x - Department of Mechanical Engineering, METU

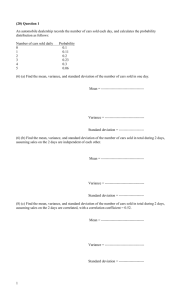

advertisement

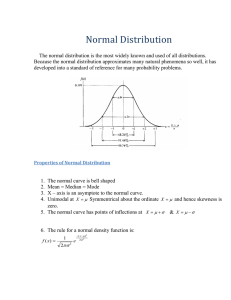

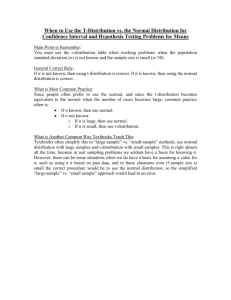

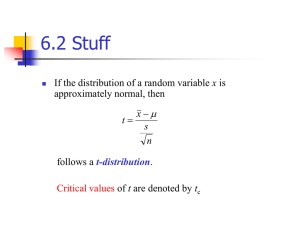

ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Binomial Distribution: P( x ) = n! p x (1 − p)n − x x ! (n − x )! x∈ℵ P(x) is the probability of obtaining “x successes” in “n independent trials” of a “discrete event” for which “p” and “1-p” are respective probabilities of “success” and “no success” in a single trial. Mean = n.x S.D. = np(1 − p) When “p” in the binomial distribution is too small and “n” is too large, the calculation of the binomial distribution becomes quite complex and approaches “Poisson” distribution. Poisson Distribution: e− µ µ x x∈ℵ P( x ) = x! P(x) is the probability of obtaining “x successive successes” of a “discrete event” during an interval of time T where “µ” is the “average number of successes” in the same interval T. Mean = µ S.D. = µ When n becomes large in binomial distribution, or µ becomes large in Poison distribution, the envelope f(x) of the resulting continuous distribution of a continuous variable x is called the “Gaussian/Normal distribution” or “Gaussian Probability Density Function”. Page 44 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Gaussian/Normal Distribution or Gaussian Probability Density Function: f (x ) = 1 e σ 2π 1⎛ x−µ⎞ − ⎜ ⎟ 2⎝ σ ⎠ 2 x∈ℜ where Mean = µ S.D. = σ or in standardized form f (z ) = 1 e 2π − z2 2 with z= x−µ σ where Mean = 0 S.D. = 1 Its “bell-shaped” curve for the standardized normal distribution looks like as follows: 0.4 f m ax = 1 2 π =0.3989 0.3 f(z) 0.2 0.1 0.0 -∞ Å -3 -2 -1 0 1 2 3 Æ +∞ z Page 45 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Properties of Gaussian Distribution: 1. f(x)>0 for all finite values of x and f(x) Æ 0 as x Æ ∞ 2. f(x) is symmetrical about its mean. 3. Mean ( x ) determines its location and S.D. (σ) determines its amount of dispersion. f(x) f1(x) x1 < x 2 σ1 < σ 2 f2(x) x 0 4. +∞ +∞ −∞ −∞ ∫ f (x ) dx = ∫ f (z) dz = 1 z2 5. P(z1 ≤ z ≤ z2) = ∫ f (z) dz or geometrically z1 f(z) Area is P(z1≤z≤z2) 0 z1 z2 z where P(z1 ≤ z ≤ z2) is the “probability” of having z between z1 and z2. Page 46 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Integrals of the Normalized Gaussian Error Function 1 2π z ∫e − z2 2 f (z ) dz 0 z 0.00 0.0 0.0000 0.1 0.0398 0.2 0.0793 0.3 0.1179 0.4 0.1554 0.5 0.1915 0.6 0.2257 0.7 0.2580 0.8 0.2881 0.9 0.3159 1.0 0.3413 1.1 0.3643 1.2 0.3849 1.3 0.4032 1.4 0.4192 1.5 0.4332 1.6 0.4452 1.7 0.4554 1.8 0.4641 1.9 0.4713 2.0 0.4772 2.1 0.4821 2.2 0.4861 2.3 0.4893 2.4 0.4918 2.5 0.4938 2.6 0.4953 2.7 0.4965 2.8 0.4974 2.9 0.4981 3.0 0.4987 3.1 0.4990 3.2 0.4993 3.3 0.4995 3.4 0.4997 3.5 0.4998 4.0 0.4999683 4.5 0.4999966 5.0 0.4999997 0 0.01 0.0040 0.0438 0.0832 0.1217 0.1591 0.1950 0.2291 0.2611 0.2910 0.3186 0.3438 0.3665 0.3869 0.4049 0.4207 0.4345 0.4463 0.4564 0.4649 0.4719 0.4778 0.4826 0.4864 0.4896 0.4920 0.4940 0.4955 0.4966 0.4975 0.4982 0.4987 0.4991 0.4993 0.4995 0.4997 0.4998 0.02 0.0080 0.0478 0.0871 0.1255 0.1628 0.1985 0.2324 0.2642 0.2939 0.3212 0.3461 0.3686 0.3888 0.4066 0.4222 0.4357 0.4474 0.4573 0.4656 0.4726 0.4783 0.4830 0.4868 0.4898 0.4922 0.4941 0.4956 0.4967 0.4976 0.4982 0.4987 0.4991 0.4994 0.4995 0.4997 0.4998 0.03 0.0120 0.0517 0.0910 0.1293 0.1664 0.2019 0.2357 0.2673 0.2967 0.3238 0.3485 0.3708 0.3907 0.4082 0.4236 0.4370 0.4484 0.4582 0.4664 0.4732 0.4788 0.4834 0.4871 0.4901 0.4925 0.4943 0.4957 0.4968 0.4977 0.4983 0.4988 0.4991 0.4994 0.4996 0.4997 0.4998 0.04 0.0160 0.0557 0.0948 0.1331 0.1700 0.2054 0.2389 0.2704 0.2995 0.3264 0.3508 0.3729 0.3925 0.4099 0.4251 0.4382 0.4495 0.4591 0.4671 0.4738 0.4793 0.4838 0.4875 0.4904 0.4927 0.4945 0.4959 0.4969 0.4977 0.4984 0.4988 0.4992 0.4994 0.4996 0.4997 0.4998 0.05 0.0199 0.0596 0.0987 0.1368 0.1736 0.2088 0.2422 0.2734 0.3023 0.3289 0.3531 0.3749 0.3944 0.4115 0.4265 0.4394 0.4505 0.4599 0.4678 0.4744 0.4798 0.4842 0.4878 0.4906 0.4929 0.4946 0.4960 0.4970 0.4978 0.4984 0.4989 0.4992 0.4994 0.4996 0.4997 0.4998 0.06 0.0239 0.0636 0.1026 0.1406 0.1772 0.2123 0.2454 0.2764 0.3051 0.3315 0.3554 0.3770 0.3962 0.4131 0.4279 0.4406 0.4515 0.4608 0.4686 0.4750 0.4803 0.4846 0.4881 0.4909 0.4931 0.4948 0.4961 0.4971 0.4979 0.4985 0.4989 0.4992 0.4994 0.4996 0.4997 0.4998 z 0.07 0.0279 0.0675 0.1064 0.1443 0.1808 0.2157 0.2486 0.2794 0.3078 0.3340 0.3577 0.3790 0.3980 0.4147 0.4292 0.4418 0.4525 0.4616 0.4693 0.4756 0.4808 0.4850 0.4884 0.4911 0.4932 0.4949 0.4962 0.4972 0.4979 0.4985 0.4989 0.4992 0.4995 0.4996 0.4997 0.4998 0.08 0.0319 0.0714 0.1103 0.1480 0.1844 0.2190 0.2517 0.2823 0.3106 0.3365 0.3599 0.3810 0.3997 0.4162 0.4306 0.4429 0.4535 0.4625 0.4699 0.4761 0.4812 0.4854 0.4887 0.4913 0.4934 0.4951 0.4963 0.4973 0.4980 0.4986 0.4990 0.4993 0.4995 0.4996 0.4997 0.4998 0.09 0.0359 0.0753 0.1141 0.1517 0.1879 0.2224 0.2549 0.2852 0.3133 0.3389 0.3621 0.3830 0.4015 0.4177 0.4319 0.4441 0.4545 0.4633 0.4706 0.4767 0.4817 0.4857 0.4890 0.4916 0.4936 0.4952 0.4964 0.4974 0.4981 0.4986 0.4990 0.4993 0.4995 0.4997 0.4998 0.4998 Page 47 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Normal Distribution Based Probability Estimates of Error (Confidence Intervals): If a data population abides by Gaussian theory, the probability that a single data item will fall into an interval in terms of the standard deviation of this population can be obtained by using the tabulated integral given in the previous page. Example 1: P(µ+σ ≤ x ≤ µ+1.2σ) = P(0 ≤ x ≤ µ+1.2σ) - P(0 ≤ x ≤ µ+σ) = P(0≤(x- µ)/σ ≤ 1.2) - P(0 ≤ (x- µ)/σ ≤ 1) = 0.3849 - 03413 = 0.0436 = 4.36 % Implying that the probability of a measurement to be in an interval [ µ+σ , µ+1.2σ ] is 4.36 % Example 2: P(µ-2σ ≤ x ≤ µ+2σ) = 2*P(0 ≤ x ≤ µ+2σ) = 2*P(0 ≤ (x- µ)/ σ ≤ 2) = 2*0.4772 = 0.9544 = 95.44 % Implying that x value will be as close to µ as ±2σ with a probability (certainty) greater than 95 %; i.e. with an uncertainty less 5 %. This information may be shown as: x = µ ± 2σ (95.44 %) or if unbiased estimates are used: x = x ± 2s (95.44 %) Example 3: P(x < µ-3σ) = P(x > µ+3σ) = P(0 ≤ x ≤ + ∞) - P(0 ≤ x ≤ µ+3σ) = 0.5 - P(0 ≤ (x- µ)/σ ≤ 3) = 0.5 - 0.4987 = 0.0013 = 1.3 ‰ Implying that x values 3σ less than µ are only likely with a probability of 1.3 ‰. Page 48 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Example 4: Let the result of measurements to determine the spring constants of a sample drawn from a very large number of valve springs manufactured be obtained as: n = 40, x = 152.5 N/cm, s = 0.889 N/cm a) Determine the range of spring constants with a “confidence level” of ±95 %. ±0.95 confidence level Æ P( x -zs ≤ x ≤ x +zs) = 0.95 Æ P(0 ≤ (x- x )/s ≤ z) = 0.475 Æ z = 1.96 (from table) x = 152.5 ± 1.96*0.889 = 152.5 ± 1.74 N/cm (95 %) b) Determine the confidence interval of the mean value with a “confidence level” of ±95 %. Standard deviation of the mean: s x = s / n = 0.889 / 40 = 0.141 N/cm µ = 152.5 ± 1.96*0.141 = 152.5 ± 0.28 N/cm (95 %) c) Determine the % probability of having springs with spring constants greater than 154 N/cm. z = (x- x )/s = (154-152.5)/0.889 = 1.69 P(x > 154) = P(z > 1.69) = P(0 ≤ z ≤ + ∞) - P(0 ≤ z ≤ 1.69) = 0.5 - 0.4545 = 0.0455 = 4.6 % Some commonly used confidence levels are: Common Name Confidence Level Probable Error ±0.6754 σ Standard Deviation ±σ 90 % Error ±1.65 σ 95 % Error ±1.96 σ Two Sigma Error ±2 σ 99 % Error ±2.58 σ Three Sigma Error ±3 σ Maximum Error ±3.29 σ Certainty P(|x- µ|>zσ) P(| x - µ|>zσ x ) % 50 68.26 90 95 95.44 99 99.74 99.9+ 1 in 2 1 in 3 1 in 10 1 in 20 1 in 22 1 in 100 1 in 369 1 in 1000 Page 49 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Student’s t-Distribution: When the sample size is small (n < 20-30), then s becomes a biased estimate of σ, and the standardized variable x−µ t = s/ n is used to determine confidence levels of the estimation of the mean, based on so-called “Student’s t-Distribution” rather than the “Normal Distribution”. Therefore, the estimation results of the mean must be presented as σ µ = x ± t n The “t value” corresponds to the limits of the integral t ∫ f (t, ν)dt = Desired Certainty (Confidence) −t where f(t,ν) is the Student’s t-distribution defined as f ( t, ν ) = ν +1 − t2 ⎞ 2 Γ[( ν + 1) / 2] ⎛ ⎜1 + ⎟ ν⎠ Γ ( ν / 2) νπ ⎝ which is independent of µ and σ, but its shape is determined only by the degrees of freedom ν=n-1, therefore by the number of data points, n. It has almost the same characteristics as the normal distribution, except that it has more probability concentrated in tails and less in the central part. ν Mean = 0 & S.D. = ν>2 ν−2 It converges to the normal distribution very fast as n gets large. Page 50 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Table of t-values Corresponding to Various Confidence Levels as a Function of Number of Data Points n 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 40 50 100 250 500 ∞ 0.5 1.000 0.816 0.765 0.741 0.727 0.718 0.711 0.706 0.703 0.700 0.697 0.695 0.694 0.692 0.691 0.690 0.689 0.688 0.688 0.687 0.686 0.686 0.685 0.685 0.684 0.684 0.684 0.683 0.683 0.681 0.680 0.677 0.675 0.675 0.674 0.6 1.376 1.061 0.978 0.941 0.920 0.906 0.896 0.889 0.883 0.879 0.876 0.873 0.870 0.868 0.866 0.865 0.863 0.862 0.861 0.860 0.859 0.858 0.858 0.857 0.856 0.856 0.855 0.855 0.854 0.851 0.849 0.845 0.843 0.842 0.842 0.7 1.963 1.386 1.250 1.190 1.156 1.134 1.119 1.108 1.100 1.093 1.088 1.083 1.079 1.076 1.074 1.071 1.069 1.067 1.066 1.064 1.063 1.061 1.060 1.059 1.058 1.058 1.057 1.056 1.055 1.050 1.048 1.042 1.039 1.038 1.036 CONFIDENCE LEVEL 0.8 0.9 0.95 0.98 3.078 6.314 12.706 31.821 1.886 2.920 4.303 6.965 1.638 2.353 3.182 4.541 1.533 2.132 2.776 3.747 1.476 2.015 2.571 3.365 1.440 1.943 2.447 3.143 1.415 1.895 2.365 2.998 1.397 1.860 2.306 2.896 1.383 1.833 2.262 2.821 1.372 1.812 2.228 2.764 1.363 1.796 2.201 2.718 1.356 1.782 2.179 2.681 1.350 1.771 2.160 2.650 1.345 1.761 2.145 2.624 1.341 1.753 2.131 2.602 1.337 1.746 2.120 2.583 1.333 1.740 2.110 2.567 1.330 1.734 2.101 2.552 1.328 1.729 2.093 2.539 1.325 1.725 2.086 2.528 1.323 1.721 2.080 2.518 1.321 1.717 2.074 2.508 1.319 1.714 2.069 2.500 1.318 1.711 2.064 2.492 1.316 1.708 2.060 2.485 1.315 1.706 2.056 2.479 1.314 1.703 2.052 2.473 1.313 1.701 2.048 2.467 1.311 1.699 2.045 2.462 1.304 1.685 2.023 2.426 1.299 1.677 2.010 2.405 1.290 1.660 1.984 2.365 1.285 1.651 1.970 2.341 1.283 1.648 1.965 2.334 1.282 1.645 1.960 2.326 0.99 0.999 63.656 636.578 9.925 31.600 5.841 12.924 4.604 8.610 4.032 6.869 3.707 5.959 3.499 5.408 3.355 5.041 3.250 4.781 3.169 4.587 3.106 4.437 3.055 4.318 3.012 4.221 2.977 4.140 2.947 4.073 2.921 4.015 2.898 3.965 2.878 3.922 2.861 3.883 2.845 3.850 2.831 3.819 2.819 3.792 2.807 3.768 2.797 3.745 2.787 3.725 2.779 3.707 2.771 3.689 2.763 3.674 2.756 3.660 2.708 3.558 2.680 3.500 2.626 3.391 2.596 3.330 2.586 3.310 2.576 3.290 Page 51 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY 0.4 Gaussian Student t 0.2 0.0 -∞ Å -3 -2 -1 0 z, t 1 2 3 Æ +∞ Example 4b (revised): Let the result of measurements to determine the spring constants of a sample drawn from a very large number of valve springs manufactured be obtained as: n = 10, x = 152.5 N/cm, s = 0.889 N/cm Determine the confidence interval of the mean value with a “confidence level” of ±95 %. Standard deviation of the mean: s x = s / n = 0.889 / 10 = 0.281 N/cm i) If normal distribution is used, z = 1.96 µ = 152.5 ± 1.96*0.281 = 152.5 ± 0.55 N/cm i) If t-distribution is used, t = 2.262 (from table) µ = 152.5 ± 2.262*0.281 = 152.5 ± 0.64 N/cm If the data were: n = 5, x = 152.5 N/cm, s = 0.889 N/cm Standard deviation of the mean: s x = s / n = 0.889 / 5 = 0.398 N/cm i) If normal distribution is used, z = 1.96 µ = 152.5 ± 1.96*0.398 = 152.5 ± 0.78 N/cm i) If t-distribution is used, t = 2.776 (from table) µ = 152.5 ± 2.776*0.398 = 152.5 ± 1.10 N/cm Page 52 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Rejection of bad data (Chauvenet's criterion) The question is here that “Whether a loner or outlier which is thought to be faulty is to be rejected or eliminated?” If one considers n measurements, then the Chauvenet’s criterion states that: “A reading may be rejected if the probability of obtaining it deviation from the mean is less than 1/2n” Example 4 (revisited): Let the result of measurements to determine the spring constants of a sample drawn from a very large number of valve springs manufactured be obtained as: n = 40, x = 152.5 N/cm, s = 0.889 N/cm It is desired to determine the range of the spring constant value to be used to eliminate a measurement (out of 40 measurements) if it happens to be located out of this range. P( x +zs ≤ |x|) < 1/2n = 1/(2*40) = 0.0125 P( x +zs ≤ x) < (1/2n)/2 = 0.0125/2 = 0.00625 0.5 - P(0 ≤ x ≤ x +zs) < 0.00625 P(0 ≤ x ≤ x +zs) > 0.5 - 0.00625 = 0.49375 Æ z ≈ 2.50 (from table) Therefore, a measurement may be rejected if it lies outside the range: x = x ± zs = 152.5 ± 2.5*0.889 = 152.5 ± 2.22 N/cm Page 53 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY The following table lists values of maximum acceptable normalized deviations (z) for various values of number of data points (n) according to this criterion: n 3 4 5 6 7 10 15 25 50 100 300 500 1000 zmax 1.38 1.54 1.65 1.73 1.80 1.96 2.13 2.33 2.57 2.81 3.14 3.29 3.48 Note that when applying the Chauvenet’s criterion: 1. n should be large. 2. End points of a curve must not be eliminated. 3. If a data point is rejected, then x and s must be recomputed. 4. Successive applications more than once are not acceptable. Page 54 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Example: The following readings (n=10) are taken of a certain physical length in cm: 5.30, 5.73, 6.77, 5.26, 4.33, 5.45, 6.09, 5.64, 5.81, 5.75 Then the best estimates of the mean and standard deviation of the true length can be computed as: x = 5.613 cm and s = 0.627 cm Now, let us test our data points for a possible inconsistency in readings using Chauvenet’s criterion: i 1 2 3 4 5 6 7 8 9 10 xi 5.30 5.73 6.77 5.26 4.33 5.45 6.09 5.64 5.81 5.75 zi 0.499 0.187 1.845 0.563 2.046 0.260 0.761 0.043 0.314 0.219 In accordance with the Table given in previous page, for n=10, a data point with zi > 1.96 may be eliminated. Hence, let us decide to reject the data point number 5 with z5 = 2.046 < 1.96. When this point is eliminated, the new estimates of the mean and the standard deviation of the true length becomes: x = 5.756 cm and s = 0.462 cm Note that the elimination of this data point has resulted in a 26.5 % reduction in s (from 0.627 to 0.462). Page 55 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY Randomness test (χ2 Chi-square test). If we want to determine how well a given set of data fit to an assumed distribution, chi-square test is used. In this test the quantity chi-square is defined as: N [(no )i − (ne )i ]2 i =1 (ne )i χ = ∑ 2 where N : the number of cells or groups of observations (no)i : number of observed occurrences in group i (ne)i : number of expected occurrences in group i (in other words, the value which would be obtained if the measurements matched the expected distribution perfectly) A plot of the chi-square function is given below. Chi-Square Function 50 P=0.001 0.01 0.05 45 40 35 0.50 χ2 30 25 0.95 20 0.99 15 10 5 0 1 3 5 7 9 11131517192123252729313335 Number of degrees of freedom, F Page 56 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY The following is tabulated data of this plot: Probability F 0.99 0.95 0.50 0.05 0.01 0.001 1 0.0002 0.004 0.45 3.84 6.63 10.83 2 0.02 0.10 1.39 5.99 9.21 13.82 3 0.11 0.35 2.37 7.81 11.34 16.27 4 0.30 0.71 3.36 9.49 13.28 18.47 5 0.55 1.15 4.35 11.07 15.09 20.51 6 0.87 1.64 5.35 12.59 16.81 22.46 7 1.24 2.17 6.35 14.07 18.48 24.32 8 1.65 2.73 7.34 15.51 20.09 26.12 9 2.09 3.33 8.34 16.92 21.67 27.88 10 2.56 3.94 9.34 18.31 23.21 29.59 11 3.05 4.57 10.34 19.68 24.73 31.26 12 3.57 5.23 11.34 21.03 26.22 32.91 13 4.11 5.89 12.34 22.36 27.69 34.53 14 4.66 6.57 13.34 23.68 29.14 36.12 15 5.23 7.26 14.34 25.00 30.58 37.70 16 5.81 7.96 15.34 26.30 32.00 39.25 17 6.41 8.67 16.34 27.59 33.41 40.79 18 7.01 9.39 17.34 28.87 34.81 42.31 19 7.63 10.12 18.34 30.14 36.19 43.82 20 8.26 10.85 19.34 31.41 37.57 45.31 21 8.90 11.59 20.34 32.67 38.93 46.80 22 9.54 12.34 21.34 33.92 40.29 48.27 23 10.20 13.09 22.34 35.17 41.64 49.73 24 10.86 13.85 23.34 36.42 42.98 51.18 25 11.52 14.61 24.34 37.65 44.31 52.62 26 12.20 15.38 25.34 38.89 45.64 54.05 27 12.88 16.15 26.34 40.11 46.96 55.48 28 13.56 16.93 27.34 41.34 48.28 56.89 29 14.26 17.71 28.34 42.56 49.59 58.30 30 14.95 18.49 29.34 43.77 50.89 59.70 31 15.66 19.28 30.34 44.99 52.19 61.10 32 16.36 20.07 31.34 46.19 53.49 62.49 33 17.07 20.87 32.34 47.40 54.78 63.87 34 17.79 21.66 33.34 48.60 56.06 65.25 35 18.51 22.47 34.34 49.80 57.34 66.62 Page 57 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY In this plot and table, F represents the number of degrees of freedom in the measurements and is given by F=N-k where N is the number of cells and k is the number of imposed conditions on the expected distribution. Obviously, the smaller the χ2-value is the better is the agreement between the assumed distribution and the observed values, because it corresponds to a larger probability value for this match. Example: An equal number of motors are purchased from a company A and company B. At the end of a year, records show 5 failures for A-type motors and 9 failures for B-type motors. Does this result imply that A-type motors are more reliable? In this problem, we have two cases (N=2): A-type failures and B-type failures; that is, (no)A = 5 & (no)B = 9. If we make the hypothesis that failures are random, then for a total of 14 failures one would expect 7 failures for A and 7 failures for B. So, (ne)A = (ne)B = 7, giving (5 - 7)2 (9 - 7)2 2 χ = + = 114 . 7 7 The only imposed condition in this problem is (no)A + (no)B = 14 hence k=1 Æ F=2-1=1 If these values are used, it is found that the probability of the difference in failure rates being coincidental has a probability of 0.286 (≈ 30 %). This is a reasonably high probability and does not allow us to say directly that A-types are more reliable than B-types. Page 58 ME 410 MECHANICAL ENGINEERING SYSTEMS LABORATORY If the same failure rates continues and at the end of a longer period we end up 50 failures for A and 90 failures for B, χ2 becomes 11.4 giving a probability value of 0.000734 (< 0.1 %) for the difference to be coincidental. In this case, we can say without a doubt that A-type motors are more reliable than B-type motors. Usually, a probability of less than 5 % allows rejection of a random difference hypothesis. If we have a series of measurements and the goodness of the fit of the measurement data to a normal distribution is in question, then the measurement range is divided somewhat arbitrarily into sampling intervals such that each interval contains at least 5 data points. Then using the number of occurrences in each interval, the hypothesis of the data distribution is normal is tested by using χ2 method. Note that k=3 for this case since • A fixed number of data points are used (1 constraint) • To estimate the expected occurrences mean and standard deviation of the sample are used (2 more constraints) Page 59