Well Control Principles And

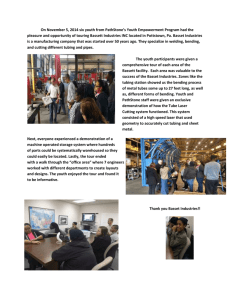

advertisement