseas orders - is now ramping back up to its preslowdown head count of 100 from around 60 earlier this year, he said. His chalkboard helpwanted sign advertises for one worker who can sew belt loops and another who can stitch pockets. He also needed a fabric stretcher, a pants hemmer and a zipper stitcher. Other factory bosses along the street displayed signs made out of red poster board or scraps of brown cardboard looking for textile workers. Source: Washington Times Source: China Textile Network Company -1- Is Obama giving up on free trade? DATE: 2009-09-25 The Star's Wednesday editorial Since taking office, President Obama has frequently declared himself a free trader. In several appearances over the last few months, he has driven home the message that protectionism is dangerous to our economic health. His rhetoric is encouraging, but his actions have been puzzling. When the Group of 20 industrial nations meets today in Pittsburgh, the participants won´t be inclined to view Obama as a free trader not after his recent decision raising a 35 percent tariff on Chinese tires.This isn´t the Smoot-Hawley tariff of 1930; far from it. But the move is worrisome nonetheless. It came under Section 421 of trade law, which allows Washington to raise tariffs in the face of import surges. With this step, Obama has encouraged other industries to bring their own cases for redress. What started with imported tires could encompass imported paper, machinery, consumer goods, steel and clothing. The National Council of Textile Organizations says it is already considering such a move.President Cass Johnson says Obama´s decision on tires means a Section 421 case is a viable option for textiles as well. When politicians bar importers from offering bargains, the resulting price increases hit lower-income consumers hardest. What makes this case especially troubling is that the tariff on Chinese tires will raise tire prices in the United States but without doing much to create U.S. jobs. Tire distributors will simply seek substitute products from other low-cost exporters, such as Mexico. Obama has talked a good game on free trade, but the rhetoric sounds increasingly hollow. He failed to put up much of a fight against the buy American provisions in the stimulus package. In May, the administration said it was ready to move ahead on pending free-trade pacts with Panama, Colombia and South Korea, but not much has happened. G-20 participants will be looking for reassurance that the United States has not abdicated its traditional leadership position on trade. The global economy depends for recovery on growing exports, and that’s especially true for the United States. Obama cannot expect to open overseas markets for American goods if he’s not willing to fight to keep our markets open as well. Source: voices China's textile industry once again stands on the cusp DATE: 2009-09-25 On September 8, the European Commission launched anti-dumping investigations on high tenacity polyester yarn made in China and other countries and regions, this is the first trade remedy investigation on Chinese textiles since the end of 2008 when the China-EU textile agreement expired. The focus of the case is the establishment of industry-standard country. The European Union has chosen the United States as a market economy of the industry-standard in its notice of the file. "If the United States would really be chosen as the industry standard, then the possibility of Chinese enterprises being charged by 30 to 50 percent anti-dumping duty will be greatly increased” said Zheng Jun Lin, the Secretary-General of China Chemical Fiber Association, "After all, production cost of the United States is much higher than China. This will undoubtedly increase negative factors to responding Chinese enterprises, but there is still a trace of turning point. Source: China Textile Network Company -2- 40 Chinese mainland enterprises are involved in the case, which involves more than US $100 million. In accordance with EU law, investigation procedures will last for 15 months since September 8, 2009 onwards. European Commission will generally provide a preliminary ruling within 9 months after the establishment of the file. The complaint was raised by the European Association of Man-made Fibers on behalf of three European companies, the three companies form more than 60 percent share of EU total production of high tenacity polyester yarn. Allegations of the complaining party state that export volume of Chinese products to Europe increased from 2800 tons in 2004 to 51,400 tons in 2008, market share of Chinese products in European market promoted from 1.2 percent to 22.4 percent in 2008. As early as February 2004, the European Union had filed anti-dumping accusations on high strength polyester fiber yarn made in China Taiwan. Taiwan’s exports of high-strength polyester yarn to the EU were only 2250 tons in 2001, but reached 5200 tons in 2002, and up to 7240 tons in the first 11 months of 2003. According to statistics of the Mainland, involved product exports from the Mainland China to Europe marked about US $1.2389 billion in 2008, an increase of 33.15 percent year on year. Source: www.ccfgroup.com Zhejiang: Textile Factory Price Down 3.3% DATE: 2009-09-24 According to the latest data from State Statistics Bureau Zhejiang investigating team, the industry product factory prices of this province went down 6.7% in August, on a yearly basis. While the negative growth rate turned to narrow, which ending the nine successive negative growth since last Nov. The monthly PPI turned to positive growth for the first time. In the 15 industry sectors, textile product factory price went down 3.3%, year over year; sewing product went down between 0.3%-1.8%. Source: CNTEX news Jinzhou Plan to Become Largest Textile Industry Base in North China DATE: 2009-09-24 An investment inviation event was held in Shenyang recently. It aimed at constructing the largest textile industry base of North China in Jinzhou. More than 40 textile companies expressed their interests to invest there. The key projects included: one million spindle scale spinning mill; 150 million pieces of garment manufacturing plant; new material, new fabrics R&D center. Its long term goal is to construct a 10-billion yuan trade volume textile market, as welll as stock and logistics base. Source: CNTEX news Source: China Textile Network Company -3- Cotton stocks in third consecutive season of decline in 2009/10 DATE: 2009-09-23 The latest U.S. Department of Agriculture (USDA) projections for 2009/10 indicate that world cotton stocks are expected to decline for the third consecutive season. Global ending stocks are currently forecast at 56.3 million bales for 2009/10, 5.2 million bales (8.5 percent) below 2008/09 and the lowest since 2003/04s 48.1 million bales. For 2009/10, the world stock reduction is largely attributable to China (the leading cotton producer and consumer) where 45 percent of the global decline is expected. However, stocks are expected to decline in most of the cotton-producing countries this season. In China, stocks are forecast to decline 2.3 million bales to 17.6 million, their lowest in 7 years. U.S. ending stocks are expected at 5.6 million bales in 2009/10, 600,000 bales below 2008/09 and the lowest in 5 years. Meanwhile, stocks in India (the second largest producer and consumer) are forecast only marginally lower and will likely play a key role in the global trade of raw cotton in 2009/10. Source: U.S. Department of Agriculture Opportunities for UK fashion companies in China DATE: 2009-09-23 The experience of launching and running Harvey Nichols in Hong Kong and sourcing for Gap in Asia Pacific are among the credentials of the speakers at a seminar to provide insight into the potential for selling in China being organised by UK Fashion Exports (UKFE), the export division of the UK Fashion and Textile Association (UKFT), on 11 November 2009 from 3-6pm at 5 Portland Place, London W1. Everyone knows something about China, but only a small percentage of fashion executives have sufficient indepth, locally-acquired knowledge to source effectively, to make the move into retailing or understand the Chinese perception of Western fashion brands, claims Paul Alger, executive director, UKFE. Our retail experts will address these issues and to allay the fears of retailers and designers keen to move into the region, but apprehensive about protecting their designs and trademarks, a top trademark attorney and a successful IP litigator will share their experiences. Speaker Meanne Ho, previously president of Gap Inc,is managing director of MH Concepts, a retail development and sourcing organisation, whose clients include Gymboree, Norma Kamali for Walmart and other established US brands/retailers. Meanne also set up a 2,000 sq ft retail store in Shanghai. Brenda Wang was CEO of Harvey Nichols Kong and spearheaded the pre-store set up and first year of business. She now runs Brandxcel, a Hong Kong-based boutique consulting firm, specialising in market entry strategies, business development and planning and retail operations for niche luxury, fashion and lifestyle branded businesses. The legal experts are David Keltie of Keltie, the UK and European patent and trade mark attorneys, and David Wragge, head of Intellectual Property and the Far East operations of Wragge & Co. UKFT is the body that represents the fashion and textile sector. Its members include major suppliers to high street retailers, as well as leading brands. Source: UK Fashion and Textile Association Source: China Textile Network Company -4- New textile e-book offers invaluable resource DATE: 2009-09-21 Global news agency International News Services Ltd in association with world-leading business publisher Aroq Ltd - has released a major new e-book compiling global textile regulation news and analysis since 2001. This comprehensive 157 page report offers clothing and textile companies, consultants and lobbyists a survey of the sector’s rapid evolution to a free, global market in the last 10 years. The report is a detailed backgrounder of the last decade’s textile policy, collected and arranged in a concise document with monthly summaries to direct and help select topics and an essential background brief for marketers seeking to break into new markets, or lobbyists wanting to understand the rationale behind trade regulations they want changed. The document, available only on Aroq’s just-style.com at http://www.juststyle.com/store/product.aspx?id="80375&lk=new" is a must-have for business, policy makers and stakeholders in the textile industry, according to Keith Nuthall, editor of International News Services. “No where else will you find such a comprehensive regulatory history compiled into one document”, he said. “Our expert and experienced contributor journalists from around the world have done a terrific job this decade in explaining the transformation of the clothing and textile sector. We are delighted to see their work compiled and edited in such a good looking e-book.” The current decade has been a tumultuous one for the clothing and textile industry, a sector spanning the entire globe and touching millions of workers, from small-scale cotton farmers to the world’s top fashion designers. Starting from 2001, there was the beginning of a slow march towards liberalised global markets, led by the World Trade Organisation´s (WTO) plan to abolish market quotas by January 2005. This transformation of what has traditionally been a well-controlled market to something close to a global free-for-all has not been peaceful, however: angry disputes have broiled between exporters and importers, each of which have had growing concerns a liberalised market may backfire; competing nations have quarrelled for years over protectionist tariffs and unfair import rules; failing textile companies have been illegally (and sometimes legally) bailed out by concerned governments;and several countries including China joined the WTO, with all the improved market access rights and commitments that follow. When planning for the future, it is always important to know the reasons behind a current government policy or law and the experiences its imposition provoked, explained Nuthall. When lobbing for regulatory change, it’s best to be on top of your brief and this e-book, produced in conjunction with just-style.com, gives textile and clothing companies worldwide a cogent tool to aid success. Source: International news Services Source: China Textile Network Company -5- China Textile and Apparel Exports Tumbled 11.12% in Jan.-Jul. DATE: 2009-09-21 Between January and July 2009, China’s textile and clothing exports declined by 11.12% compared with a year ago to $91.464 billion and cotton products exports plummeted 0.97 compared to last month, as demand from all of the nation’s major markets deteriorated. Cotton textiles led the slump During the first seven months of the year 2009, China's textile exports plummeted 5.72 percent; garment exports decreased by 5.39 percent. Looking further into the materials, cotton textiles led the slump, down 5.36 percent from the previous year's period; chemical textiles down 2.42 percent; wool textiles down 0.84 percent; silk textiles down 0.27 percent; and linen textiles down 0.05 percent. Looking further into the manufactured products, knitted garment & accessories led the slump, down 3.16 percent from the previous year's period; woven garment & accessories down 1.93 percent; special lace down 1.16 percent; chemical filament & textiles down 1.03 percent; cotton textiles down 0.99 percent; chemical staple fibre & textiles down 0.84 percent; wool textiles down 0.42 percent; silk textiles down 0.16 percent; and linen textiles down 0.03%. Looking further into the export products with an export turnover of above US$100 million, fleece fabric, synthetic filament yarn, embroidery and worsted fabric led the slump, down above 40 percent from the previous year's period. Many Chinese textile and garment enterprises have felt the chill and decided to turn their eyes away from European and American markets and focus back on the domestic market. But, sales in domestic market will not always enjoy a royal road. According to some exporters, to sell products in the home market their business had to go through complex examination and approval procedures to change from its previous corporate identity of an enterprise dedicated to processing materials supplied by overseas clients to a common domestic market oriented venture. Export price continue to fall In July 2009 the percentage change in China textile & garment export price index was -1.14% compared to June 2009. Of which, the percentage change in China textile export price index was 0.9% compared to June 2009; the percentage change in China garment export price index was 1.43% compared to June 2009. Experts attributed the export price index fall to three factors. First, material and energy prices continue to fall. Second, labor costs in China remain stable. Third, demand is not strong enough to offset the surplus supplies. The high cost of inputs in the textile sector including the Dollar to RMB rate, high cost of power and increasing cost of work force are fuelling the negative sentiments in the textile sector. Between January-June 2009, the total textile & garment import by US was down 14.29%, of which import from China was down 3.36%, while import from Vietnam in the same period was up 1.5% and import from Bengal in the same period was up 7.78%. SMEs feeling the chill of crisis According to data collected from statistics-worthy Chinese textile enterprises surveyed by National Bureau of Statistics, the growth ratio of business operating profit of China's chemical fibre industry increased to 16.5 percent in Jan. - Jul. 2009 from -4.6% in Jan. - Jun. 2009. Industrial added value of statistics-worthy Chinese textile enterprises was up 8.6% year-on-year. The result may Source: China Textile Network Company -6- demonstrate the statistics-worthy textile enterprises ability to generate consistently good profitability, and underscore their confidence that it will enter the recovery period. On the other hand, a huge amount of small and medium textile enterprises in China are now feeling the chill of crisis due to lack of financial resources, which is a vital ingredient to start off a business. The operators of small and medium textile enterprises need to be trained in managerial skills, which will enable them to recruit, manage, develop and control inter-business activities. There is also the need for organizations to provide a friendly manufacturing environment for the SMEs, as this will reduce the cost incurred during production and also make them have access to the market especially the importation of new technology to enhance standards and quality production. Source: CNTEX Source: China Textile Network Company -7-