Introduction to Buckling Analysis

advertisement

1/3/2012 C:\W\whit\Classes\306\Notes\3_Buckling\1_buckling.docx 1 of 2 Volume III Analysis of Buckling

1/4/2012

p. 1 of 113

1/3/2012 C:\W\whit\Classes\306\Notes\3_Buckling\1_buckling.docx 2 of 2 The notes on buckling have two options for deriving the buckling equations. One is based on total potential energy and the other virtual work. If there is time, the total potential energy approach has the advantage of giving more breadth to the course. The virtual derivation has the advantage of being a direct extension of what has already been covered, so it takes less time. The major sections of notes are as follows: (Choose Version1 or 2 and then proceed with the rest of the notes.)

Version 1: Introduction to buckling based on virtual work o Unique to this version: coverage of nonlinear coupling of extension and bending Version 2: Introduction to buckling based on total potential energy o Unique to this version: much more coverage of stability of mechanisms o I will probably leave this version out of your notes to avoid confusion. Regardless of how one obtains the governing equations, they are the same. Hence, the following is independent of whether Total Potential Energy or Virtual Work was selected above. Classical beam buckling Finite element analysis of beam buckling Buckling of a frame (theory and ABAQUS) Buckling of plates (ABAQUS)

Page # Virtual Work Formulation……………………………………………………………………………. o Nonlinear Analysis of Beam Using Differential Equation………………….. o Derivation of Nonlinear Virtual Work Equation………………………………… Nonlinear and “Linear Buckling” Analysis…………………………….. Classical Virtual Work………………………………………………. Single FEA Model……………………………………………………… o Buckling of Mechanisms………………………………………………………………….. o Examples of Buckling Analysis of Mechanisms and Beams……………….. Total Potential Energy Formulation……………………………………………………………… 1/4/2012

p. 2 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

1 of 14

Introduction to Buckling

Analysis

Derivation of Equations Based on Virtual Work

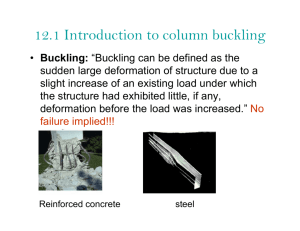

Buckling (often referred to as loss of stability) refers to a large increase in displacement when there is a

small increment in load. To illustrate the phenomena, we will start by performing a nonlinear analysis of

a beam with a distributed transverse load and an axial load. We will observe a highly nonlinear behavior

when the axial load is too large. We can identify a load level that is “critical”.

Then we will consider what happens when there is no transverse load, but still an axial load. Note that if

linear analysis is performed for this axial loading, the response is very simple. This is not the case when

we consider even the simplest approximation that accounts for nonlinearity. The analysis of such

configurations is referred to as buckling analysis. (More accurately, it is referred to as linear buckling

analysis, but we will not get into why.)

We will derive matrix formulas for performing buckling analysis that are like what we derived for linear

analysis, except for an additional term.

Here are a few pictures that illustrate buckling of “beams”.

http://en.wikipedia.org/wiki/Sun_kink

Spoorspatting_Landgraaf.jpg

1/4/2012

p. 3 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

2 of 14

Why are we interested in buckling ?

In most structures the displacements increase gradually with increased applied load. If

the applied load is too large (particularly for compressive structures), a small increase in applied

load can lead to a sudden large increase in the displacements. Buckling refers to this transition to

large, often catastrophic displacements. Buckling can occur due to thermal or mechanical loads.

Sometimes this abrupt behavior can be exploited for useful purposes.

Buckling is one type of instability. Instability is a state in which small perturbations (e.g.

small increments in load) can cause large changes in the response of the structure. Instability can

be due to geometric effects (as is usually the case in buckling) or change in material properties.

(e.g. material yielding or failure) Instability occurs in a variety of physical systems other than

structures, such as those involving heat transfer and fluid flow. In this course we will limit

ourselves to instability of structures due buckling.

Examples of buckling

• collapse of yardstick due to excess axial load

• collapse of assemblage of white-board markers due to excess axial load

• buckling of roads on hot days

• collapse of large towers (comprised of trusses and stay wires)

• bi-metallic strip used for thermostat

• truss bridges

• collapse of thin shell (Coke can)

• etc.

1/4/2012

p. 4 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

3 of 14

Nonlinear Analysis of a Beam

The load for the plots below = lambda * Pcritical => When lambda = 1.0, the buckling load has been

reached. We have not discussed how to determine the buckling load yet, but we will very soon. Note

that the load at which displacement heads for infinity does not depend on the magnitude of the

transverse distributed load q. See the Maple worksheet beamNonlinear_ODE.mws to see the details of

the solution. The governing differential equation (for this particular problem) is derived at the end of

this file. The general differential equation and the virtual work are derived in

3_derivation_DEQN_VirtualWork.docx. Also, this problem has been solved using a single finite element

and the results summarized in the file 4_beamNonlinear_FEA.docx. These last two files are the next files

in your notes.

Distributed load intensity = 1

Distributed load intensity = 5

For

bot

h

cas

es,

the

dis

pla

ce

me

nt

becomes very large when the load

approaches Pcritical (i.e. lambda =1 .0)

1/4/2012

p. 5 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

4 of 14

Derivation of equilibrium equation for this particular problem (… see general derivation

next)

1/4/2012

p. 6 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

5 of 14

Derivation of Nonlinear Beam Equations Using Differential Element

In 306 we will always be able to obtain P(x) from statics. In general, a stress analysis would have to be

done first to determine P(x).

ΣFx 0

1) =

ΣFy 0

2) =

ΣM 0

3) =

dP

+ fx = 0

dx

dV

+ fy =0

2) − V + V + dV + f y dx = 0 ⇒

dx

3) Sum moments about centroid

dv

*offset between axial forces = dx

dx

dx

dx

− M + M + dM + V

+ (V + dV )

2

2

dv dx

dv dx

+(− P)

− ( P + dP)

=0

dx 2

dx 2

1) − P + P + dP + f x dx = 0 ⇒

dM

dV

dv

dv 1

+V +

− P − dP

=

0

dx

2

dx

dx 2

Eliminate high order terms

dM

dv

+V − P =

0

dx

dx

Now we could calculate the weak directly from the DEQNS.

(alternative=subject differential element to virtual

displacements and add up the virtual work.

This is the "306" way.)

1/4/2012

p. 7 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

6 of 14

Very Important! This derivation assumes that the axial

force "P" is positive if it is tensile. If we assume P is

positive when it is compressive, then simply change the

sign of P in the equations above.

Hence, the governing differential equations are

dV

+ fy =

0

dx

dM

dv

=

+V − P

0

dx

dx

Note that V ≠

dM

dx

Derivation of Virtual Work from FBD

Impose virtual vertical translation and rotation of the differential element shown on the previous page.

We have done this before for the linear case. The only new contribution is from P. The contribution to

the VW due to P is as follows:

1 dv

1 dv

dVWP =

dx ( P + dP ) + δθ

dx ( − P )

−δθ

2 dx

2 dx

1 dv

dx ( P + dP + P )

=

−δθ

2 dx

dv

=

−δθ dx P − H .O.T .

dx

dv dv

dv

dx since θ ≈

=

> contribution to VW = -∫ P δ

dx dx

dx

When we derive the matrix form of the equations, we will see that this is a contribution to the stiffness

matrix of

∫P

dN i dN j

dx

dx dx

The matrix Kσ is often referred to as the geometric stiffness matrix, since it is related to geometric

nonlinearity.

Comment: The lateral deflection causes a shortening of the beam-column, but we still obtain

− P + ( P + dP)δ u for the virtual work due to P. This is the same as for a linear uniaxial rod unless we

use the nonlinear strain displacement in writing P. In this class (aero 306) we will typically know the axial

force distribution P… either by inspection or from simple statics.

1/4/2012

p. 8 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

7 of 14

Add the geometric stiffness matrix to what we obtained from the linear approximation

K 0 = ∫ EI

2

d 2 Ni d N j

F.

dx and we have the nonlinear equations ( K 0 + Kσ ) a =

dx 2 dx 2

Since the stiffness contribution K σ is a function of the axial force in the beam, this is a nonlinear

problem.

Next (in a few pages) we will solve the nonlinear problem for various values of axial load. This will reveal

that there is a critical value of the axial load at which the beam becomes unstable.

When a structure is unstable, small perturbations result in large responses. One way to view this is that

the stiffness of the structure has become very small. In fact, the search for the critical load is based on

determining the value of the load that causes the stiffness matrix to become singular. In particular, at

the critical load we obtain the following

( K 0 + Kσ ) ∆a =0

Note that these equations indicate that there can be a change in the displacements without any loading,

which is obviously not a stable situation. This set of equations has non-trivial solutions for only particular

values of the loading. For small problems (few dof), we can find these special (critical) values by solving

K 0 + Kσ =

0 for the load. When there are more than a few dof, we need to recast the problem as an

eigenvalue problem. First we express the applied load as λ P , P is a known level of loading and λ is how

much we must scale it up or down to reach the critical value. We can rewrite ( Κ 0 + Kσ ) ∆a =0 as

( K 0 + λ Kσ ) ∆a =0

( K 0 + λ Kσ ) ∆a =0

K 0 ∆a =−λ Kσ ∆a

or

Kσ−1 K 0 ∆a =−λ∆a

λ Kσ ∆a =− K 0 ∆a

=

> K 0−1 Kσ ∆a =

−

1

λ

∆a

Generally, we will use the form on the left.

We have taken advantage of the fact that Kσ is a linear function of the applied load. The last equation

is in the form of the standard eigenvalue problem Ax = α x where α is an eigenvalue if we take

•

The matrix to be Kσ−1 K 0

• The eigenvalues to be −λ

In summary, what we have done is derive governing equations that account for moderate nonlinearity.

It is possible for the structure to lose stability if the load is too large. The critical values of the load are

called the buckling loads.

1/4/2012

p. 9 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

8 of 14

Note that I used the phrase “buckling loads”, not the singular form. When one solves a multi-dof

problem, multiple critical values of the load will be calculated that correspond to particular buckling

modes (deformed shapes). For simple structures, this is just an interesting mathematical oddity, since

the structure is destroyed once the smallest buckling load is reached. For more complex configurations,

the structure actually only loses part of its stiffness when the “critical load” is reached and it is possible

to reach other “critical loads”.

1/4/2012

p. 10 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

9 of 14

Appendix

Alternate Derivations

These are for those of you that are a bit more curious. Only read if you already understand the

previous derivation.

Alternate derivation 1

Rather than repeat what we did previously for the linear case, note two things:

1) When we calculate the virtual work for the differential element for the linear case, we obtained

the following:

dV

0

δ vdx =

dM

dv

0

∫ dx + V δ dx dx =

∫ dx + f

y

2) The only difference we have for this approximate nonlinear analysis is the additional term in the

second equation. Let’s see how this contributes to the virtual work and eventually the matrix

equations.

dv dv

dv dN i

dx

δ dx = −Σδ ai ∫ P

dx dx

dx dx

where we assumed v = ΣN i ai

−∫ P

Recall that we factored out the Σδ aі before and set the coefficient to zero. Hence, the contribution to

the equilibrium equation is

∫

- P

dv dN i

dx

dx dx

Now put the approximation for v into this integral:

∫ PΣ

dN j dN i

dN dN j

−∑ ∫ P i

− Kσ a

a j dx =

dx a j =

dx dx

dx dx

j

where Kσ = ∫ P

dN i dN j

dx

dx dx

Alternate derivation 2

1/4/2012

p. 11 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

10 of 14

When the differential element deforms, there is axial displacement that is strictly due to the rigid body

rotation. If we assume the beam is inextensible (i.e. along the neutral axis the axial strain is zero), then

all of the axial displacement is due to the rotation. The virtual work is

− Pδ uleft + Pδ uright + H .O.T .

= P(δ uright − δ uleft )

Hence, we need to obtain an expression for amount of stretch that occurs in the x-direction during

deformation and then take the variation of it. Note that the stretch will be negative, since the projection

on the x-axis must shrink during rotation. The amount of axial displacement can be calculated as

follows:

dv 2 2

ds =dx + dv =1 + dx

dx

2

2

2

1/2

dv 2

1 dv 2

=

> ds =+

dx

≈

1

(Taylor series approximation)

1 + dx

dx

dx

2

Since the beam is asumed to be inextensible, ds = original projection on the x-axis

2

1 dv

=> projection shrinks by ds − dx = dx

2 dx

Recall that the virtual work contribution is P (δ uright − δ uleft ) , which = P*(variation of lengthening of

projection on x-axis).

1 dv 2

dv dv

variation of lengthening of projection on x − axis =

dx

−δ dx =

− δ

2 dx

dx

dx

Hence the contribution to the virtual work for the differential element is

−P

dv dv

δ dx . Integrate this to get the total contribution. The result is that the total internal virtual

dx dx

work (including that from the linear contributions) is −

∫

P

dv dv

d 2v d 2v

δ dx − ∫ EI 2 δ 2 dx

dx dx

dx dx

This is identical to what we obtained earlier. It might have seemed that in the first derivations we were

ignoring the axial displacements… and in fact we were. What we did not ignore in the first derivation

was the variation of the axial displacements which were due to the virtual rotation. This is all we

needed to calculate the virtual work due to P. In the second derivation we calculated the axial

displacements and then used them only for determining the variation of the axial displacement.

Alternate derivation 3 using Green-Lagrange strain (this is a bit advanced)

1/4/2012

p. 12 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

11 of 14

The linear strain-displacement relations are valid only for infinitesimal displacements and rotations.

There is another measure of strain that is still valid when there is finite rotation. The meaning of this

strain measure is the same as for the linear strain measures as long as the strains are infinitesimal.

These measures of strain are called the Green-Lagrange strains. For the normal strain n the x-direction,

the formula for 2D is

2

2

∂u 1 ∂u ∂v

+ +

ε xx =

∂x 2 ∂x ∂x

∂u

For the first order approximation of nonlinear beam behavior, one normally ignores the term

and

∂x

2

∂u 1 ∂v

+ . Recall that the internal virtual work for a uniaxial rod is

∂x 2 ∂x

2

so the formula simplifies to ε=

xx

− ∫ EAε xxδε xx dx . For the uniaxial rod we assumed that the axial displacement is constant over the

cross section. If we relax this assumption, we can obtain a formula for the internal virtual work for a

beam. In particular, let’s assume that u ( x, y )= u ( x, 0) − y

dv

dx

≡

u0 − y

dv

. Since there is variation

dx

in the y-direction, we need to integrate in both the x- and y-directions. That is, the internal virtual work

for a beam is −

L

h /2

0

− h /2

∫ ∫

Ebε xxδε xx dydx .

Substitute the expression for the displacement u(x, y) into the formula for the strain and we will obtain

∂u0

∂ 2 v 1 ∂v

−y 2 + .

∂x

∂x

2 ∂x

2

ε xx =

Note that δε xx =δ

∂u0

∂ 2 v ∂v ∂v

− yδ 2 + δ

∂x

∂x ∂x ∂x

Using this nonlinear formula for the strain in the integrals for virtual work will give us the virtual work

for a nonlinear beam that includes extension and flexure.

1/4/2012

p. 13 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

12 of 14

If the applied loads are not a function of the deformation state, then

(

L h /2

∂ 2VWint

∂2

−

=

−

− ∫ ∫ Ebε xxδε xx dydx

K ij =

0 − h /2

∂δ qi ∂q j

∂δ qi ∂q j

∂δε xx

∂ L h /2

dydx

∫0 ∫− h /2 Ebε xx

∂q j

∂δ qi

=

∫

=

=

)

∂ε ∂δε

∫− h/2 Eb ∂qxxj ∂δ qxxi dydx +

L

h /2

0

L

h /2

0

− h /2

∫ ∫

Eb

∂ε xx ∂δε xx

dydx +

∂q j ∂δ qi

∫

F

∫

L

0

∂ 2δε xx

∫− h/2 Ebε xx ∂δ qi ∂q j dydx

h /2

∂ 2δε xx

dx

∂δ qi ∂q j

If the beam is symmetric, some terms cancel and we are left with just

M =EI

d 2v

dx 2

du 1 dv 2

F =EA 0 + =EA ( axial strain along neutral axis )

dx 2 dx

If the loads are a function of the deformation state, then

K ij =

−

∂ 2VW

∂δ qi ∂q j

…to be continued

Maple notebook that illustrates use of Green-Lagrange strain

….end of Appendix

1/4/2012

p. 14 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

13 of 14

Integration of General Equations to Obtain Equations for Pinned-Pinned Case

1/4/2012

p. 15 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\1_buckling_VirtualWork.docx

14 of 14

1/4/2012

p. 16 of 113

4a_beamNonlinear_classical.mw

transverse and axial load

The formulas used to account for nonlinearity assume only moderate nonlinearity=> large displacements

cannot be predicted accurately.

Utility routine

> restart:

currentdir();

with(linalg):with(plots):

"C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork"

(1.1)

Get valid approximation (need to satisfy v(0)=0, v(L)=0)

We will use a cubic approximation, which results in a 2-term solution.

> v:= c1+ c2*x + c3*x^2+c4*x^3:

v0 := subs(x=0,v):

vL := subs(x=L,v):

ans:=solve({v0=0,vL=0},{c1,c2,c3,c4}):

v := subs(ans,v):

print(`Valid assumed solution: v(x)=`,v);

Valid assumed solution: v(x)=, Kc4 L2 Kc3 L x Cc3 x2 Cc4 x3

(2.1)

Now calculate derivatives and the variations of v and the derivatives

> vx := diff(v,x);

vxx:= diff(vx,x);

del_v

:= diff(v, c3) * del_c3 + diff(v, c4) * del_c4;

del_vx := diff(vx, c3) * del_c3 + diff(vx, c4) * del_c4;

del_vxx := diff(vxx,c3) * del_c3 + diff(vxx,c4) * del_c4;

2

2

vx := Kc4 L Kc3 L C2 c3 x C3 c4 x

vxx := 2 c3 C6 c4 x

2

2

3

del_v := KL x Cx del_c3C KL x Cx del_c4

del_vx := KL C2 x del_c3C KL2 C3 x2 del_c4

del_vxx := 2 del_c3C6 x del_c4

(2.2)

Calculate the virtual work, the governing equations, and solve

them

1/4/2012

p. 17 of 113

We are assuming that the internal axial force "F" is constant in the structure.

> VW := int(f * del_v, x=0..L) - int(EI * vxx * del_vxx,x=0..L) int(F*vx*del_vx,x=0..L);

1

1

1

VW :=

f del_c4 L4 C

f del_c3 L3 C

f KL del_c3KL2 del_c4 L2

(3.1)

4

3

2

3

K12 EI c4 del_c4 L K

K

1

2

9

1

F c4 del_c4 L5 K

5

4

2

12 EI c3 del_c4C12 EI c4 del_c3 L K4 EI c3 del_c3 L

6 F c3 del_c4C6 F c4 del_c3 L4 K

Kc3 L del_c4C4 F c3 del_c3C3 F c4 KL del_c3KL2 del_c4

Kc4 L2 Kc3 L del_c3C2 F c3 KL del_c3KL2 del_c4

1

3

3 F Kc4 L2

L3 K

1

2

2F

L2 KF Kc4 L2 Kc3 L

KL del_c3KL2 del_c4 L

We have two equations:

> eq1 := diff(VW, del_c3)=0;

eq2 := diff(VW, del_c4)=0;

1

3

1

eq1 := K f L3 K6 EI c4 L2 K4 EI c3 L K

F c4 L4 K

6

2

3

K

1

2

4 F c3 K3 F c4 L L3

2 F Kc4 L2 Kc3 L K2 F c3 L L2 CF Kc4 L2 Kc3 L L2 = 0

1

9

1

1

f L4 K12 EI c4 L3 K6 EI c3 L2 K

F c4 L5 K

F c3 L4 K

4

5

2

3

eq2 := K

3 F Kc4 L2

(3.2)

Kc3 L K3 F c4 L2 L3 CF Kc4 L2 Kc3 L L3 = 0

Solve the equations to obtain the unknowns c3 and c4

> ans := solve({eq1,eq2},{c3,c4});

1

f L2

K

, c4 = 0

ans := c3 =

2 12 EI CF L2

(3.3)

Hence, our solution for the deflection is as follows.

> v := subs(ans, v);

1

f L3 x

1

f L2 x2

v :=

K

2 12 EI CF L2

2 12 EI CF L2

(3.4)

Note that the displacement is a linear function of the transverse load and a nonlinear function of the

axial load.

Since we have already plotted the exact solution previously in the notes, I will not repeat it here.

Next we will predict the critical (buckling) loads.

Critical load

Note that this stiffness matrix is different than what we will obtain using FEA interpolation, but the

1/4/2012

p. 18 of 113

answer is the same, since both used cubic approximation.

> K := [ [diff(VW, del_c3,c3),diff(VW, del_c3,c4)],

[diff(VW, del_c4,c3),diff(VW, del_c4,c4)] ]:

print(`The stiffness matrix = `,evalm(K));

print(`Note that the stiffness matrix does not depend on the

transverse load, f`);

1

1

K4 EI L K

F L3 K6 EI L2 K

F L4

3

2

The stiffness matrix = ,

1

4

K6 EI L2 K

F L4 K12 EI L3 K

F L5

2

5

Note that the stiffness matrix does not depend on the transverse load, f

(4.1)

> criticalLoads := solve(det(K)=0,F);

60 EI

12 EI

criticalLoads := K 2 , K 2

L

L

(4.2)

2

For comparison, the exact answer for the lowest buckling load

=

π EI

L2

> Pi^2*EI/L^2:

print(`This evaluates to `, evalf(%));

This evaluates to ,

9.869604404 EI

L2

(4.3)

This means that our cubic approximation is significantly overpredicting the buckling load. We need

a higher order approximation to get a good solution.

1/4/2012

p. 19 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\4b_beamNonlinear_FEA.docx 1 of 3

Summary of Maple Worksheet

These results are from the file beamNonlinear_FEA.mws

The problem was also solved using Classical Virtual Work in the file beamNonlinear_classical.mws. Since a cubic

approximation was used, the solution is the same as for the single finite element. In this document, numerical values of

the parameters were used.

EI=32552. (Transverse load does not affect the critical load.)

Finite element formulas

12 EI

L 3

6 EI

2

Linear stiffness, K = L

12 EI

−

L3

6 EI

2

L

6 F

5 L

F

Ksigma = 10

6 F

− 5 L

F

10

6 EI

L2

4 EI

L

6 EI

L2

2 EI

L

−

F

10

2FL

15

F

−

10

FL

−

30

6F

5L

F

−

10

6F

5L

F

−

10

−

12 EI

L3

6 EI

− 2

L

12 EI

L3

6 EI

− 2

L

−

6 EI

− 2

L

4 EI

L

6 EI

L2

2 EI

L

F

10

F L

−

30

F

−

10

2 F L

15

L2 f

f L L2 f f L

Equivalent nodal loads= 2 , 12 , 2 , − 12

1/4/2012

p. 20 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\4b_beamNonlinear_FEA.docx 2 of 3

Recall that loss of stability is supposed to occur if det(K) = 0, so let's examine behavior around this value of loading. First,

let’s find out when det(K)=0 occurs.

1/4/2012

p. 21 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\4b_beamNonlinear_FEA.docx 3 of 3

Note that det(K) =0 for two values of axial force F. There are two “critical” values that correspond to two

modes (shapes) of buckling.

Here is the nonlinear behavior

These displacements are getting large, but they are predicted to go to infinity as we approach the critical load, as shown

below.

The worksheet also illustrates how one can exploit symmetry, but that material is optional and is not included in this file.

1/4/2012

p. 22 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\5_mechanismBuckling.docx 1

of 2

Buckling of a Mechanism

Previously, we derived the conditions for buckling of a beam. We found that the critical load was

determined by examining when the stiffness matrix became singular (e.g. K ij = 0 ).

When we studied mechanisms early in the class, we did not generally bother to define a stiffness

matrix. Part of the reason is because the problems were generally nonlinear… and the problems

were generally single dof problems, so it was not worth the trouble. Now there is a reason to

define a stiffness matrix.

When a structure exhibits “geometric nonlinearity”, the stiffness depends on the deformation

state. In fact, there are two types of stiff nesses: secant stiffness and tangent stiffness. For a

single dof problem, the secant stiffness is simply force/displacement. The tangent stiffness is the

increment in force due to an increment in displacement. When predicting buckling, it is the

tangent stiffness that is of interest. What we set out to determine is when there can be a change

in displacements without there being a change in forces. Such a state is unstable.

Consider the following:

The virtual work consists of external virtual work due to the applied load and internal virtual

work due to the deformation of the body. At equilibrium, there is a balance between the virtual

work of the applied loads and that due to deformation (VW=0). Because the virtual work is

linearly related to the variation of the dof, we can obtain the equilibrium equations by taking

partial derivatives as follows: (The qi are the dof.)

∂VW

=0

∂δ qi

If we can change the magnitudes of the dof without changing the loads, the system is

unstable. This corresponds to the case that

∂

∂q j

∂VW

=0

∂δ qi

The incremental stiffness of the system for a multiple dof problem is

K ij = −

∂ 2VW

∂δ qi ∂q j

Hence, the buckling load is obtained from the condition K ij = 0 where K ij is the incremental or

tangential stiffness matrix for the system and is given by K ij = −

∂ 2VW

. I have used the terms

∂δ qi ∂q j

incremental and tangential stiffness. For linear problems, there is only one stiffness. For

1/4/2012

p. 23 of 113

12/29/2011

C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork\5_mechanismBuckling.docx 2

of 2

nonlinear problems, there is a secant stiffness, which for a single dof problem =

force

.

displacement

∆force

. Strictly speaking,

∆displacement

for buckling analysis it is the incremental stiffness that determines stability, so the formula

There is also an incremental or tangential stiffness, which =

K ij = −

∂ 2VW

is applicable.

∂δ qi ∂q j

Alternate derivation

The equilibrium requirement is that Virtual Work=0. Since the Virtual Work is a linear function

of the virtual displacements δ qi and the virtual displacements are arbitrary and independent, the

equilibrium equations are

∂VW

= 0.

∂δ qi

∂VW

Now let’s rewrite this slightly:

= ψ=

and ψ i 0 . The ψ i are the residual forces and

i

∂δ qi

must equal zero for there to be equilibrium. Now calculate the change in residual forces due to

changes in the displacements. This would be a collection of stiffness terms.

K ij = −

∂ψ i

∂q j

If changing the displacements only (note the partial derivative) causes no change in the residual

forces, something is wrong. In particular, the system is unstable. This corresponds to K ij = 0 .

∂ 2VW

Note: The calculation of the stiffness matrix using Kij = −

is also valid

∂δ qi ∂q j

for uniaxial bars, beams, etc. You should try this for the beam and see that we

get the same result that we obtained before.

1/4/2012

p. 24 of 113

6a_5_30_smallAngleApprox.mw

p. 1 of 4

Buckling Loads and Modes

5.30 Allen & Haisler

6a_5_30_smallAngleApprox.mw

1. Calculate the virtual work

2. Select an equilibrium state to be evaluated. There are several options:

a) Select the state based on "common sense". For example, in this problem, we know intuitively that

one of the equilibrium states = the configuration where both bars are vertical.

b) Perform an initial analysis to determine the various equilibrium states. For nonlinear problems like

this one, that can be a major problem.

If there is only one dof or two dof, it might be practical.

3. For mechanisms, we will calculate the stiffness matrix (combination of linear and geometric)

directly using

After you calculate the stiffness matrix, impose the equilibrium state. In this worksheet, we made small

angle approximations, which implicitly imposed the condition that we were considering the equilibrium

state with the bars vertical. In this case, there is nothing more to impose. If we had not imposed the

small angle approximation (which is the case in the next example), there is something to impose in

order to specify the equilibrium state being considerd.

4. Determine when the stiffness matrix is singular by solving det(K) =0. For larger problems, it is

necessary to recast the problem as a standard eigenvalue problem. To do this you must calculate the

linear and nonlinear contributions to K. It is not difficult, but we don't have time to discuss it.

When you solve det(K)=0, the answers = critical values of the applied load.

5. If the mode shapes are needed, we need to determine the "eigenvectors". (note: if there is only one

dof, we are through)

We consider one eigenvalue at a time. For each eigenvalue we do the following:

a)Substitute the eigenvalue into the stiffness matrix.

b) Impose a unit value of one of the dof and solve the set of equations

Kq=0

c) The values of q = eigenvector. (don't forget the dof you set to 1)

If you were solving a beam problem, the buckling mode shapes = these dof multiplied with the

interpolation functions.

Assume the springs are undeformed when the rods are vertical.

1/4/2012

p. 25 of 113

6a_5_30_smallAngleApprox.mw

p. 2 of 4

> restart:

with(linalg):currentdir();

"C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork"

(1)

Virtual work

Make small angle approximations: sin(angle) = angle cos(angle) = 1- 1/2 * angle^2

This implicitly assumes that we are considering instability from a vertical orientation. We will also

be able to ignore rotation of the spring.

What if we do not make this approximation at the beginning?

> sin_t1 := theta[1]:

sin_t2 := theta[2]:

cos_t1 := 1-theta[1]^2/2:

cos_t2 := 1-theta[2]^2/2:

L1 := L/2:

L2 := L/2:

u := L1*sin_t1 + L2*sin_t2;

v := -(1-cos_t1)*L1 - (1-cos_t2)*L2;

del_u := diff(u,theta[1])* del_theta1 + diff(u,theta[2]) *

del_theta2;

del_v := diff(v,theta[1])* del_theta1 + diff(v,theta[2]) *

del_theta2;

1

1

L θ1 C

L θ2

u :=

2

2

1 2

1 2

θ1 L K θ2 L

4

4

v := K

1/4/2012

p. 26 of 113

6a_5_30_smallAngleApprox.mw

del_u :=

p. 3 of 4

1

1

L del_theta1 C

L del_theta2

2

2

1

1

L θ1 del_theta1 K

L θ2 del_theta2

2

2

del_v := K

(1.1)

> VW := -P * del_v - K1 * u * del_u - K2 *(theta[2]-theta[1]) *

(del_theta2- del_theta1);

K := -[ [ diff(VW, del_theta1, theta[1]), diff(VW, del_theta1,

theta[2]) ],

[ diff(VW, del_theta2, theta[1]), diff(VW, del_theta2,

theta[2]) ] ]:

evalm(K);

1

1

1

VW := KP K L θ1 del_theta1 K

L θ2 del_theta2 KK1

L θ1

2

2

2

C

1

L θ2

2

1

1

L del_theta1 C L del_theta2 KK2 θ2 Kθ1

2

2

del_theta2

Kdel_theta1

1

1

P LC

K1 L2 CK2

2

4

K

1

K1 L2 KK2

4

1

K1 L2 KK2

4

(1.2)

1

1

K P LC

K1 L2 CK2

2

4

Solve for buckling loads

Determine the critical loads by solving det(K)=0. We obtain two values that correspond to two

buckling modes (shapes).

> ans:=solve(det(K)=0, P);

4 K2

ans :=

, K1 L

(2.1)

L

Calculation of mode shapes (getting the eigenvectors)

Recall that we were solving to obtain non-trivial solutions.

First mode

Substitute the first eigenvalue into the matrix K and define the resulting matrix to be KK

> KK := map( proc(zz) subs(P=ans[1],zz) end, evalm(K) );

1

1

K1 L2 KK2

K1 L2 KK2

4

4

KK :=

(3.1.1)

1

1

2

2

K1 L KK2

K1 L KK2

4

4

We need to specify the magnitude of one of the components of the eigenvector. (otherwise, there

are an infinite number of solutions)

1/4/2012

p. 27 of 113

6a_5_30_smallAngleApprox.mw

Assume that theta[1] = 1 and then determine theta[2]

> r:=evalm( KK &* [1, theta[2] ]);

1

1

1

K1 L2 KK2 C

K1 L2 KK2 θ2

K1 L2 KK2 C

r :=

4

4

4

p. 4 of 4

1

K1 L2 KK2 θ2

4

(3.1.2)

I now have two equations... r[1] =0 and r[2] =0. We can choose either one to solve for theta[2].

> solve( r[1]=0, theta[2] );

solve( r[2]=0, theta[2] );

K1

K1

(3.1.3)

Hence, the first eigenvector (mode) is (1,-1). What does this mean?

I could have assumed that theta[2] = 1 and solved for theta[1]. The result would be the same.

Important This procedure gives the mode shape, not the magnitude of the displacements.

Second mode

Repeat the process process for the second mode. Now we use the second eigenvalue.

> KK := map( proc(zz) subs(P=ans[2],zz) end, evalm(K) );

r:=evalm( KK &* [1, theta[2] ]);

solve( r[1]=0, theta[2] );

1

1

K K1 L2 CK2

K1 L2 KK2

4

4

KK :=

1

1

K1 L2 KK2 K K1 L2 CK2

4

4

r :=

1

K1 L2 CK2 C

4

K

1

1

1

K1 L2 KK2 θ2,

K1 L2 KK2 C K K1 L2

4

4

4

CK2 θ2

1

(3.2.1)

This shows that the second mode is (1,1).

1/4/2012

p. 28 of 113

6b_5_30.mw

p. 1 of 4

Buckling Loads and Modes

6b_5_30.mw

det(K)=0

This version does not impose the small angle approximation.

5.30 Allen & Haisler

Assume the springs are undeformed when the rods are vertical.

> restart:

with(linalg):currentdir();

"C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork"

(1)

Virtual work

Make small angle approximations: sin(angle) = angle cos(angle) = 1- 1/2 * angle^2

This implicitly assumes that we are considering instability from a vertical orientation.

What if we do not make this approximation at the beginning?

> sin_t1 := sin( theta[1] ):

sin_t2 := sin( theta[2] ):

1/4/2012

p. 29 of 113

6b_5_30.mw

p. 2 of 4

cos_t1 := cos( theta[1] ):

cos_t2 := cos( theta[2] ):

L1 := L/2:

L2 := L/2:

u := L1*sin_t1 + L2*sin_t2;

v := -(1-cos_t1)*L1 - (1-cos_t2)*L2;

del_u := diff(u,theta[1])* del_theta1 + diff(u,theta[2]) *

del_theta2;

del_v := diff(v,theta[1])* del_theta1 + diff(v,theta[2]) *

del_theta2;

1

1

u :=

L sin θ1 C

L sin θ2

2

2

1

2

v := K

del_u :=

1 Kcos θ1

LK

1

2

1 Kcos θ2

L

1

1

L cos θ1 del_theta1 C

L cos θ2 del_theta2

2

2

1

1

L sin θ1 del_theta1 K

L sin θ2 del_theta2

2

2

del_v := K

(1.1)

> VW := -P * del_v - K1 * u * del_u - K2 *(theta[2]-theta[1]) *

(del_theta2- del_theta1);

K := -[ [ diff(VW, del_theta1, theta[1]), diff(VW, del_theta1,

theta[2]) ],

[ diff(VW, del_theta2, theta[1]), diff(VW, del_theta2,

theta[2]) ] ]:

evalm(K);

1

1

1

VW := KP K L sin θ1 del_theta1 K L sin θ2 del_theta2 KK1

L sin θ1

2

2

2

C

1

L sin θ2

2

Kθ1

1

1

L cos θ1 del_theta1 C

L cos θ2 del_theta2 KK2 θ2

2

2

del_theta2 Kdel_theta1

1

1

P L cos θ1 C

K1 L2 cos θ1

2

4

K

C

1

L sin θ2

2

L sin θ1 CK2,

2

K

1

K1

2

1

L sin θ1

2

1

K1 L2 cos θ2 cos θ1 KK2 ,

4

1

1

1

K1 L2 cos θ2 cos θ1 KK2, K P L cos θ2 C

K1 L2 cos θ2

4

4

2

K

1

K1

2

(1.2)

1

1

L sin θ1 C

L sin θ2

2

2

2

L sin θ2 CK2

Solve for buckling loads

1/4/2012

p. 30 of 113

6b_5_30.mw

p. 3 of 4

Determine the critical loads by solving det(K)=0

Assume buckling occurs from the vertical position=> set the angles to zero before trying to

solve det(K)=0.

> for i from 1 to 2 do

for j from 1 to 2 do

K[i,j] := subs({theta[1]=0, theta[2]=0}, K[i,j]);

od: od:

evalm(K);

1

1

1

K P LC

K1 L2 CK2

K1 L2 KK2

2

4

4

(2.1)

1

1

1

2

2

K1 L KK2

K P LC

K1 L CK2

4

2

4

The critical values of the load are

> ans:=solve(det(K)=0, P);

ans :=

4 K2

, K1 L

L

(2.2)

Calculation of mode shapes (getting the eigenvectors)

Recall that we were solving

to obtain non-trivial solutions.

First mode

Substitute the first eigenvalue into the matrix K and define the resulting matrix to be KK

> KK := map( proc(zz) subs(P=ans[1],zz) end, evalm(K) );

1

1

K1 L2 KK2

K1 L2 KK2

4

4

KK :=

(3.1.1)

1

1

2

2

K1 L KK2

K1 L KK2

4

4

We need to specify the magnitude of one of the components of the eigenvector. (otherwise, there

is an infinite number of solutions)

Assume that theta[1] = 1 and then determine theta[2]

> r:=evalm( KK &* [1, theta[2] ]);

1

1

1

1

K1 L2 KK2 C

K1 L2 KK2 θ2

K1 L2 KK2 C

K1 L2 KK2 θ2 (3.1.2)

r :=

4

4

4

4

I now have two equations... r[1] =0 and r[2] =0. We can choose either one to solve for theta[2].

> solve( r[1]=0, theta[2] );

solve( r[2]=0, theta[2] );

K1

K1

(3.1.3)

Hence, the first eigenvector (mode) is (1,-1). What does this mean?

I could have assumed that theta[2] = 1 and solved for theta[1]. The result would be the same.

Important This procedure gives the mode shape, not the magnitude of the displacements.

1/4/2012

p. 31 of 113

6b_5_30.mw

p. 4 of 4

Second mode

Repeat the process process for the second mode. Now we use the second eigenvalue.

> KK := map( proc(zz) subs(P=ans[2],zz) end, evalm(K) );

r:=evalm( KK &* [1, theta[2] ]);

solve( r[1]=0, theta[2] );

1

1

K K1 L2 CK2

K1 L2 KK2

4

4

KK :=

1

1

K1 L2 KK2 K K1 L2 CK2

4

4

r :=

1

K1 L2 CK2 C

4

K

1

1

1

K1 L2 KK2 θ2,

K1 L2 KK2 C K K1 L2

4

4

4

CK2 θ2

1

(3.2.1)

This shows that the second mode is (1,1).

1/4/2012

p. 32 of 113

7_singleDof.mw

p. 1 of 2

7_singleDof.mw

*Assume inextensional rod

*L = 10

* K = 2 and assume the spring stays horizontal

* Unstretched spring when theta=0 (The symbol "t" is used for theta in this notebook.)

> restart:

with(plots):

currentdir();

"C:\W\whit\Classes\306\Notes\3_Buckling\1_BucklingIntro_VirtualWork"

> w := L *

del_w :=

u := L *

del_u :=

VW := -P

(1)

(cos(theta) -1):

diff(w,theta) * del_theta;

sin(theta):

diff(u,theta) * del_theta;

* del_w - k * u * del_u;

del_w := KL sin θ del_theta

del_u := L cos θ del_theta

2

VW := P L sin θ del_theta Kk L sin θ cos θ del_theta

(2)

Solve for equilibrium

> Pequil := solve(diff(VW, del_theta)=0, P);

Pequil := k L cos θ

(3)

> #Don't confuse k and K!

VW := -P * del_w - k * u * del_u;

K := -diff(VW, del_theta, theta);

L := 10:

1/4/2012

p. 33 of 113

7_singleDof.mw

p. 2 of 2

k := 2:

K := unapply(K, P, theta);

plot(K(Pequil, theta ), theta = 0..Pi/2);

This looks like the stiffness is zero or negative. However, when theta = 0, the force can be any

value for equilibrium, so if the load is less than the critical value, the structure is stable. For all

other values of theta (except for theta = Pi), the structure is not stable.

VW := P L sin θ del_theta Kk L2 sin θ cos θ del_theta

K := KP L cos θ Ck L2 cos θ

2

Kk L2 sin θ

K := P, θ /K10 P cos θ C200 cos θ

0

K50

π π

16 8

π

4

θ

3π

8

2

2

K200 sin θ

2

π

2

K100

K150

K200

>

1/4/2012

p. 34 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 1 of 8 Examples of Buckling Analysis (including convergence) Buckling of beams: classical Virtual Work o Based on det(K)=0 o Based on eigenvalue formulation Buckling of beams: finite elements (eigenvalue formulation) 1/4/2012

p. 35 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 2 of 8 Summary of Results from variousBeamConfigurations_loopVersion.mws Location: 306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_Determinant_formulation Here are the solutions for several configurations with approximations from 1‐term to 7‐terms in the valid assumed solution. Comments:

Higher modes are less accurate than the lower modes. Predictions converge quite rapidly. Often, adding another term does not change the predictions for the lower modes. Why? 1/4/2012

p. 36 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 3 of 8 1/4/2012

p. 37 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 4 of 8 1/4/2012

p. 38 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 5 of 8 Influence of boundary conditions on critical load (Exact Solutions) From book by Brush and Almroth 1/4/2012

p. 39 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 6 of 8 Collapse of Column under Own Weight Let’s do a 2‐term solution (Classical Virtual Work) The interpolation functions are [ x 2 , x 3 ] The axial force in the column = P := -W * (1-x/L), where W=weight of column 3

4 EI L1 W L 3

6 EI L 2 W L 4

3

10

K :=

3

3

2

4

3

5

6

EI

L

12

EI

L

W

L

W

L

10

10

The stiffness matrix is Solve det(K)=0 to obtain The exact answer is 7.837EI

L2

Now let’s solve this using the eigenvalue formulation. In this case, I am using a 3‐ term solution. The interpolation functions are [ x 2 , x 3 , x 4 ] Linear stiffness matrix K0 Geometric stiffness matrix, Ksigma, for unit weight 4 EI L 6 EI L 2

6 EI L 2 12 EI L 3

8 EI L 3 18 EI L 4

8 EI L 3

18 EI L 4

144 EI L 5

5

L3

3

3 L4

10

5

4 L

15

3 L4

10

3 L5

10

2 L6

7

4 L5

15

2 L 6

7

2 L 7

7

1

Combine these matrices to obtain K mod K sigma

K0 Now calculate the eigenvalues for Kmod to determine the critical loads. Predicted critical loads: 1/4/2012

p. 40 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 7 of 8 Winkler Foundation This is analyzed using total potential energy. We could also do this using virtual work or just go straight to the matrix formulas. In the latter case, you could not tell which whether total potential energy or virtual work had been used. One application of this simplified configuration is prediction of face sheet stability of sandwich structures with a foam core. These are not discrete springs. They foundation with a certain stiffness per there were discrete springs? represent a inch. What if VU

2

d2v

1

1

U= EI 2 dx Kv 2 dx

2

2

dx

K stiffness/unit length

L

du

dx

dx

0

where u(L)

V Pu(L)

assume inextensible length of beam does not change

projection does change

du 1 dv

dx 2 dx

L

V

P

2 0

2

du

1 dv

0

dx

2 dx

2

2

1 dv

u(L) dx

2 dx

0

L

2

dv

dx

dx

d2v

P dv

1

1

dx EI 2 dx kv 2 dx

2 dx

2

2

dx

2

Equilibrium: 0

Instability: 2 0

Assume:

1/4/2012

n x

v a sin

L

p. 41 of 113

1/4/2012

C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical\1_variousBeamConfigurations.d

ocx 8 of 8 Note that the Virtual Work = -

dv dv

d2v d2 v

dx EI 2 2 dx- kv vdx dx dx

dx dx

2

VWint

Instability when K 0

K ij

qi q j

VW P

Virtual work n 4 4 EI L4 k

n 2 2 EI L2 k

2 2

Pcr

L2 2 n 2

L2

n

What is the lowest critical load?

when k 0

agrees with Brush & Almroth p.36

n 2 2 EI

2 EI

min

.when

n

1

(pinned-pinned solution)

L2

L2

If EI 0 :

L2 K

buckling load goes to zero if n ! 2n 2

1/4/2012

p. 42 of 113

2_beamBucklingModes.mw

p. 1 of 5

2_beamBucklingModes.mw

Eigenvalue Formulation

I have hidden the Maple code so that it will not obscure the most important details. You can see the

details if you open the file and select

View->Hide Content

and uncheck "Hide input"

Uses the formulas

"C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\1_Classical"

(1)

Constraints

This worksheet is set up to work more than one configuration. The configuraration selected is printed

out below.

clamped-freepinned-pinned

con := subs x = 0, v = 0, subs x = 0, vx = 0

Solving Clamped-Free Beam

con := subs x = 0, v = 0, subs x = L, v = 0

Solving Pinned-Pinned Beam

Obtain valid interpolation functions by deriving valid assumed

solution and then picking out the interpolation functions.

Getting a valid assumed solution is exactly the same as what you did weeks ago for linear analysis=>

Satisfy the kinematic constraints.

Interpolation functions = ,

Kx L~ Cx2 Kx L~2 Cx3 Kx L~3 Cx4

(2.1)

Form linear and geometric stiffness matrices

6 EI~ L~2

8 EI~ L~3

6 EI~ L~2 12 EI~ L~3

18 EI~ L~4

8 EI~ L~3 18 EI~ L~4

144

EI~ L~5

5

4 EI~ L~

Linear K = ,

(3.1)

1/4/2012

p. 43 of 113

2_beamBucklingModes.mw

p. 2 of 5

1

1

3

L~3

L~4

L~5

3

2

5

1

4

L~4

L~5

2

5

Ksigma = ,

3

L~5

5

L~6

L~6

(3.1)

9

L~7

7

Form matrix for eigenvalue analysis and solve

I used the Maple function eigenvals.

0.4500000000

KK :=

9.000000000

348.

K0.03500000000 K0.9000000000 K36.00000000

0.0008750000000 0.02625000000

1.050000000

Eigenvalues = , 0.425312256240101, 0.0246877437598985, 0.150000000000000

(4.1)

Now let's get the buckling modes

I used the Maple function eigenvects.

Eigenvectors

ev1 :=

43.71636359 K3.597527941 0.08993819853

ev2 :=

6.851721450 K9.713737020 0.2428434255

ev3 :=

K300.0000000 10.00000000 K1.000000000 10-10

Eigenvalues

e1 := 0.4253122562

e2 := 0.02468774376

e3 := 0.1500000000

(5.1)

Plot the buckling modes

1/4/2012

p. 44 of 113

2_beamBucklingModes.mw

100

p. 3 of 5

3000

10000

2000

50

8000

1000

0

5 10 15 20

x

6000

0

K50

4000

K100

2000

K150

5 10 15 20

x

K1000

K2000

K3000

0

0 5 10 15 20

x

Normalize the curves & plot together

m1 := 484.6536410

m2 := 36308.94796

m3 := 12344.26799

1/4/2012

p. 45 of 113

2_beamBucklingModes.mw

p. 4 of 5

0.3

0.2

0.1

0

5

10

x

K0.1

15

20

K0.2

K0.3

Summary of predictions

Pinned-pinned beam

0.3

0.2

0.1

0

5

K0.1

10

x

15

20

K0.2

K0.3

Clamped-free beam

1/4/2012

p. 46 of 113

2_beamBucklingModes.mw

p. 5 of 5

0.4

0.3

0.2

0.1

0

5

K0.1

10

x

15

20

K0.2

K0.3

1/4/2012

p. 47 of 113

1/4/2012C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\2_FEA\1_FEA_buckling.docx 1 of 4 FEA Buckling Analysis 1/4/2012

p. 48 of 113

1/4/2012C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\2_FEA\1_FEA_buckling.docx 2 of 4 Formulas for Stiffness Matrices for Standard Beam Element Linear stiffness matrix 12 EI

3

L

6 EI

L 2

12 EI

L 3

6 EI

2

L

6 EI

L2

4 EI

L

6 EI

L2

2 EI

L

12 EI

L3

6 EI

2

L

12 EI

L3

6 EI

2

L

6 EI

2

L

4 EI

L

6 EI

L2

2 EI

L

Geometric stiffness matrix 6 F

5L

F

10

6 F

5 L

F

10

F

10

2FL

15

F

10

FL

30

6F

5L

F

10

6F

5L

F

10

F

10

F L

30

F

10

2 F L

15

Results for Various Configurations Using a Mesh with 2 Beam Elements The global stiffness matrices were assembled just like you did for linear analysis, except now you have two matrices to assemble. When I did these calculations, I formed the global stiffness matrices one time. For each configuration, I made a copy of the global stiffness matrices, imposed the kinematic boundary conditions on each one, and then formed the new matrix K 1K 0 and then passed this matrix to an eigenvalue/eigenvector extraction function. The eigenvalues give me the negative of the scale factor needed to reach the critical load. The eigenvectors give me the nodal displacements to multiply with the interpolation functions to obtain the deformed shape. EI=1.0e6 Total beam length = 10 Here are the original global matrices. Linear stiffness matrix -96000

240000

0

0

96000 240000

240000 800000 -240000

400000

0

0

-96000 -240000 192000

0

-96000 240000

240000 400000

0 1600000 -240000 400000

0

0

-96000 -240000

96000 -240000

0

0 240000

400000 -240000 800000

1/4/2012

p. 49 of 113

1/4/2012C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\2_FEA\1_FEA_buckling.docx 3 of 4 Geometric stiffness matrix

6

25

1

10

-6

25

1

10

1

10

2

3

-1

10

-1

6

0

0

0

0

-6

25

-1

10

12

25

0

-6

25

1

10

1

10

-1

6

0

4

3

-1

10

-1

6

0

0

-6

25

-1

10

6

25

-1

10

0

0

1

10

-1

6

-1

10

2

3

Here are the buckling modes Clamped‐free Clamped‐pinned 1/4/2012

p. 50 of 113

1/4/2012C:\W\whit\Classes\306\Notes\3_Buckling\2_BeamBuckling\2_FEA\1_FEA_buckling.docx 4 of 4 Pinned‐pinned Clamped‐clamped Details are in the file beamBuckle_FEA.mws 1/4/2012

p. 51 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 1 of 14

Buckling analysis of a Frame in Abaqus

Warning: do not use linear elements. (they do not allow bending) I f you use

lots of them, it might work OK. Note that there is no such thing as a linear

element in your derivations of a beam of frame. ABAQUS must be using a

different formulation that has some advantages in certain circumstances.

• Create Parts

Double Click Parts from Model Tree

Draw your part using lines: Create Lines: Connected

• Create Profile

Double Click Profiles from Model Tree.

1/4/2012

p. 52 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 2 of 14

I created a square profile, you beam profile can be anything depending upon your

design.

• Create Sections

Double Click Sections from Model Tree.

1/4/2012

p. 53 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 3 of 14

Since we have not created a material yet, click the Create button next to

Material name and create one. (See plate with hole tutorial if not clear how

to do this.)

1/4/2012

p. 54 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 4 of 14

• Assign sections

Open the part by clicking on the + on the part that we created. Double Click the

“section Assignments icon”.

Select the regions to be assigned a section: here select the whole part using

rectangular drag tool: All the part will become red after selection.

• Assign beam section orientations. Top toolbar (When Property Module

is loaded)

select the whole part and then click done: and put (0,0,-1) for approximate n1 direction.

1/4/2012

p. 55 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 5 of 14

After you assign the direction, you get a plot like this (this particular plot is from another

problem)

To get more information about what this means, go to the documentation:

“12.13.3 Assigning a beam orientation”

• Assembly

Open Assembly from Model Tree and double click on instances to create an instance.

• Mesh

Open the mesh module or select the mesh from the instance.

1/4/2012

p. 56 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 6 of 14

• seed

click on seed part instance and select the whole part

select a global size and click OK. Make the size large enough that you only get one

element per member.

The seeding shown is actually more than is typically needed.

• Assign element type

• create mesh

1/4/2012

p. 57 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 7 of 14

Click “mesh part instance”, select the instance and say Yes.

Abaqus will mesh the part: You will not see the mesh, but a message appears in the

message window saying: 73 elements have been generated on instance: Part-1-1

• Create step

Double Click Steps from Model Tree.

Let’s specify 6 eigenvalues.

1/4/2012

p. 58 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 8 of 14

• BC (in step-1)

Expand step-1 and Double Click BCs from Model Tree.

Select region to be constrained

1/4/2012

p. 59 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 9 of 14

you will see symbols

• Create Load

Open Step1 (by clicking on the + sign) and Double Click Loads.

1/4/2012

p. 60 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 10 of 14

select the nodes where you want to apply load.

you will see arrows appearing for loads.

1/4/2012

p. 61 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 11 of 14

• Create JOB

Double Click Jobs from Model Tree.

in edit job, let all the default options stay and click OK. (Make sure Full Analysis is

selected)

• Run analysis

Right click on Job 1 and click submit.

you will see mesaages:

The job input file "Job-1.inp" has been submitted for analysis.

Job Job-1: Analysis Input File Processor completed successfully.

Job Job-1: ABAQUS/Standard completed successfully.

Job Job-1 completed successfully.

Now Right click on Job 1 and click results

.

By clicking on Animate.Time History, you can see different mode shapes. This is not

a true animation! It just has 6 frames… one for each buckling mode. The first frame is the

lowest mode. At the bottom of the screen is information about mode. In particular, the

eigenvalue is given.

1/4/2012

p. 62 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 12 of 14

1/4/2012

p. 63 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 13 of 14

1/4/2012

p. 64 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\1_frame_Beambuckling_v2

.doc Deepak Goyal

p. 14 of 14

1/4/2012

p. 65 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\2_frameBuckling_summary.docx

p. 1

Buckling of a Frame

Instructions for performing buckling analysis of a frame are given the file

frame_Beambuckling_v2.doc.

If you use a single linear order element for each member, the predictions are very bad. The results are

shown in the file

frameBuckling_summary_coarse_linearElements.docx

Fixed on left side and loaded in compression on right side.

Options.Common to thicken the lines

Eigenvalues

1/4/2012

p. 66 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\2_frameBuckling_summary.docx

p. 2

Eigenmodes

1/4/2012

p. 67 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\2_frameBuckling_summary.docx

1/4/2012

p. 3

p. 68 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\2_frameBuckling_summary.docx

1/4/2012

p. 4

p. 69 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\3_frameBuckling_summary_coarse_linearE

lements.docx p. 1

Buckling of a Frame Truss?

Using a coarse mesh with the linear elements gives very bad predictions.

Options.Common

1/4/2012

p. 70 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\3_frameBuckling_summary_coarse_linearE

lements.docx p. 2

1/4/2012

p. 71 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\3_frameBuckling_summary_coarse_linearE

lements.docx p. 3

1/4/2012

p. 72 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\3_FrameBuckling\3_frameBuckling_summary_coarse_linearE

lements.docx p. 4

1/4/2012

p. 73 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\1_summary_Buckling_square_CAE_nice.doc

x

Buckling of a Square Plate under Compression

1/4/2012

p. 74 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\1_summary_Buckling_square_CAE_nice.doc

x

1/4/2012

p. 75 of 113

C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\1_summary_Buckling_square_CAE_nice.doc

x

1/4/2012

p. 76 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\2_plateBuckling_tutorial.docx 1

of 5

Analysis of Plate Buckling Using

ABAQUS

1/4/2012

p. 77 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\2_plateBuckling_tutorial.docx 2

of 5

PROBLEM DEFINITION:

Buckling of a plate.

PART:

3D->deformable->shell->Planar (size = 25)

sketch the part using rectangle tool, click done.

Dimensions of plate = 10x5

MATERIAL

create-name steel-mechanical-elasticity-elastic-isotropic.

E=200E9, nu = 0.3

SECTION

create->shell->homogenous.

shell thickness = 0.5

ASSIGN SECTION

Parts->Part1->section Assignments->select whole region->done->section1->OK->see color change.

ASSEMBLY

instances->dependent

1/4/2012

p. 78 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\2_plateBuckling_tutorial.docx 3

of 5

STEPS

create step->step1->Type.Linear Perturbation ->buckle->continue->#ofeigenVals=5.

BCs

BC1:= Mechanical ->Disp/rotations -> continue -> select left edge->done ->clamp the end, u1, u2, u3, r1,

r2, r3.

BC2:= Mechanical ->Disp/rotations -> continue -> select top edge->done -> u3=0, r1=0.

LOAD

create ->mechanical ->shell edge load ->continue ->select right edge ->done ->traction normal,

magnitude = 10 -> OK

By end of it, you should have something like this.

1/4/2012

p. 79 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\2_plateBuckling_tutorial.docx 4

of 5

MESH

part1->mesh->seed part->global size 0.5 ->OK->done->

from meshing toolbar

assign element type -> geometric order quadratic, rest all defaults ->OK

from meshing toolbar ->Mesh part ->OK

JOB

create ->Full analysis (you can do data check and continue analysis also)

job1->submit

After Job Job-1 completed successfully,

right click Job1->results

USE THE BUTTONS WITH ARROWS

1/4/2012

p. 80 of 113

12/29/2011C:\W\whit\Classes\306\Notes\3_Buckling\4_PlateBuckling\2_plateBuckling_tutorial.docx 5

of 5

1/4/2012

p. 81 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 1of 10

Introduction to Buckling Analysis

Based on Total Potential Energy

1/4/2012

p. 82 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 2of 10

Variational and Energy Methods

Principle of Virtual Work

Principle of Complementary Virtual Work

Actual forces * virtual displacement

Actual displacement * virtual forces

Virtual displacement: satisfy kinematic

Virtual forces: satisfy equilibrium equations

constraints

and force type boundary conditions

Special cases:

Minimum total potential energy

Minimum total complementary energy

Castigliano #1

Castigliano #2

Approximate solution

Kinematic constraints satisfied exactly

Equilibrium (interior and boundary)

satisfied exactly

Equilibrium equations are derived

Compatibility equations are derived

(approximation satisfaction of equilibrium) (approximation satisfaction of

compatibility)

1/4/2012

p. 83 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 3of 10

Introduction to Energy Principles

Thus far we have constructed equilibrium equations two ways: using summation of forces =0

and virtual work=0. We will consider another way that is based on energy. In particular, we will

use the Principle of Minimum Total Potential Energy. We will also mention an alternate way

to express compatibility (i.e. kinematic) requirements using the Principle of Minimum Total

Complementary Energy.

These two principles can be stated as follows: (Allen & Haisler)

Principle of Minimum Total Potential Energy:

Of all the possible displacements that satisfy the boundary conditions of a deformable body or

structural system, those corresponding to the stable equilibrium position make the total potential

energy a relative minimum. If the first variation of the total potential energy is zero (also known

as being “stationary”), but not at a relative minimum, the equilibrium configuration is not

stable. We will discuss stability below.

Principle of Minimum Total Complementary Energy:

Of all the possible stresses and forces that satisfy the equilibrium conditions and stress boundary

conditions of a deformable body or structural system, those corresponding to the true stable

deformation state make the total complementary energy a relative minimum. (This principle is

used to derive compatibility equations, not equilibrium equations.)

The total potential energy consists of two parts: the potential of the applied loads (“V” … not to

be confused with shear!) and the strain energy that is stored inside an elastic body (“U”). We will

discuss how to calculate these very soon. Mathematically, we can express the requirement for

finding a “stationary” value of total potential energy as setting the first variation of Π to zero,

i.e. δ Π =0 . In general, we will be working to obtain approximate solutions that have been

expressed in terms of a collection of unknown parameters. If we call these unknown

parameters qi , then the requirement that the first variation be zero is given by

∂Π

∂Π

∂Π

=

0

δΠ

δ q1 +

δ q2 +

δ q=

3 + ...

∂q1

∂q2

∂q3

To satisfy this requires that each partial derivative equal zero.

∂Π ∂Π ∂Π

=

=

= ...= 0

∂q1 ∂q2 ∂q3

Thus if there are n unknowns, we will obtain n simultaneous equations that we can use to solve

for the unknowns.

Example

Consider a linear spring subjected to a force P. The resulting displacement is u.

1

Show that the strain energy in the spring, U = ku 2 .

2

1/4/2012

p. 84 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 4of 10

The potential of the applied load = - (force vector ) (displacement vector) . In other words, a

force loses potential when it moves in the direction of the force. The amount of loss is simply the

dot product of the force and displacement vectors. For our spring, the potential V= -Pu

1

Hence, Π = − Pu + ku 2 . Setting δ Π =0 gives the familiar equilibrium equation P=ku.

2

Until now you have solved equilibrium equations and never worried about whether the

equilibrium state was stable or unstable. In real structures this is a critical concern. The following

sketch illustrates the concept of stability using a ball on a curved surface and gravity acting

downward. The total potential energy Π = w y, where w= the weight of the ball and y= the

height. All three balls are in equilibrium, but the stability is different. Imagine what would

happen to each ball if it was perturbed slightly. (e.g. you hit each one with a small ball) The

reaction is determined by the stability. This sketch illustrates “stable”, “unstable”, and

“conditional or neutral” equilibrium.

Π

Comments

•

•

•

•

•

1 2

ku

2

potential of applied load = - (force vector ) (displacement vector)

change in potential is generally not equal to the work done by the force (only equal if the

force is constant during the motion)

What is the potential of a distributed load?

A force F is used to stretch a spring “b” inches. Assume the spring is non-linear with

force vs. displacement relationship of F = a u3, where a = a constant.

o How much work is done by the force?

o What is potential of the force at equilibrium? Assume the potential is zero before

the spring begins to stretch.

strain energy of a linear spring, U =

F,b

1/4/2012

p. 85 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 5of 10

Summary of Terms

(no thermal effects)

The following assume nonlinear elastic behavior.

Internal

cε, F h

εδF

δF

F

U o′

Fδε

Uo

ε

δε

External

u δP

cu , P h

P δu

P

u

1/4/2012

p. 86 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 6of 10

Total Potential Energy for a Spring

Let’s look at total potential energy for a linear spring. The work done on the spring = strain

energy stored in the spring, since there is no dissipation.

This plot below shows how the strain energy U, the potential of the applied load V, and the total

potential energy U+V vary with u.

•

•

•

The strain energy, U, increases monotonically.

The potential of applied load, V, decreases monotonically

The total potential energy, U+V, decreases and then increases. There is a location where

U+V has a minimum value, which can be calculated by setting

∂Π

(for this problem, this is equivalent to

0) . Calculate the minimum point and

δ Π 0=

∂u

compare it to the plot.

(Plot is from the file springEnergy.mws)

1/4/2012

p. 87 of 113

12/29/11 - C:\W\whit\Classes\306\Notes\3_Buckling\0_TotalPotentialEnergy\1_energyPrinciples.doc

page 7of 10

Strain Energy for a Linear Elastic Bar

For an elastic body, the work done by the

forces that deform the body = the energy

stored by the body. This is because there is

no dissipation of energy. We will calculate

the work of the applied loads… and then we

will know the strain energy in the body.

The work done by the forces on the

differential element is (why the ½?)

du

1

dW = − Fu + ( F + dF ) ( u + du ) + fdx u +

2

2

f

F + dF

u + du

F,

u

dx

f

1

= − Fu + Fu + Fdu + udF + dFdu + fudx + dxdu

2

2

1

(High order terms are dropped.)

=

[ Fdu + udF + fudx ]

2

Now let’s determine the work for the entire bar. We need to add up the differential work for all

W final

x2 dW

of the differential elements. We need to integrate. ∫

dW = ∫

dx

Winitial

x1 dx

dW 1 du

dF

1 du

dF

1 du

=

F

+u

+ fu

=

F

+u

+ f=

F

Why?

dx 2 dx

dx

2 dx

dx

2 dx

x

1 2 du

=

∴W

=

F

dx strain energy ≡ U

2 x∫1 dx

2

1

du

To use this we will need to express F in terms of displacement, which gives U = ∫ EA dx

20

dx

Comment

dU

dW

(which is equal to

), is referred to as the strain energy density for a uniaxial bar.

dx

dx

L

Modification for thermal load

There is more than one way to include thermal effects. Two possibilities are

2

L

du 2

1

1

du

du

and U

U

EA − 2 α∆T dx =

=

∫0 EA dx − α∆T dx

2

2 ∫ dx

dx

At first, one might expect a problem, since these are obviously different formulas. However,

there is no practical difference, since the typical use of “U” is in determining the equilibrium