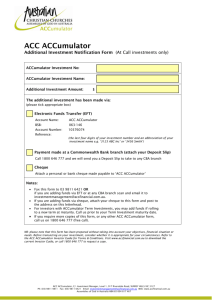

Volumetric Capacity Determination for Accumulators

advertisement