Risk Relia

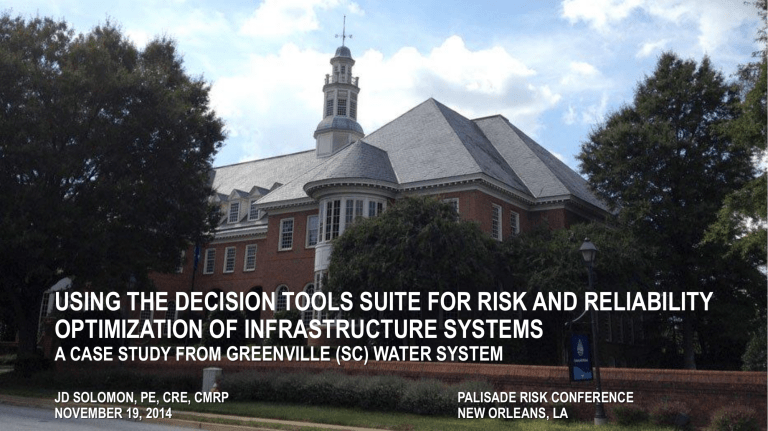

USING THE DECISION TOOLS SUITE FOR RISK AND RELIABILITY

OPTIMIZATION OF INFRASTRUCTURE SYSTEMS

A CASE STUDY FROM GREENVILLE (SC) WATER SYSTEM

JD SOLOMON, PE, CRE, CMRP

NOVEMBER 19, 2014

WBG052114205536FLL

PALISADE RISK CONFERENCE

NEW ORLEANS, LA

Overview

Summary of Use of Palisade Tools for Infrastructure Challenges

Case Study from Greenville (SC) Water System

•

Summary Presentation of Findings

•

StatTools

•

@Risk

Integration with Reliability Software

Summary Remarks

Palisade Tools to Help Solve Infrastructure Challenges

Long Range Demand Forecasting

•

Cary, Apex, Morrisville, and western Wake County

•

StatTools, @Risk

Systems Analysis and Optimization

•

Town of Clayton and Pharmaceutical

•

Town of Clayton, with links to county and another city

•

@Risk, TopRank, Evolver, and Optimizer

Emergency Capital Funding Forecasting

•

PRASA

•

@Risk, TopRank

Palisade Tools to Help Solve Infrastructure Challenges

System Renewal & Replacement Forecasting

•

Gwinnett County

•

@Risk, TopRank

Partnering Agreements

•

Marion County

•

Town of Clayton

•

PrecisionTree, @Risk, TopRank

Communications with Boards, Elected Officials, and the Public

•

Palisade Suite, especially graphics

WBG052114205536FLL

GREENVILLE WATER CASE STUDY:

SUMMARY OF BOARD PRESENTATION

Summary Observations

Question of capital improvements to North Saluda System is not “if” but “when”

Current capacity is sufficient for the intermediate term (5 to 10 years)

Some flexibility in terms of timing of capital improvements*

•

1 of 3 pumps required, and only required on limited basis

•

No significant breakdowns related to pumps

•

Local service providers believe they can keep at least 1 of 3 MCCs running

•

No significant failures related to transmission pipeline

•

GW is confident they can repair PCCP pipeline break in a couple of days

•

The system demands are not likely to shift upward significantly in short- to intermediate term

Mitigation planning around the most significant failure modes for highest risk system

Condition and costs associated with piping from intake to pump station require short-term

* 2009 Master Plan (CIP) recommended $5.8M in pump station electrical upgrades and generators in the short term; beyond 2015, $4.3M to replace pumps and $50.6 M for parallel transmission main

6

Summary Recommendations

Preventative Maintenance (PM) and Mitigation Plan – Sleeve Valve

Mitigation Plan – Motor Control Centers (MCCs)

Condition Assessment Intake to Station

Mitigation Plan – Intake to Station

Portable Generator Hook-up

Mitigation Plan – Pumps and Motors

PM Plan – Pumps and Motors

Mitigation Plan – Difficult Transmission Areas

MCC Replacement

Standby Generator

Parallel Transmission Line

Short-term

Short-term or

Intermediate

Longer-term

7

Seasonal Raw Water Supply Patterns – North Saluda

2007 2006 2008 2009

Drought Year

2011 2010 2012

“Normal” Weather

2013

TR 42” Construction TR 42” Online

TR 42” Online

System Orientation

Table Rock

North Saluda

1. 23 mgd gravity

3. 9 mgd pump

31-32 mgd total

2. 25 mgd gravity

4. 20 mgd pump (1 of 3 working)

Stovall

WTP

75 mgd of 95-100 mgd maximum day system demand

Targeted Reliability: 45 mgd

Note: North Saluda by permit can supply 63 mgd over 30 days; this would require 2 of 3 of the rated 30 mgd pumps to operate at 20 mgd each. This has never been needed.

9

Summary of Evaluation Process

Demand Projections

•

Deconstructed 2009 Master Plan Projections

•

Updated based on observations of past 4 years

•

Added a probabilistic component to address risk

O&M Review and Condition Assessment

StatTools

StatTools

@ Risk

•

Interviews, discussions, and site visits

•

Review of existing O&M records

•

Non-destructive evaluation using thermography and vibration analysis

•

Discussions with local service providers and vendors

Reliability Analysis

•

Reliability Block Diagrams

•

Fault Tree Analysis (FTA) and limited Failure Modes and effects Analysis (FMEA)

•

Calculations and modeling using ReliaSoft @Risk [& ReliaSoft]

Analysis of 2009 Master Plan –

Reconstruction of Demand Forecast

Data indicates more variability since around 1989-1990

The master plan used the 95 percentile estimate of gpcd

Relatively high peaking factor may also have overstated

MDD forecast

Probably in the range of 8 to 20 percent overstated

11

Analysis of 2009 Master Plan

12

Analysis of 2009 Master Plan –

Construction of our new Demand Forecast

13

Simulated Future North Saluda Raw Water Supply Pumping

2015-2022 Simulated Annual Raw Water System Operating Range

~95 th Percentile

(similar to 2007 pattern but with future demand)

Pumping Hours

5,500 hours

3,200 hours

1,000 hours

Reflective of a

3,200 hour pump operating scenario (2007)

Reliability - Defined

Reliability is the probability that an item will perform its intended function for a specified interval under stated conditions

Basic Reliability Mapping

Problem Statement

Reliability Block Diagram (RBD)

Fault Tree Analysis (FTA) – logic

Failure Modes and Effects Analysis (FMEA) - touched

Fault Tree Analysis – 1 of 3 Pumps (20 MGD)

17

Fault Tree Analysis – 45 MGD (25 MGD + 20 MGD)

Each Pump System has same components

18

Benefit of “1 of 3” versus Single Pump

One

1 of 3

19

Hourly Scatterplot Comparison of North Saluda and Table

Rock Raw Water Supplies

Dry Weather Year “Normal” Weather Year

2007

2009

Hourly Scatterplot Comparison of North Saluda and Table

Rock Raw Water Supplies

2012

Table Rock 42” Online

2013

Table Rock 42” Online

Failure Modes – All Flow Stops from North Saluda

(High Consequences)

North Saluda to Stovall WTP Transmission Line

•

Mode: Line collapses Repair Time: less than 1 week

(staff can perform)

Sleeve Valve at Stovall WTP

•

Mode: Valve fails closed or partially closed

Reservoir to North Saluda Transmission Line

•

Mode: Line Collapses

Repair time: Unknown

Repair Time: Unknown

22

Transmission Pipeline - Potential Problem Areas

Area 1: North Saluda Pump Station tie in

Area 2: Turn from US 25 to River Road

Area 3: River Road - North Saluda River too close for 2 nd pipe

Area 4: Crossing of SC Hwy 11

Area 5: Diagonal crossing of River Road

Area 6: Golf course

Area 7: Crossing of SC 414

Area 8: Road crossing at Bates Crossing Road

Failure Modes – Flow Above 27 MGD stops from N.S.

(Consequences High, but depends on operating scenario)

North Saluda Pumping (All)

•

Mode: Power Loss to Plant Repair Time: normally less than a few hours

North Saluda Pumping (single unit)

•

Mode: MCC Fails

•

Mode: Motor Fails

•

Mode: Pump Fails

Repair time: Unknown; switch to another unit

Repair time: Unknown; switch to another unit

Repair time: Unknown; switch to another unit

North Saluda Pumping (two units)

•

Mode: MCC Fails

•

Mode: Motor Fails

•

Mode: Pump Fails

Repair time: Unknown; switch to another unit

Repair time: Unknown; switch to another unit

Repair time: Unknown; switch to another unit

24

WBG052114205536FLL

StatTools

Our Approach

Dissected the 2009 Master Plan

Statistical Analysis of Historical Data – both sales and production

Analysis of How MP Demand Projections used the Historical Data

Reconstructed MP Demand Projections

Residential, Commercial, Wholesale, Unbilled Water, Population, Per Capita Use

Constructed our own 2035 Demand Projections

Probabilistic Analysis of 2009 MP

Probabilistic Analysis of our 2035 Demand Projections

Trued both based on 2010, 2011, 2012, and 2013 actuals

Forecasted impacts on North Saluda risk and reliability analysis

Analysis of 2009 MP – Statistical Analysis

1966-2008

1989-2008

Note:

Average Day R 2 :

1966-2008: 0.9176

1989-2008: 0.6762

Analysis of 2009 Master Plan – Historical Data

Statistical Analysis

6-, 12-, and 15-bin histogram generation

Lilliefors Test for normality

28

Analysis of 2009 Master Plan – Historical Data

The ADD data is more normally distributed than the MDD or MHD

20-year data is more normally distributed than the 10-year day

The MDD data appears to be significantly different post-1997 to 2008

Data suggests a meaningful degree of uncertainty related to MDD and MHD

29

WBG052114205536FLL

@Risk

Reconstructed Master Plan Projection

RECO N STRUC TION O F 2 0 0 9 MA ST E R P LA N

160.00

140.00

120.00

100.00

80.00

MP MDD

60.00

40.00

20.00

-

1 2 3 4 5 6 7 8

Actual MDD

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Analysis of 2009 Master Plan –

Construction of our own Demand Forecast

32

Analysis of 2009 Master Plan –

Application to North Saluda

33

How we simulated future North Saluda Pumping Requirements:

Future Hourly Pattern

For North Saluda, 2015-2022

Annual

Pattern

For

Hourly

Flow

Probabilistic

Average Day

Forecast for

Entire

System

Raw Water Supply

Operational Rules

**Determine

Average Day

North Saluda

Demand

Simulated Future North Saluda Raw Water Supply Pumping

2015-2022 Simulated Annual Raw Water System Operating Range

Average operating conditions for 2006-

2013 (1,000 hour pumping/year)

Simulated Future North Saluda Raw Water Supply Pumping

2015-2022 Simulated Annual Raw Water System Operating Range

~95 th Percentile

(similar to 2007 pattern but with future demand)

Pumping Hours

5,500 hours

3,200 hours

1,000 hours

Reflective of a

3,200 hour pump operating scenario (2007)

Simulated Future North Saluda Raw Water Supply Pumping

2015-2022 Simulated Annual Raw Water System Operating Range

2 pumps operating Reflective of a

3,200 hour pump operating scenario (2007)

1 pump operating

A Few Observations

The current master plan is a deterministic model and provides no estimates of uncertainty or risk. For North Saluda, the master plan suggests that the system will require 2 of 3 pumps working on a regular basis at the present time. This is not remotely the case.

If uncertainty is accounted for in the current master plan, there would be an approximate 3 year range over which an outcome could be expected to occur.

Based on our analysis, the need for 2 of 3 pumps working at North Saluda on a possibility (approximately 5%) that 2 of 3 pumps will be needed regularly in 2016.

We estimate that there is an approximate 7 year range over which an outcome could be expected to occur.

Integration With Other Applications

WBG052114205536FLL

Infrastructure Risk and Reliability

Reliability calculations are dependent on a number of variables and probability distributions.

Current off-the-shelf software(s) do not have a probabilistic component

Palisade has developed an application for Fault Tree Analysis but still in the beta stage

For JD

•

Continue to work by sensitivity analysis with FTA and RBD reliability analysis

•

Will work with several upcoming projects with the Palisade

Summary Remarks

Palisade Suite continues to be a great tool for all types of infrastructure analyses and risk evaluations

Case study shared today demonstrates how the current offering can be used to support reliability analysis

Moving forward will continue to integrate the Palisade Suite, especially @Risk and StatTools, into reliability analysis

WBG052114205536FLL

JD Solomon, PE, CRE, CMRP jd.solomon@ch2m.com

THANK YOU

42