Bega Cheese: Waste to Resource Nano Filtration Case Study

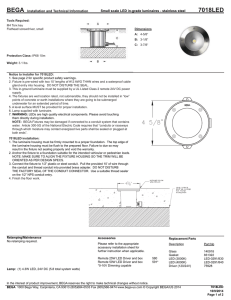

advertisement

CASE STUDY BEGA CHEESE: TURNING WASTE TO RESOURCE USING NANO FILTRATION The costs involved in this project were approximately $400,000. The benefits included: • Water conservation benefits include a 95% reduction in BOD for this specific process line • Financial benefits included additional revenue for the site • Other benefits include: Bega Cheese has installed a nano filtration plant to treat its whey solids which made up a large proportion of the North Coburg facility’s 7 million litres of trade waste discharge. This process allows the treated waste to be shipped back to its NSW drying facility and turned into raw material to be sold to other manufacturers. Drivers for change Bega Cheese undertook this project to: – Additional product for the company to market – Reduction in trade waste charges – Incremental business activity for NSW dryer – Plant is low maintenance with very few moving parts Staff training To ensure that the new filtration plant worked successfully Bega Cheese undertook special training for staff both theoretical and practical in relation to a number of key aspects to the plant. • Reduce product loss – dairy solids/raw materials that the company had paid for that were not being utilised • Reduce trade waste cost – high cost of treating whey solids in trade waste • Improve the site’s environmental performance • ‘De-risk’ the site’s operations by reducing operating cost Funding, costs and benefits Bega Cheese funded this project from its own capital expenditure budget, and it had very strong support from the executive management team. For more information contact Richard Paine. Telephone 03 9350 5766 Email richard.paine@begacheese.com.au WWW.YVW.COM.AU EMAIL: ENQUIRY@YVW.COM.AU GENERAL ENQUIRIES: 13 1721 EMERGENCIES AND FAULTS: 13 2762 TRANSLATOR AND INTERPRETER SERVICE: 13 1450 Printed on Australian-made recycled paper. Yarra Valley Water Lt, Lucknow Street, Mitcham. Private Bag 1, Mitcham Victoria 3132