DOC

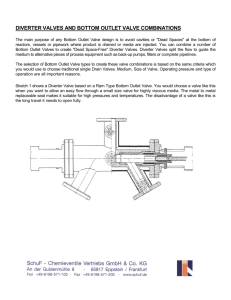

advertisement

Text for Tender Air flow control valve, Type PRD in solid design, provided for installation in the ductwork. Valve pneumatically operated over the input range of 0.07 – 1.0 bar positive pressure Casing manufactured of stainless steel AISI 316 with a removable side panel for airfoil access without requiring valve removal from the duct Expandable pneumatic flexible cells manufactured of EPDM rubber capable of operating at temperatures as high as 120 degrees C Airfoils manufactured of stainless steel An air distribution manifold manufactured of virgin material and designed to withstand pressures of at least 2.0 bar. Manifold shall be supported by a strain relief bracket and terminated in a brass, ¼” barbed fitting. Air valve operation shall be such that supplemental actuation motors and linkages are not required. The airflow control valve shall not have a dead-band at any point in the operational range. Air valves shall exhibit linear modulation of airflow and shall provide a minimum of a fifty to one turndown on flow. Leakage through a closed valve shall not exceed 1% of a rated flow volume at 10 m/s face velocity. Casing leakage shall be less than 10 l / (h · m2) at 1 bar, 20 °C and ∆p = 2 000 Pa. Valves shall withstand a continuous control pressure of up to 1.5 bar and temporary overpressure to 2.5 bar. Valves shall be capable of withstanding control pressure of up to 3.5 bar without bursting. Valves shall be able to withstand 100% relative humidity and particulate coatings up to 5 mm without a detrimental effect on performance. Technical data Fabricate: Krantz Type: PRD Design: circular rectangular Dimensions W x H: ____________ mm (see table 1 page 5) Diameter: _________mm (see table 2 page 5) Pressure drop Δp: max. _______Pa (see table 3 and 4 on page 6 and 7) Adm. operating temperature for damper: up to + 120 °C Adm. leakage rate in flow direction acc. EN 1751, class 2 Adm. leakage rate for housing acc. to DIN 25 496: 10 l / (h · m2) at 1 bar, 20 °C and ∆p = 2 000 Pa Vortex Shedding Flow Sensor Option Where specified, valves are to be provided with factory installed vortex shedding flow sensors and an electronic transmitter. Transmitters shall operate on either 20 – 28 VAC or 15 – 20 VDC power and shall output a 4 – 20 mA or 2 – 10 VDC signal linear and proportional to the flow volume. Transmitter accuracy shall be plus or minus 3 % of reading over the operation range. Flow sensors shall indicate actual air flow (m³/h) and shall not be effected by particulate, moisture, temperature, or ambient pressure. Flow sensors are to be wind tunnel tested. Subject to technical alterations.