Riga Technical University

15.04.2014 14:24

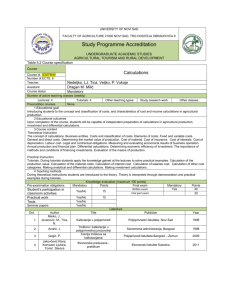

RTU Course "Machine Elements"

15513 Aparātu būvniecības katedra

General data

Code

Course title

Course status in the programme

Course level

Course type

Field of study

Responsible instructor

Academic staff

Volume of the course: parts and credits points

Language of instruction

Possibility of distance learning

Maximum auditorium capacity

Maximum number of students per semester

Abstract

Goals and objectives of the course in terms of

competences and skills

Structure and tasks of independent studies

Recommended literature

Course prerequisites

MKI290

Machine Elements

Compulsory/Courses of Limited Choice

Undergraduate Studies

Professional

Mechanics, Mechanical Engineering, Machine Building

Gunārs Upītis

Ivans Griņevičs

1 part, 3.0 Credit Points, 4.5 ECTS credits

LV, EN, RU

Not planned

50

100

"Machine Elements" course deals with constructions, applications and calculation methods of

typical machine elements - transmissions, connections etc. "Machine elements" is the first course

in curriculum where knowledge from basic courses (Technical Drawing, Material Science,

Strength of Materials and similar) is used for solving real technical problems. Study course

introduces with tasks of machine design and methods for solving them, as well as with literature,

standards and technical means used in this field.

To obtain basic design skills of machines, mechanisms and their elements by strengthening and

specifying knowledge gained during basic engineering courses. To create competency in solving

technical projects by developing skills in engineering analysis, calculations and elaboration of

technical documentation.

Independent work throughout the semester is based on a complex problem, formulated according

to requirements of real project situation, and issued in the first lesson. Common questions of

design are sequentially discussed in practical work and afterwards student independently solves the

corresponding tasks on the basis of his study work assignment, using literature intended for study

designs. After performing calculations of the project, student independently works out graphical

documentation by using CAD software of the RKI computer–class, private software, or by means

of traditional techniques. Throughout the design process student consults and coordinates his work

with teacher.

1. Shigley J.E., Mischke C.R., Budynas R.G., Mechanical Engineering Design, McGraw Hill,

2004.

Collins J.A., Busby H., Staab G., Mechanical Design of Machine Elements and Machines, John

Wiley & Sons, 2010.

Norton R.L., Machine Design. An Integreted Approach, Pearson - Prentice Hall, 2006.

2. "Mašīnu elementu" teorijas un projektēšanas mācību grāmatas un metodiskie norādījumi no

RTU un RKI bibliotēkām,

3. G. Upītis, "Mašīnu elementi. Kursa palīgmateriāli", RKI, 2008.

4. Interneta materiāli, piem.:

Douglas Wright, Design and Analysis of Machine Elements,

http://www.mech.uwa.edu.au/DANotes

Collins, Mechanical Design of Machine Elements and Machines,

http://bcs.wiley.com/he-bcs/Books?action=contents&itemId=0471033073&bcsId=1857

Statics, kinematics, dynamics. Properties of engineering materials. Calculations of stresses and

deformations. Projection drawing.

Course outline

Theme

1. Introduction. Basic criteria of calculations of machine elements: strength, rigidity, wear and vibration resistance

2. Power transmission: general characteristics and relationships. Practice : hoisting mechanism of column crane

3. Friction drives. Forces, creep, kinematics, calculation for strength. Variable speed friction drives

4. Belt drives. Belt types, geometry of drives, forces, stresses, creep, kinematics, power eficiency.

5.Gear drives. Classification. Spur and helical gears: geometry, kinematics, standard parameters, loads

6. Calculation of surface strength. Calculation of bending strength. Practice: calculation of helical gearset

7. Bevel and worm gears: geometry, kinematics, criteria and principles of calculations

8. Toothed belt and chain drives. Construction, geometry, kinematics. Forces, criteria and principles of calculation

9. Shafts. Classification, preliminary design and proportioning of shafts, calculation of fatigue life

10. Bearings. Clasification of rolling-element bearings, fatigue life. Practice: calculations of gearset bearings

11. Plain bearings: types, construction, materials, calculation of wear and heat resistance.

12. Joints. Clasification. Press and shrink fits. Calculations of load capacity and strength

Hours

4

3

2

4

4

4

2

2

4

4

2

3

13. Threaded joints. Geometry of threads, parameters; Strength of threads, bolts and connections

14. Riveted and welded joints: types, calculation of strength. Practice: calculation of welded joint

15. Mechanical springs: types, parameters, calculations

Learning outcomes and assessment

Learning outcomes

Understanding of tasks and sequence of machine design process, specifics of technical calculations.

Ability to synthesize and analyze kinematical schemes of machines, to evaluate parameters of

drives.

Skills of selection, geometry determination and strength and fatigue life calculations of transmission

drives (frictional, belt, gear) and their elements (shafts, bearings). Skills to design technically wellgrounded joints of machine and structural elements (welded, threaded, interference fits).

Knowledge about engineering materials, standardization, factors influencing service life and

technological demands of manufacturing.

Ability to create constructions of machines and mechanisms, to perform sketch design, to work out

assembly and detail drawings. Basic skills of computer-aided design and engineering.

Study subject structure

Part

CP

1.

3.0

ECTS

4.5

Lectures

2.0

Hours per Week

Practical

1.0

Lab.

0.0

4

4

2

Assessment methods

Home work, individual verification and

correction of results, defence of the study

project.

Individual verification and correction of

results, defence of the study project. Exam.

Individual verification and correction of

results, defence of the study project. Exam.

Defence of the study project.

Test

Tests

Exam

*

Work