Laboratory 4 Drag Measurements in a Subsonic Wind Tunnel

advertisement

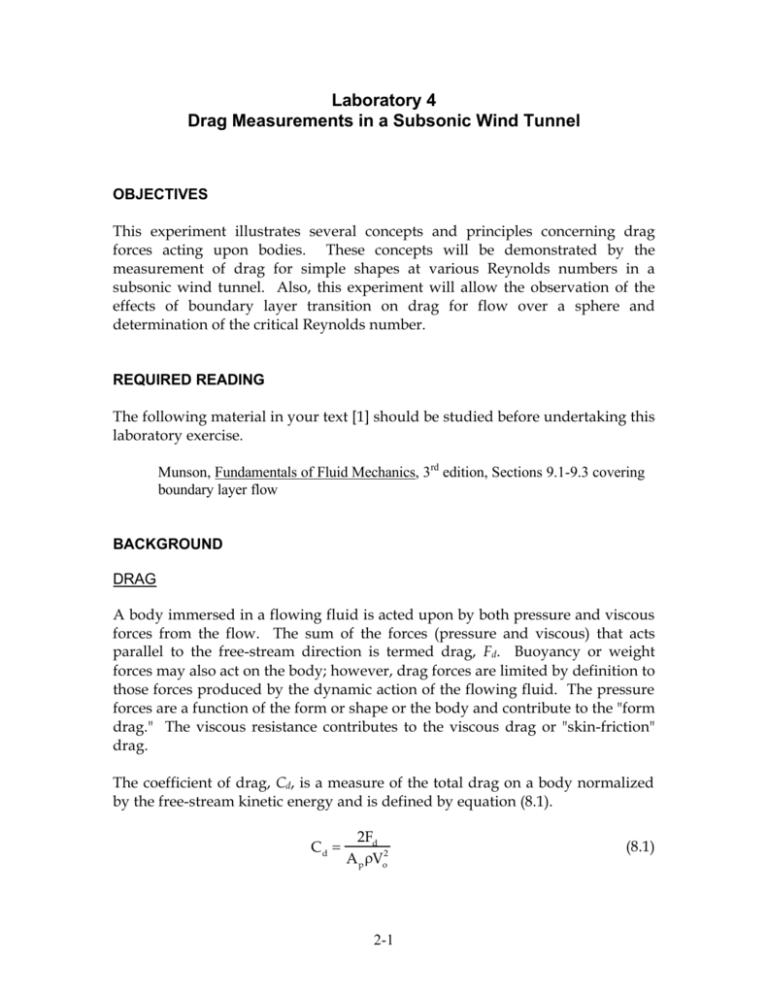

Laboratory 4 Drag Measurements in a Subsonic Wind Tunnel OBJECTIVES This experiment illustrates several concepts and principles concerning drag forces acting upon bodies. These concepts will be demonstrated by the measurement of drag for simple shapes at various Reynolds numbers in a subsonic wind tunnel. Also, this experiment will allow the observation of the effects of boundary layer transition on drag for flow over a sphere and determination of the critical Reynolds number. REQUIRED READING The following material in your text [1] should be studied before undertaking this laboratory exercise. Munson, Fundamentals of Fluid Mechanics, 3rd edition, Sections 9.1-9.3 covering boundary layer flow BACKGROUND DRAG A body immersed in a flowing fluid is acted upon by both pressure and viscous forces from the flow. The sum of the forces (pressure and viscous) that acts parallel to the free-stream direction is termed drag, Fd. Buoyancy or weight forces may also act on the body; however, drag forces are limited by definition to those forces produced by the dynamic action of the flowing fluid. The pressure forces are a function of the form or shape or the body and contribute to the "form drag." The viscous resistance contributes to the viscous drag or "skin-friction" drag. The coefficient of drag, Cd, is a measure of the total drag on a body normalized by the free-stream kinetic energy and is defined by equation (8.1). Cd = 2Fd A p ρVo2 2-1 (8.1) By measuring the total drag, Fd, on various bodies and the free-stream velocities, Vo, the variation of the coefficient of drag with Reynolds number (equation (8.2)) may be obtained. Vod (8.2) ν An inspection of the different shapes used in this experiment will indicate that some may be classified as "blunt" shapes, with well defined separation points, or as rounded shapes. Little "scale" effect (variation of Cd with Red) is expected with blunt shapes while considerable scale effect is expected on rounded shapes. Re d = TRANSITION EFFECTS The drag coefficient of a sphere experiences a marked reduction when the flow in the boundary layer upstream of the separation point undergoes transition from laminar to turbulent flow (see Figure 8.1). This boundary layer transition causes a delay in the separation point resulting in a reduction of the form drag. The Reynolds number associated with this transition is known as the critical Reynolds number. cp < 0 U∞ cp > 0 P∞ P −P ∞ 2 ρ U ∞ /2 c p = To measure Vo a Pitot tube is used in conjunction with a digital manometer. By determining the difference between the total and static pressures, the free-stream velocity may be determined using equation (8.3). 2-2 Vo = 2gh ρw ρ (8.3) The difference between the two patterns of streamlines shown in Figs (8.1) and (2.2) is in the position of the point of flow separation. The position of the point of flow separation is determined by the condition of flow in the boundary layer at the surface of the cylinder. In Fig (8.1) the flow in the boundary layer remains laminar up to the point of flow separation. In Fig (8.2) the flow in the boundary layer in the front portion of the cylinder is turbulent. Fluid, in turbulent motion, possesses more momentum and can be expected to move farther along the surface and to make its into regions of higher pressure. The position of the point of separation therefore is farther downstream toward the rear of the cylinder. At high Reynolds numbers, the flow separation is limited to a very small region in the tail. PROCEDURE: An AEROLAB subsonic wind tunnel, 6 various shaped objects, a digital manometer and a pitot tube will be available for use in this laboratory exercise. cp < 0 cp > 0 U∞ P∞ P−P ∞ 2 ρ U ∞ /2 c p = To perform the exercise, follow the following steps. 2-3 1. Turn control panel on. 2. Install 0.75 inch diameter calibration barrel on the sting balance. 3. Adjust angle of attack of sting assembly to 30 degrees, and record the value of the axial force readout. 4. Hang the 1 kg weight on the calibration barrel, and record the new axial force readout value. The linear calibration constant of the axial force readout (counts per pound) may be determined. 5. Remove calibration barrel from the sting balance, readjust angle of attack to 0o, and install first test body, but do not over-tighten the set-screw. 6. Remove all tools and loose objects from the test section and close the viewing window. 7. Turn on wind tunnel, and adjust air speed to 45 mph. 8. Record axial force readout. 9. Repeat step 8 for air speeds of 60, 80, 100, 120, and 130 (or maximum wind tunnel velocity) mph. 10. Repeats steps 7 through 9 for other 5 test bodies. 11. Shut off wind tunnel. Flow Straighteners 1 ft. by 1 ft. Test Section Fan Outlet Inlet Control Box 2-4 Figure 8.2 Schematic of AEROLAB apparatus. ASSIGNMENT Write a formal lab report-due in two (2) weeks at the beginning of the lab period. Make sure to address the following topics in your report. 1. Plot the drag coefficient vs. Red for each shape of all shapes. (A log-log plot with all data overlaid on a single axis.) 2. Classify shapes as "blunt" and "round" and a. Explain discrepancies between expected and experimental results. b. From the plot of the drag coefficient vs. Reynolds number, explain observed scale effects. How do these effects relate to boundary layer separation? c. Explain if similitude is observed in the drag coefficient trends of the different shapes. Why or why not? d. Evaluate the reasonable accuracy of the drag coefficient by comparison with published values. e. Explain whether or not the critical Reynolds number was observed for any of the shapes tested? REFERENCE [1] White, F., 1994, Fluid Mechanics, Third Edition, McGraw-Hill, Inc. 2-5 NOMENCLATURE Ap Cd d Fd g h Red Recrit Vo ρ ρw ν = area of the test shape projected in the free-stream direction = Drag coefficient = cross-sectional width of object = axial force = Gravitational acceleration constant = Manometer reading = Reynolds number = Reynolds number associated with boundary layer transition = Free-stream velocity = free-stream density of air = free-stream density of water = kinematic viscosity 2-6 [ft2] [dimensionless] [ft] [lbf] [m/s2] [m h20] [dimensionless] [dimensionless] [ft/s] [lbm/ft3] [lbm/ft3] [ft2/s2] DATA SHEET FOR DRAG EXPERIMENT Shape Axial Force, counts Acheivable Vel 45 MPH 80 MPH 100 MPH 2- 120 inches H2 MPH