I LII II

advertisement

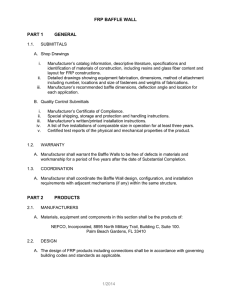

J ELaag9 .,2 3 I `'TE 'AL LETTE R NORTH AMMAN AVIATON INC. TO H . V . Wright AD DRESS 096-213 (ON . Dept ., o- a, Rocketdyne, SanSu Location) Q1 V FL11-4..4690 DATE FROM J . D . Dunn ADORM 096-21 1 Rocketdyne, SanSu & PHONE SUBJECT 20 October 1964 5107 Optimum Anti-Vortex Baffle Configuration and Lowest Usag e Level Allowable for YT3-2 and VTS-3 After Dip Tube Remova l References : (1) IL J-2E-4-1023, dated 14 October 1964, to E . G . Spencer, from H . W . Wright , Subjeet : Yortexing Difficulties, Test Stands VTS-2 and VTS-3, Bowl Area . (2) IL J2-EB-4-232 , dated 13 October 1964, to H . Weiss, from E . E . Erickson, Subject : Safe Fuel Tank Low Level Cut-Off After Dip Tube Removal, VTS-2 and VTS-3 . lZ'1',RIBUTI ON 24 V . Nichol S. Cal l R . Roberts 19. Erickson A . Kern V . Watson 2 . #iarmon ' . Wiegan d 096-200 L Rutmacher a. Weis s 6 ',1 t 11.. Fento n 1. Spence r 1,e FL1 I In reply to your request for the optimum anti-vortex baffle configuration and the lowest usage level allowable, the fallowing information is forwarded : Determination of the optimum anti-vortex baffle configuration for VTS-2 and VTS-3 would require extensive experimental investigation and the shortage of time does not permit testing . To expedite a solution to the problem, a survey of available literature on anti-vortex devices was conducted and outlide help was sought from Douglas Aircraft . Mr. R . Overman of Douglas Aircraft stated that analysis of their anti-vortex devices was heavily dependent upon emperical data and did not believe that any of their anti-vortex devices were directly applicable to the VTS-2 and VTS-3 problem . Approximately two years ago, scale model tests were conducted at PFL on various anti-vortex devices . Of the devic tested, the most effective was the largest horizonal circular flat plate consistant with allowable flow area and pressure drop that can be mounted in a vessel . Based on PFL tests and other information avialable, the antivortex baffle configuration presented in Figure 2 is recommended for the VTS-2 modification. Although less efficient tha n the configuration presented in Figure 2, the configuration presented in Figure 3 is recommended for VTS-3 modification because the dip tube has already been removed up to the vessels bulkhead . FORM 131-R-I NEW 1-63 I LI I I BNA00583967 HDMSpO1756505 IL TO : FBs SUBJECT : 4 Optimum Anti ..Yortex Baffle Configuration and . Lowest Usage Level Allowable for VTS-2 and VTS.*3 After Dip Tube Removal ?L11-4-46 b 20 Cctober 194 Page 2 Based on SSFL' s experience , it was concluded that a realistic incipient vortexing liquid level Jis 3 feet above the anti-vortex baffle for the configuration presented in Figure 2, (and 4 feet above the anti-vortex baffle for the configuration in Figure 3 . When taking into consideration the ten second run time mentione d in Reference 2, and possible variations in liquid saturation pressures (saturation pressures from 15 psia to 45 psia), the lowest usag e of the tunne would be approximately 30 inches, with Mr . J . Boyd, D/210 . but should be checke d For less conventional anti-vortex baffle configurations such as the one shown in Figure 1 (this configuration was suggested by E . Erickson, D/213 in Reference (2)), testing would be required before a safe low cut-off point can be established . D. Dunn Test Systems Uni t Analysis and Equipdent Sectio n JDD .ji IBNA00583968 I I LII I I HDMSpO1756506 477-ACA.' ? 4 -c> 74 FG //- 4~ ~a RC?CKll- PREPARED BY : PAGE NO . ' A DIVISION CC NC-RTLJ nMER CLN 6 aT .QA. 1SC// M.9T/C OF p,eo/ 2S~D AN T%- vae7FX BAIIC- LE s CHECKED BY : ©C7 /2 .N C OF REPORT NO . /9441 DATE: MODEL NO . /5GIk TR/C V/Flit/ 4F /'A?h l/D.PTEX E4FFLE PE'OP©5 EL7 /rV .P£FE.~ENG E . (A) rI /J.eE4. . ~1/GC',sS 7-4'. rLa4T GU/DE` A /i~fi9Ai 5iWEV 7' 2 ------>- i FLAAT (,U/lE- Alc z s FD.2 f'LGb4r GU/06 /GU?E c' . C/C Y1LA~ FLAT !PLATE A.NTJ-,/OR7 X BAFFLE R CO~Yi L7fND D / d ' l/TS F/61/KC'E 3? C/A?CUL ASP FLAT PLATL' ANT/-V/QIeTEX SArFGE A-Z-tf:,0ZKA69E,VD 27 FOR !/' 7S - ,3 LII I BNA00583969 HDMSp01756507