Chapter 12: Hydrodynamic and Hydrostatic Bearings

advertisement

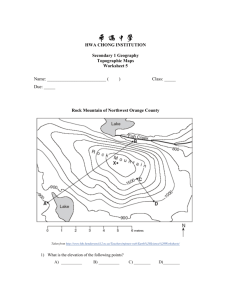

Chapter 12: Hydrodynamic and Hydrostatic Bearings A cup of tea, standing in a dry saucer, is apt to slip about in an awkward manner, for which a remedy is found in introduction of a few drops of water, or tea, wetting the parts in contact. Lord Rayleigh (1918) A Kingsbury Bearing. Hamrock • Fundamentals of Machine Elements Density Wedge and Stretch p p ρ ub ub(x) Figure 12.1 Density wedge mechanism. Figure 12.2 Stretch mechanism. Hamrock • Fundamentals of Machine Elements Physical Wedge and Normal Squeeze p p wa ub wb Figure 12.3 Physical wedge mechanism. Figure 12.4 Normal squeexe mechanism. Hamrock • Fundamentals of Machine Elements Translation Squeeze and Local Expansion p p ua ub Figure 12.5 Translation squeeze mechanism. Heat Figure 12.6 Local expansion mechanism. Hamrock • Fundamentals of Machine Elements ua Aa Moving ua Da Ca E Velocity Profiles in Slider Bearings Ba B A Stationary A (a) Aa Ba B A (b) N ua A′ B′ z ua Aa h A Wz L ua Ka Ba ua Da H B x I B Stationary Figure 12.7 Velocity profiles in a parallel-surface slider bearing. Ca Ja M J A z A (c) Figure 12.8 Flow within a fixed-incline slider bearing (a) Couette flow; (b) Poiseuille flow; (c) resulting velocity profile. Hamrock • Fundamentals of Machine Elements Thrust Slider Bearing ω Bearing pad A Wt A′ ro ri Thrust bearing Lubricant Bearing pad Figure 12.9 Thrust slider bearing geometry. Hamrock • Fundamentals of Machine Elements Force and Pressure Profiles for Slider Bearing Film pressure distribution & sh Wz Wa ub Wxa ho q z Wza Wzb Fa q qs sh ho Fb qs (both sides) l x ub Figure 12.10 Force components and oil film geometry in a hydrodynamically lubricated thrust slider bearing. Figure 12.11 Side view of fixedincline slider bearing. Hamrock • Fundamentals of Machine Elements Design Procedure for Fixed-Incline Thrust Bearing 1. Choose a pad length-to-width ratio. A square pad (λ = 1) is generally thought to give good performance. If it is known whether maximum load or minimum power loss is more important in a particular application, the outlet film thickness ratio Ho can be determined 2. from Fig. 12.13. Once λ and Ho are known, Fig. 12.14 can be used to obtain the bearing number Bt. 3. From Fig. 12.15 determine the temperature rise due to shear heating for a given λ and Bt. The volumetric specific heat Cs = ρCp, which is the dimensionless temperature rise 4. 6 2 parameter, is relatively constant for mineral oils and is equivalent to 1.36 × 10 N/(m °C). Determine lubricant temperature. Mean temperature can be expressed as !tm t˜m = tmi + 2 where tmi = inlet temperature, °C. The inlet temperature is usually known beforehand. Once the mean temperature tm is known, it can be used in Fig. 8.17 to determine the viscosity of SAE oils, or Fig. 8.16 or Table 8.4 can be used. In using Table 8.4 if the temperature is different from the three temperatures given, a linear interpolation can be used. (continued) Hamrock • Fundamentals of Machine Elements Design Procedure for Fixed-Incline Thrust Bearing 5. Make use of Eqs. (12.34) and (12.68) to get the outlet (minimum) film thickness h0 as h0 = Hol ! !0ubwt WzBt Once the outlet film thickness is known, the shoulder height sh can be directly obtained from sh = ho/Ho. If in some applications the outlet film thickness is specified and either the velocity ub or the normal applied load Wz is not known, Eq. (12.72) can be rewritten to establish ub or Wz. 6. Check Table 12.1 to see if the outlet (minimum) film thickness is sufficient for the pressurized surface finish. If ho from Eq. (12.72) ≥ ho from Table 12.1, go to step 7. If ho from Eq. (12.72) < ho from Table 12.1, consider one or both of the following steps: a. b. Increase the bearing speed. Decrease the load, the surface finish, or the inlet temperature. Upon making this change return to step 3. 7. Evaluate the other performance parameters. Once an adequate minimum film thickness and a proper lubricant temperature have been determined, the performance parameters can be evaluated. Specifically, from Fig. 12.16 the power loss, the coefficient of friction, and the total and side flows can be determined. Hamrock • Fundamentals of Machine Elements Slider Bearings: Configuration and Film Thickness Sliding surface or runner ro ri Na Dimensionless minimum film thickness, Ho = ho /sh 1.0 .8 Maximum normal load .6 .4 .2 0 l Minimum power consumed 1 2 3 4 Length-to-width ratio, λ = l/wt Figure 12.13 Chart for determining Pads minimum film thickness corresponding to maximum load or Figure 12.12 Configuration of minimum power loss for various multiple fixed-incline thrust slider pad proportions in fixed-incline bearing bearings. Hamrock • Fundamentals of Machine Elements Film Thickness for Hydrodynamic Bearings Surface finish (centerline average), Ra µm µin. 0.1-0.2 4-8 Examples of manufacturing methods Grind, lap, and superfinish Grind and lap Approximate relative costs 17-20 Allowable outlet (minimum) film thicknessa , ho µm µin. 2.5 100 Description of surface Mirror-like surface without toolmarks; close tolerances .2-.4 8-16 Smooth surface with17-20 6.2 250 out scratches; close tolerances .4-.8 16-32 Smooth surfaces; close Grind, file, 10 12.5 500 tolderances and lap .8-1.6 32-63 Accurate bearing surGrind, precision 7 25 1000 face without toolmarks mill, and file 1.6-3.2 63-125 Smooth surface withShape, mill, 5 50 2000 out objectionable toolgrind and marks; moderate turn tolerances a The values of film thickness are given only for guidance. They indicate the film thickness required to avoid metal-to-metal contact under clean oil conditions with no misalignment. It may be necessary to take a larger film thickness than that indicated (e.g., to obtain an acceptable temperature rise). It has been assumed that the average surface finish of the pads is the same as that of the runner. Table 12.1 Allowable outlet (minimum) film thickness for a given surface finish. Hamrock • Fundamentals of Machine Elements Thrust Bearing - Film Thickness 10 Dimensionless minimum film thickness, Ho = ho /sh 6 Length-towidth ratio, λ 4 0 2 1/2 1 1 2 3 4 .6 .4 .2 .1 0 1 2 4 6 10 20 40 60 100 200 400 1000 Bearing number, Bt Figure 12.14 Chart for determining minimum film thickness for fixed-incline thrust bearings. Hamrock • Fundamentals of Machine Elements Thrust Bearings - Temperature Rise 1000 Dimensionless temperature rise, 0.9 Cs wt l ∆t m /Wz 600 400 Length-towidth ratio, λ 200 100 4 3 60 2 40 1 20 1/2 0 10 6 4 0 1 2 4 6 10 20 40 60 100 200 400 1000 Bearing number, Bt Figure 12.14 Chart for determining dimensionless temperature rise due to viscous shear heating of lubricant for fixed-incline thrust bearings. Hamrock • Fundamentals of Machine Elements Thrust Bearings - Friction Coefficient 1000 Dimensionless coefficient of friction, µl / sh 600 Length-towidth ratio, λ 400 200 100 4 60 40 1/2 1 3 2 0 20 10 6 4 2 1 0 1 2 4 6 10 20 40 60 100 200 400 1000 Bearing number, Bt Figure 12.16a Chart for determining friction coefficient for fixedincline thrust bearings. Hamrock • Fundamentals of Machine Elements Thrust Bearings - Power Loss 1000 Power loss variable, 1.5 hpl / Wz ub sh, W-s/N-m 600 Length-towidth ratio, L 400 200 4 100 1 60 40 3 2 1/2 0 20 10 6 4 2 1 0 1 2 4 6 10 20 40 60 100 200 400 1000 Bearing number, Bt (b) Figure 12.16b Chart for determining power loss for fixed-incline thrust bearings. Hamrock • Fundamentals of Machine Elements Thrust Bearings - Lubricant Flow 4 q q – qs 0 Dimensionless flow, q/wt ub sh qs (both sides) Length-towidth ratio, L 1/2 1 3 2 4 3 1 0 2 1 2 4 6 10 20 40 60 100 200 400 1000 Bearing number, Bt (c) Figure 12.16c Chart for determining lubricant flow for fixedincline thrust bearings. Hamrock • Fundamentals of Machine Elements Thrust Bearings - Side Flow 1.0 Volumetric flow ratio, qs /q .8 Length-towidth ratio, λ .6 4 3 .4 2 .2 1 1/2 0 0 1 2 4 6 10 20 40 60 100 200 400 1000 Bearing number, Bt Figure 12.16d Chart for determining lubricant side flow for fixedincline thrust bearings. Hamrock • Fundamentals of Machine Elements Wr Journal Bearing Pressure Distribution e 0a 0 Wb hmin F0 & Film pressure, p Fmax Figure 12.17 Pressure distribution around a journal bearing. pmax Hamrock • Fundamentals of Machine Elements Concentric Journal Bearing u Na Figure 12.18 Concentric Journal Bearing r c wt 2πr u u Bearing h=c Journal Figure 12.19 Developed journal bearing surfaces for a concentric journal bearing. Hamrock • Fundamentals of Machine Elements Typical Radial Load for Journal Bearings Application Automotive engines: Main bearings Connecting rod bearing Diesel engines: Main bearings Connecting rod bearing Electric motors Steam turbines Gear reducers Centrifugal pumps Air compressors: Main bearings Crankpin Centrifugal pumps Average radial load per area, Wr∗ psi MPa 600-750 1700-2300 4-5 10-15 900-1700 1150-2300 120-250 150-300 120-250 100-180 6-12 8-15 0.8-1.5 1.0-2.0 0.8-1.5 0.6-1.2 140-280 280-500 100-180 1-2 2-4 0.6-1.2 Table 12.2 Typical radial load per area Wr* in use for journal bearings. Hamrock • Fundamentals of Machine Elements Journal Bearing - Film Thickness Figure 12.20 Effect of bearing number on minimum film thickness for four diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Journal Bearings - Attitude Angle Attitude angle, Φ, deg 100 Diameter-towidth ratio, λj 80 0 1 60 2 4 40 20 0 10 –2 10 –1 100 101 Bearing number, Bj Figure 12.21 Effect of bearing number on attitude angle for four different diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Journal Bearing - Friction Coefficient 2 × 102 Dimensionless coefficient of friction variable, rbµ /c 102 Diameter-towidth ratio, λj 2 1 10 0 4 1 100 0 10 –2 10 –1 Bearing number, Bj 100 101 Figure 12.21 Effect of bearing number on coefficient of friction for four different diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Journal Bearing - Flow Rate Dimensionless volumetric flow rate, Q = 2πq/rbcwtω b 8 Diameter-towidth ratio, λj 6 4 2 1 4 0 2 0 10 – 2 10 –1 100 101 Bearing number, Bj Figure 12.23 Effect of bearing number on dimensionless volume flow rate for four different diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Journal Bearing - Side Flow Side-leakage flow ratio, qs /q 1.0 4 .8 Diameter-towidth ratio, λj 2 .6 .4 1 .2 0 10 –2 10 –1 100 101 Bearing number, Bj Figure 12.21 Effect of bearing number on side-flow leakage for four different diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Journal Bearing - Maximum Pressure Dimensionless maximum film pressure, Pmax = Wr /2rb wt pmax 1.0 .8 Diameter-towidth ratio, λj 0 .6 1 .4 2 4 .2 0 10 – 2 10 –1 100 101 Bearing number, Bj Figure 12.25 Effect of bearing number on dimensionless maximum film pressure for four different diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Diameter-towidth ratio, λj φ0 φmax 100 25 0 1 2 4 80 20 4 60 2 40 15 10 1 20 5 0 0 0 10 – 2 10 –1 100 Location of maximum pressure, φmax, deg Location of terminating pressure, φ0, deg Journal Bearing - Maximum and Terminating Pressure Location 101 Bearing number, Bj Figure 12.21 Effect of bearing number on location of terminating and maximum pressure for four different diameter-to-width ratios. Hamrock • Fundamentals of Machine Elements Minimum film thickness, h min; power loss, hp; outlet temperature, tmo; volumetric flow rate, q Journal Bearing - Effect of Radial Clearance hmin hp t mo q 0 .5 1.0 1.5 2.0 2.5 3.0 × 10–3 Radial clearance, c, in. Figure 12.27 Effect of radial clearance on some performance parameters for a particular case. Hamrock • Fundamentals of Machine Elements Squeeze Film Bearing w = – ∂h ∂t l z ho Surface b x Surface a Figure 12.21 Parallel-surface squeeze film bearing Hamrock • Fundamentals of Machine Elements Wz Wz Bearing runner Bearing pad Bearing recess Restrictor Recess pressure, pr = 0 pr > 0 Flow, q=0 Supply pressure, ps = 0 ps > 0 Manifold Fluid Film in Hydrostatic Bearing (b) (a) Wz Wz ho q p = pl q=0 p = ps p = pl (d) (c) Wz + ∆Wz Wz – ∆Wz ho + ∆ ho ho – ∆ho q q p = pr + ∆ pr p = ps (e) p = pr p = pr – ∆ pr p = ps Figure 12.29 Formation of fluid film in hydrostatic bearing system. (a) Pump off; (b) pressure buildup; (c) pressure times recess area equals normal applied load; (d) bearing operation; (e) increased load; (f) decreased load. (f) Hamrock • Fundamentals of Machine Elements Wz Radial Flow Hydrostatic Bearing ro ri p=0 sh pr q ho Figure 12.30 Radial flow hydrostratic thrust bearing with circular step pad. Hamrock • Fundamentals of Machine Elements