REFRACTORIES

advertisement

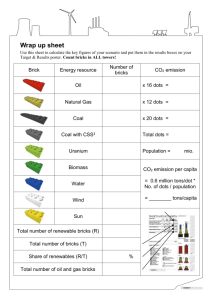

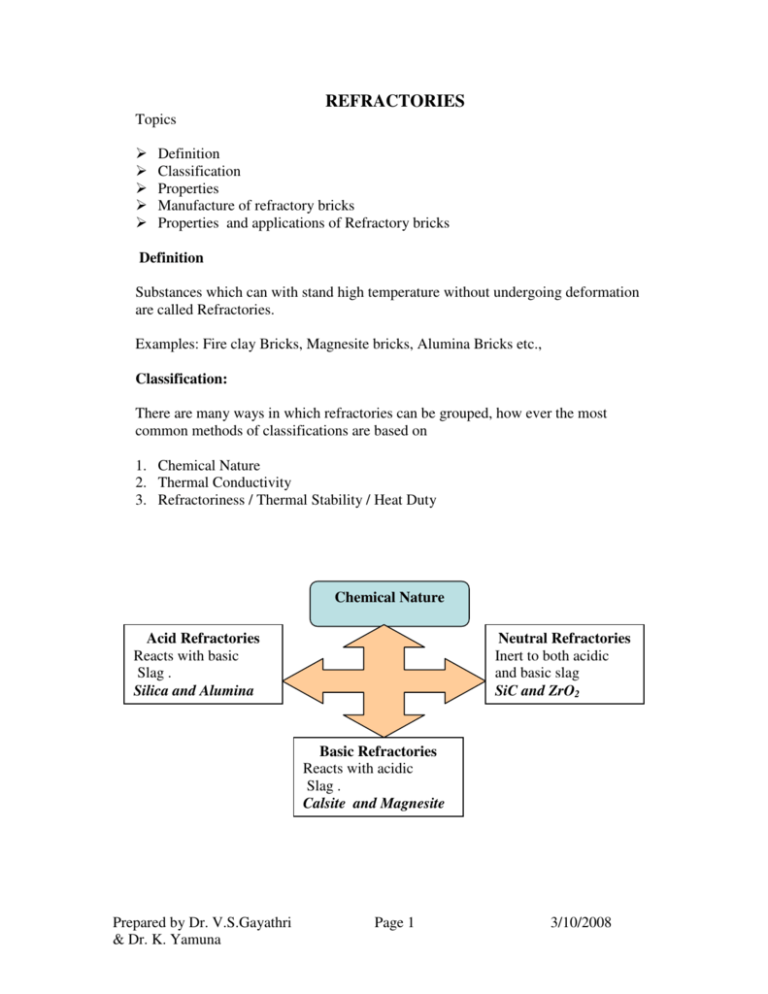

REFRACTORIES Topics Definition Classification Properties Manufacture of refractory bricks Properties and applications of Refractory bricks Definition Substances which can with stand high temperature without undergoing deformation are called Refractories. Examples: Fire clay Bricks, Magnesite bricks, Alumina Bricks etc., Classification: There are many ways in which refractories can be grouped, how ever the most common methods of classifications are based on 1. Chemical Nature 2. Thermal Conductivity 3. Refractoriness / Thermal Stability / Heat Duty Chemical Nature Acid Refractories Reacts with basic Slag . Silica and Alumina Neutral Refractories Inert to both acidic and basic slag SiC and ZrO2 Basic Refractories Reacts with acidic Slag . Calsite and Magnesite Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 1 3/10/2008 Conductivity Conducting Ex.: SiC, ZrC Non-conducting Ex.: Silica, Alumina Low 1520 - 1630 PCE 19 –28 Calcite Intermediate 1631-1670 PCE 28-30 Fireclay Heat Duty (in oC) High 1671-1730 PCE 30-33 Chromite Super >1730 PCE 33-38 Magnesite Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 2 3/10/2008 The following properties of refractory play an important role in selection of a refractory material for specific application • • • • • Refractoriness Refractoriness Under Load Thermal Conductivity Porosity Thermal Spalling Refractoriness Refractoriness is defined as the ability of a material to withstand high temperature. It is measured in terms of Pyrometric cone equivalence. This method was first adopted by Seger, hence also called Seger cone equivalence Pyrometric cones Test Method This method is used in ceramic industries to test ‘refractoriness’ of refractory bricks The test material cone is mix of oxides that melt at specific temperatures The cone has a equilateral triangular base (19mm) Height of the cone is 38mm The cone is heated at standard conditions (ie. at the rate of 10oC/min ) Pyrometric Cone Equivalent (PCE) Measurement Temperature at which the refractory brick or the cone bend (ie) the temperature at which apex touches the base is called refractoriness (units PCE) Refractory cannot be used above this temp Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 3 3/10/2008 Cone # 29: Stiff at test temperature Cone # 28: Just started Softening Cone # 27: Apex almost touching base Refractoriness under Load (RUL) In actual practice the refractoriness of the material is much less compared to that found by Serger cones method This may be due to the load it is exposed during the process of extraction In order to study the exact serviceable conditions, RUL is adopted Measure of deformation under load Test specimen: rectangular in shape with a base area of 5cm2 and height 75cm Test load:1.75Kg/cm2 (3.75 Kg/cm2) Heating at a std .rate of 10oC/min. Temperature at which 10% deformation occurs is RUL Height in cm RUL -10% deformation Temperature in oC Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 4 3/10/2008 Thermal Conductivity Thermal Conductivity of refractory bricks depends on the composition and Porosity High thermal conductivity bricks are used when Heat transfer through brickwork is required E.g. recuperators, regenerators Low thermal conductivity bricks are used when Heat conservation is required (insulating refractories) E.g. heat treatment furnaces Porosity It is the measure of number of pores incorporated during the manufacture of refractory bricks It is expressed as the ratio of volume of open pores to total refractory volume Low porosity results in less penetration of molten material and high strength of bricks Amount of pores present in a refractory material P = W ─ D x 100 W─A Porosity decreases Chemical resistance Strength Thermal Conductivity Thermal Spalling Porosity increases abrasion corrosion Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 5 3/10/2008 Dimensional Stability It is the measure of ability of a refractory material to resist any change in the volume during working conditions. Dimensional changes could be reversible or irreversible Irreversible or permanent changes may be due to contraction or expansion of brick material Phase transformations may also occur during heating and cooling Reversible change occur in most bricks at temperature less than 750oC Irreversible changes occur in the following cases i. Shrinkage Magnesite (amorphous) Heat ▬▬▬▬▬► Periclase (crystalline) ii. Expansion ∆ ∆ Quartz ▬▬▬▬▬▬▬▬▬▬▬►Tridymite ▬▬▬▬▬▬▬▬▬► Crystobalite (crystalline) 870oC &load 1470oC &Load Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 6 3/10/2008 Thermal Spalling The process of peeling of refractory material under the influence of high temperature is called thermal spalling. It is due to uneven expansion and contraction of refractory material (picture shows the seeping of molten slag ,through a crack formed due to thermal spalling) Effects of thermal spalling Slag penetration Corrosion Abrasion Thermal Spalling can be reduced by using materials with low coefficient of expansion and avoiding sudden temperature fluctuation for example addition of alumina in small quantities decreases expansion to a large extent Using high porosity bricks Using good thermal conductivity bricks Overfiring refractory bricks at high temperature By designing the furnace such that stress is alineated Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 7 3/10/2008 Chemical Activity A good refractory must be chemically inert Acidic refractories are affected by basic slag Basic refractories are affected by acidic slag Neutral refractories are not affected by both acids and bases Porosity increases chemical acitivity. Application of refractory as a lining material in furnace Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 8 3/10/2008 General Method of Manufacture of Refractory Bricks Crushing Aim: To crush large lumps of raw material to ~25 mm size. Method: Hammer mills / Machine crushing Grinding Aim: To powder the 25mm size raw material to 200 mesh size Method: Jaw crushers / Ball mills Screening Aim: To remove impurities from raw material Method: Settling / Magnetic separation / Chemical methods Mixing Aim: To mix various raw materials for proper distribution in order to facilitate moulding Moulding Aim: To provide the required shape and structure Method: Hand moulding / Mechanical moulding followed by deairing Drying Aim: To remove moisture and volatile matter Method: Tunnel driers heated by steam Firing Aim: To strengthen and stabilize the refractory Method: Heating in Tunnels / Shaft / Rotary kiln Firing Temperature: 1480oC for Super duty bricks, 1700oC for Acidic bricks and 1870oC for Basic bricks Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 9 3/10/2008 The raw materials are crushed, ground, screened and stored separately Just before moulding they are mixed in the required ratio and processed Moulding can be done by either one of the following ways Hand moulding: For low density and low strength bricks Mechanical Moulding: For high density and high strength bricks Note: Deairing is essential for hand pressed refractory Deairing methods Vacuum- Sucking air through pores Double pressing Deairing increases Density strength Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 10 3/10/2008 Method of Manufacture of High Alumina Bricks Crushing Calcined Bauxite and clay are crushed to ~25 mm size, separately Method: Hammer mills / Machine crushing Grinding The crushed ores are powdered to 200 mesh size separately Method: Jaw crushers / Ball mills Screening Impurities are removed from raw material by adopting one of the methods depending on the nature of impurity Method: Settling / Magnetic separation / Chemical methods Mixing The above raw materials are mixed for proper distribution and made into slurry in order to facilitate moulding Moulding The plastic (i.e. flexible) slurry is poured into moulds to get required shape and size by either Hand moulding / Mechanical moulding followed by deairing Drying The moisture and volatile matter are removed by heating the moulded brick in Tunnel driers heated by steam Firing The dried bricks are fired at 1700 – 1800oC in Tunnels / Shaft / Rotary kiln Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 11 3/10/2008 Properties Acidic and Non conducting (high porosity) Medium Duty: 50 –60 % alumina Heavy Duty: 75 % alumina Low coefficient of expansion hence high resistance to thermal spalling Appreciable RUL and Abrasion resistance Applications Lining of cement rotary kilns, Soaking pits, Hearth furnace Aluminium and Brass melting furnaces Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 12 3/10/2008 Manufacture of Zirconia Bricks Crushing Zirconite , CaO or MgO (acts as stabilizer) , and alumina ( acts as binding material ) are crushed separately to ~25 mm size. Method: Hammer mills / Machine crushing Grinding The crushed ores are powdered to 200 mesh size separately Method: Jaw crushers / Ball mills Screening Impurities are removed from raw materials by adopting one of the Settling / Magnetic separation / Chemical methods Mixing The above concentrated raw materials are mixed for proper distribution and made into slurry in order to facilitate moulding Moulding The plastic (i.e. flexible) slurry is poured into moulds to get required shape and size by either Hand moulding / Mechanical moulding followed by deairing Drying The moisture and volatile matter are removed by heating the moulded brick in Tunnel driers heated by steam Firing The dried bricks are fired at 1700oC in Tunnels / Shaft / Rotary kiln Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 13 3/10/2008 Properties Zirconia is a Special Neutral refractory PCE 2000 – 2600oC RUL- 1900oC at 3.5 Kg/cm2 Good Thermal shock resistance Good resistance to spalling Application Expensive hence application is limited Used as lining in high frequency electric furnace. Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 14 3/10/2008 Method of Manufacture of Magnesite Bricks Crushing Calcined magnesite, a little amount of caustic magnesia or iron oxide binding material are crushed into ~25 mm size, separately Method: Hammer mills / Machine crushing Grinding The crushed ores are powdered to 200 mesh size separately Method: Jaw crushers / Ball mills Screening Impurities are removed from raw material by adopting one of the methods depending on the nature of impurity Method: Settling / Magnetic separation / Chemical methods Mixing The above raw materials are mixed for proper distribution and made into slurry in order to facilitate moulding Moulding The plastic (i.e. flexible) slurry is poured into moulds to get required shape and size by either Hand moulding / Mechanical moulding followed by deairing Drying The moisture and volatile matter are removed by heating the moulded brick in Tunnel driers heated by steam Firing The dried bricks are fired at 1500oC in Tunnels / Shaft / Rotary kiln Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 15 3/10/2008 Properties: It is a Basic refractory and exhibit excellent resistance to basic slag PCE 2000oC RUL 1500oC at 3.5 Kg/ cm2 very little shrinkage poor abrasion resistance Extremely sensitive to temperature hence possess poor spalling resistance Applications Lining in open hearth furnace, copper reverbarators and reverbarators used for smelting lead and antimony. Lining in furnaces used for refining Au, Ag and Pt. Hot zones of cement rotary kilns Prepared by Dr. V.S.Gayathri & Dr. K. Yamuna Page 16 3/10/2008