2012 Annual Information Form

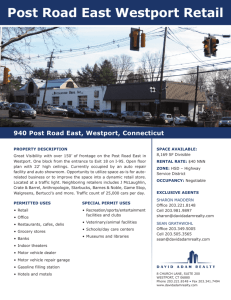

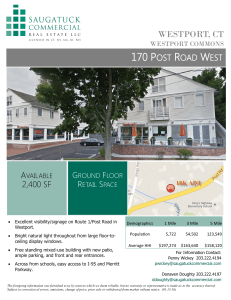

advertisement