Chapter 21: Masonry - Civil and Environmental Engineering

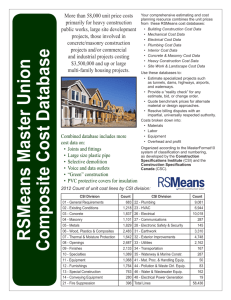

advertisement