rainfall simulator for laboratory studies

advertisement

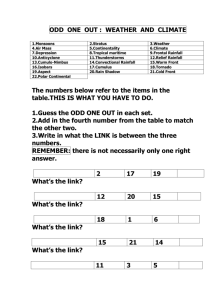

sw 3524 ms 8/22/01 2:51 PM Page 641 RAINFALL SIMULATOR FOR LABORATORY STUDIES T. P. Regmi, A. L. Thompson ABSTRACT. Numerous types of rainfall simulators have been used to study the fundamental behavior of sediment transfer and chemical movement in soil from rainfall. For results of these studies to be representative, it is essential that the artificial rainfall have characteristics similar to that of natural rainfall. In this study, a number of design modifications were made to a stationary rainfall device in order to achieve rainfall simulation comparable to natural rainfall. A 1 m × 1 m laboratory-scale rainfall simulator was designed and constructed using the positive volume displacement principle to provide a precise and broad range of rainfall intensities from 0.025 to 16 cm/h in increments of 0.025 cm/h. The dropforming mechanism consisted of a telescopic arrangement of 21 and 9 gauge stainless steel tubings, producing a mean droplet diameter of 4.5 mm. A drop-size distribution with characteristics similar to natural rainfall was produced when droplets passed through a suspended drop redistribution screen. When the droplet size spectrum for different height of screen suspension was mapped with the spectrum produced by different intensities of natural rainfall, it was possible to estimate a height of suspension corresponding to a desired application rate with characteristics similar to natural rainfall at that given rate. The fully automated rainfall simulator was arranged in a closed loop using a feed tank and automated solenoid valves. The entire rainfall simulation system was installed at a height of 14 m to allow droplets up to 4.3 mm diameter to reach 95% of their respective terminal velocities. Flow rate variation among the 216 individual drippers, used in the rainfall simulation design, was less than 15% of the mean at system application rates less than 1.5 cm/h, and less than 9% at rates greater than 8 cm/h. Reproducibility of system application rate for a given air inlet tube position was within 1%. The best commercial unit available had an advertised ± 20% variation in system application rate with only 50% of the range in rate of the unit developed here. Keywords. Rainfall intensity, Rainfall simulator, Telescopic drop formers, Terminal velocity, Volume displacement. R aindrop energy is known to have a major influence on soil erosion (Wischmeier and Smith, 1978). The transfer of chemicals to runoff from the subsurface is thought to be a result of turbulence in soil water generated by the impact of raindrops (Ahuja et al., 1983; Ahuja, 1990). Using physical principles, relationships have been quantified to predict the interactions among application rate, droplet size, kinetic energy, and droplet energy flux (Thompson and James, 1985). However, the relationship between chemical transfer and movement into the soil, and the interaction with infiltration through a developing surface seal, is not well understood (Ahuja and Lehman, 1983). Numerous types of rainfall simulators have been used to study the fundamental behavior of sediment transfer and chemical movement in soil resulting from rainfall. The use of rainfall simulators generally provides a more rapid, efficient, controlled, and adaptable tool than natural rainfall (Meyer, 1965). The influence of water droplet kinetic energy can be examined by either varying fall height of the Article was submitted for publication in January 2000; reviewed and approved for publication by the Soil & Water Division of ASAE in July 2000. The authors are Tulsi P. Regmi, Graduate Research Assistant, and Allen L. Thompson, ASAE Member Engineer, Associate Professor, Agricultural and Biological Engineering Department, University of Missouri, Columbia, Missouri. Corresponding author: Allen L. Thompson, University of Missouri, 251 Agricultural Engineering Bldg., Columbia, MO 65211, phone: 573.882.4004, fax: 573.882.1115, e-mail: <thompsona@missouri.edu>. droplets, changing droplet sizes, or protecting the soil surface with a residue cover to absorb droplet energy. Droplets from gravity-fed simulators all start at rest and accelerate to a unique terminal velocity based on diameter. The smaller the droplet, the lower the terminal velocity and the less fall height required to reach that velocity (Laws and Parsons, 1943). Droplet kinetic energy, which is directly related to droplet size and the square of droplet velocity at impact, will vary accordingly. The effect of droplet kinetic energy on soil movement and the chemical transfer process is critical, therefore both the size distribution and fall velocity of droplets should be simulated as closely as possible to natural rainfall. Design of a rainfall simulator should address the control of application rates in both time and space, the reproduction of drop size distributions observed with different intensities of natural rainfall at the corresponding application rates, and the reproduction of the terminal velocities of drops in natural rainfall (Hall, 1970; Mech, 1965). Application rate for a given drop former is controlled by two methods: areal density of drop formers, and hydrostatic head (Mutchler and Moldenhauer, 1963; Mutchler and Hermsmeier, 1965). Generally, rainfall simulators can be categorized into two types: tubing-tip simulators and nozzl;e simulators (Hall, 1970). If a nozzle-type rainfall simulator is used, an increase in working pressure increases the average intensity but decreases the range and mean of drop sizes within the spray—just the opposite that is observed with natural rainfall. Alternatively, if a tubing-tip rainfall Applied Engineering in Agriculture VOL. 16(6): 641-647 © 2000 American Society of Agricultural Engineers 0883-8542 / 00 / 1606-641 641 sw 3524 ms 8/22/01 2:51 PM Page 642 simulator of fixed tube diameter is used, the result is the production of uniform drop sizes (Hall, 1970). Ekern and Muckenhirn (1947) used hypodermic needles enclosed with various diameters of glass tubing to produce drops ranging from 2.75 to 5.8 mm in diameter. Mutchler and Moldenhaur (1963) used drop formers consisting of 25 mm lengths of four different gauges of hypodermic tubing telescoped with overlap (9, 10, 12, and 14 gauge). The smallest tube controlled the flow and the largest tube produced drops varying from 5.02 to 5.45 mm in diameter depending upon the head. Bryan and De Ploey (1983) used capillary-tube drop formers that produced 4.1 to 4.2 mm drops. The drop former bed was installed at a height of 7.1 m with a 3.07-mm square mesh drop redistributionscreen suspended 1.7 m below the drippers. This drop redistribution-screen reworked the 4.1 to 4.2 mm drops to give the following drop size distribution: 0 to 1 mm (2.2%); 1 to 2 mm (29.4%); 2 to 3 mm (41.4%); 3 to 4 mm (23.2%); 4 to 5 mm (3.8%). The mean diameter of the redistributioned drops was 2.3 to 2.4 mm, which was somewhat smaller than natural rainfall. Generally, the major difficulties encountered in designing a rainfall simulator are: (1) determination of an appropriate density of drop formers; under conditions of constant head, intensity of application increases as the spacing of drop formers decreases; (2) uniformity of application; (3) droplet size distribution; (4) consistent control of application rate; and (5) reaching terminal velocity for the droplet distribution. Therefore, the objective of this study was to design and construct a laboratory-scale, stationary rainfall simulator that would produce droplet characteristics similar to that of natural rainfall. SYSTEM DESIGN Three fundamental criteria are commonly considered in designing a rainfall simulator (Hall, 1970), namely: • The control of application rates in both time and space. • The reproduction of drop-size distributions observed in different intensities of natural rainfall at the corresponding application rates. • The reproduction of the terminal velocities of drops in natural rainfall. A laboratory-scale rainfall simulator was constructed as shown in figure 1. The design considerations included the use of telescopic drop formers and drop redistribution screen, and the hydraulic principle of positive volume displacement. The telescopic drop formers used in the design consisted of differential lengths of two gauges of stainless steel hypodermic tubing to control the drop size and rate of application (fig. 2). The hypodermic tubing used for the simulator was 5 cm lengths of 21-gauge capillary tubing (for flow control) and 2 cm lengths of 9-gauge tubing (drop size control) placed in a telescopic arrangement in 1.9-cm long (2.4-cm long including bolt head), 0.79-cm-diameter bronze bolts as illustrated in Figure 1–Design schematic of the laboratory-scale rainfall simulation system. 642 APPLIED ENGINEERING IN AGRICULTURE sw 3524 ms 8/22/01 2:51 PM Page 643 Figure 2–Design schematic of the telescopic drop former. figure 2. Metal burrs were removed from the ends of all tubing after cutting to desired lengths. The head end of each brass bolt was drilled 1.5 cm deep for housing the outside diameter (OD) of the 9-gauge tubing, with the remaining bolt length drilled to house the 21-gauge tubing. The 21-gauge tubing was inserted into the bolt, even with the bolt head and overlapping 1.5 cm of the 2-cm-long 9-gauge tubing. Both the 21- and 9-gauge tubes were secured to the bolt with epoxy as shown in figure 2. Operational design of this laboratory-scale rainfall simulator is based on the principle of positive volume displacement in an otherwise sealed container. This principle simply states that ∆Va = ∆Vf at constant pressure head, where ∆Va = change in volume of air entering the system and ∆Vf = change in volume of liquid leaving the system. The pressure head in the tank is measured from the bottom of the air inlet tube to the lower tip of the drop former. The point of air entry at the bottom of the air inlet tube registers atmospheric pressure (P atm ) within the dripper tank. Hence, the water head above the drop formers is manipulated by raising and/or lowering the air inlet tube. For example, when the tube is raised, the distance from the outer tip of the drop former to the bottom of the tube increases, increasing the pressure head above the drop formers, and vice versa. Because flow rate varies proportionately with head, this provides a precise control of application rates (fig. 1). In a pre-design pilot study, a relationship between flow rate and static head for different diameters of telescopic drop formers was quantified as described by figure 3. The results indicated that flow rate varied greatly with the size of the capillary tubing used, and was described by the power function (Q = kP x), where k and x are coefficients and Q and P are flow rate and static pressure, respectively. VOL. 16(6): 641-647 The larger the capillary-tube size, the steeper and more non-linear the slope of the curve. The drop formers with 22-gauge tubing showed very little change in flow rate with head. For capillary tubes 21-gauge and larger, flow resistance was considerably lower providing greater flexibility in applying a wide range of intensities for a small change in head. The 9-gauge tubing was selected for the outlet tip because it produced a maximum droplet diameter of 5 mm similar to Mutchler and Moldenhaur (1963). Figure 4 describes the relationship between the ratio of flow rate to head as a function of length of the 21-gauge capillary tube selected for flow control. This ratio is unique for each tube diameter and water head as a function of tube length. Figure 4 can be used to determine the resulting system application rate for any dripper spacing by dividing the flow rate per dripper by the area of the desired dripper spacing. As this ratio increases, flow control decreases. Tube lengths less than 2.5 cm provided too limited flow rate control. Tube lengths greater than 7.5 cm had a much smaller ratio, but this resulted in a very restricted range of intensity rates (0.2 to 8.5 cm/h at static heads up to 50 cm with drop former spacing of 7.7 cm). Rainfall application rates commonly used in erosion and chemical transfer studies are between 3.2 and 13.4 cm/h (Ahuja, 1990). Capillary tubing with 5 cm length provided an adequate flow rate range for the selected equilateral dripper spacing of 7.7 cm used in the design. The dripper unit consisted of a stainless steel tank, 1m × 1 m × 0.6 m, with 0.64-cm wall thickness which was enclosed using a 1 m × 1 m, 0.95-cm-thick stainless steel dripper bed module. All structural components of the dripper tank were built with stainless steel because of its excellent strength and anti-corrosion properties. The bottom of all four sides was bent into a 5 cm lip at 90° angle, and the top and all four sides of the tank were MIGwelded along the seams. The bed module was attached to the lip using 0.79-cm-diameter bolts spaced 5 cm apart and sealed with a rubber gasket. A total of 216 drippers were screwed into pre-threaded holes of the bed module in a geometric configuration of equilateral triangles, 7.7 cm apart to minimize the number of drippers while maintaining adequate range of intensity rates, raindrop coverage, and application uniformity. The tank was equipped with a graduated 20 mm inside diameter air inlet tube (2-mm wall thickness) of clear polyurethane material used to control application rates. Polyurethane was chosen for its strength, smoothness, and resistance to abrasion. The raising and lowering of the flow control mechanism was accomplished using a fully automated stepper motor coupled with a nylon rack and brass pinion system with precision of 0.9 mm head differential. Air seal of the flow control tube mechanism at the tank entrance was ensured with a set of Teflon V-rings set within a 1.9 cm thick stainless steel housing with adjustable tension. A stainless steel drop redistribution screen composed of 0.4 mm wires with 3.07-mm mesh (opening) size, similar to Bryan and De Ploy (1983), was suspended below the dripper tank to facilitate reworking drops into a broader drop-size distribution spectrum. During this study, exact placement of the screen was selected to produce drop-size 643 sw 3524 ms 8/22/01 2:51 PM Page 644 Figure 3–Flow rate as a function of hydraulic head for different capillary tube diameters. Figure 4–Ratio of flow rate to head as a function of capillary length for 21-gauge tubing. 644 APPLIED ENGINEERING IN AGRICULTURE sw 3524 ms 8/22/01 2:51 PM Page 645 distributions at different application rates which would yield characteristics similar to natural rainfall. The system was installed in the rain tower at a height of 14 m which was determined to be adequate to ensure 95% of terminal velocity for droplets 4.3 mm in diameter and smaller. The dripper tank was suspended with heavy-duty steel chains (9.5-mm link diameter) from all four corners, which were fastened to a custom-built steel saddle placed on an existing I-beam at the top of the rain tower. An electric winch, rated for a half-ton weight, was installed on the supporting I-beam permitting lowering and raising of the dripper unit for routine maintenance. The dripper tank has sufficient water-holding capacity to apply 0.65 m depth over a 1-m2 bed area. For tests requiring greater application depths, water is supplied from a 1.89-m3 auxiliary tank connected to the dripper tank through air and water delivery lines, allowing continuous operation (fig. 1). The rainfall simulation system is supplied with reverse osmosis (RO) treated water. The modified flour method of Kohl (1974) was employed for measuring droplet size. Circular pans 21 cm in diameter and 2 cm deep were filled with flour and leveled with a straight edge. The flour pans were exposed to the simulated rain for one second, and air dried for 24 h. After drying, the flour pellets were separated using a set of sieves ranging from 0.5 mm to 5 mm in mesh size and weighed. Diameter of water droplets was computed using the following relationship: water droplet diameter = 1.1 × sieve mesh size. RESULTS AND DISCUSSION At the beginning of each operation, the entire rainfall simulation system is maintained in the absolute closed mode, i.e., all solenoid valves are closed (fig. 1). The air inlet tube is positioned at the desired height based on the calibration curve for application rates (fig. 5). To begin water application, the air inlet valve is opened and air enters the tank as droplets begin to form. Each water droplet is replaced by an equal volume of air entering the system through the inlet tube. As air rises to the top of the dripper tank, it is immediately transported into the feed tank through the air conduit pushing the net volume of liquid into the dripper tank, ensuring a constant application rate throughout the application period (fig. 1). Rainfall can be stopped by simply closing the air inlet valve. The areal uniformity of application for individual drippers describes how uniformly drop formers perform in the spatial framework, and is quantified as the standard deviation about the mean for the observations made in the study. Results obtained during the flow simulation indicated that the aerial flow uniformity improved with increasing intensity rates. At an intensity rate as low as 1.25 cm / h , the areal flow uniformity had a standard deviation of 15%; whereas, it improved to 7.5% at 8.5 cm/h. The non-linearity of the flow performance of drop formers may be associated with overcoming the internal friction forces and capillary surface tension. Figure 5 shows the flow calibration curve for the rainfall simulation system for the relationship between static head and application rate. The system is capable of controlling Figure 5–Application rate calibration curve of the rainfall simulation system. VOL. 16(6): 641-647 645 sw 3524 ms 8/22/01 2:51 PM Page 646 static head over the dripper bed in 0.9 mm increments, with resulting intensity rates that range from 0.025 cm/h to 16 cm/h in increments of 0.025 cm/h, adequate for both chemical transfer and erosion studies. System application rates were reproducible to 1%. Figure 6 shows the drop-size distributions obtained with different distances of screen suspension below the droplet formers as a function of intensity rate. The results obtained from the flour method for the droplet size distribution indicated that the drop formers produced an average drop size of 4.5 mm. As shown by the experimental results with no drop redistribution screen (fig. 6), about 70% of the droplets were between 4 and 5 mm in diameter, with 90% of all drops between 3 and 5 mm diameter independent of the application rate. When the droplet size spectrum for different height of screen suspension was mapped with the spectrum produced by different intensities of natural rainfall (Laws and Parsons, 1943), it was possible to estimate a height of suspension for the desired intensity rate, which would approximate the characteristics of natural rainfall at that given rate. For example, the suspension distance of 0.5 m, operated at 5.1 cm / h (2 in./h), produced drop size characteristics very similar to that of a 5.1-cm/h (2-in./h) natural rainfall (Laws and Parsons, 1943). At the given height of suspension, the drop redistribution screen reworked average 4.5 mm drops to give the following drop size spectrum: 0 to1 mm (7.5%); 1 to 2 mm (24.5%); 2 to 3 mm (40.5%); 3 to 4 mm (24%); 4 to 5 mm (3.5%) with mean diameter of reworked drops between 2.5 and 2.75 mm. Bryan and De Ploy (1983) reported similar characteristics of simulated rainfall with 3.07-mm mesh size drop redistribution screen but at a suspension distance of 1.7 m below the dripper bed. Overall, the screen suspension distance of 0.3, 0.5, and 1.0 m closely simulated the droplet size distribution spectrum corresponding to intensity rates of 15.24 cm/h (4 in./h), 5.1 cm/h (2 in./h), and 1.27 cm/h (0.5 in./h) of natural rainfall, respectively. The greater the screen suspension distance, the finer the droplets due to greater droplet impact force on the screen causing increased droplet shear. Results also indicated that for a fixed screen suspension distance, droplet size distribution of the simulated rain was essentially constant for various application rates, indicating the droplet size distribution was solely a function of screen suspension distance. In this study, the effect of oscillation of the drop redistribution screen on the droplet size distribution pattern was also evaluated. It was determined that compared to the droplet rework of a stationary redistribution screen, the screen oscillation operated at less than 2 strokes/s with an approximate 5-cm stroke length did not substantially enhance the droplet spectrum of the simulated rain. No splash was observed near the sides of the drop redistribution screen because the screen was slightly larger than the effective dripping area of the drop former bed module and droplet impact on the screen was not great enough to produce excessive splash. The effects of droplet drift during the descent were minimal because the rain Figure 6–Droplet size volume distribution as affected by the screen suspension distance. 646 APPLIED ENGINEERING IN AGRICULTURE sw 3524 ms 8/22/01 2:51 PM Page 647 tower is completely enclosed limiting lateral air circulation across the droplet trajectory. SUMMARY The objective of this study was to design and construct a stationary laboratory-scale rainfall simulator to produce droplet conditions similar to natural rainfall. The results show that a system designed with the volume displacement principle provides precise control of variable application rates, and the use of telescopic drop formers combined with suspended drop redistribution screen greatly enhances the rainfall simulation and produces rainfall characteristics similar to natural rainfall. The results of this study are summarized as follows: 1. The rainfall simulation system was fully automated with a precise control of within 1% for application rates ranging from 0.025 to 16 cm/h. 2. The precision of the variable application rate was 0.9 mm of head, which translates to 0.025 cm/h. 3. Drop formers consisting of telescopic tubing arrangement (9 and 21 gauge) produced an average drop size of 4.5 mm. The redistribution screen reworked drops to produce a drop-size distribution similar to natural rainfall with intensity rates ranging from 1.27 to 15.24 cm/h. 4. Droplet size distribution of the simulated rain did not vary significantly with application rate for a fixed suspension distance of the drop redistribution screen. 5. Droplet size spectrum characteristics for the simulated rain as a function of application rates was approximated by varying the height of the screen suspension. 6. The oscillation of the suspended screen did not enhance the droplet size spectrum as compared to the stationary suspension. 7. The entire rainfall simulation system was installed at a height of 14 m permitting rain droplets of 4.3 mm diameter and smaller to reach 95% of their respective terminal velocities. REFERENCES Ahuja, L. R. 1990. Modeling soluble chemical transfer to runoff with rainfall impact as a diffusion process. Soil Sci. Soc. Am. J. 54: 312-321. Ahuja, L. R., and O. R. Lehman. 1983. The extent and nature of rainfall-soil interaction in the release of soluble chemicals to runoff. J. Environ. Qual. 12: 34-40. Ahuja, L. R., O. R. Lehman, and A. N. Sharpley. 1983. Bromide and phosphate in runoff water from shaped and cloddy soil surfaces. Soil Sci. Soc. Am. J. 47: 746-748. Bryan, R. B., and J. De Ploey. 1983. Comparability of soil erosion measurements with different laboratory rainfall simulators. In Rainfall Simulation, Runoff and Soil Erosion, CATENA Supplement 4, Braunschweig, ed. J. De Ploey, 33-56.New York, N.Y.: Elsevier Science Pub. Ekern P. C., and R. J. Muckenhirn. 1947. Water drop impact as a force in transporting sand. Soil Sci. Soc. Am. Proc. 12: 441-444. Hall, M. J. 1970. A critique of methods of simulating rainfall. Water Resour. Res. 6(4): 1104-1113. Kohl, R. A. 1974. Drop size distribution from medium-sized agricultural sprinklers. Transactions of the ASAE 17(5): 690-693. Laws, J. O., and D. A. Parsons. 1943. Relation of raindrop-size to intensity. Trans. Am. Geophys. Union 24: 452-460. Mech, S. J. 1965. Limitations of simulated rainfall as a research tool. Transactions of the ASAE 8(74): 63, 75. Meyer, L. D. 1965. Simulation of rainfall for soil erosion research. Transactions of the ASAE 8(63): 63-65. Mutchler, C. K., and L. F. Hermsmeier. 1965. A review of rainfall simulators. Transactions of the ASAE 8(67): 67-68. Mutchler, C. K., and W. C. Moldenhauer. 1963. Applicator for laboratory rainfall simulator. Transactions of the ASAE 6(3): 220-222. Thompson, A. L., and L. G. James. 1985. Water droplet impact and its effect on infiltration. Transactions of the ASAE 5(28): 15061510, 1520. Wischmeier, W. H., and D. D. Smith. 1978. Predicting rainfall erosion losses—A guide to conservation planning, USDA Handbook No. 537. Washington, D.C.: USDA. ACKNOWLEDGMENT. Acknowledgment is extended to the University of Missouri Research Board, the University of Missouri Agricultural Experiment Station, and to the CSWQRU, USDA-ARS, Columbia, Missouri, for financial and technical support of this project. VOL. 16(6): 641-647 647 sw 3524 ms 8/22/01 2:51 PM Page 648