Production One provides extended manufacturing production order capabilities to SAP Business One™. Production One

is ideal for companies looking to track the detailed costs and production processes during the assembly or production of

work orders. Production oriented organisations can now flexibly and easily manage their labour and material costs using

touch screen and bar code collection devices each step of the way on the shop floor. They can schedule jobs, and cost

jobs in a real-time environment.

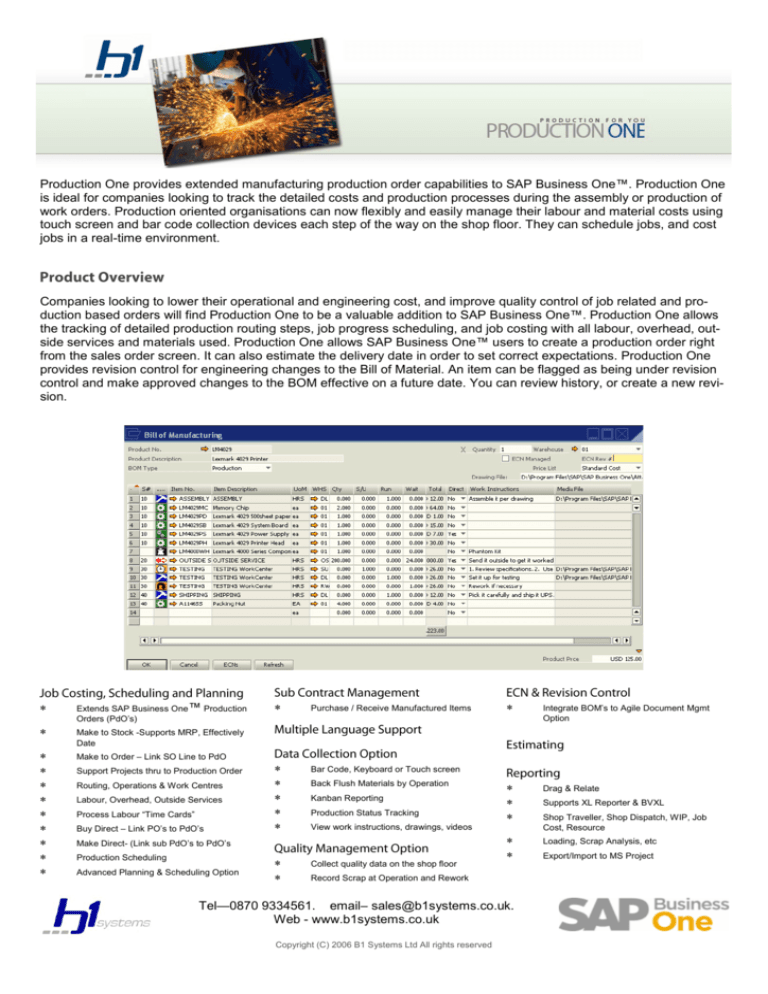

Companies looking to lower their operational and engineering cost, and improve quality control of job related and production based orders will find Production One to be a valuable addition to SAP Business One™. Production One allows

the tracking of detailed production routing steps, job progress scheduling, and job costing with all labour, overhead, outside services and materials used. Production One allows SAP Business One™ users to create a production order right

from the sales order screen. It can also estimate the delivery date in order to set correct expectations. Production One

provides revision control for engineering changes to the Bill of Material. An item can be flagged as being under revision

control and make approved changes to the BOM effective on a future date. You can review history, or create a new revision.

Extends SAP Business One™ Production

Orders (PdO’s)

Purchase / Receive Manufactured Items

Integrate BOM’s to Agile Document Mgmt

Option

Make to Stock -Supports MRP, Effectively

Date

Make to Order – Link SO Line to PdO

Support Projects thru to Production Order

Bar Code, Keyboard or Touch screen

Routing, Operations & Work Centres

Back Flush Materials by Operation

Labour, Overhead, Outside Services

Kanban Reporting

Process Labour ―Time Cards‖

Production Status Tracking

Buy Direct – Link PO’s to PdO’s

View work instructions, drawings, videos

Advanced Planning & Scheduling Option

Supports XL Reporter & BVXL

Shop Traveller, Shop Dispatch, WIP, Job

Cost, Resource

Loading, Scrap Analysis, etc

Make Direct- (Link sub PdO’s to PdO’s

Production Scheduling

Drag & Relate

Collect quality data on the shop floor

Record Scrap at Operation and Rework

Tel—0870 9334561. email– sales@b1systems.co.uk.

Web - www.b1systems.co.uk

Copyright (C) 2006 B1 Systems Ltd All rights reserved

Export/Import to MS Project

Production One also allows for the

capture of quality data collected at

each routing step on the shop

floor and at receiving inspection.

Costs will be tracked and automatically posted to the associated

job or product ion order upon job

completion.

Production One can be deployed

in a variety of ways to suit an individual organisations needs, including touch screen entry, bar

code data collection device entry

or manual data entry directly into

a PC screen.

Once logged in, the SAP Business

One™ user is presented with a list

of operations or jobs which are

scheduled for a given department,

and they can begin recording their

time and track the materials used

for the orders assigned to them.

After completing their assigned operations, the user can record actual item quantities produced and the system will time

stamp the duration of the production order, and the production labour is posted to the job or production order within the

SAP Business One™ application.

Production One includes predefined package cost accounting reports which provide improved visibility of operational

profitability in summary and detail formats, users can also create their own reports using the BVXL for SAP Business

One™.

View work instructions, pictures, drawings, and videos on the shop floor

Tel—0870 9334561. email– sales@b1systems.co.uk.

Web - www.b1systems.co.uk

Copyright (C) 2006 B1 Systems Ltd All rights reserved

Production One provides extended manufacturing production order capabilities to SAP Business One™. Production One

is ideal for companies looking to track the detailed costs and production processes during the assembly or production of

work orders. Production oriented organisations can now flexibly and easily manage their labour and material costs using

touch screen and bar code collection devices each step of the way on the shop floor. They can schedule jobs, and cost

jobs in a real-time environment.

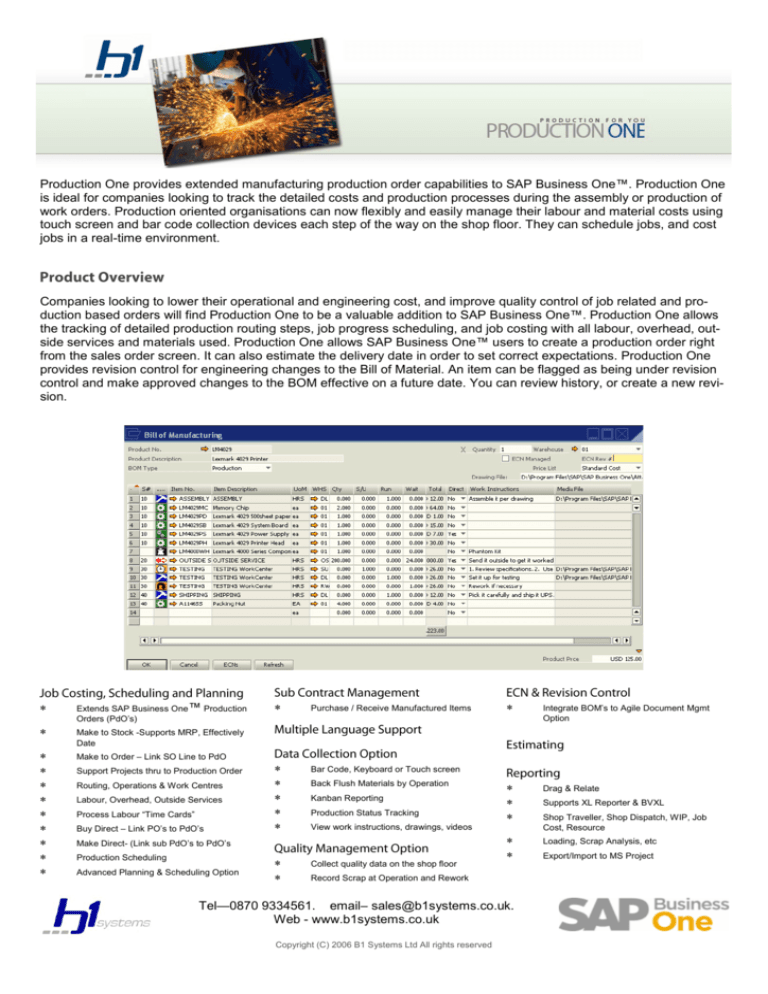

Companies looking to lower their operational and engineering cost, and improve quality control of job related and production based orders will find Production One to be a valuable addition to SAP Business One™. Production One allows

the tracking of detailed production routing steps, job progress scheduling, and job costing with all labour, overhead, outside services and materials used. Production One allows SAP Business One™ users to create a production order right

from the sales order screen. It can also estimate the delivery date in order to set correct expectations. Production One

provides revision control for engineering changes to the Bill of Material. An item can be flagged as being under revision

control and make approved changes to the BOM effective on a future date. You can review history, or create a new revision.

Extends SAP Business One™ Production

Orders (PdO’s)

Purchase / Receive Manufactured Items

Integrate BOM’s to Agile Document Mgmt

Option

Make to Stock -Supports MRP, Effectively

Date

Make to Order – Link SO Line to PdO

Support Projects thru to Production Order

Bar Code, Keyboard or Touch screen

Routing, Operations & Work Centres

Back Flush Materials by Operation

Labour, Overhead, Outside Services

Kanban Reporting

Process Labour ―Time Cards‖

Production Status Tracking

Buy Direct – Link PO’s to PdO’s

View work instructions, drawings, videos

Advanced Planning & Scheduling Option

Supports XL Reporter & BVXL

Shop Traveller, Shop Dispatch, WIP, Job

Cost, Resource

Loading, Scrap Analysis, etc

Make Direct- (Link sub PdO’s to PdO’s

Production Scheduling

Drag & Relate

Collect quality data on the shop floor

Record Scrap at Operation and Rework

Tel—0870 9334561. email– sales@b1systems.co.uk.

Web - www.b1systems.co.uk

Copyright (C) 2006 B1 Systems Ltd All rights reserved

Export/Import to MS Project

Production One also allows for the

capture of quality data collected at

each routing step on the shop

floor and at receiving inspection.

Costs will be tracked and automatically posted to the associated

job or product ion order upon job

completion.

Production One can be deployed

in a variety of ways to suit an individual organisations needs, including touch screen entry, bar

code data collection device entry

or manual data entry directly into

a PC screen.

Once logged in, the SAP Business

One™ user is presented with a list

of operations or jobs which are

scheduled for a given department,

and they can begin recording their

time and track the materials used

for the orders assigned to them.

After completing their assigned operations, the user can record actual item quantities produced and the system will time

stamp the duration of the production order, and the production labour is posted to the job or production order within the

SAP Business One™ application.

Production One includes predefined package cost accounting reports which provide improved visibility of operational

profitability in summary and detail formats, users can also create their own reports using the BVXL for SAP Business

One™.

View work instructions, pictures, drawings, and videos on the shop floor

Tel—0870 9334561. email– sales@b1systems.co.uk.

Web - www.b1systems.co.uk

Copyright (C) 2006 B1 Systems Ltd All rights reserved