Food Purchasing and Receiving Control

advertisement

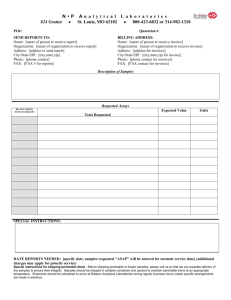

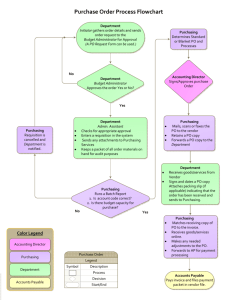

18/07/2008 Objective Food Purchasing & Receiving Control • By the end of this course you will be able to: Outline the purchasing process in F&B Distinguish perishable & non perishable food Calculate quantity standards Give 6 reasons for establishing Purchase Specification Compare perpetual inventory & periodic order List the normal sources of supplies for F&B Explain “Centralized Purchasing” & “Standing Orders” 18/07/2008 Review of the Purchasing Cycle in the Hotel Objective 7 Store Products 5 Purchase Order Record Receiving Purchasing Accounting Identify the purpose of receiving control List and explain 3 standards established to govern the receiving process Explain the receiving process List the duties of the receiving clerk Identify the information listed on invoices List the information contained on the receiving clerk’s daily report 2 Issue Required Products 8 Invoice F&B Dep. 3 Purchase Requisition 4 Purchase Order/ Record 3’ Selling Producing and Serving 9 Check Supplier 18/07/2008 Introduction Review: The Control Process • In all F&B Businesses, we make purchases (by phone, fax, email, letter, sales person…) we receive the supplies when they arrive, we inspect quantity, quality and prices, we store the supplies (dry, refrigerator, freezer). When needed food is issued for preparation, sold and served to guests. • At each of these steps, unwanted costs can develop. • 18/07/2008 5 Purchase Order Record 1 Requisition Form 18/07/2008 CC3 Storeroom 6 Deliver Product & Invoice • By the end of this course you will be able to: The 4 steps of the control process applied to Purchasing and Receiving: 1. Establish Standards and SOP for operations 2. Train all individuals to follow established standards and SOPs 3. Monitor performance and compare actual performances with established Standards 4. Take appropriate action to correct deviations from Standards 18/07/2008 1 18/07/2008 Responsibility of Purchasing Perishable & Non-perishable • One or more persons may be involved (owner, chef, purchasing department) • But only one person should have the authority to purchase food. This person can then be held accountable for the system of control procedures established by the food controller. • Perishable foods are: Fresh food that have short useful life after they have been received (lettuce, fresh fish loose their quality very quickly. Meat and cheeses also deteriorate fast) High risk of spoilage! • Non-perishable foods are: Those that have longer shelf lives. Purchased in cans, bottles, bags and boxes. Frozen food is considered non perishable. Low risk of spoilage • Geographic location often determine if a food item is considered perishable or not (close or not to production) 18/07/2008 Developing Standards & SOP for purchasing Establishing Quality Standards • The primary purpose of purchasing is to ensure a continuing supply of sufficient quantity of the necessary foods each of the quality appropriate to its intended use, purchased at the most favorable price. Therefore Standards should cover: • Standard Purchase Specifications (“specs”) example: Quality of Food Purchased Quantity of Food Purchased Prices at which Food is Purchased 18/07/2008 Salmon • Whole, dressed, fresh day of delivery • Minimum 8lbs, maximum 12lbs • Fish firm and elastic, meat pink and slightly translucent • Gills free from slime and reddish-pink in color • Scales adhering tightly to the skin • No stale odors of ammonia 18/07/2008 6 reasons why Purchase Specs are useful 6 reasons why Purchase Specs are useful 1. They force managers to determine exact requirements in advance for any product 2. They are useful in menu preparation. For example, it is possible to use one cut of meat, purchased to specifications to prepare several different menu items. 3. They eliminate misunderstanding between steward and purveyor. 4. Circulation of “specs” for one product to several purveyors makes true competitive bidding possible 5. They eliminate the need for detailed verbal descriptions of product each time it is ordered 6. The facilitate checking at receiving 18/07/2008 CC3 18/07/2008 18/07/2008 2 18/07/2008 Establishing Quantity Standards Establishing Quantity Standards • Purchase Specs do not need to be updated often, however Quantity Standards must be reviewed and revised regularly. • Procedures for determining purchase quantities differ from Perishable and Non-perishable • Perishable In F&B operations we always use products on hand (in stock) before purchasing additional quantities. So we always must know what we have in stock We must decide the total quantity needed The difference between the 2 is the correct amount to order. 18/07/2008 18/07/2008 Establishing Quantity Standards Establishing Quantity Standards • Perishable • Perishable The quantity needed is called the PAR or PAR STOCK. (but the term is used in a variety of ways in the industry) Let’s say that PAR STOCK is defined as the quantity of any item required to meet anticipated needs in some specific upcoming period A basic requirement of the purchasing routine is that the steward take a daily inventory of perishable on the Market Quotation List On Hand 20 10 18/07/2008 Duck Breast 10 To Order -- 18/07/2008 Establishing Quantity Standards • Non-perishable • Maintaining inventories: 2 methods: 18/07/2008 Quotations 12 Establishing Quantity Standards Although non perishable foods do not present the problem of rapid deterioration they represent considerable amount of money invested in material in storage. The goal is to minimize stock without “running out” of any item. Always label fixed locations for products, it is easier to find products and avoids multiple locations of food and high stocks. CC3 Article: Par POULTRY Chicken 32 Breast PERIODIC ORDER METHOD (in contrast to methods for ordering perishables, this method allows less frequent ordering. With periodic order methods, the steward orders on a regular basis (weekly, monthly… depending of storage space and policies) He conducts a physical inventory and orders as follow: 18/07/2008 3 18/07/2008 Establishing Quantity Standards Exercise • Calculation of the amount of each item to order: • The Grand View Bistro orders non perishable every two weeks. Amount required for the upcoming period - Amount presently on hand + Amount wanted on hand at the end of the period to last until the next delivery = Amount to order One item to be ordered is “Crushed Tomatoes” purchased in cans, packed 6 cans per case. The item is used at the rate of 7 cans per week, and delivery normally takes 5 days from the date an order is placed. If the steward has 9 cans on hand, how many cans should he order? • Include a “safety stock” equal to the quantity used during delivery period) 18/07/2008 18/07/2008 Establishing Quantity Standards Establishing Price Standards • Maintaining inventories: 2 methods: • Having established Purchase Specification and inventory procedures to determine Quantities to order, one can turn to the question of Price. PERPETUAL INVENTORY METHOD • To ensure that quantities purchased are sufficient to meet anticipated nee without being excessive • To provide effective control over those items that are being stored for future use Food purchases are made on the basis of competitive prices obtained by several possible suppliers Availability of supplies varies from a location to another (City, Island, Jungle resort…) Excel exercise: Create a perpetual inventory card from the following sample. 18/07/2008 Categories of Suppliers Operators deal with: Means of obtaining Price Quotations • • • • • • • • • • • Wholesalers Local producers Manufacturers Packers Local farmers Retailers Cooperative Associations 18/07/2008 CC3 18/07/2008 Telephone Fax Quotation Sheets obtained by mail Information supplied by salespersons who call on customers • Direct computer links with purveyors via the internet or dedicated phone lines 18/07/2008 4 18/07/2008 Prices of Perishables Prices of non-perishables • Prices of perishables generally change daily. • Stewards prefer to deal with a small quantity of suppliers for non-perishables (use of wholesale supply houses by mail, fax and supplier webpage) Contact several suppliers and use the Market Quotation List Beside Price, the steward should consider delivery time, manager’s preferences for a supplier, reliability of supplier in meeting the Specs, and the number of items to order. Note: Stewards don’t automatically choose the lowest prices. (depending of minimum order sizes, credit options, delivery time and other factors) 18/07/2008 18/07/2008 Centralized Purchasing Advantages of Centralized Purchasing • Used in Chain operations or small groups of independent operators. • Requirements of a restaurant is relayed to a central office which determines total requirements of all unites and then purchases that total either for delivery to the individual units by the dealer of for delivery at the central warehouse. • Obtain lower prices because of volume purchased • Desired quality is obtained easily because the buyer has more market choice • Larger inventories can be maintained ensuring reliable supply to individual units • Lower the possibilities of dishonest purchasing in individual units 18/07/2008 Disadvantages of Centralized Purchasing Standing Orders • Each unit must accept the standard item in stock and has little freedom to purchase for its own particular need • Individual units may not be able to take advantage of local “specials” at reduced prices • Menus are normally standardized, thus limiting the individual unit manager’s freedom to change a menu • Arrangement of delivery of goods without specific orders. Example: 18/07/2008 CC3 18/07/2008 One arrangement could be the daily delivery of 12 baguettes (bread) by the local baker. The number remains constant unless specifically changed by the steward. Another arrangement could be the daily replenishing of Milk up to a par of 20 Liters 18/07/2008 5 18/07/2008 Receiving Controls Establishing Standards for Receiving • Ordering specific quantities and qualities at optimum prices does not guarantee that the product ordered will actually be delivered • Therefore, the objective of Receiving is to inspect what you expect: • The standards must enable verification of Quantity Quality Price The right quality (check Specs/ Invoice/ Product) The right quantity (watch for extra deliveries!) The right price (same as when ordered was placed) 18/07/2008 18/07/2008 The Invoice A standard procedure for Receiving • Every food delivery is accompanied by a document that lists the items being delivered: THE INVOICE which is the same as a bill • Usually comes in duplicate: 1 for the receiving clerk, and 1 to sign and return to delivery person. 1. Verify Quantity, Quality and Price for each item delivered 2. Acknowledge that quantity, quality and price have been verified by stamping the invoice with the rubber invoice stamp provided for that purpose 3. List all invoices for food delivered on a given day on the receiving Clerk Daily Report for that day and complete the report as required, or enter appropriate information directly in the computer system 4. Forward completed paperwork to proper personal 5. Move food to appropriate storage area Exercise: Create the following Invoice on your favorite Spreadsheet 18/07/2008 Checking Quantities Checking Quality • This entails weighting, counting, or otherwise enumerating the quantity of a particular food delivered by the vendor and then checking to see that the same quantity appears on both the INVOICE AND THE ORDER. • This part requires knowledgeable inspection of delivered foods and careful comparison of perceived quality with the quality established in the Standard Purchase Spec’. 18/07/2008 CC3 18/07/2008 Salmon • • • • • • Whole, dressed, fresh day of delivery Minimum 8lbs, maximum 12lbs Fish firm and elastic, meat pink and slightly translucent Gills free from slime and reddish-pink in color Scales adhering tightly to the skin No stale odors of ammonia • Keep in mind that Clerks receive products they do NOT use… products then do NOT always understand. Operators often require another employee (a chef) to inspect for quality. 18/07/2008 6 18/07/2008 Checking Price Posting Invoices on the Daily Report • Stamping the invoice • The Receiving Clerk Daily Report is an important accounting document Verify the date on which food was received Verify the arithmetical accuracy of the bill Sign and stamp to vouch for the accuracy of quantities, quality and prices. 18/07/2008 18/07/2008 Directs and Stores Forwarding Completed Paperwork • Directs • Once the receiving clerk has stamps and signed all invoices, completed the Daily Report, this sheet, with the invoices attached is sent to the steward who signs the invoices and route them to the food controller who checks the arithmetical accuracy of each invoice. When the checking is complete, the controller sends the receiving sheet and invoices to accounting where figures will be entered in the purchase journal. • The Cost controller will use the DIRECT total to compute the daily food cost Are those extremely perishable food which are purchased on a more or less daily basis for immediate use. And therefore issued immediately to outlets and charged to food cost as received. • Stores Are those foods that in contrast will not diminish significantly in quality (not extremely perishable) if they are not used immediately, they are transferred to the storeroom. 18/07/2008 18/07/2008 Moving all Delivered food Completing the Control Process • Once deliveries have been received, food must be stored and secured immediately to prevent spoilage • …or theft • The 4 steps of the control process: 18/07/2008 CC3 Example here In food control, all foods that are charged to cost immediately are called DIRECTS and all foods that are charged to cost when issued from inventory are called STORES. 1.Establish Standards and SOP for operations 2.Train all individuals to follow established standards and SOPs 3.Monitor performance and compare actual performances with established Standards 4.Take appropriate action to correct deviations from Standards 18/07/2008 7 18/07/2008 Chapter Essentials • The application of the 4 steps control process to Food Purchasing and Receiving • Responsibilities in establishing Standard Purchase Specification, Quantity Standards and obtaining optimum Prices • The difference between Perishable and Non Perishable foods and between Direct and Sores food categories • Overview of documents (Inventory Cards, Invoices and Receiving Clerk Daily Report) 18/07/2008 CC3 8