Formalised Sales & Operations planning (S&OP) – KFC case study

advertisement

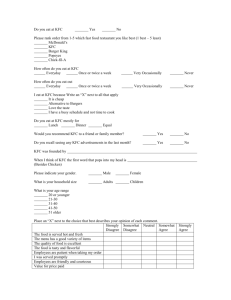

Formalised Sales & Operations planning (S&OP) – KFC case study ELIZBE ROHDE About KFC Yum! Restaurants International opened South Africa’s first KFC outlet in Orange Grove Johannesburg in 1971. KFC is one of the brands operating under Yum! Brands Inc. which is one of the largest restaurant companies in the world. Yum! is the parent company of the brands KFC, Pizza Hut and Taco Bell – global leaders in the chicken, pizza and Mexican-style food categories. KFC has had a proud heritage in South Africa for the past 40 years with ~800 restaurants across the country. In addition to this number, ~120 restaurants have been opened in Africa and KFC is working hard at further expanding its footprint on the continent. Complexity in the Quick Service Restaurant (QSR) industry Within the QSR industry it is imperative that the right stock is available at the right place, time, price and quality. Consumers are expecting rapid service delivery whilst behind the scenes menu items are the culmination of several ingredient supply chains, which range from chicken, bread, cheese, lettuce, sauces, spices etc. Each of these brings with it unique challenges, lead times and quality constraints. Added to that, demand patterns are heavily influenced by weekends, month-ends and holidays. The dynamics in a QSR store differ significantly from those within other industries. As a result, the way in which forecasting is done differs. In the case of KFC the franchise-based group has 800 stores with similar menu items and trends (not multiple brands) sold directly to consumers. Its products are sold directly to consumers with immediate consumption vs. buying for future use, resulting in clear POS sales data and trends. A further dynamic that impacts planning complexity is the significant growth that KFC is experiencing (40 new stores opened in 2014), which has a direct bearing on the demands placed on the forecasting process, system and team. One can not only consider volume growth when forecasting, but also store growth. Further complexities within the KFC store network includes there being different store types such as breakfast stores and different menu types which include Permanent Items and Limited Time Offers (LTO’s) as well as the need to consider abnormal activities in the past, which affects forecasts such as strikes impacting supply. The large component of LTO’s is a key driver of supply chain complexity that has a high level of uncertainty. KFC LTO promotions run for an average of 7 to 15 weeks. They require a combination of unique and existing ingredients and have a unique lifecycle, needing to balance out-of-stock vs. writeoff through careful planning. The challenge that lies therein is that all ingredients must arrive in stores on time and with a high level of sales uncertainty which is greatest within start-up and growth phases. With regards to the conversion of menu items to ingredients, this is done based on the Bill of Material (BOM) or recipe. Forecasting is being done based on menu item store sales: • Menu item sales are converted through the BOM to ingredients and gives a view of ingredient sales out of the store PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 1 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY • • Ingredient sales out of the store is compared to ingredients sales into the store from the 3PL supplier Ingredients to Menu items have a one-to-many relationship The need for and the importance of a formalised Sales & Operations Planning (S&OP) process and system that balances supply and demand The Sales and Operations Planning (S&OP) process at KFC South Africa was previously more reactive, uncoordinated, ad-hoc and non-standardised. Due to this it became particularly cumbersome, largely due to the process being manually driven. As a result, the process needed to be reviewed to maintain good stock availability (involving less effort). The volatility of sales in today’s highly competitive marketplace lends itself to less reliable sales forecasts and the consequent necessity of higher stock levels to maintain reasonable customer service levels. This combined with KFC’s strong growth and innovation complexity results in significant complications in demand and supply planning highlighting the need to bridge the gap between strategic-, tactical- and operational planning that existed. KFC South Africa S&OP journey and the way forward Given the previously uncoordinated S&OP process prior to 2013, KFC developed a journey map to transition over time to a centralised PMO function for LTO’s with bi-monthly demand planning sessions in 2014 which was mainly excel based. This formed a good basis for the Barnton implementation project to transition to advanced planning and an end-to-end S&OP process in 2015 and beyond. Figure 1: KFC South Africa S&OP journey and the way forward The objective of the project The overall objective of the project was to implement a formal demand and supply planning system and process that will allow KFC to be more pro-active and flexible by: PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 2 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY • • • Giving visibility of actual vs. forecasted demand Managing stock-availability and write-offs better Allowing us to pro-actively re-align supply to changing demand We did this by focusing on 2 key areas: • • Forecasting: Used by Finance & Marketing for demand planning Planning: Used by Supply Chain, Suppliers, 3PL for supply planning The overall outcome that KFC is working towards: • • • Maintain good stock availability (involving less effort) Improved supply chain control & pro-active forward visibility (less crisis management) Increased visibility on permanent items (given the amount of effort involved) Figure 2: The objective of the project PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 3 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY Figure 3: Detailed sub-objectives defined to guide the journey Planning for the KFC South Africa Supply Chain Special consideration had to be given to how supply and demand planning is required for KFC’s unique supply chain and complexities associated with it as multiple supply chains exist pertaining to the store, 3PL and our suppliers; each with its unique challenges, lead time and quality requirements. Figure 4: The KFC Supply Chain PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 4 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY The next step in the S&OP journey through a tailored system In order to get to the next step in the maturity curve a tailored system was required to support the new S&OP process that has been defined. Figure 5: The system had to support the newly defined process Master Data is synchronised weekly from various sources, it is loaded into a staging environment where after it is aggregated, processed and cleansed before finally having statistical algorithms applied to it yielding our final updated weekly forecast and planning data via the respective tools. Information is available for the respective data artefacts at various echelons in the KFC business: • • KFC Menu Item Sales (POS data) available at regional level 3PL Ingredient Sales available at DC level The relation between Menu Item Sales and Ingredient Sales are defined by the BOM. . PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 5 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY Figure 6: How the system works Key Learnings and Critical Success Factors Looking back at the overall vision behind formalising the Sales & Operations Planning (S&OP) process and system at KFC, the following were critical to the success of the project: • • • • • • • Strong project management and a rigorous approach with strong governance Implementation of consensus S&OP (Demand Planning) process prior to systems implementation The project leadership was very involved in understanding and guiding solution design Solid buy-in achieved across the Cross Functional Team together with stakeholder involvement and communication Choosing the right demand and supply planning solution (Barnton), which in the case of KFC required flexibility to tailoring it to the group’s specific functional needs Defining of new roles and responsibilities in line with the S&OP process (one new role) Hands-on training with KFC’s real data and on-the-job coaching As within any project, there were some key learnings to note or areas of improvement. For example, a clearly defined scope is imperative for the likes of BOM module development. The team also initially underestimated the interface effort and complexity, as well as the data cleansing effort required. Availability of key stakeholders also presented certain challenges. Since formalising the S&OP process, write-off spend has reduced by ~60% whilst doubling the number of promotions and Out of Stocks at DC’s have reduced by 48% despite 6% volume growth in the last year with significant benefits expected now that a system has been implemented to support the process. PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 6 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY Figure 7: Reducing write-off spend whilst doubling number of promotions Figure 8: Out of Stock at DC’s PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 7 FORMALISED SALES & OPERATIONS PLANNING (S&OP) – KFC CASE STUDY SPEAKER PROFILE Elizbe is a Supply Chain Manager at Yum! Restaurants International, managing multiple aspects of Supply Chain with a key focus on Sourcing and Procurement. She has over 8 years of experience and has developed leading edge skills at the world’s largest management consulting firm. During this time she has helped organisations assess and maximise their performance and realise their vision in achieving rapid progression in managing major Supply Chain projects across various industries. Given her strong project management experience, Elizbe was made responsible for the end to end implementation of the Sales & Operations Planning (S&OP) project for KFC. Contact details Email address Website Telephone elizbe.rohde@yum.com http://www.yum.com/ 0824167029 PAPER PRESENTED AT SAPICS 37TH ANNUAL CONFERENCE AND EXHIBITION © SAPICS 2015, www.sapics.org.za ISBN 978-0-620-64684-0 31 MAY – 2 JUNE 2015, SUN CITY, SOUTH AFRICA PAGE 8