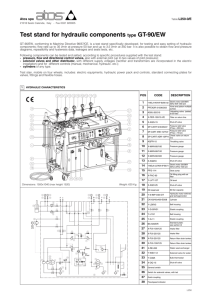

fluid power control systems

advertisement